- Published:

- Written by: B.F.S Industries

How to Prevent Cracks in Your Concrete Projects

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

Concrete cracking is a persistent challenge in construction, often viewed as an inevitable consequence of the material’s inherent properties. However, for large-scale, high-durability projects, hairline fractures are unacceptable. The successful mitigation of cracking—especially those initial, damaging fissures that occur within the first 72 hours—demands a sophisticated, systematic approach that goes beyond rudimentary site practices. At B.F.S Industries, we understand that controlling the structural integrity of concrete begins long before placement and requires meticulous attention to thermodynamics, hydrational chemistry, and mechanical restraint. This guide provides an expert-level technical breakdown of the most effective, site-proven methods to prevent Cracks During Concrete Pouring and subsequent early-age development, ensuring the longevity and performance of your structures. We will cover everything from initial mix design adjustments to advanced thermal and curing protocols necessary for achieving crack-free concrete.

Foundational Mix Design Adjustments for Durability

Controlling the internal chemistry and physical volume stability of the concrete matrix is the first and most critical step in preventing early-age failure. Structural failure caused by Cracks During Concrete Pouring is frequently initiated by internal stresses that develop due to poor mix balance or component selection. An expert approach leverages precise material proportions to minimize the volumetric changes associated with cement hydration and drying. This level of optimization requires a deep understanding of how each component—cement, aggregates, water, and admixtures—interacts under specific ambient and structural conditions. By adjusting the composition to control heat generation and water demand, engineers can drastically reduce the propensity for shrinkage and thermal stress before the material is fully set.

Controlling the Water-Cement Ratio

The water-cement ratio control is arguably the most influential factor in both concrete strength and susceptibility to cracking. A lower ratio significantly reduces the amount of free water available for evaporation, thereby minimizing shrinkage potential and increasing the density and tensile strength of the hardened paste. This strategy directly combats the development of Cracks During Concrete Pouring by limiting the volume change as the concrete sets. However, engineers must carefully balance the reduced workability of low-w/c mixes with the need for proper consolidation and placement.

Utilizing Supplementary Cementitious Materials (SCMs)

Integrating SCMs, such as fly ash, slag cement, and silica fume, offers a multifaceted defense against cracking. These materials replace a portion of the cement, leading to slower heat generation (reducing thermal gradient risks) and producing a finer, more durable paste structure that is less permeable. Furthermore, SCMs modify the microstructure to better resist drying shrinkage. This deliberate adjustment in the concrete mix design adjustments ensures a slower, more stable setting process, critically reducing the internal stresses that cause Cracks During Concrete Pouring.

