- Published:

- Written by: B.F.S Industries

Formwork Process Step by Step: Complete Guide for Concrete Construction

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

Formwork process step by step at BFS Industries begins with creating a temporary mold that shapes and supports freshly poured concrete until it hardens, ensuring the structure achieves the desired shape, dimensions, and surface finish. Proper formwork is essential for foundations, walls, slabs, columns, and beams, as it directly impacts quality, safety, cost, and project timelines. Traditionally, formwork relied on timber and plywood, requiring labor-intensive on-site assembly, which could lead to inconsistencies and higher waste. BFS Industries’ modern modular formwork systems are designed for efficiency, durability, and reusability, reducing labor, minimizing waste, and accelerating construction cycles.

Choosing the right system depends on project scale: traditional methods suit small or custom projects, while modular systems are ideal for large-scale commercial or industrial developments. Beyond simply containing concrete, proper formwork ensures smooth finishes, correct reinforcement placement, and accommodates inserts for openings like windows and doors. In this guide, BFS Industries covers the formwork process step by step, from materials and installation to innovations and safety practices, helping builders execute concrete construction efficiently and flawlessly.

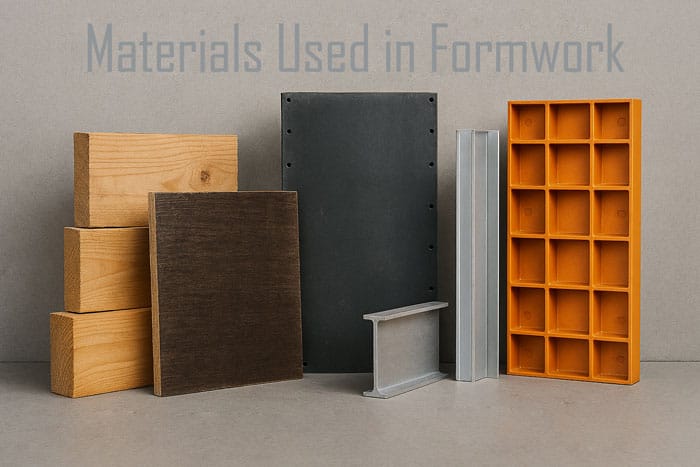

Materials Used in Formwork

Selecting the right materials for formwork is crucial to the success of any concrete construction project, as the choice directly affects the quality, durability, and efficiency of the finished structure. Several factors must be considered, including the scale of the project, budget constraints, environmental conditions, and the desired number of reuse cycles. Choosing an inappropriate material can lead to structural defects, increased labor costs, or wasted resources. The most commonly used formwork materials include timber, plywood, steel, aluminum, and plastic, each offering unique advantages and limitations. By understanding their characteristics and suitability, builders can make informed decisions that optimize both performance and cost-effectiveness in their concrete construction projects.

Timber Formwork

Timber formwork, often made from softwoods like pine or spruce, is one of the oldest and most accessible options for concrete construction. It is cost-effective for small projects and easy to cut and shape on-site, making it ideal for traditional setups. However, timber absorbs moisture, which can cause warping or swelling, and it is less reusable, typically lasting only 5-10 cycles. Pro tip: Always treat timber with preservatives to extend its lifespan and prevent mold growth.

Plywood Formwork

Plywood, a layered wood product, enhances timber formwork by providing a smoother surface for concrete. Film-faced plywood, coated with phenolic resin, is particularly valued for its water resistance and ability to deliver a high-quality finish without extra release agents. Lightweight and versatile, plywood is ideal for wall and slab formwork. However, it can delaminate under repeated use or exposure to harsh weather. Compared to timber, plywood reduces assembly labor but requires careful storage to prevent damage.

Steel Formwork

Steel formwork is known for its strength and durability, making it suitable for large-scale projects such as dams, tunnels, or bridges. Prefabricated steel panels can withstand high concrete pressures and are highly reusable—up to 100 cycles or more—with minimal maintenance. Steel aligns perfectly in modular systems, ensuring precise structures. The main drawbacks are its heavier weight, which increases transportation costs, and susceptibility to rust if not properly galvanized.

