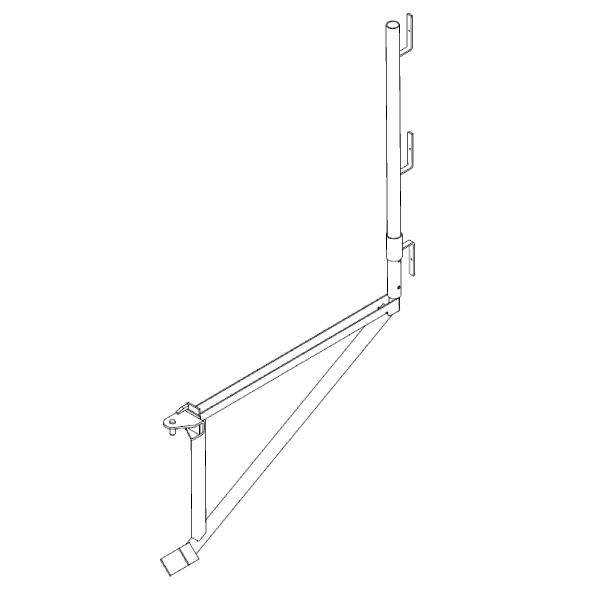

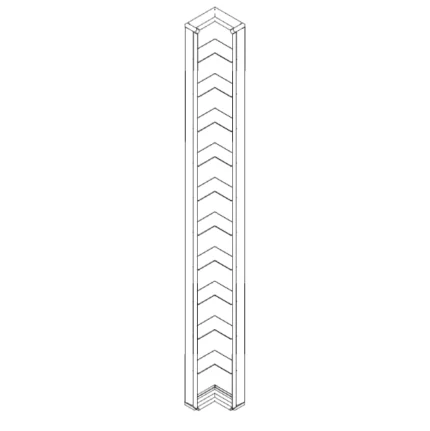

Zigma Pouring Platform

| Product Name |

Zigma Pouring Platform |

|---|---|

| Manufacturer |

BFS Industries |

| Primary Use |

Safety and efficiency during concrete pouring in wall formwork |

| Safety Features |

Integrated handrails, stable platform design |

| Assembly |

Quick and easy setup with minimal crane use |

| Durability |

Weather-resistant, high-quality materials |

| Compatibility |

Integrates with Zigma Panel, Corner, and Lock systems |

| Finish Quality |

Ensures even concrete distribution for smooth finishes |

The Role of Modern Formwork Solutions in the Future of the UAE Construction Industry: From Challenge to Opportunity

In recent decades, the construction industry in the United Arab Emirates has faced increasing challenges, ranging from tight project timelines to the demand for high standards of quality and safety. In this dynamic environment, modern formwork solutions in Concrete Construction have emerged not merely as technical tools but as strategic drivers of project success. By combining rapid assembly, high durability, and adaptability to complex designs, these solutions enable cost reduction, increased efficiency, and improved safety. Smart adoption of modern formwork allows contractors to overcome traditional limitations and deliver projects with greater quality and productivity, transforming today’s challenges into opportunities for growth and innovation in the UAE construction market.

The Macro View of the Construction Market in the UAE

The construction industry in the United Arab Emirates is recognized as one of the most dynamic and resilient economic sectors in the region. With active projects valued at over $600 billion shaping the country’s skyline, this sector makes a significant contribution to the non-oil gross domestic product (GDP). Several factors have driven this growth, including a strong non-oil economy, a booming real estate market, and ambitious government plans for infrastructure and urban development. The UAE government, with major initiatives like “Dubai Smart City” and “Masdar City,” aims to create data-driven and human-centric urban environments, which in turn increases the demand for innovation and advanced technologies in construction.

In this evolving landscape, Concrete Wall Formwork plays a central role by enabling faster, safer, and more cost-effective methods of execution in large-scale projects. Furthermore, other key trends are emerging in the industry, such as a focus on sustainable and eco-friendly buildings, aligning with goals like the “UAE Net Zero by 2050” initiative. These trends highlight the need for environmentally friendly materials and modern construction methods, where advanced concrete wall formwork systems reduce waste, improve efficiency, and ensure precision in complex structures.