Mastering Early-Age Volume Stability

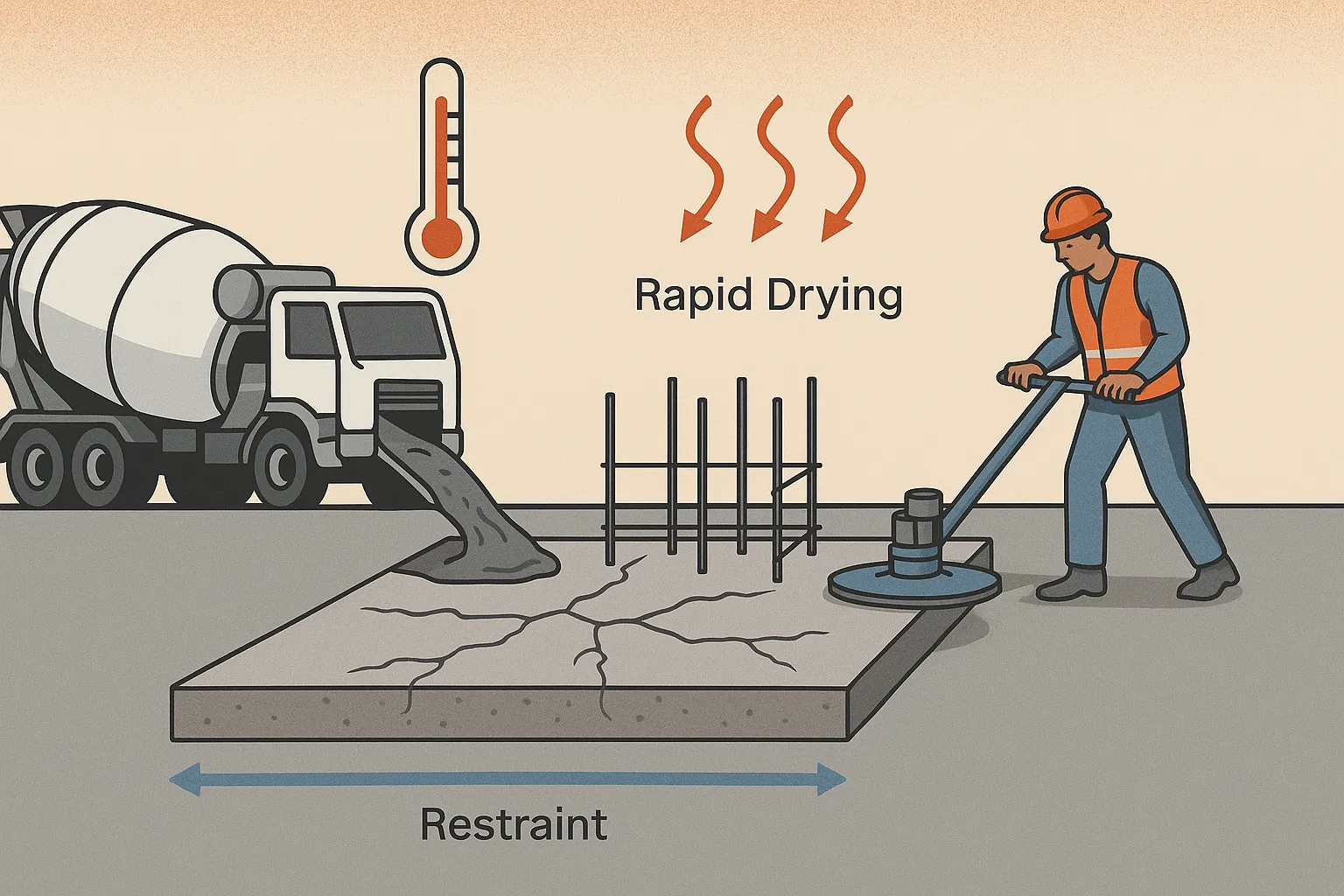

The period immediately following placement is the most volatile phase, where concrete is highly vulnerable to external environmental factors. The primary challenge during this stage is managing the rapid loss of moisture from the exposed surface, which can generate tensile stresses far exceeding the concrete’s nascent strength. Controlling this vulnerability requires proactive intervention to ensure the surface and internal moisture gradients remain shallow and manageable. Effective early-age volume stability measures are paramount to overcoming the risk of surface degradation and structural compromise.

Mitigating Plastic Shrinkage Cracks

Plastic shrinkage cracks occur when the rate of surface evaporation exceeds the rate at which bleed water can rise to the surface. This creates immediate, wide, but shallow fissures. To mitigate this, tools like evaporation retarders (monomolecular films) or fog sprays must be deployed immediately after screeding and before finishing. Crucially, if high ambient temperatures or low humidity are predicted, adjusting the pouring temperature limits or shading the slab is non-negotiable to limit moisture loss and prevent this immediate form of damage.

Optimizing Evaporation Rate Management

Effective evaporation rate management requires real-time monitoring of site conditions, including air temperature, relative humidity, and wind speed. When the calculated evaporation rate exceeds $1.0 \text{ kg/m}^2/\text{h}$, the risk of cracking becomes critical. Advanced site planning should include movable windbreaks or temporary overhead covers, which create a micro-climate above the fresh concrete. This preemptive control of the surrounding air limits the tensile forces that propagate Cracks During Concrete Pouring, particularly in large, exposed slab areas.

Strategic Reinforcement and Joint Planning

While reinforcement does not eliminate cracking, it is essential for controlling crack width and distribution. Properly designed and placed reinforcement ensures that any inevitable micro-cracks are held tightly, preventing them from propagating into wide, structurally compromising fissures that expose the steel to corrosion. Furthermore, effective joint planning manages the structural consequences of volume change, directing the movement of the concrete to predetermined locations where cracks can be concealed and controlled.

