Tunnel Lining Formwork

Introduction

Easy international payment and all official international banks.

Be in touch with our experts at any time of the day or night.

Choose the products you need from B.F.S products

Be aware of discounts by registering on the site in addition to shopping.

What is formwork for tunnel lining?

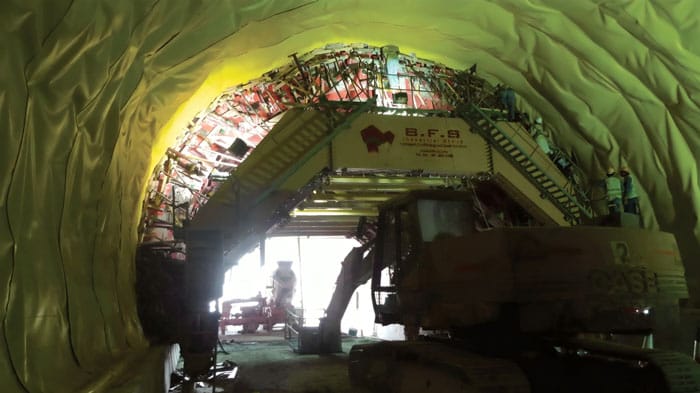

Let’s start with the basics. During tunnel building, a temporary construction structure we employ is tunnel lining formwork. Think of it as a gigantic, reusable mold that shapes the tunnel’s walls and roof, holding the concrete in place as it hardens. We remove the formwork once the concrete sets so that a strong, long-lasting lining maintains the stability and security of the tunnel.

Although on a much larger scale, it’s somewhat similar to scaffolding around a building under construction. Tunnel lining formwork shapes the very form of the tunnel itself, not alone supports workers. It keeps the tunnel from collapsing under the weight of the ground or water above it. And believe us, under hundreds of tons of pressure, that is not a stroll in the park.

Formwork is actually not a one-size-fits-all solution. We apply different kinds depending on the design, location, and intended usage of the tunnel. Mobile and hydraulic tunnel lining formwork are two of the most sophisticated and extensively used technologies available today. These are game-changers that speed up, are safer and more efficient—not simply trendy jargon. Let us examine closely every one of them.

Variations in Tunnel Lining Formwork

Tunnel lining formwork has different forms, and it’s crucial to consider the most suitable one for your business based on your needs and criteria. Let’s dive in:

Hydraulic Tunnel Lining Formwork: Precision Meets Power

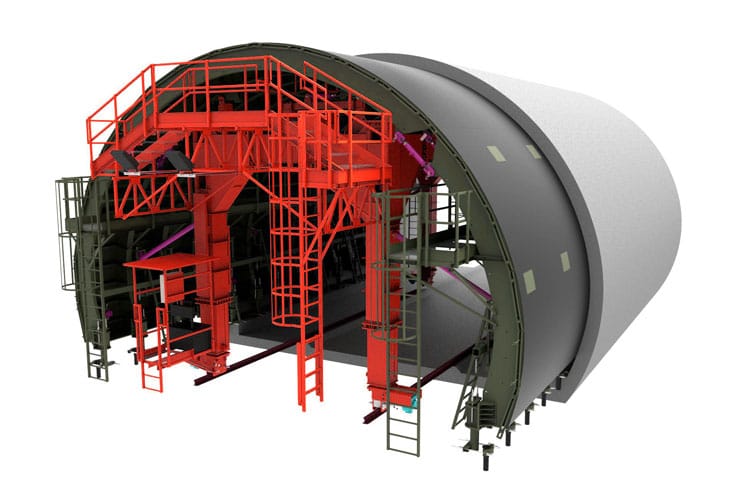

When we discuss hydraulic tunnel lining formwork, we are discussing the Swiss Army knife of tunnel building. It is remarkably efficient, flexible, and exact. How, then, does it work?

Hydraulic formwork uses hydraulic jacks to position and adjust formwork panels precisely.