In the luxury real estate sector, projects like “Dubai Creek Harbour” and the futuristic “Binghatti Ghost” towers indicate a growing market that places a high value on quality and aesthetics. These projects increasingly demand complex and modern designs that require concrete wall formwork solutions that are not only structurally strong but can also provide high-quality, smooth concrete surfaces that reduce the costs of final finishes.

Overall, these broad market developments are pushing construction companies toward adopting innovative systems such as concrete wall formwork, guaranteeing efficiency, sustainability, and final quality simultaneously, while transforming ambitious architectural visions into tangible realities across the UAE.

The Critical Challenges Facing the Industry in 2025

Despite the promising outlook, the UAE construction industry faces significant challenges that will become more prominent in 2025. One of the most critical and persistent challenges is the rising cost and volatility in the supply chain. The prices of key materials like steel and concrete are increasing sharply, with construction costs in the UAE projected to rise by 3% to 5%. This is due to global inflation, logistical disruptions, and intense competition for resources from the region’s massive projects. Another major challenge is the shortage of skilled labor. Despite strong demand, this industry faces a growing scarcity of skilled workers and specialists in fields such as Building Information Modeling (BIM) and AI technologies. This labor gap can slow down large-scale projects, increase costs, and affect overall work quality.

Project timeline delays and legal disputes have also become a common concern. According to a 2025 analysis, over 80% of companies expect an increase in disputes, primarily stemming from contractual ambiguity, design changes, and tight schedules. Finally, increasing environmental pressures and stricter safety regulations have heightened the need for solutions that comply with sustainability standards like LEED and Estidama, while also ensuring worker safety. For example, the UAE government has banned outdoor work in the hottest hours of the day in summer. These challenges demonstrate that the successful companies of the future will be those that offer innovative and comprehensive solutions to address these issues, rather than simply being suppliers of traditional materials and tools.

Strategic Insights for Overcoming Challenges

In the complex UAE market, traditional, single-use solutions can no longer keep pace with the future standards of this market. The growth of luxury projects with intricate designs and a need for architectural-grade finishes is creating a demand for formwork that can deliver flawless concrete surfaces. Such formwork, by reducing the need for post-pour finishing, leads to direct savings in time and cost. Furthermore, the national goal of “UAE Net Zero by 2050” and the need for construction waste management are key drivers for selecting solutions with high reusability. These conditions make formwork systems like Zigma, which emphasize durability, high-quality finishes, and reusability, an essential strategy for contractors.

In addition, the general slow adoption of technology in the regional construction industry, where reports suggest only 1% of companies have embraced digital transformation, presents a major competitive opportunity for companies that position themselves as pioneers in using new technologies. When a company highlights its capabilities in “robotic manufacturing” and the development of “patented systems,” it quickly differentiates itself from traditional competitors and establishes itself as an innovative and reliable leader in the industry. This approach turns a common challenge into a direct and powerful marketing advantage for companies like B.F.S Industries.

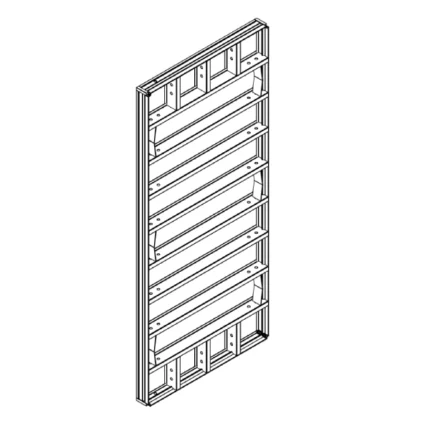

Introducing the Zigma Modular Formwork System: Engineered for Excellence

The Zigma Concrete Modular Formwork represents a new standard in construction efficiency and precision. Engineered for excellence, this system combines robust materials, innovative design, and effortless assembly to deliver superior performance on every project. Its modular structure allows for rapid installation and flexibility, adapting seamlessly to diverse architectural requirements while minimizing material waste and labor costs. By integrating the Zigma system into construction workflows, contractors can achieve faster project completion, enhanced safety, and consistent quality, making it not just a tool, but a strategic asset that drives long-term value and operational success.

