- Published:

- Written by: B.F.S Industries

Hot Rolled Steel vs. Cold Rolled Steel – Complete Comparison Guide

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

The selection of appropriate steel material is a foundational decision in any engineering or fabrication project, impacting structural integrity, dimensional precision, final cost, and overall performance. Two primary categories dominate the conversation for structural and general-purpose applications: hot rolled steel and cold rolled steel. Understanding the fundamental differences between these two materials—from their distinct manufacturing pathways to their resultant mechanical properties and application envelopes—is critical for engineers, procurement managers, and technical buyers. This comprehensive guide, informed by the deep industrial expertise of B.F.S Industries, provides a technical breakdown of the characteristics, advantages, and disadvantages of each type of steel, ensuring informed material specification for every project, whether it involves heavy construction, intricate component fabrication, or precision machinery parts. By exploring the core technical characteristics, including surface quality, yield strength, and tolerance, this analysis will clarify the material science behind the choice between hot rolled steel and cold rolled steel.

Understanding the Steel Rolling Process

The journey of steel, from molten iron ore to a usable flat sheet, beam, or bar, involves thermal and mechanical processes that fundamentally define its final state. The generic term “rolled steel” refers to steel that has passed through a set of rollers, a process designed to reduce its thickness, achieve a specific profile, and improve its metallurgical grain structure. All carbon and alloy steels must undergo this shaping process, but the temperature at which this occurs is the primary determinant classifying the steel as hot rolled or cold finished. The rolling process itself is not just about shaping; it is a critical method for achieving density, reducing porosity, and setting the initial mechanical properties of the steel, making the control of temperature and pressure essential for quality control and material consistency.

The choice of rolling temperature dictates whether the steel’s crystal structure remains malleable (hot) or strain-hardened (cold). Above the steel’s recrystallization temperature—typically above 926°C (1700°F)—the metal is considered “hot.” When steel is rolled in this state, its grain structure can instantaneously reform, preventing the metal from becoming plastically deformed or hardened, which allows for massive size reductions with minimal force. Conversely, rolling below this critical temperature, even if the process begins with pre-rolled hot steel, results in “cold work,” which significantly alters the material’s internal structure and surface characteristics, providing a crucial distinction in the difference between hot rolled and cold rolled steel that directly affects its final use.

How Hot Rolling Works

Hot rolling is the foundational steel process, typically beginning immediately after the primary casting of steel into slabs or billets. This process involves heating the steel above its recrystallization temperature, ensuring that the rolling operations, which involve passing the material through a series of mill stands, do not result in work hardening. The high heat makes the steel highly ductile and easy to form, allowing for the rapid production of large quantities of standard shapes and structural members like I-beams, channels, angles, and heavy plates, all of which are essential components in heavy construction and infrastructure projects.

The advantage of operating at such high temperatures is the lack of internal stress built into the material during shaping. Since the steel’s grain structure recrystallizes immediately, the final product retains high ductility, making it easy to weld and further form. However, the downside of thermal expansion and contraction is an inherent lack of dimensional precision, as the hot steel shrinks upon cooling. This temperature-related phenomenon results in wider dimensional tolerances compared to cold-finished products, making hot rolled steel the primary choice for applications where ultimate strength and broad dimensions are more critical than exact measurements.

How Cold Rolling Works

Cold rolling, strictly speaking, is a finishing process rather than a primary shaping operation, as it utilizes pre-rolled, cooled, and descaled hot rolled steel as its starting material. The term refers to rolling that occurs below the recrystallization temperature, often near room temperature. By working the steel in this “cold” state, the process takes advantage of strain hardening: the mechanical deformation forces the atomic structure into a highly stressed, aligned state, dramatically increasing the material’s yield strength and hardness while reducing its ductility.

The precise control over the rolling mill and the absence of thermal shrinkage in cold rolling allow for the creation of components with superior surface finish and exceptional dimensional accuracy. This method is the manufacturing basis for thin-gauge sheets, strips, bars, and rods that demand tight tolerances and a smooth surface, often used in aesthetic, enclosure, or high-precision mechanical applications. While requiring more energy and rolling force than the hot rolling process, cold rolling imparts mechanical properties that are unattainable through heat alone, fundamentally defining its niche in modern manufacturing.

What Is Hot Rolled Steel?

Hot rolled steel is a ubiquitous and essential material produced by rolling steel at temperatures exceeding 926°C (1700°F). It represents the most common and cost-effective form of steel manufacturing, forming the backbone of heavy industries worldwide. Its properties are characterized by high ductility, relative ease of fabrication, and mass-market versatility, making it the default choice for applications that prioritize bulk strength and cost efficiency over fine surface quality or extreme dimensional precision. The large, continuous rolling mills used in this process allow for the rapid and economical production of massive profiles, which are then used in foundational structural work.

This steel is defined by its isotropic mechanical properties, meaning its strength and ductility are generally uniform throughout the material, which is a direct benefit of the thermal uniformity achieved during recrystallization. While it exhibits lower yield strength compared to cold-finished products, its high ductility is crucial for load-bearing applications that might experience plastic deformation without catastrophic failure, providing a necessary safety margin in construction. The material’s rough, dark oxide layer, known as mill scale, is a signature characteristic of hot rolled steel, which is a direct byproduct of high-temperature processing in an oxygen-rich environment.