Aluminum Formwork

Aluminum formwork is a lightweight alternative to steel, weighing about one-third as much, making it easier to handle and assemble. It is corrosion-resistant, recyclable, and ideal for high-rise buildings where speed is essential. Modular aluminum systems allow rapid cycling, such as pouring a floor every 4-5 days. While more expensive upfront than timber, its long-term reuse potential—up to 250 cycles—reduces overall costs. Proper bracing is essential to prevent deformation under concrete pressure.

Plastic Formwork

Plastic formwork, an emerging and innovative option, is made from materials like polypropylene or fiberglass-reinforced plastics. It is lightweight, waterproof, and easy to clean, reducing the need for release agents. Plastic systems are modular, eco-friendly, and produce minimal waste. While they may not withstand extreme pressures like metal systems, they are perfect for residential projects or areas with high humidity where traditional materials may fail.

Traditional vs. Modular Formwork

When comparing traditional and modular systems, timber and plywood are flexible but less sustainable, while steel, aluminum, and plastic prioritize efficiency, durability, and reuse. Best practice: Conduct a cost-benefit analysis based on project requirements to select the optimal material, ensuring high quality while minimizing environmental impact.

Planning and Preparation Before Formwork Installation

Before diving into the formwork process step by step, thorough planning and preparation set the foundation for success. This phase involves assessing the site, planning layouts, and selecting the appropriate formwork type to avoid delays and ensure structural integrity. Site assessment is the first step. Evaluate soil conditions, topography, and weather forecasts, as these factors influence formwork stability. On uneven terrain, additional shoring may be needed to prevent shifting. Check for underground utilities or obstacles that could interfere with foundations. Pro tip: Use laser levels or GPS for accurate mapping to identify potential issues early.

Layout planning follows, where detailed drawings and blueprints guide the formwork design. This includes marking positions for walls, column formwork, and slabs, considering dimensions, tolerances, and load-bearing requirements. Expansion joints and reinforcement placement should also be incorporated. In modular formwork systems, pre-planning with 3D modeling software like AutoCAD or Revit can simulate assembly, reducing on-site errors. A common mistake is skipping this step, which can lead to misalignments requiring costly corrections.

Selecting the right formwork type is critical. For vertical elements like walls and column formwork, choose between traditional timber for custom shapes or modular aluminum for speed. Slab formwork might favor steel for heavy loads or plastic for lighter residential floors. Factor in reuse: modular systems are preferable for repetitive pours. Accessibility is also important—ensure materials can be transported and stored safely on-site.

Preparation also includes gathering tools and equipment, such as levels, hammers, clamps, and release agents. Train the workforce on formwork safety tips, including proper lifting techniques to avoid injuries. Troubleshooting tip: If budget constraints arise, hybrid systems (e.g., timber with steel bracing) can balance cost and performance. By investing time in careful planning, you mitigate risks, enhance efficiency, and ensure the formwork process step by step flows seamlessly into installation.

Step-by-Step Formwork Installation Process

The core of the formwork process step by step lies in the installation phase. This systematic approach ensures that temporary concrete molds are secure, properly aligned, and ready for pouring. Correct installation is crucial for achieving structural integrity, minimizing defects, and maintaining safety on-site.

For vertical elements, including walls and circular column formwork, precise alignment and bracing are essential. Modular systems from BFS Industries allow for efficient assembly, ensuring that even complex shapes like circular columns maintain consistent dimensions. Slabs, beams, and other horizontal elements also require careful setup to prevent sagging or deformation under concrete pressure. By following these steps methodically, builders can ensure that every component of the formwork system is correctly positioned, secure, and ready for the concrete pour, forming the backbone of a successful construction project.

Step 1 – Preparing the Base and Foundations

The first step in the formwork process step by step is preparing a stable base to support the formwork. Start by clearing the site of debris, vegetation, and loose soil, then compact the ground using rollers or vibrators to achieve an even surface. For foundations, excavate to the required depth and install footings or pads as needed. In modular systems, base plates or sleepers are laid out to distribute loads evenly, while traditional setups use timber mudsills to create a level platform. Proper drainage is essential to prevent water accumulation, which could weaken the base, and in slab formwork, a gravel sub-base can further improve stability. To ensure accuracy and avoid common issues, verify levels using a spirit level or theodolite, conduct soil tests to prevent settlement problems, and if the ground is soft, reinforce it with geogrids to provide a solid and reliable foundation.