The Engineering Philosophy of B.F.S Industries and the Design of Zigma

The Zigma Panel Formwork system is a prime example of B.F.S Industries‘ engineering philosophy to create powerful, efficient, and versatile solutions for concrete construction. With over two decades of experience from its base in the Jebel Ali Free Zone, Dubai, the company is recognized as a leader in concrete formwork, steel structures, and scaffolding. Its focus is on providing solutions specifically designed to address the critical needs of contractors and builders in a competitive market. The design of Zigma is founded on the principle that a formwork system must be more than a collection of components; it must be a tool for optimizing the entire construction process. The system’s panels are made from a high-strength steel frame with a facing of premium plywood or propylene, ensuring unparalleled durability and performance.

Technical Specifications and Precision Engineering

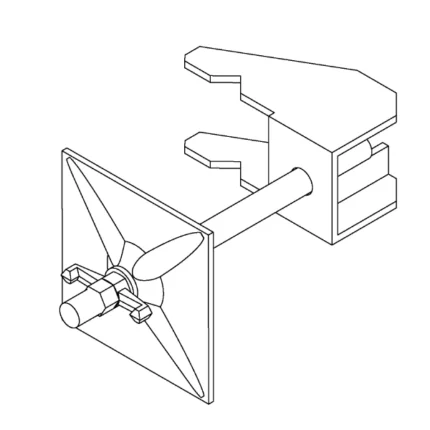

The Zigma Panel Formwork system is engineered for exceptional structural performance in the most demanding projects. One of its most important technical specifications is its flexural strength of 80 kN/m², which adheres to the strict DIN 18202 standard. This high strength demonstrates the panels’ ability to withstand the significant hydrostatic pressure exerted by fresh concrete, a crucial factor for casting tall walls, columns, and foundations, and a key indicator of safety and structural integrity. The system’s stability is further enhanced by the use of high-strength DW 15 Bolts, engineered to tolerate the immense forces of concrete pouring.

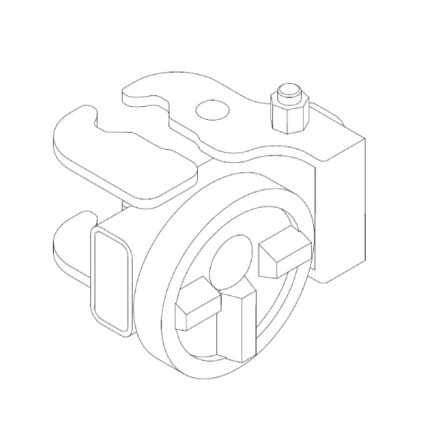

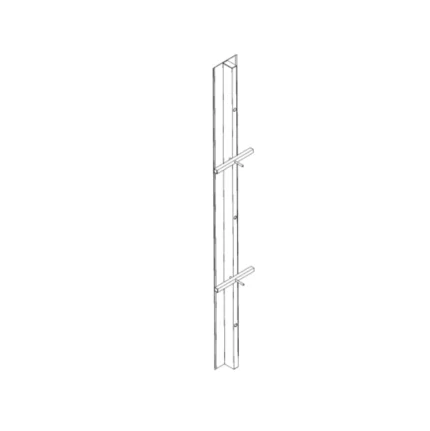

Another key engineering feature of the Zigma system is its modular design. The panels are available in a wide range of heights (150, 270, 300, and 330 cm) and widths (30, 45, 60, 75, 90, 120, and 240 cm), which are multiples of 15 cm. These dimensions align with standard building sizes, helping to reduce material waste and the number of panels needed for a project. The panels can also be used in both horizontal and vertical orientations, providing extensive flexibility for diverse structural layouts. The system’s user-friendly assembly mechanism is also of high importance. The panels are connected with a simple locking mechanism that can be easily engaged or disengaged with a hammer. This simplicity eliminates the need for specialized tools or extensive training, which reduces labor costs and accelerates project timelines. Zigma’s design also eliminates the need for additional props or underpinnings in many cases, which not only reduces assembly time but also creates a safer and more organized work environment.