Implementing Effective Reinforcement Detailing

Beyond using the specified quantity of steel, reinforcement detailing must focus on cover accuracy and placement stability. The rebar cage must be securely supported by high-quality chairs or bolsters to ensure it remains precisely where designed, particularly in deep sections. Misplaced reinforcement—such as steel that sags below the neutral axis or is too close to the surface—dramatically reduces its effectiveness in managing tensile stresses, leading to uncontrolled Cracks During Concrete Pouring and subsequent structural failure.

Precise Contraction Joint Placement

Contraction joints are the engineer’s primary tool for managing restrained drying shrinkage. The placement and depth of these joints must adhere strictly to established design codes, typically dividing slabs into bays where the joint spacing does not exceed 24 to 30 times the slab thickness. Joints must be cut early—within the first 4 to 12 hours after finishing—to a depth of at least $1/4$ of the slab thickness to ensure they are activated before the internal tensile stress causes random cracking.

Thermal Stress Management

Thermal cracking is a major concern in mass concrete elements and large slabs, driven by the heat generated during the exothermic hydration of cement. The differential temperature between the core of the concrete and its cooler surface (or between a new pour and a hardened adjacent structure) induces powerful tensile stresses that can cause through-section cracks. Mitigating these stresses is crucial, especially when large volumes of concrete are placed, demanding a comprehensive thermal control strategy.

Controlling Temperature Differential in Slabs

The maximum allowable temperature differential between the core and the surface of a concrete element is a key metric in crack prevention, often limited to $20^{\circ}\text{C}$ ($36^{\circ}\text{F}$). Exceeding this limit rapidly increases the risk of tensile failure. Control measures include utilizing low-heat-of-hydration cement, cooling aggregates or mixing water before batching, and, post-placement, applying thermal blankets or insulation to the exposed surfaces to slow the heat exchange rate and homogenize the temperature gradient, thereby preventing significant Cracks During Concrete Pouring.

Preventing Thermal Cracking in Concrete

To prevent thermal cracking in concrete, engineers must calculate the adiabatic temperature rise of the mix and establish a thermal control plan. This plan should include pouring temperature limits which might require chilling the concrete mix to $10^{\circ}\text{C}$ to $15^{\circ}\text{C}$ ($50^{\circ}\text{F}$ to $59^{\circ}\text{F}$) in hot weather. Furthermore, for mass concrete applications, installing temperature probes allows real-time monitoring of the core-to-surface differential, enabling immediate and targeted responses, such as surface wetting or insulation adjustment, to maintain the thermal stability of the element and mitigate the most destructive forms of early-age concrete cracking.

Formwork and Placement Preparation

The quality of the special formwork in construction and the methods used during placement have a direct and immediate impact on the final stress state of the concrete. Formwork provides restraint, which, if improperly managed, can exacerbate the development of Cracks During Concrete Pouring due to mechanical resistance to shrinkage or movement. Placement practices, especially consolidation via vibration, are critical for eliminating voids and ensuring the concrete achieves its designed density and strength potential.

Best Practices for Formwork Vibration Methods

Proper consolidation through formwork vibration methods is essential for eliminating entrapped air and achieving maximum density, which translates directly to higher strength and lower permeability. However, over-vibration can lead to segregation, where heavy aggregates settle, and fines/water rise, weakening the concrete matrix and increasing the potential for Cracks During Concrete Pouring at the surface. The expert method involves using high-frequency vibrators for the shortest effective duration—just long enough to see the surface flatten and air bubbles cease to rise.

Utilizing BFS Industries and Special Formwork in Construction for Complex Geometry

The geometry of the structure heavily influences crack risk. Complex, highly restrained shapes, particularly those with abrupt changes in cross-section, are crack-prone. This is where specialist providers like BFS Industries become essential. We engineer and supply special formwork in construction that not only provides the required structural support but also accounts for thermal movement and stripping schedules. For instance, designing formwork with controlled release points or using materials with specific thermal properties can aid in managing the internal stresses that cause early-age concrete cracking in intricate precast or cast-in-place elements. This strategic formwork design is integral to a comprehensive crack prevention plan.