Manufacturing Process of Hot Rolled Steel

The process begins with a large piece of steel, called a billet or slab, which is initially heated in a furnace until it glows bright red, reaching the required temperature for recrystallization. This ensures that the steel can be easily manipulated without fracturing and that any induced mechanical stress is instantly relieved. The slab is then passed through a series of rolling stands, where its thickness is progressively reduced, and it is formed into the desired profile, such as a plate, strip, or beam. These initial passes are often referred to as “roughing” and progressively move to “finishing” passes, all while maintaining the critical temperature threshold.

Following the final rolling pass, the steel is then cooled, often in ambient conditions. This slow cooling, or “normalizing” process, is responsible for the material’s final microstructure and contributes to its low internal stress state. As the material cools, the outer layer reacts with atmospheric oxygen, forming the distinct, blue-grey mill scale surface. This process, while quick and economical, results in a final product with some variance in dimension due to thermal contraction, necessitating post-processing like cleaning or machining if a smoother finish or tighter tolerance is required by the end user.

Key Characteristics and Surface Finish

The most identifiable characteristic of hot rolled steel is its surface finish. The presence of mill scale—a dark, flaky, iron oxide layer that forms during the high-temperature cooling process—gives the material a rough, matte appearance. While this mill scale offers a degree of temporary corrosion resistance, it must often be removed before painting, galvanizing, or precision welding, typically through pickling (acid bath) or abrasive blasting. The secondary defining characteristic is the material’s dimensional tolerance. Because the steel shrinks non-uniformly as it cools from its high-temperature state, the final product exhibits broader size variances compared to cold rolled products.

These characteristics mean that hot rolled products are generally unsuitable for applications requiring polished, aesthetic surfaces or components that must fit together with micrometric precision. Instead, hot rolled steel is accepted where the visual appearance is secondary and where the inherent variability of dimensions can be accommodated. The steel profile also exhibits slightly rounded edges and corners—a result of the forming process at high temperatures—which further distinguish it from the sharp, square profiles typical of cold-finished products.

Advantages and Disadvantages of Hot Rolled Steel

One of the principal advantages of hot rolled steel is its cost-effectiveness, largely driven by the speed and scale of its production process and the lack of complex post-rolling steps. This economic benefit makes it the default material for large-scale structural work. Furthermore, the absence of internal stress, due to the rolling occurring above the recrystallization temperature, means the material is highly ductile and less prone to warping when subjected to secondary processes like heat treatment or heavy welding, which is a major benefit in complex fabrication projects.

Conversely, the disadvantages stem primarily from the high temperatures involved. The formation of mill scale requires extra surface preparation steps (cleaning, descaling) before final finishing. More significantly, the lack of precise dimensional control due to thermal contraction necessitates more liberal tolerances, meaning hot rolled steel cannot be used for components requiring exact, calibrated fits. The material also possesses lower yield strength and hardness compared to its cold-finished counterpart, a direct consequence of the stress-free annealing that occurs during the hot rolling process.

Applications of Hot Rolled Steel in Construction and Fabrication

Hot rolled steel is primarily employed in applications where large sections, high strength-to-weight ratios, and cost are the main criteria, and where surface finish or precise dimensional tolerance is less critical. Its high ductility and ease of welding make it the material of choice for large-scale Steel Structure projects, including the fabrication of bridge supports, building frameworks, and heavy machinery chassis. The common structural shapes, such as I-beams, H-beams, and wide-flange beams, are almost exclusively produced through hot rolling due to the need for bulk material at a competitive price point.

A significant industrial application where the attributes of hot rolled steel are essential is in heavy fabrication and infrastructural works. For instance, the use of heavy hot rolled plates and sections is fundamental in Modular Pipe Rack Fabrication for the petrochemical and energy sectors, where strength and weldability take precedence over surface aesthetics. Other common uses include rail tracks, shipping containers, simple automotive components, and large-diameter piping, all of which benefit from the material’s low internal stress and robust nature, even if post-processing is sometimes required to remove mill scale.

What Is Cold Rolled Steel?

Cold rolled steel is a premium product derived from hot rolled steel that has been further processed in specialized rolling mills at or near room temperature. It is often referred to as “cold finished” steel and is recognized for its superior surface quality, tighter dimensional tolerances, and enhanced mechanical properties, including increased strength and hardness. This finishing process is designed to overcome the limitations of hot rolling, making cold rolled steel the material of choice for precise component manufacturing and aesthetically driven applications where surface perfection is paramount.

The core distinction of cold rolled steel is that it is fundamentally strain-hardened. The mechanical deformation below the recrystallization point alters the material’s grain structure, increasing the density of crystal dislocations, which manifests as higher yield and tensile strength. However, this cold work also reduces the steel’s ductility, making it slightly harder to bend or deep-draw without intermediate annealing. Despite the higher cost, the material’s consistency and quality often offset the price increase through reduced machining time and minimized waste in precision manufacturing processes.

Manufacturing Process of Cold Rolled Steel

The manufacturing process for cold rolled steel begins with a fully cooled and descaled coil of hot rolled steel, often referred to as a hot-rolled pickled and oiled (HRPO) product. This feedstock is then fed into a sequence of roll stands while operating well below the steel’s recrystallization temperature, ensuring strain hardening occurs. The reduction in thickness during this cold processing stage can vary significantly but results in the material being dimensionally accurate and exhibiting a mirror-like or matte surface, free from the characteristic mill scale.