Presenting precise technical specifications and mentioning international standards like DIN 18202 goes beyond a simple marketing claim. It assures the professional audience that the product is credible, tested, and reliable. In a market like the UAE with complex regulations and a growing focus on safety and quality, citing recognized international standards is a strong signal of credibility. This directly addresses the concerns of engineers and project managers regarding compliance. Furthermore, Zigma’s user-centric design, which requires no specialized tools or extensive training, directly responds to the challenge of skilled labor shortages in the region. In a situation where companies struggle to hire specialists, a system that can be quickly operated by general labor is a major operational and strategic advantage, allowing companies to push projects forward quickly without reliance on expensive or scarce specialized labor.

Operational Advantages and Commercial Value of the Zigma Platform in Construction Projects

The Zigma Platform offers a unique combination of operational efficiency and commercial value that sets it apart in modern construction projects. Its streamlined modular design reduces assembly time and labor requirements, enabling faster project delivery without compromising quality or safety. By minimizing material waste and optimizing resource utilization, the system directly contributes to cost savings and improved profitability. Beyond operational benefits, the Zigma Platform enhances project predictability and reliability, allowing contractors and stakeholders to make informed decisions with confidence. In essence, it transforms construction processes into more efficient, sustainable, and commercially viable ventures, positioning itself as a critical strategic asset for long-term success in the industry.

Reducing Operational Costs and Increasing ROI

The Zigma formwork system, by converting its technical features into tangible commercial benefits, to directly helps reduce operational costs and increase the return on investment for construction Projects. The quick and easy assembly and dismantling mechanism directly lowers labor costs, as it requires fewer working hours and a less specialized workforce. The modular design of the panels also minimizes material waste. This feature not only reduces material purchasing costs but also significantly lowers the expenses related to construction waste management and disposal. One of the most important economic savings comes from the final concrete surface quality. The high-quality facing of the panels minimizes concrete adhesion, resulting in smooth and uniform concrete surfaces. This reduces the need for costly and time-consuming post-pour finishing (such as plastering), saving significant time and money for the project.

Accelerating Project Timelines and Improving Efficiency

Zigma’s ability to accelerate project timelines is one of its greatest advantages. The system’s large panels (such as 330 x 240 cm and 270 x 240 cm) cover a large work area in a short period, which dramatically increases assembly speed. The simple, prop-free assembly mechanism speeds up the process, ensuring projects stay within their planned timelines. This efficiency not only helps reduce project overhead costs but also lowers financial risk by minimizing common delays in the construction industry. Furthermore, by eliminating the need for props, the system creates a safer and more organized worksite, preventing potential accidents.

Durability and Long-Term Longevity

The durability and reusability of Zigma justify its economic value in the long run. In comparison to timber/plywood formwork, which is typically reusable 10 to 20 times, Zigma’s steel panels can be used 200 to 500 times. This exceptional lifespan means a dramatic reduction in the “cost per pour,” making the system highly cost-effective for large-scale, repetitive projects. This high reusability allows companies to recoup their initial investment over time and continuously benefit from it on multiple projects.

The advantages of Zigma directly address the key challenges of 2025 in the UAE construction industry. The high reusability and lower labor requirements help mitigate the effects of rising material and labor costs. Furthermore, quick assembly and the use of large panels offer a direct solution to the common problem of project delays in the region. Given the UAE’s stricter safety regulations, Zigma’s simple and stable design helps companies comply with these requirements while increasing efficiency. In addition, the focus on a “high-quality finish” directly connects Zigma to the growing market for luxury and architecturally focused real estate in the UAE. In a market where luxury properties command the highest transaction values, using a formwork system that delivers a smooth, flawless concrete surface is a major competitive advantage. This feature transforms Zigma from a mere tool into a key component for achieving design goals and enhancing a project’s final value.