In tunnels with intricate forms or variable cross-sections—like those curved underground passageways in subway systems—this is a major concern. The hydraulic system allows us to adjust the location of the formwork so that the concrete is poured exactly where it is required. It is like having a mold that responds to our will.

One of the main advantages of hydraulic formwork is that it can simultaneously manage vast stretches of the tunnel. This greatly accelerates things on a wide scale. Its extreme accuracy also reduces the potential for error, therefore reducing delays and maintaining control of expenses. Given that speed and accuracy are essential in big projects, hydraulic systems are not surprising as the preferred choice.

Having said that, things are not always smooth sailing. Skilled operators who know their business are needed for hydraulic formwork; consider them the tunnel-building equivalent of a master chef. And those hydraulic jackings? Given their weight and thickness, moving and setting them up can be a logistical challenge—especially in confined or far-off areas. Still, the advantages usually exceed the drawbacks, hence, we choose this option first hand.

Mobile Tunnel Lining Formwork: Flexibility on the Move

Let us now turn to moveable tunnel lining formwork. If hydraulic formwork is the precision tool, mobile formwork is the nomadic arrangement that keeps the project essentially rolling. Perfect for long, straight tunnels where the cross-section remains constant, it is made to be simply moved along the tunnel as we build.

Imagine a massive, rolling scaffold we could spin from one section to the next. Simply said, that is movable formwork. Mounted on rails or wheels, it can be swiftly repositioned without the trouble of separating and reassembling it. This minimizes downtime between concrete pours, allowing us to stay on schedule without unnecessary delays.

We see great adaptation in mobile formwork. It’s a lifesaver on projects like highway or railway tunnels where time is critical as it can be customized to accommodate various tunnel widths and forms. For handling intricate or irregular designs, however, it is not as flexible as hydraulic formwork. Therefore, even if simple projects are great, they may not be the best option for every tunnel available.

Benefits and Drawbacks of Tunnel Lining Formwork

To be honest, building tunnels is not easy.

Tunnel construction is a high-stakes environment where cost, efficiency, and safety are constantly in flux.

In tunnel construction, our constant balancing act is between budget, speed, and safety.

For us, then, tunnel lining formwork is really important. This makes it shine:

- More safety: Formwork lowers the possibility of collapses or mishaps by keeping everything in place throughout the concrete pouring operation. It is like a safety net keeping the tunnel—and our crew—safe.

- Faster Construction: Mobile systems, as well as hydraulic ones, are designed for speed. While mobile formwork keeps us rolling without needless stops, hydraulic formwork precisely addresses large pours.

- Financial Effectiveness: Although the initial outlay is painful, over time, it pays off. Faster building results in reduced labor expenses; since formwork is reusable, we are not always shopping for fresh materials.

- Consistency and excellence: Formwork guarantees that every part of the tunnel is built according to the same specifications, therefore producing a consistent, first-rate finish. Like a concrete cookie cutter, every bit comes out exactly the same.

Nevertheless, nothing is flawless. Here are some difficulties we deal with:

- You Need Experts: Operating hydraulic or mobile formwork is not a piece of cake using skilled labor. Trained experts who can properly and safely operate the equipment are much needed.

- Limitations Specific to Sites: Not every tunnel location fits formwork nicely. Setting it up in exceptionally tight or irregularly shaped tunnels can be a challenge, much like trying to fit a square peg in a round hole.

- Initial Expenses: Particularly for smaller ventures, the initial outlay may be somewhat high. Not every contractor can afford the initial investment, but it’s a long-term gain.

- Tunnel lining formwork has clear advantages even with these challenges that are difficult to dispute. This is the reason some of the most amazing tunnels in the world feature us.

Applications in the Real World: Tunnels Changing the Landscape

Let’s take a quick look at some famous tunnels that were made possible by tunnel lining formwork. These projects are amazing; formwork was instrumental in bringing them to pass.

Connecting Continents: the Channel Tunnel

Take the Channel Tunnel, for example. You are aware of the undersea wonder connecting France and England. Among the longest submarine tunnels constructed, it stretches more than 31 kilometers. Building it was no picnic, and we were quite grateful for hydraulic tunnel lining formwork. The accuracy of the hydraulic system allowed a waterproof liner capable of withstanding the English Channel’s crushing pressure.

