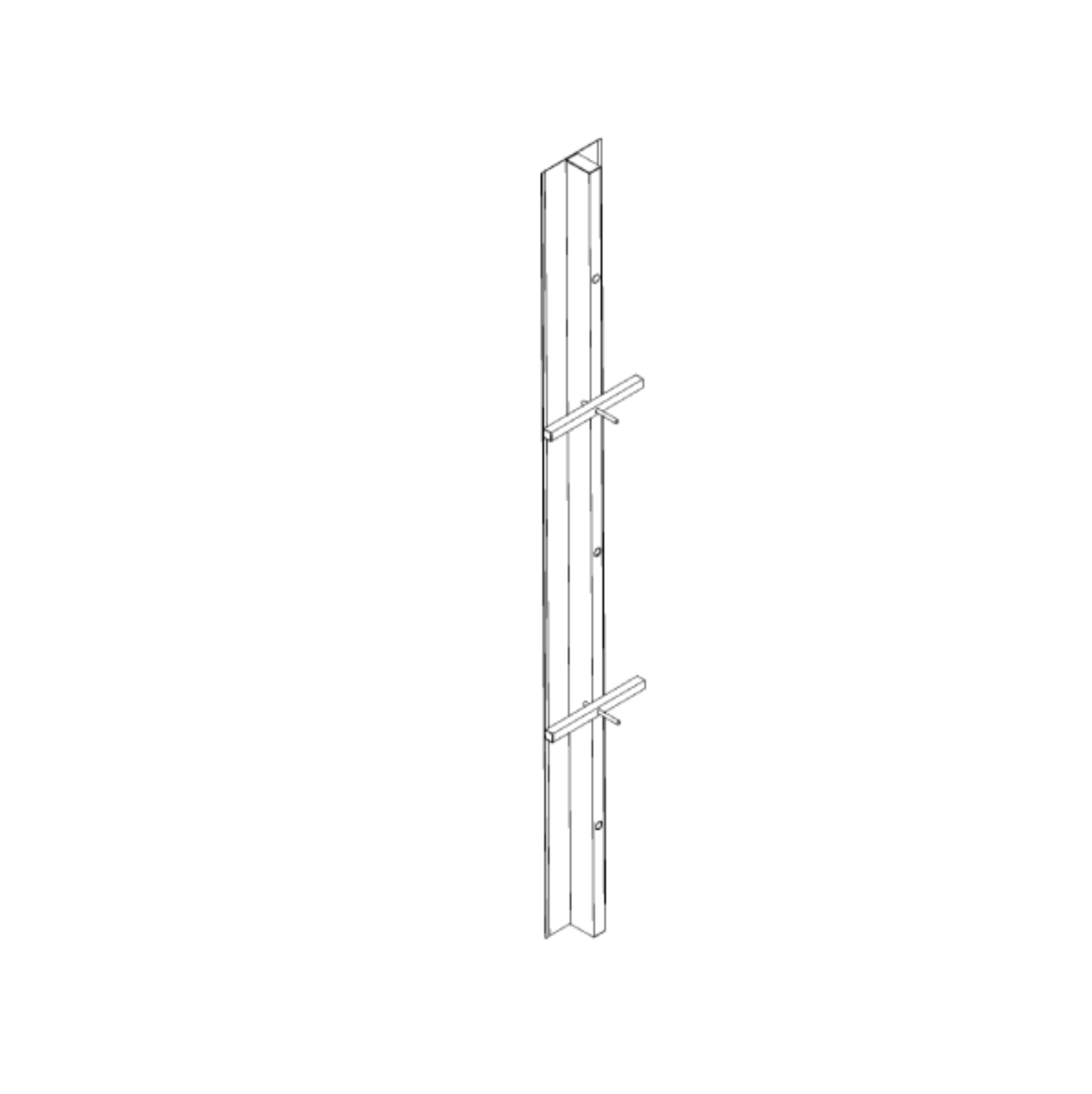

Zigma Filler Plate

| Purpose |

Fills gaps between adjacent formwork panels for seamless connections |

|---|---|

| Sizes |

330×30 cm, 270×30 cm, 150×30 cm |

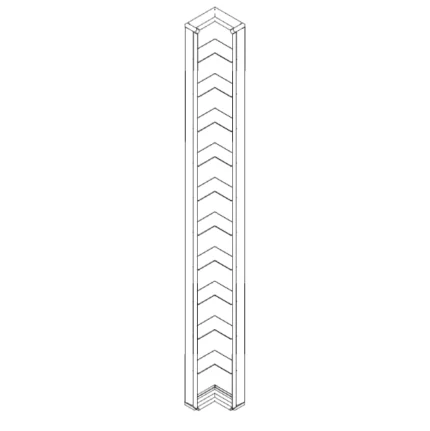

| Corner Design |

Special shape for easy horizontal and vertical movement without hammering |

| Profile |

Sturdy and stable section shape for durability and cost efficiency |

| Material |

Premium quality facing materials for easy cleaning and extended lifespan |

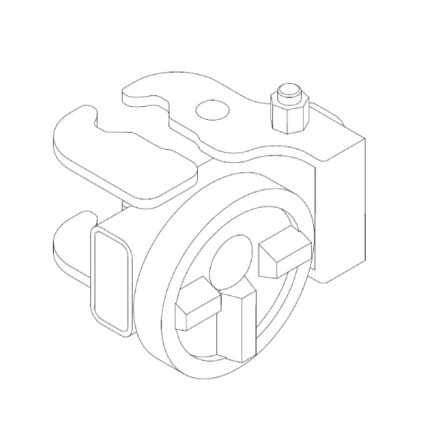

| Connection System |

Modular locks with hammer-driven ball or nut for secure, level connections |

| Applications |

Walls, columns, foundations, and flat concrete structures |

The Formwork Imperative: From Blueprint to Reality

In the demanding world of concrete construction, the journey from architectural blueprint to physical structure is a meticulous process. Formwork, the temporary or permanent mold into which concrete is poured, stands as a critical, foundational element of this process. The quality, precision, and structural integrity of the final concrete structure are directly dependent on the performance of the formwork system. However, this critical stage is fraught with potential challenges. Failures or imperfections in formwork can have catastrophic consequences, jeopardizing not only project timelines and budgets but also the safety and long-term stability of the finished building.

The High Cost of Imperfect Connections

The most common and costly problems in concrete formwork often stem from seemingly minor issues, such as using defective or damaged parts, incorrect assembly, and, most critically, panel misalignment. The presence of small gaps between adjacent formwork panels, whether due to alignment variations or non-standard dimensions, can compromise the entire project. When misaligned, formwork can become unstable during construction, increasing the risk of accidents or even a complete collapse.

The implications of these imperfections extend far beyond the immediate construction phase. Gaps between panels allow a phenomenon known as grout leakage, where the liquid cement matrix escapes, leaving the concrete with a porous, defective surface. This results in significant and visible defects such as honeycombing—exposed coarse aggregate on the surface without any mortar—and bugholes, small air pockets that weaken the concrete. These surface imperfections are not merely aesthetic flaws; they are a direct threat to a project’s structural integrity and profitability. The cost of a simple filler plate is negligible when compared to the expenses associated with a structural failure or the extensive rework required to fix these defects. For a project manager, these issues translate directly to increased labor time, material costs, and inevitable project delays, transforming a seemingly small imperfection into a significant business liability.