Demonstrating B.F.S Industries’ Expertise: A Review of Landmark Projects Executed with Advanced Systems

B.F.S Industries has consistently demonstrated its expertise through the successful execution of landmark construction projects, leveraging advanced formwork and modular systems to achieve exceptional results. By integrating innovative technologies with deep industry knowledge, the company has delivered projects that exemplify efficiency, precision, and structural excellence. Each project showcases B.F.S Industries’ ability to address complex architectural challenges, optimize timelines, and maintain the highest standards of safety and quality. This track record not only reflects the company’s technical proficiency but also highlights its commitment to providing clients with reliable, forward-thinking solutions that transform ambitious designs into tangible, enduring structures.

B.F.S Industries: An Engineering Partner, Not Just a Supplier

B.F.S Industries positions itself as an engineering firm that goes beyond being a simple supplier of building materials. As a subsidiary of B.F.S Holding, and with its headquarters in the UAE, the company has over 20 years of experience in concrete formwork, steel structures, and scaffolding. Its well-equipped factory in the Jebel Ali Free Zone allows it to design and manufacture custom and complex solutions for specific projects. This approach is clearly visible in the landmark projects mentioned below.

Case Study 1: The Diftah-Shish Road and Tunnel Project (UAE)

The Diftah-Shish Road and Tunnel project was a critical infrastructure development in Sharjah that required a highly efficient formwork solution for fast and optimal completion. B.F.S Industries responded to this challenge by designing and manufacturing a “patented full-hydraulic, full-steel, self-propelled tunnel lining formwork system.” This innovative technology, used for the first time in the UAE, was specifically engineered to meet the precise and demanding requirements of this project. The system led to a record-breaking concrete placing efficiency of 10.5 meters every 24 hours for each part of the tunnel, which was considered a major achievement.

Case Study 2: Laleh Tower (Dubai)

The Laleh Tower project is an example of B.F.S Industries’ ability to handle the unique challenges of high-rise construction. The main challenge here was to accelerate the construction of post-tensioned slabs, a complex and time-consuming process. B.F.S Industries’ Dubai office responded by developing the proprietary “BFS-Table Form Systems” and a “2-level lifting C-hook system.” This innovation allowed for lifting the formwork tables two floors at a time, significantly speeding up the project’s timeline. This engineered solution not only improved operational efficiency but also demonstrated B.F.S Industries’ commitment to creating solutions specifically designed to meet the needs of large-scale urban projects.

Case Study 3: The Dubailand Residential Project

The Dubailand residential project, with its 177 buildings, highlights the extensive scale of construction projects in the UAE and the market’s need for reliable and scalable solutions. In this project, B.F.S Industries played a pivotal role in supplying a “specialized one-sided formwork system” for a 3.5-meter retaining wall. This case study demonstrates the company’s capability to create bespoke and cost-effective solutions for unique structural challenges. Each of these case studies serves as tangible proof of three key concepts: innovation through patented and self-propelled systems, versatility in addressing different types of structures (tunnels, towers, and walls), and efficiency in accelerating timelines and reducing labor costs. These projects tangibly prove that B.F.S Industries and its products, including Zigma, are valuable tools for achieving project success in the competitive environment of modern construction.

The Zigma Difference: Engineered for Efficiency, Precision, and Sustainability

The Zigma Difference lies in its seamless integration of efficiency, precision, and sustainability within modern construction practices. Designed with cutting-edge engineering, the system streamlines assembly processes, reduces labor requirements, and ensures consistent structural accuracy across diverse project types. Its durable, reusable components minimize material waste, supporting environmentally responsible construction while lowering operational costs. By delivering faster project completion, enhanced safety, and long-term reliability, the Zigma system not only elevates the quality of each build but also empowers contractors to achieve sustainable, economically viable outcomes, setting a new benchmark for excellence in the construction industry.

Technical Features and Operational Advantages

The Zigma platform is the result of a comprehensive approach to formwork design, where every technical feature is engineered to provide a tangible operational advantage. The system’s modular design, composed of prefabricated panels, allows for quick assembly and dismantling. This efficiency directly leads to reduced labor costs and time savings, as the installation process requires minimal tools and a smaller workforce. The simple hammer-driven locking mechanism has a profound impact on project management, allowing contractors to progress quickly without the need for specialized workers.