It’s crazy to consider the millions of people who depend on that tunnel annually—and it all comes down to some quite ingenious engineering—whatever we’re racing through it.

Gotthard Base Tunnel: An Exceptional Feat

Then there is the Gotthard Base Tunnel, the longest and deepest railway tunnel in the world, found in Switzerland. Cutting straight across the Alps, it is more than 35 miles long. The hero here was mobile tunnel lining formwork, which helped us pour concrete and reinforce the tunnel as we progressed from section to section with great efficiency. This beast of a project would have cost far more and taken far more time without movable formwork.

Though they are only a handful, these projects illustrate how important formwork is to us. It’s about creating a safe, long-lasting tunnel that will withstand time, not only about excavating a hole.

Future Directions to Tunnel Lining Formwork

Where then was the formwork of the tunnel lining? Looking ahead, we are finding things to get excited about. The following could be on store:

Automation and Robotics

Automation and robotics could lead to formwork that moves along the tunnel automatically or adjusts itself as needed. As robotics gathers momentum, this might drastically reduce hand labor and greatly increase safety.

Becoming More Environmentally Friendly

As building becomes green, we may find formwork created from environmentally friendly materials or intended to waste less. Right now, sustainability is a hot issue.

Smart Formwork

Could formwork with sensors track the real-time curing of the concrete? That might improve our schedules and raise the caliber of our work.

Though they are predicated on where tech is headed, these concepts are not fixed in stone. One thing is obvious: tunnel lining formwork is changing to fit the demands of the future rather than being stationary.

Conclusion

In essence, tunnel lining formwork is an act of valuing the unseen engineering.

Whether you’re on a train, in a car, or even on foot, the next time you’re speeding through a tunnel, stop for a moment to consider what went into it. With tunnel lining formwork right at the core of it, behind those smooth, sturdy walls lies a tale of accuracy, inventiveness, and tenacity.

From the on-the-go flexibility of mobile tunnel lining formwork to the accuracy of hydraulic tunnel lining formwork, these techniques are the hidden heroes of tunnel building. They ensure tunnels are constructed fast, safely, and to last. Though they might not be the center of attention, every tunnel we depend on is built upon them.

Hopefully, this has helped you appreciate the engineering genius behind the scenes! Just let us know whether you need anything more; we are here to assist. Here come the future’s tunnels!

FAQs on Tunnel Lining Formwork

1. What is tunnel lining formwork?

Tunnel lining formwork is a temporary structure used during tunnel construction. It holds the concrete in place while it cures, shaping the tunnel’s walls and roof. Once the concrete hardens, the formwork is removed, leaving a durable lining that helps stabilize the tunnel.

2. Why is tunnel lining formwork important?

Tunnel lining formwork ensures the structural integrity of the tunnel. It prevents the tunnel from collapsing under the weight of the surrounding earth or water. The formwork helps create a uniform, strong surface that can withstand high pressure from traffic or environmental factors.

3. How does hydraulic tunnel lining formwork work?

Hydraulic tunnel lining formwork uses hydraulic jacks to adjust the formwork’s position as concrete is poured. This technology allows precise placement of the formwork, making it ideal for tunnels with complex shapes or variable cross-sections. It speeds up the construction process while ensuring high accuracy.

4. What are the advantages of mobile tunnel lining formwork?

Mobile tunnel lining formwork is highly adaptable and designed to be moved along the tunnel as it progresses. It’s particularly useful for long, straight tunnels with consistent cross-sections. This method reduces downtime, improves efficiency, and allows for continuous pouring of concrete, making it ideal for projects with tight schedules.

5. What types of tunnels use tunnel lining formwork?

Tunnel lining formwork is used in various types of tunnels, including subway tunnels, highways, railways, and even underwater tunnels. The specific type of formwork—whether hydraulic or mobile—depends on the tunnel’s design and construction requirements.