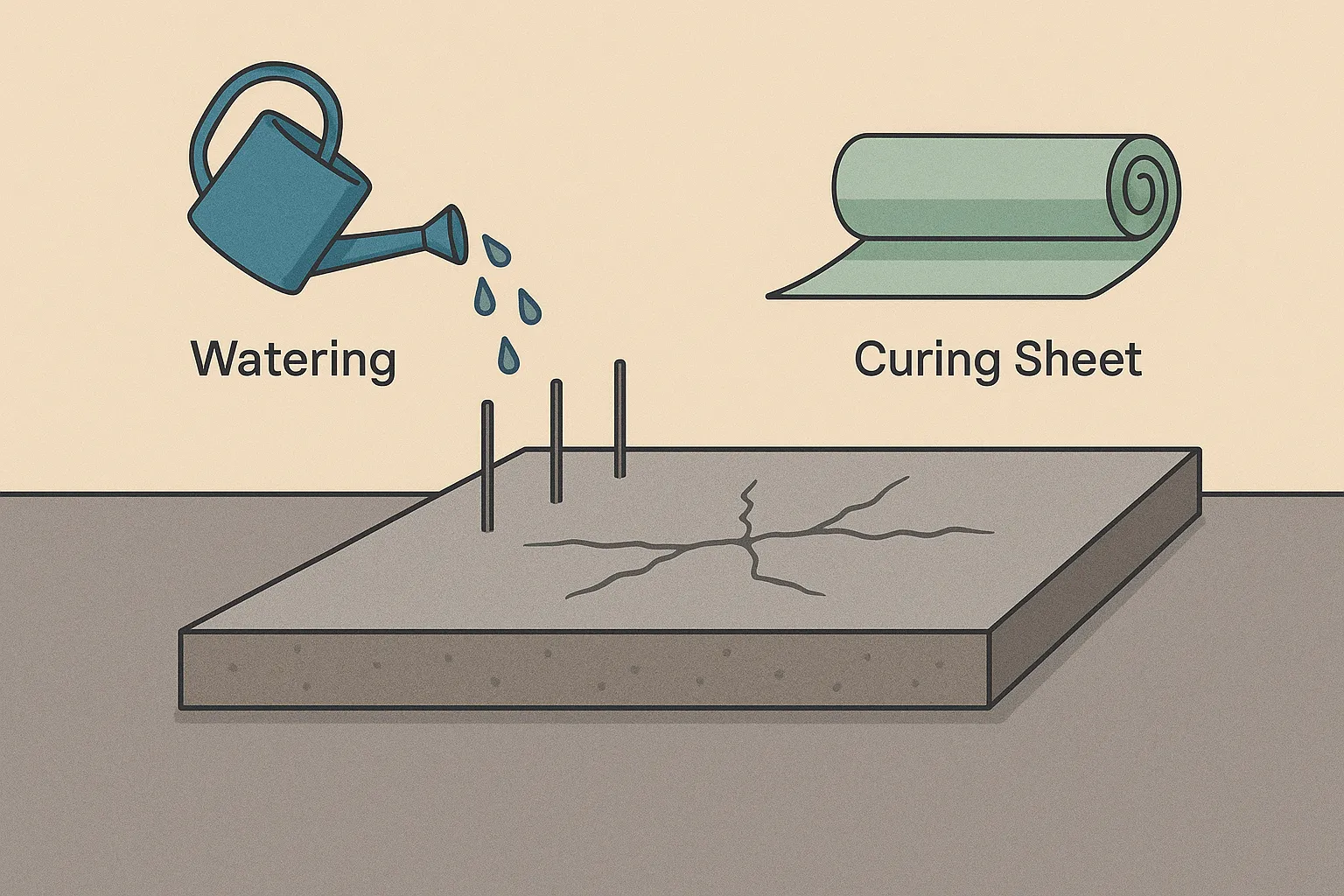

Advanced Curing Protocols

Curing is arguably the most neglected phase of concrete construction, yet it is where the concrete gains its ultimate strength and durability. An aggressive, premature drying environment can strip the concrete of the water needed for continued cement hydration, resulting in severely reduced surface strength and the immediate onset of drying shrinkage. Proper curing is the final protective measure against cracking and is non-negotiable for high-performance concrete.

Executing Comprehensive Concrete Curing Techniques

Comprehensive concrete curing techniques involve maintaining both moisture and temperature. Techniques include continuous ponding, applying water-saturated coverings (burlap), or using high-quality liquid membrane-forming curing compounds. For structural concrete, especially pavements and slabs, a minimum continuous curing period of seven days is mandatory. Discontinuities in curing, such as allowing a wet surface to dry out for even a few hours, can initiate surface cracking that propagates into the structure, worsening the effects of Cracks During Concrete Pouring observed earlier.