The intensity of the cold work determines the final mechanical properties; a higher percentage of reduction leads to greater hardness but lower ductility. Since the process operates without the heat-induced expansion and contraction of hot rolling, extremely tight dimensional tolerances—often measured in hundredths of a millimeter—can be achieved. Following rolling, the material is frequently subjected to secondary processes like annealing to restore some ductility (if required for forming) or temper rolling to refine the surface texture and flatness, resulting in a product ready for demanding final applications.

Mechanical Properties and Surface Quality

A defining feature of cold rolled steel is its significantly enhanced mechanical properties, particularly yield strength and hardness, often exceeding hot rolled steel by 20% to 50% for similar chemistry. This strength increase is a direct result of the strain hardening induced during the cold work, which physically changes the microstructure of the steel. The trade-off for this superior strength is a decrease in ductility, making the material less suitable for extreme forming operations without risk of cracking unless subsequent annealing is performed to relieve the induced stresses.

In terms of surface quality, cold rolled steel presents a smooth, clean, and often bright finish that is immediately ready for painting, plating, or other cosmetic treatments without extensive surface preparation. Does cold rolled steel have mill scale? The answer is unequivocally no, as the starting hot rolled material is pickled to remove all mill scale before the cold finishing begins. This smooth finish, coupled with superior flatness and straightness, makes cold rolled steel the optimal choice for exposed components where aesthetic quality, precise fitting, and consistency are essential design parameters.

Advantages and Disadvantages of Cold Rolled Steel

The primary advantage of cold rolled steel lies in its superior finish and dimensional accuracy. The clean, smooth surface and sharp edges simplify pre-treatment for painting or coating, saving significant time and cost in high-volume production. Furthermore, the tighter tolerances achieved through cold finishing are critical for parts that must fit together precisely in complex assemblies, reducing assembly time and improving the overall quality of the final product. The enhanced mechanical properties, including higher tensile strength and yield strength, allow designers to use thinner material gauges, potentially saving weight and material costs in certain applications.

However, cold rolled steel comes with significant drawbacks, mainly cost and internal stress. Due to the extra processing steps—pickling, cold rolling, and potential annealing—cold rolled steel is inherently more expensive than hot rolled steel. The cold work also introduces residual stresses into the material, which, if not relieved through annealing, can cause the material to warp or distort when cut or machined, a critical consideration for precision machining operations. Its reduced ductility compared to hot rolled steel also limits its use in applications requiring deep draws or extensive cold forming without specialized equipment.

Applications of Cold Rolled Steel in Precision Engineering

Cold rolled steel is the material of choice for applications that demand high-quality surface finish, superior strength, and exceptional dimensional precision. It is extensively used in manufacturing consumer goods and precision engineering. Examples include complex automotive body panels, household appliances (refrigerator doors, washing machine casings), and furniture components where a smooth, paintable surface is required. The material’s superior flatness also makes it ideal for architectural trim, precision stamping, and components for computer hardware and electronics enclosures.

Due to its enhanced strength, cold rolled steel is highly effective in mechanical components, such as shafts, gears, pins, and small structural components that must bear precise loads. While Cold rolled steel vs stainless steel is a comparison often made regarding corrosion resistance and specialized strength, standard cold rolled steel excels in areas requiring high surface quality and machinability without the cost of high-alloy stainless steel. Its consistent properties also make it preferred for high-speed automated production lines where material consistency is non-negotiable for smooth operation.

Hot Rolled Steel vs. Cold Rolled Steel – Key Differences

The differences between hot rolled steel and cold rolled steel are rooted in the physics of their manufacturing processes, resulting in dramatically different material characteristics. These differences directly influence the suitability of each material for specific engineering applications, ranging from heavy-duty structural work to precision component manufacturing. Understanding the technical divergence across these key parameters is essential for optimal material selection, affecting cost, performance, and overall project efficiency.

1. Manufacturing Temperature and Process

The most fundamental divergence is the operating temperature relative to the steel’s recrystallization point. Hot rolled steel is processed at temperatures typically above 926°C (1700°F), allowing the steel to be shaped and reformed without increasing its strength through work hardening. This high-temperature process makes the steel highly malleable and minimizes internal stress, but results in dimensional inaccuracy upon cooling. Cold rolled steel, conversely, is processed at or near room temperature, a secondary process performed on already hot-rolled stock that has been cooled and cleaned.

This difference in process defines the material’s final state. Hot rolling is a primary shaping operation that yields high-volume structural profiles with low residual stress. Cold rolling is a finishing process that involves strain hardening the metal, leading to higher internal stress and enhanced mechanical properties. The temperature disparity is the single most important factor determining the outcome: hot rolling prioritizes speed and volume, while cold rolling prioritizes precision and surface quality.

2. Surface Finish and Dimensional Tolerance

The visual and physical surface characteristics offer an immediate way to distinguish between the two types of steel. Hot rolled steel is characterized by a rough, blue-grey surface covered in mill scale, which is an oxide layer formed during cooling. Its dimensional tolerances are relatively loose (up to 2% to 5% of the total dimension) due to the unpredictable shrinkage that occurs when cooling from the high rolling temperatures. The edges of hot rolled bars and structural shapes tend to be rounded or tapered, reflecting the bulk nature of the process.

Cold rolled steel, in sharp contrast, features a smooth, clean, and often bright finish, completely free of mill scale, since the base material is pre-cleaned. Its dimensional tolerances are exceptionally tight—often less than 0.01% variability—making it superior for applications requiring exact fit and minimal machining. The corners and edges of cold rolled bars, strips, and sheets are typically sharp and square, a physical representation of the precision imparted during the cold working process.