Step 2 – Erecting Formwork Panels

In the formwork process step by step, the next stage is erecting the panels that form the mold’s sides. Start with vertical elements such as walls or column formwork, positioning each panel carefully according to the planned layout. For modular systems, prefabricated panels can be quickly clipped or bolted together, while traditional timber sheets are nailed or screwed in place. Begin assembly from one corner and work systematically, ensuring all joints are tight to prevent concrete leakage. In wall formwork, the inner and outer panels create the cavity for the concrete pour, and using spacers helps maintain consistent thickness throughout. Modular aluminum panels offer a significant advantage in speed, reducing labor by 30–40% compared to timber. Common mistakes include over-tightening joints, which can cause cracks, but applying sealant at seams ensures watertightness and a smooth, defect-free finish.

Step 3 – Assembling Support and Bracing Systems

In the formwork process step by step, assembling supports and bracing systems is essential to prevent the formwork from collapsing under the weight of freshly poured concrete. Props, shores, and trusses should be installed both vertically and horizontally, with adjustable steel props commonly used for slabs and diagonal braces for walls. It is important to calculate loads based on concrete density (approximately 2400 kg/m³) and the height of the structure. Modular systems often include integrated bracing, which simplifies installation and ensures precision. For high walls, adding horizontal walers provides extra support and enhances stability. To maintain safety and efficiency, braces should be spaced evenly to distribute forces, while considering potential wind loads that could shift or destabilize the formwork. In exposed areas, additional supports or guy wires can be used to reinforce the structure, ensuring secure and safe installation throughout the concrete pouring process.

Step 4 – Installing Accessories (Tie Rods, Inserts, Chamfers)

In the formwork process step by step, installing accessories is essential to enhance both the functionality and finish of the concrete structure. Tie rods connect opposing panels and resist outward pressure, typically spaced at 600–900 mm intervals, while inserts allow embedding items such as conduits, anchors, or other fixtures into the concrete. Chamfers create beveled edges that improve aesthetics and make formwork removal easier, and in modular systems, these features are often built into the panels. Using plastic cones on tie rods can simplify extraction after the concrete has cured. Common mistakes include neglecting waterproofing around inserts, which can cause leaks, and insufficiently checking the strength of ties before pouring. Careful attention to these details ensures the formwork remains secure and the finished concrete structure meets both quality and safety standards.

Step 5 – Ensuring Proper Alignment and Leveling

In the formwork process step by step, ensuring proper alignment and leveling is crucial for structural accuracy. Vertical and horizontal elements, including walls and rectangular column formwork, should be checked using plumb bobs, spirit levels, or laser tools, and adjustments made with shims or jacks as necessary. For large areas, string lines or total stations can help maintain consistency, while slab formwork may include a slight camber to account for deflection under load. Modular formwork systems further aid precision with adjustable components, making alignment faster and more reliable. To achieve optimal results, check multiple points throughout the structure rather than relying solely on visual inspection, and if any misalignment occurs, correct it immediately before proceeding with concrete pouring.

Step 6 – Applying Release Agents for Smooth Concrete Finish

In the formwork process step by step, the final step of installation is applying release agents to panel surfaces to prevent concrete from sticking. This ensures easy stripping of the formwork and a smooth, defect-free concrete finish. Brushes or sprays can be used to achieve even coverage, and it is important to choose agents compatible with the formwork material—for example, water-based release agents for plywood panels. In plastic formwork, release agents may be optional due to their natural non-stick properties. Over-application should be avoided to prevent staining, while skipping this step on reused forms can lead to rough or uneven surfaces. Testing a small area before full application helps ensure optimal results. Completing this step-by-step installation process ensures that temporary concrete molds are robust, secure, and fully prepared for the concrete pouring phase.

Concrete Pouring and Monitoring

Once the formwork is securely in place, the formwork process step by step moves to concrete pouring. Concrete should be filled evenly using pumps or chutes, starting from one end to prevent segregation, while vibration is applied carefully to eliminate air pockets and ensure proper compaction without shifting the formwork. During pouring, it is crucial to monitor for leaks or bulges and reinforce the formwork if necessary. For walls and slabs, pouring in layers of 300–500 mm helps manage pressure, and modular systems can handle higher pour rates due to their inherent strength. Temperature sensors can be used to track curing, as heat significantly affects setting times, and scheduling pours during cooler weather can prevent rapid drying. Pouring too quickly is a common mistake that risks blowouts, so having repair kits on hand allows for quick fixes. After pouring, protecting the concrete from adverse weather with covers and maintaining adequate moisture ensures optimal strength and a durable finish.