Furthermore, the long-term consequences of compromised formwork are even more severe. Misalignment and defects can expose the internal reinforcement steel to moisture and the elements, leading to corrosion. This corrosion weakens the steel, which in turn reduces the structure’s overall lifespan and load-bearing capacity. The initial challenge of formwork gaps evolves into a major liability and safety concern, demonstrating the fundamental link between precise formwork and the durability of the final structure. This nexus of immediate operational problems, long-term structural risks, and financial impacts underscores the necessity for innovative solutions that address these issues at their root.

The B.F.S. Industries Advantage: A Heritage of Engineered Solutions

B.F.S. Industries, LLC is not merely a supplier of construction equipment; it is an organization with a deep-seated heritage in engineering excellence and the manufacturing of high-performance systems. For over 70 years, the company has specialized in the design and manufacture of boiler room auxiliary equipment. These are complex, highly engineered systems that must operate under immense pressure and critical performance demands without fail. The core values of the organization, centered on quality, reliability, and precision manufacturing, are evident in its processes, which include multiple levels of inspections and the exclusive use of high-quality components.

From High-Performance Boiler Systems to Cutting-Edge Formwork

At first glance, the company’s expansion from boiler equipment to concrete formwork might seem like a disparate product line. However, a deeper analysis reveals that this transition is a natural and strategic extension of the company’s foundational engineering culture. Boiler systems are a form of critical infrastructure that demands meticulous design, precision manufacturing, and rigorous quality control to function safely and reliably. These same engineering disciplines are directly applicable to the demanding world of concrete formwork. Formwork systems must be robust enough to withstand the high hydrostatic pressure exerted by a fresh concrete pour without deforming or failing. The integrity and structural performance required for a boiler system are the very same attributes that define a high-quality formwork solution.

This narrative transforms a potential brand weakness into a unique and compelling competitive advantage. B.F.S. Industries brings the proven reliability and engineering excellence of a critical infrastructure manufacturer to the construction site. The company’s decades-long track record of creating robust, reliable systems provides a powerful testament to its capabilities in the Concrete Construction sector. This experience reinforces the brand’s authority and builds trust with a professional B2B audience that values proven performance and reliability over superficial product features. It is this foundation of engineering discipline that informs every product in the B.F.S. Industries portfolio, including the Zigma filler plate.