3. Strength, Hardness, and Ductility

There is a significant and predictable difference in the mechanical properties of hot rolled vs cold rolled strength. Cold rolled steel exhibits higher yield strength and tensile strength compared to its hot rolled counterpart, often by 20% or more. This enhancement is directly attributable to the strain hardening (work hardening) that occurs when the steel is plastically deformed below its recrystallization temperature, which increases its hardness and load-bearing capacity. This allows designers to use less material for the same load, a key consideration for weight-sensitive projects.

Hot rolled steel, due to the high-temperature recrystallization, has much lower internal stress and retains high ductility and toughness. This material is more pliable, easier to bend, and better suited for operations involving significant plastic deformation, deep drawing, or where a risk of shock loading is present. While cold rolled steel is stronger and harder, its reduced ductility means it is more brittle and may crack if bent too sharply or subjected to extreme forces without prior stress-relief annealing.

4. Cost and Availability

The manufacturing complexity dictates the price and market dynamics of the two materials. Hot rolled steel is significantly more affordable, typically costing 20% to 40% less than cold rolled steel on a per-ton basis. The primary reason for this cost advantage is the high-speed, high-volume nature of the hot rolling process, which involves fewer processing steps and lower energy consumption per unit of reduction, making Hot rolled vs cold rolled price a major factor in material selection for large-scale projects. Furthermore, hot rolled steel is readily available in a vast array of standard structural shapes and large sizes.

Cold rolled steel, as a secondary finished product requiring additional steps like pickling, cold rolling, and sometimes annealing, carries a higher processing cost. The need for specialized rolling mills and stricter quality control measures contributes to its premium pricing. While widely available in sheet, strip, and small bar form, cold rolled steel is not typically produced in the large structural sections (like I-beams) common to hot rolling. Therefore, Hot Rolled Steel prices remain the benchmark for economical structural projects where material costs must be minimized.

Performance Comparison in Construction and Fabrication

In the real-world industrial environment, the choice between hot rolled and cold rolled steel is a performance-driven decision, heavily influenced by the end application’s requirements for structural stability, ease of assembly, and fabrication methods such as welding and machining. The material’s behavior under thermal stress and mechanical load determines its fit for critical infrastructure projects versus precision component manufacturing.

Structural Applications in Steel Frames and Pipe Racks

For heavy structural engineering, hot rolled steel is the undeniable champion. Its low internal stress, high ductility, and availability in large, thick cross-sections make it ideal for the primary load-bearing members of buildings, bridges, and industrial supports. In constructing Modular Pipe Rack Fabrication systems for industrial plants, the inherent warp-resistance of hot rolled steel during the extensive welding required is a major benefit, ensuring the final structure maintains its geometric integrity. Hot rolled steel’s inherent toughness also provides superior resistance to fatigue and fracture in demanding, variable load environments.

Cold rolled steel is rarely used in primary structural applications due to its higher cost and the size limitations of the cold rolling process. However, it finds its niche in secondary structural roles where its strength-to-weight ratio and superior finish are valuable, such as in lighter support frames, non-load-bearing architectural elements, and paneling systems. Its tighter tolerance and surface quality can also be beneficial for non-welded, bolted assemblies where precision alignment is crucial, but these applications remain ancillary to the bulk use of hot rolled sections.

Suitability for Welding, Forming, and Machining

The suitability of each steel type for fabrication is another key differentiator. Hot rolled steel is generally preferred for heavy welding applications. Its low residual stress means it is far less likely to warp or distort severely when heat is applied during the welding process, leading to more predictable and robust joints. When it comes to forming, hot rolled steel’s superior ductility allows for greater manipulation without cracking, making it excellent for applications involving bending, roll-forming of heavy sections, or simple press operations.

Cold rolled steel presents a different set of challenges and opportunities for fabrication. The higher carbon and alloying content sometimes present in cold finished grades can make it less weldable without special attention to pre-heat and post-weld treatment. Furthermore, the high internal stress can cause significant distortion when the material is cut, deep-drawn, or heavily machined, often necessitating stress-relieving annealing. However, its clean surface and precision dimensions make it superior for high-tolerance, low-stock-removal machining, as its consistent surface simplifies automated operations and requires less material to be removed to achieve the final dimension.

Hot Rolled vs. Cold Rolled Steel Grades and Standards

Both hot rolled and cold rolled steels are subject to stringent industry standards that govern their chemical composition, mechanical properties, and tolerance limits. These grades ensure that engineers can specify material with predictable performance characteristics, regardless of the producer. The most common standards bodies are ASTM (American Society for Testing and Materials) in North America and EN (European Norm) in Europe, with specific designations applied to the finished product based on its processing method.

The grades often dictate material chemistry (e.g., carbon content, manganese, silicon) and the minimum yield strength required. The careful selection of the correct grade is crucial, especially in high-consequence applications like pressure vessels or seismic Steel Structure components. While the grades might share similar chemistries (e.g., A36 is a common hot rolled grade, while 1018 is a common cold finished grade often derived from a similar base chemistry), the rolling process itself imparts the final critical properties that distinguish their performance envelope.

Common ASTM and EN Standards

Hot rolled steel is commonly referenced by the ASTM A36 standard for structural purposes, which defines a minimum yield strength of 36,000 psi (250 MPa). Other common hot rolled standards include A572 for high-strength low-alloy (HSLA) structural steel and A516 for pressure vessel plate applications. The corresponding European norm is often S235, S275, and S355, where the number refers to the minimum yield strength in megapascals. These standards focus primarily on ensuring the material’s bulk strength, toughness, and acceptable weldability for general construction and fabrication uses, reflecting the primary use case of hot-rolled products.