Importance of Early-Age Strength Development

The development of sufficient tensile strength at an early-age concrete cracking stage is crucial to resisting both drying and thermal stresses. Concrete gains about $70\%$ of its final strength within the first seven days, and most cracking occurs before the fourth day. By implementing concrete mix design adjustments (such as incorporating chemical accelerators) and applying rigorous curing, the concrete’s tensile capacity is boosted rapidly, allowing it to withstand the internal and external restraint forces that attempt to pull it apart.

Site Logistics and Pouring Temperature Limits

Effective crack prevention extends into the logistics of the construction site itself. The environment in which the concrete is mixed, transported, and placed is rife with variables that can increase cracking risk. Controlling the consistency and temperature of the concrete delivered to the site, coupled with a well-orchestrated placement sequence, is vital.

Managing Pouring Temperature Limits on Site

Strict adherence to pouring temperature limits—typically between $10^{\circ}\text{C}$ and $32^{\circ}\text{C}$ ($50^{\circ}\text{F}$ and $90^{\circ}\text{F}$) depending on the element size—is critical. In hot weather, elevated initial concrete temperatures accelerate hydration, increase water demand, and exacerbate heat generation, all of which magnify shrinkage and thermal stresses. Site managers must implement protocols for cooling the delivery trucks, rejecting concrete that exceeds the specified maximum temperature, and coordinating delivery to minimize time between mixing and placement, thereby controlling the risk of premature stiffness that leads to Cracks During Concrete Pouring.

Case Study: Preventing Cracks in Manhole Forms

A regional utility project encountered severe radial Cracks During Concrete Pouring in precast concrete manhole forms due to a high heat of hydration and quick stripping times. The formwork, being metal, provided excellent restraint and heat transfer, creating a massive temperature differential.

-

Initial Problem:

The high cement content used to achieve rapid strength gain caused internal core temperatures to exceed 80 °C (176 °F), while the steel form surface remained at 30 °C (86 °F). This 50 °C temperature differential led to severe radial cracking when the forms were stripped.BFS Industries Solution:

Two corrective measures were implemented:-

Revised Mix Design: Replaced 30% of the cement with ground granulated blast-furnace slag (GGBFS) to reduce the heat of hydration.

-

Controlled Cooling: Extended the stripping time by 24 hours and immediately covered stripped manholes with insulated blankets to ensure gradual, uniform cooling.

Result:

The combination of mix optimization and thermal management reduced the temperature differential to below 15 °C (27 °F), completely eliminating thermal cracking during demolding and significantly enhancing the concrete’s long-term durability. -

Quality Control and Post-Pour Assessment

Rigorous quality control (QC) is the final line of defense, ensuring that all planning and precautionary measures translate into successful execution. A two-part QC approach—verification before the pour and assessment after curing—provides a continuous feedback loop to correct deviations immediately and improve future pours.

Checklist: Pre-Pour and Post-Pour Verification

| Phase | Checkpoint | Required Action/Tolerance |

|---|---|---|

| Pre-Pour | Subgrade/Formwork Integrity | Subgrade moist, stable, $\pm 5\text{ mm}$ tolerance. Formwork sealed and securely braced. |

| Reinforcement Detailing | Correct size/spacing. Concrete cover verified by spacers/chairs ($\pm 3\text{ mm}$ tolerance). | |

| Mix Compliance & Temp | Batch ticket checked for w/c ratio and SCM inclusion. Concrete temperature measured (must be within pouring temperature limits). | |

| Site Readiness | Curing materials (mats, spray, retarders) and finishing tools/personnel ready on site. | |

| Post-Pour | Curing Application | Curing compound applied immediately after finishing, or continuous water application maintained for $7+$ days. |

| Joint Activation | Saw-cuts performed on time (4-12 hours) and to correct depth ($1/4$ thickness). | |

| Crack Mapping | Survey and record any surface cracks (type, width, location) to analyze root cause (e.g., plastic shrinkage cracks). | |

| Thermal Monitoring | For mass pours, confirm temperature differential in slabs never exceeded $20^{\circ}\text{C}$. |

Analyzing Formwork Pricing vs. Risk Mitigation Costs

The cost of high-quality formwork or specialized mix components often faces scrutiny during project budgeting. However, expert analysis reveals that increased Formwork Pricing for superior systems—like those facilitating thermal control or complex geometry—is dwarfed by the long-term expense of crack repair. The cost of patching, joint sealing, and waterproofing after early-age concrete cracking can escalate rapidly, far exceeding the initial investment in preventive measures. Choosing cheap formwork or mix designs to save $5\%$ upfront can easily lead to a $25\%$ increase in maintenance costs over five years, validating the choice for quality and proactive risk mitigation.