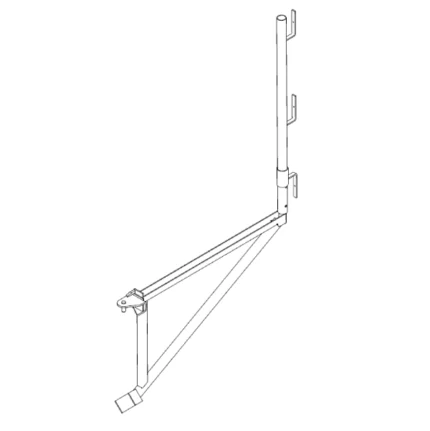

The Zigma Filler Plate: An Engineered Solution for the Modern Jobsite

The Zigma filler plate is not just a formwork accessory; it is an engineered solution designed to address the primary challenges of formwork assembly and alignment. It is specifically created to fill the gaps that inevitably occur between formwork panels, providing a sturdy, reliable connection. The product’s design goes to the heart of preventing the issues caused by incorrect assembly and imprecise connections, which are widely recognized as major risks on any job site.

Simplifying Formwork with Smart Design

The innovative design of the Zigma filler plate streamlines the entire formwork process. Unlike traditional fillers that may require excessive hammering or manual adjustments, the Zigma plate features a specially designed corner profile that allows for seamless horizontal and vertical movement, enabling quick and effortless installation. Its modular lock system is another key innovation, designed for both speed and precision. A single hammer stroke on the lock’s nut or ball is all that is required to secure the connection, eliminating the need for additional props or underpinning and ensuring a tight, gap-free fit. This intuitive, one-step process is a powerful symbol of the product’s focus on efficiency and labor savings.

This ease of use has direct and significant implications for a project’s operational efficiency. The simplification of the assembly process reduces labor time and can even minimize the need for highly specialized labor. The system can be used by workers with less prior experience, as seen in other modern formwork examples. This accelerates the erection and installation process, helping contractors meet aggressive project timelines with confidence.

Beyond efficiency, the Zigma system’s design provides a substantial safety benefit. By ensuring that all components are properly connected and securely fastened, the system actively mitigates one of the leading causes of formwork collapse: loose connections. The secure, level connections eliminate the risk of panel misalignment or instability during concrete pours, creating a safer working environment and providing tangible reassurance to contractors and project managers.

From Cost Center to Profit Driver: The Zigma ROI

In the world of B2B construction, a product’s value is measured not by its features alone, but by its contribution to a project’s overall profitability and success. The Zigma filler plate is designed to be more than a one-time expense; it is a strategic investment that delivers a significant return.

The Economics of Durability and Reusability

The Zigma filler plate is built from premium quality materials and has a rigid, stable profile that is engineered to withstand the high pressures of concrete pours. This robust construction ensures long-term durability and reusability across multiple projects. The high-grade facing material is a critical feature, as it minimizes concrete adhesion, making the plate exceptionally easy to clean after each use.

The durability and reusability of the Zigma plate transform it from a consumable item into a long-term capital asset. This means that the initial investment can be spread out over numerous projects, significantly reducing the cost per use and providing a powerful answer to the B2B client’s primary concern: cost-effectiveness. This reusability also has the added benefit of reducing on-site waste, aligning with modern, eco-conscious construction practices. By using high-quality, long-lasting components, contractors can also avoid the costly failures associated with using defective or low-quality formwork, thereby mitigating the risk of project delays and on-site mishaps.

The Flawless Finish: Eliminating Rework, Maximizing Quality

The value of the Zigma filler plate extends to the final outcome of a concrete pour: the surface finish. The precision design ensures a tight, gap-free connection between formwork panels, which in turn prevents grout leakage. This leads to a seamless, high-quality concrete finish that is free of defects like honeycombing and bugholes. The premium facing materials prevent concrete from sticking to the plate, resulting in a clean, professional-grade surface.

The elimination of these common surface defects translates directly into substantial cost savings. By achieving a flawless, professional finish straight from the pour, the Zigma filler plate minimizes the need for costly and time-consuming post-pour treatments such as grinding, filling, and patching. This is a direct and quantifiable reduction in labor and material costs, making the product a clear value-add.

In an increasingly competitive market, the ability to consistently deliver superior concrete finishes can provide a significant competitive advantage. B.F.S. Industries can position the Zigma plate as the key to achieving the kind of flawless, “architectural concrete” that commands higher-value projects. The product’s value proposition moves beyond simple formwork functionality to impact a contractor’s ability to secure new business and build a reputation for quality.