Cold rolled steel is often referenced by general-purpose grades like AASTM 366 (for sheets/strips) or specific mechanical grades like ASTM A1008 (for sheet) or ASTM A108 (for bar). Many cold rolled products are also designated by their base chemistry (e.g., 1018, 1045, or 1215), where the emphasis is on achieving a clean surface and tight tolerance for machining or forming, often with a greater range of available hardness levels. The standards for cold rolled steel place a heavy emphasis on dimensional consistency, flatness, and surface finish requirements, reflecting the material’s role in precision applications.

Quality and Inspection Parameters

The quality assurance and inspection parameters for hot rolled steel typically focus on chemical composition, minimum yield and tensile strength, and macro-structural integrity (e.g., absence of internal defects or laminations). Dimensional inspection primarily checks the overall cross-sectional profile and length, accepting the wider tolerances inherent in the process. While surface quality is noted, the presence of mill scale is an expected and acceptable feature, contingent on the final application not being surface-critical.

For cold rolled steel, inspection parameters are far stricter regarding dimensional accuracy, with precise checks on thickness, width, and flatness to ensure compliance with the tight tolerances. Surface quality is also a key inspection point, checking for blemishes, pitting, or inconsistency in the finish. The material must also be tested for its final, achieved mechanical properties, including the higher hardness and yield strength resulting from the cold work. These demanding quality checks contribute directly to the higher manufacturing cost and the premium nature of cold rolled products.

Price and Market Trends – Which Is More Cost-Effective?

When considering hot rolled vs cold rolled price, hot rolled steel consistently emerges as the more cost-effective option, a factor driven by the lower energy input, faster production cycle, and high-volume nature of the hot rolling process. The cost difference is substantial enough that for any application where dimensional tolerances are liberal and surface finish is secondary (e.g., large structural beams, rail lines, heavy plate), hot rolled steel is the default economic choice, allowing large-scale infrastructure and fabrication projects to minimize raw material expenses.

The higher price of cold rolled steel is justified by its enhanced material properties and the elimination of many secondary fabrication steps. While the initial material cost is greater, the superior surface finish negates the need for pre-cleaning and descaling before painting or plating. The tighter tolerance significantly reduces material waste and machining time in precision components. Therefore, while Hot Rolled Steel prices are lower, cold rolled steel can be more cost-effective in the long run for precision components where labor and waste savings outweigh the initial material premium, especially in high-volume, automated manufacturing.

Comparison Table – Hot Rolled Steel vs Cold Rolled Steel

To summarize the technical differences, the table below provides a concise comparison of the key parameters that dictate material selection:

| Feature | Hot Rolled Steel | Cold Rolled Steel |

|---|---|---|

| Manufacturing Temp. | Above Recrystallization (Typically >926°C) | Below Recrystallization (Near Room Temp.) |

| Process Type | Primary Shaping Operation | Secondary Finishing Process |

| Surface Finish | Rough, Scaly (Mill Scale Present) | Smooth, Bright, Clean (No Mill Scale) |

| Dimensional Tolerance | Loose (Wider Variability) | Tight (Exceptional Precision) |

| Yield Strength | Lower (Due to Recrystallization) | Higher (Due to Strain Hardening) |

| Ductility | Higher (More pliable, easier to form) | Lower (Harder, more brittle) |

| Internal Stress | Low (Stress-free) | High (Can cause warping when cut) |

| Cost | Lower (Most cost-effective) | Higher (Premium, due to extra processing) |

| Common Shapes | I-Beams, Wide Flange, Rail, Thick Plate | Sheet, Strip, Small Bar, Rod, Tube |

| Typical Use | Heavy Steel Structure, Rail, Structural Fabrication | Automotive Panels, Appliances, Precision Components, Machined Parts |

Choosing the Right Steel for Your Project

The decision between hot rolled and cold rolled steel must be a calculated one based on a clear understanding of the project’s non-negotiable requirements. If the application involves large-scale load-bearing structures, requires extensive welding, and dimensional variance can be tolerated (e.g., large industrial supports, general construction), hot rolled steel is the optimal choice for its cost efficiency, weldability, and superior ductility. This is particularly true in heavy infrastructure projects where material volume is high, and budget constraints are tight.

Conversely, cold rolled steel is the correct choice when the final product demands a smooth, paint-ready surface, extremely tight dimensional tolerances, or enhanced strength is required from a thinner material section. Precision mechanical parts, aesthetically exposed components, and automated stamping operations should almost always utilize cold rolled stock. By systematically evaluating the required tolerance, surface quality, and necessary hot rolled vs cold rolled strength, engineers can select the material that optimizes performance while controlling costs, ensuring the project meets all technical and economic specifications.

Conclusion – Steel Expertise by BFS Industries

The differences between hot rolled steel and cold rolled steel are fundamental, stemming directly from the thermal conditions of their manufacture and leading to distinct properties, applications, and cost profiles. Hot rolled steel offers the structural integrity and cost-efficiency necessary for heavy construction and primary structural fabrication, while cold rolled steel provides the dimensional accuracy and superior finish required for precision engineering and aesthetic applications. Navigating this choice effectively is key to delivering successful, durable, and cost-optimized projects.