Addressing Common Types of Early-Age Concrete Cracking

Cracks are generally categorized by their root cause: volume change (shrinkage/thermal) or mechanical failure (settlement/restraint). A thorough understanding of each type allows for targeted prevention, minimizing the widespread issue of Cracks During Concrete Pouring. Addressing the nuances of each mechanism allows engineers to apply the correct technical fix.

Settlement Cracks and Bleeding Control

Settlement cracks occur over rebar or formwork elements when the fresh concrete settles around a fixed element. If the concrete is too stiff, or if it has been over-vibrated leading to excessive bleed water, the resulting downward movement is restrained, causing a crack at the surface profile of the fixed object. This can be mitigated by ensuring the rebar and formwork are dampened, controlling the bleed rate through concrete mix design adjustments (e.g., adding air-entrainment), and revibrating the concrete before it begins to set.

The Role of Subgrade Preparation

The foundation upon which the concrete is poured—the subgrade—is often overlooked as a crack contributor. An unconditioned or poorly compacted subgrade can wick away essential moisture from the bottom of a slab, creating a moisture differential between the top and bottom. This acts as a restraint, leading to differential shrinkage and warping that propagates Cracks During Concrete Pouring from the base upward. The subgrade must be uniformly compacted, free of standing water, and fully pre-moistened to a saturated surface-dry (SSD) condition to prevent moisture loss during placement.

Frequently Asked Questions (FAQs) on Concrete Cracking

Q: Does a higher slump always mean more cracking?

A: Not always, but it significantly increases the risk. A high slump indicates a high water content, which directly correlates to greater drying shrinkage potential. While a higher slump improves workability, the increased amount of water available for evaporation heightens the risk of plastic shrinkage cracks and long-term drying shrinkage. Expert practice dictates using superplasticizers to achieve high workability at a low, crack-resistant water-cement ratio control.

Q: How effective are synthetic fibers (e.g., polypro) in preventing early-age cracking?

A: Synthetic fibers are highly effective at controlling early-age concrete cracking, particularly plastic shrinkage cracks. They create a secondary, uniform reinforcing matrix at the near-surface level, resisting the micro-tensile forces that develop when the bleed water is insufficient to compensate for evaporation. They are a valuable tool in mitigating surface Cracks During Concrete Pouring, but they do not replace structural reinforcement for load-bearing control.

Q: Is cracking worse in cold weather or hot weather?

A: Both are problematic, but in different ways. Hot weather increases the risk of immediate plastic shrinkage cracks and rapid heat gain leading to high temperature differential in slabs. Cold weather slows hydration, prolonging the period of vulnerability to damage and potentially leading to freeze-thaw cracking if the concrete is not sufficiently protected and insulated during its early, critical strength-gain period. Proper planning and strict adherence to pouring temperature limits are essential in both extremes.

Conclusion

Preventing concrete cracks is not a matter of luck but of rigorous, systematic engineering and quality control across every phase of construction. The development of Cracks During Concrete Pouring is a symptom of internal stresses—thermal, chemical, or mechanical—that have been allowed to exceed the concrete’s tensile capacity at its most vulnerable early-age concrete cracking stage. By focusing on the scientific principles detailed here—specifically, through strict water-cement ratio control, strategic use of SCMs, vigilant thermal management, and comprehensive concrete curing techniques—you can produce high-performance, durable structures that meet the most demanding specifications. We encourage your project teams to review these technical guidelines and collaborate with BFS Industries to integrate these expert-level preventive measures into your standard operating procedures. Let us know if you would like to explore options for implementing these specialized mix design or curing protocols, or if you need assistance in optimizing your reinforcement detailing for your next project.