The Zigma panels are made with high-strength steel frames that enable them to withstand the heavy loads of concrete pouring. This strength not only ensures safety on the worksite but also provides exceptional durability and longevity for repeated use across multiple projects. A critical component of the system is the use of the engineered DW 15 Bolt, which is specifically designed to tolerate the immense forces of concrete pouring and ensure the formwork remains stable and secure throughout the process. Furthermore, the simplicity of the Zigma system eliminates the need for additional underpinnings or props during setup. This not only makes the worksite safer and more organized but also dramatically reduces operational costs and time, allowing contractors to allocate their resources more effectively. These features collectively position Zigma as a tool for optimizing the entire construction process, from logistics to execution.

Final Quality and Reduced Ancillary Costs

One of the most important benefits of the Zigma platform is its impact on the final quality of the concrete surface. The system is designed to produce a smooth and precise concrete finish, minimizing the need for final finishing work or post-pour operations. This is not just an aesthetic advantage but a practical one that results in significant cost savings. Post-pour finishing work, including plastering, filling voids, and surface repairs, often accounts for a substantial portion of a project’s time and labor costs. By minimizing the need for these processes, Zigma drastically reduces time, labor, and material costs. This not only improves project efficiency but also enhances the overall quality of construction.

In addition, the choice of formwork material has a direct impact on the physical characteristics of the concrete surface. Scientific research shows that different materials such as galvanized steel, wood, and PVC affect surface density, porosity, voids, and even the chemical composition of the concrete. The use of high-strength steel frames in the Zigma system not only ensures durability but also leads to a uniform, high-quality finish that requires minimal additional work. The Zigma panels are also easy to clean due to their engineered design, which is a crucial detail for their reusability and long-term cost-effectiveness. This commitment to quality at every step of the process positions Zigma as an essential tool for achieving high-quality results efficiently and enhancing a project’s overall value.

Comparative Table: The Value of Steel vs. Timber

| Feature / Advantage | Steel (Zigma) | Timber |

|---|---|---|

| Initial Cost | Higher (22.5% higher than timber) | Lower |

| Reusability | Hundreds of times | Less than 10 times |

| Cost Per Use | Very Low | High |

| Best Use Case | Large-scale, repetitive projects | Small or custom projects |

| Impact on Labor | Fast assembly, less labor needed | Slow assembly, requires skilled labor |

| Sustainability Impact | Lower Global Warming Potential over its lifespan | Higher Global Warming Potential over its lifespan |

Conclusion: Partnering with B.F.S. Industries for the Future of Construction

The Zigma Pouring Platform is not just an advanced formwork system but a strategic tool for addressing the complexities of modern, dynamic construction in the Middle East and Africa. With its focus on efficiency, precision, and durability, the platform directly responds to the industry’s key challenges, including rising costs, skilled labor shortages, and the need for sustainability. Its exceptional reusability, which can reach hundreds of uses, makes it a cost-effective option for large-scale projects and significantly reduces long-term costs. Furthermore, its steel durability and simple assembly process help lower labor costs and accelerate project timelines.

B.F.S Industries, with over 20 years of innovation and commitment to quality, has established itself as a thought leader in the industry. From critical infrastructure projects like the Diftah-Shish tunnel to complex urban developments like the Laleh Tower, the company has consistently demonstrated its ability to provide engineered solutions that exceed expectations. The company’s focus on providing a “real competitive edge in the market” shows that B.F.S Industries sees itself not just as a vendor but as a partner in its clients’ project success. The Zigma platform, as an embodiment of this philosophy, is a tool for the future of construction: smarter, faster, more cost-effective, and more sustainable. To learn how Zigma can meet your project’s specific needs, request a consultation through B.F.S Industries’ customer service channels.

مهند الكبيسي –

هل المنصة مزودة بحواجز أمان جانبية؟ وأريد معرفة طريقة التثبيت على السقالات.