At BFS Industries, we leverage decades of expertise in both structural steel and precision fabrication to advise clients on the most suitable material selection for their specific needs. Whether your project demands the high ductility of hot rolled sections for a heavy-duty Modular Pipe Rack Fabrication or the high-tolerance sheets of cold rolled material for advanced enclosures, our commitment to technical excellence ensures the right steel is used for the right application. We provide deep technical support to help you achieve the ideal balance of performance, cost, and finish quality on every component.

Recommended Image Placement

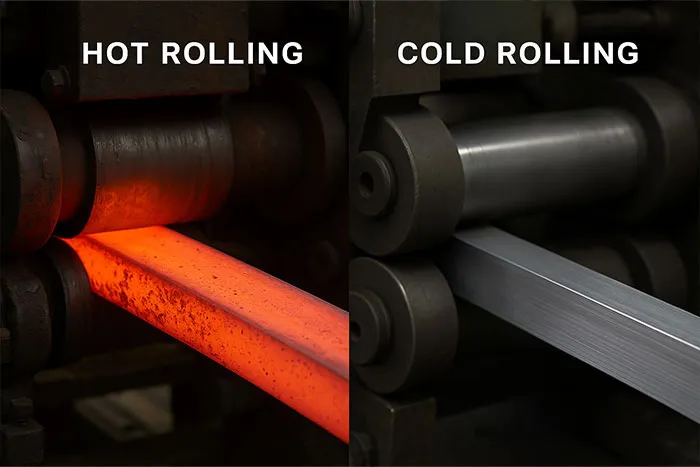

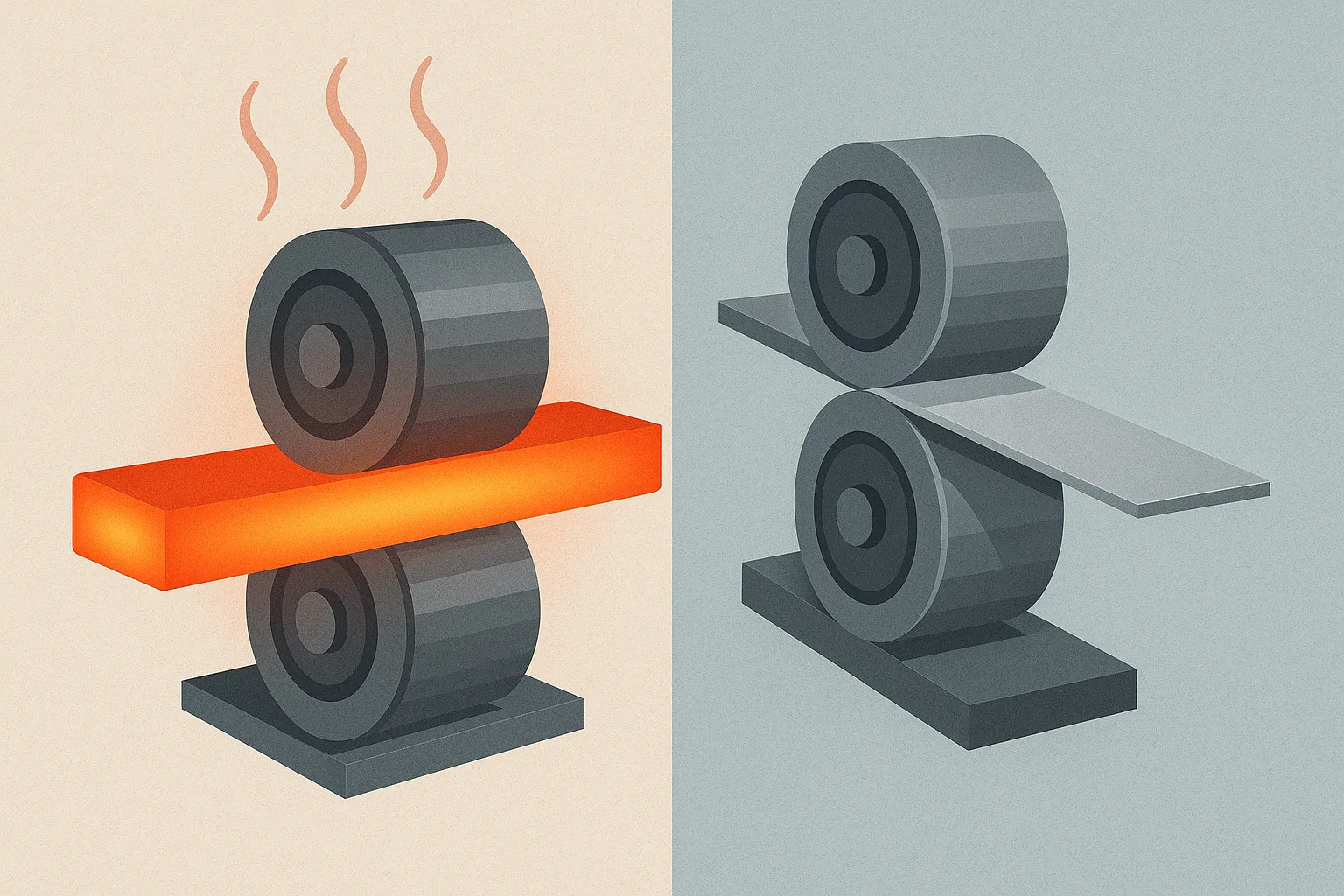

- Image 1 (After H2 “Understanding the Steel Rolling Process”): A simple, clear infographic showing two parallel processes. One side illustrates “Hot Rolling” with a red glow and large rollers, emphasizing shrinkage. The other side illustrates “Cold Rolling” with a blue tinge, showing the material passing through tight rollers, emphasizing precision.