Formwork Removal (Stripping) Process

The final stage in the formwork process step by step is the removal, or stripping, of the formwork once the concrete has reached adequate strength—typically 50–70% of its design strength, as verified through cube tests (for example, 3–7 days for walls and 14–21 days for slabs). Begin with non-load-bearing elements, such as side panels, carefully using levers or jacks to avoid damaging the concrete. In modular systems, disassembly is simpler thanks to quick-release mechanisms. The proper sequence is to remove ties first, followed by braces, and then panels, cleaning and storing all components immediately for future reuse. Stripping early can accelerate formwork turnover, but premature removal may cause cracking. Common mistakes include forcing panels off, which can chip or damage the concrete, while troubleshooting may involve using additional release agents or retarders in future pours. Safety is paramount—ensure workers wear proper PPE and perform the task in teams to maintain a safe and efficient removal process.

Post-Formwork Considerations

After stripping the formwork, it is essential to inspect the concrete for defects such as voids or honeycombing and patch them with grout if necessary. Proper curing of the surface using membranes or water spraying enhances durability and ensures long-term strength. At the same time, evaluate the formwork components for reuse—repair any dents in steel panels or replace warped timber—and document lessons learned to improve efficiency in future projects. In modular systems, keeping an inventory of panels helps track wear and plan maintenance. From an environmental perspective, recycling damaged materials reduces waste and promotes sustainability. Best practice includes conducting thorough quality checks against the project drawings, while common issues like surface imperfections can be addressed with grinding or finishing techniques. Following these steps ensures both the longevity of the structure and the overall efficiency of the construction project.

Safety Measures During Formwork Installation

Safety is a top priority in the formwork process step by step, as any mishaps can lead to injuries or structural collapses. Conduct thorough risk assessments and provide comprehensive training on formwork safety practices. Workers should always wear proper PPE, including helmets, gloves, and harnesses when working at heights, and ladders and scaffolds must be securely positioned with loads limited on platforms. Bracing should follow engineering specifications to prevent failures, and in windy conditions, additional ties may be necessary. Hazards such as falling objects should be mitigated with toe boards, and implementing daily inspections helps maintain a safe work environment. Modular systems often reduce risks by requiring fewer manual adjustments compared to traditional setups. Common mistakes include overloading formwork, which underscores the importance of training workers on proper load calculations, and emergency protocols such as first-aid and evacuation plans should always be in place. Prioritizing safety not only protects workers but also prevents project delays and legal issues, ensuring a smooth and efficient construction process.

Modern Innovations in Formwork Systems

The formwork industry continues to evolve with innovations that enhance efficiency, precision, and sustainability. Self-climbing formwork, commonly used in high-rise construction, allows panels to be hydraulically lifted floor by floor, significantly reducing construction time. 3D-printed formwork enables the creation of complex architectural shapes with minimal waste, while smart sensors integrated into modular systems monitor pressures and alignment in real time, helping to prevent failures. Eco-friendly alternatives, such as recycled plastic or bamboo formwork, contribute to lowering the carbon footprint of construction projects. Building Information Modeling (BIM) further improves planning by simulating the concrete formwork process for greater accuracy. Compared to traditional methods, these modern systems reduce labor requirements and minimize errors, even though they may involve higher initial costs. Looking forward, AI-optimized designs promise to make formwork installation faster, safer, and even more efficient.

Conclusion

Mastering the formwork process step by step is crucial for achieving successful and durable concrete construction, from initial planning to final removal. By carefully selecting materials, following systematic installation steps, and prioritizing safety at every stage, builders can ensure high-quality results efficiently. Key strategies include opting for modular systems to save time and allow multiple reuses, emphasizing thorough preparation to prevent mistakes, and adopting innovative solutions to enhance sustainability. Whether working with traditional timber, plywood, or advanced aluminum and plastic systems, quality formwork provides the foundation for strong, long-lasting structures. Implementing these best practices not only improves project outcomes but also helps construction teams remain competitive and forward-thinking in the civil engineering industry.