A Versatile Asset for a Broad Range of Applications

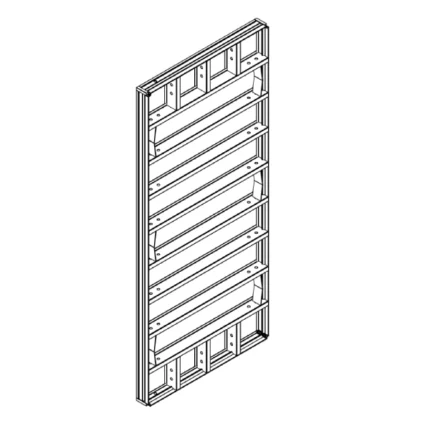

The Zigma filler plate is designed for seamless integration into the entire B.F.S. Industries formwork ecosystem. Available in three versatile sizes—330×30 cm, 270×30 cm, and 150×30 cm—the plate is engineered to align with standard formwork dimensions, ensuring compatibility with a wide range of formwork systems. This adaptability makes it suitable for a diverse array of applications, including walls, columns, and foundations.

Seamless Integration into the B.F.S. Ecosystem

By offering a comprehensive formwork portfolio that includes everything from Concrete Wall Formwork Systems and column formworks to specialized solutions for dams and tunnels, B.F.S. Industries positions itself as a full-service partner, not just a parts supplier. The Zigma filler plate enhances this ecosystem by providing a key component that improves the performance of any system it is used with. This strategic approach encourages cross-selling and establishes B.F.S. as a “total system solution provider,” shifting the conversation from a single product purchase to a long-term, valuable partnership.

The following table demonstrates how the Zigma filler plate serves as a versatile, indispensable component within various formwork applications, showcasing its compatibility and broad utility.

| Component | Typical Applications | Key Function |

|---|---|---|

| Zigma Filler Plate | Walls, Foundations, Columns | Bridges gaps, prevents grout leakage, ensures level connections |

| Wall Formwork | Load-bearing and non-load-bearing walls | Provides structural shape for vertical elements |

| Column Formwork | Square, rectangular, or circular columns | Ensures stable gap-filling for precise casting |

| Foundation Formwork | Building footings and support structures | Enhances integrity of pours by eliminating gaps |

This versatility makes the Zigma filler plate a solution for a wide array of project types, from residential and commercial developments to large-scale infrastructure projects. This allows B.F.S. Industries to target a broader market segment and demonstrate its capacity to meet diverse structural requirements.

Partnership for Success: Choosing B.F.S. Industries

The decision to choose a formwork partner is about more than just finding the right product; it is about establishing a relationship with a reliable and expert collaborator. B.F.S. Industries prides itself on its “tremendous innovative strength” and a team of around 70 employees who are dedicated to providing the best individual solutions for their customers. This is not simply a number; it is a testament to the company’s commitment to forging genuine partnerships with its clients, a value proposition that is highly sought after in the B2B construction sector.

Beyond the Product: A Commitment to Your Project’s Success

B2B clients purchase not just products but also expertise and reliability. By emphasizing the company’s ability to provide custom solutions designed by its in-house engineers, B.F.S. Industries positions itself as a consultative partner, not a transactional vendor. The company’s focus on providing “engineering and project solutions” resonates deeply with a market that values authority-building content and collaborative relationships. This approach ensures that a contractor receives not just a high-quality product but also the technical support and guidance needed to ensure project success. The Zigma filler plate is a prime example of this philosophy in action, a product born from decades of engineering experience and a singular focus on solving complex problems for the benefit of the customer.

Ready to Build a Flawless Future

The Zigma filler plate represents a new standard in formwork accessories, offering a blend of unmatched ease of use, durability, and precision. It addresses the core pain points of the concrete construction industry, transforming formwork connections from a potential liability into a source of efficiency and quality. By eliminating gaps, reducing errors, and accelerating project timelines, this innovative accessory empowers contractors to deliver superior results on time and within budget.

For contractors and project managers seeking to enhance their formwork systems, the path forward is clear. It is time to move beyond traditional, time-consuming methods and embrace a solution that is engineered for the modern job site. The Zigma filler plate is not just a part; it is the key to achieving flawless concrete structures with ease and efficiency.

The next step is to initiate a conversation with an expert. By choosing to consult with a B.F.S. Industries professional, decision-makers can gain deeper insights into how the Zigma filler plate can be seamlessly integrated into their specific project workflows. This is more than a sales inquiry; it is a strategic invitation to partner with a company that has built its reputation on engineering excellence and a steadfast commitment to customer success.

مصطفى العدواني –

هل يمكن قص هذه القطعة حسب الحاجة في الموقع؟ وما نوع المعدن المستخدم في تصنيعها؟