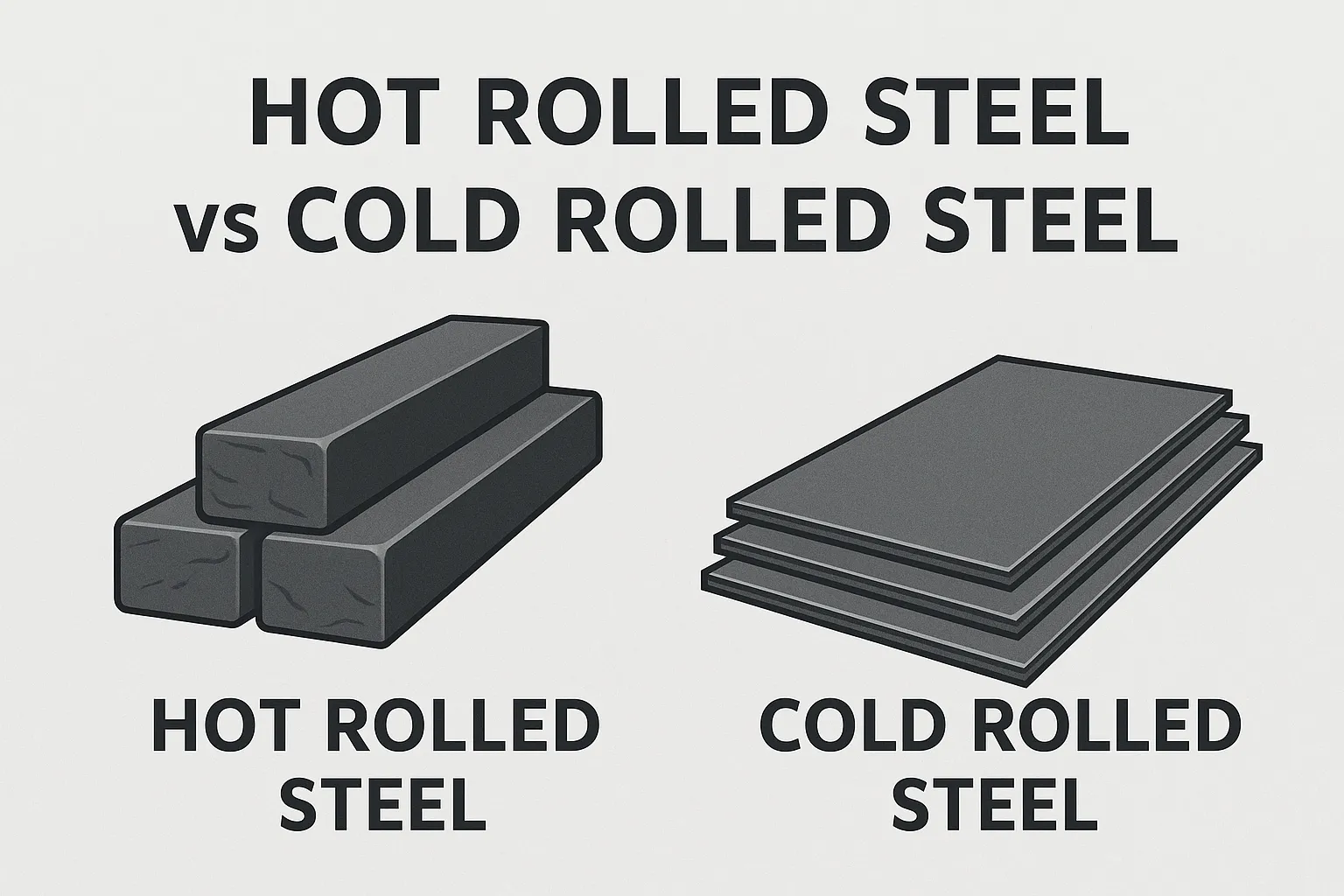

- Image 2 (Within H3 “Key Characteristics and Surface Finish” under Hot Rolled Steel): A close-up photograph clearly showing the difference between the rough, blue-grey mill scale surface of hot rolled steel and the smooth, brighter surface of a neighboring piece of cold rolled steel.

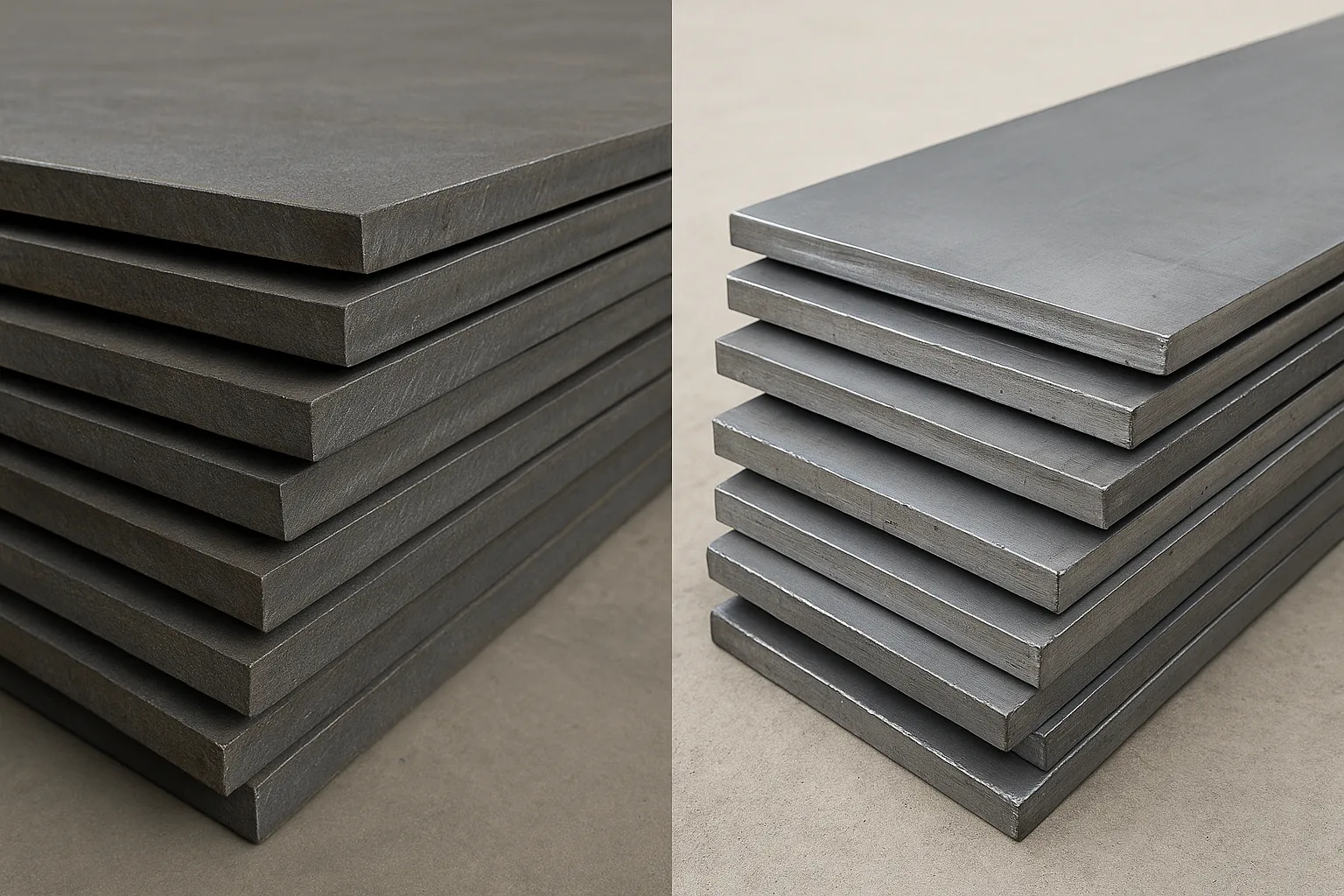

- Image 3 (After H3 “Applications of Cold Rolled Steel”): A photo montage or collage showing real-world applications: a large I-beam in a structural frame (Hot Rolled) next to a sleek appliance casing or precision-machined gear (Cold Rolled).

Frequently Asked Questions (FAQ)

What is the main difference between hot rolled and cold rolled steel?

The main difference is the temperature at which the steel is rolled. Hot rolled steel is processed at high temperatures (above 926°C or 1700°F), allowing it to be easily shaped and resulting in a rougher, scaled surface and wider dimensional tolerances. Cold rolled steel is further processed at room temperature, which strain hardens the material, giving it a much smoother, brighter surface, tighter dimensional tolerances, and higher strength. The fundamental distinction is the trade-off between bulk volume/low cost (Hot) and surface quality/precision/high strength (Cold).

Which is stronger — hot rolled or cold rolled steel?

Cold rolled steel is significantly stronger than hot rolled steel of the same grade and composition. The cold working process (rolling below the recrystallization temperature) induces strain hardening, which increases the material’s yield strength and tensile strength by up to 20% or more. This makes cold rolled steel the better choice when maximum strength per unit thickness is required. However, hot rolled steel has superior ductility, meaning it is less brittle and can withstand more forming and bending without fracturing.

Is cold rolled steel more expensive than hot rolled steel?

Yes, cold rolled steel is inherently more expensive than hot rolled steel, typically costing 20% to 40% more. This price difference is due to the additional manufacturing steps required for cold rolled steel, including pickling (to remove mill scale) and the specialized cold rolling and finishing processes. While the upfront cost is higher, the superior dimensional precision and smooth finish of cold rolled steel can lead to cost savings in subsequent manufacturing stages by reducing waste and minimizing the need for extensive pre-finishing preparation.

Where is hot rolled steel commonly used?

Hot rolled steel is primarily used in large-scale structural, heavy fabrication, and general construction applications where high strength, high material volume, and cost-effectiveness are crucial, and precise dimensional control is less important. Common uses include structural frames for buildings and bridges, Hot rolled steel structure components, rail tracks, sheet pile walls, storage tanks, and large-diameter piping. Its high weldability and ductility make it ideal for these demanding, large-section applications.

How does BFS Industries utilize hot and cold rolled steel in fabrication projects?

BFS Industries utilizes hot rolled steel for large-scale, load-bearing applications, such as the fabrication of heavy Modular Pipe Rack Fabrication and primary structural components, valuing its low cost, superior weldability, and structural integrity. Cold rolled steel is used for precision applications requiring tight tolerances and superior finishes, such as in high-precision mounting plates, equipment enclosures, shims, and architectural components where dimensional accuracy and surface quality are critical to the final fit and aesthetic.