- Published:

- Written by: B.F.S Industries

Decoding Concrete Foundation Types: A Structural Engineering Perspective

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

Structural integrity begins beneath the surface. For any construction project, the foundation is the critical interface that transfers the structure’s load safely to the earth. Selecting the correct concrete foundation types is not merely a decision based on size, but a complex engineering judgment rooted in geotechnical reports, load calculations, and site conditions. At BFS Industries, we understand that mastering these foundational elements is paramount to delivering durable, safe, and efficient structures. This expert-level technical guide dives deep into the design principles, application methodologies, and integrated construction solutions—from formwork to concrete pouring—that define successful modern foundation engineering. We move beyond basic definitions to focus on the technical execution and specialized considerations necessary for high-performance buildings.

Shallow Foundations: Design for Near-Surface Soil Bearing Capacity

Shallow foundations are those systems where the depth of embedment is less than or equal to the width of the foundation, and they transfer loads directly to a competent soil stratum close to the ground surface. These systems are highly effective and economically viable when the existing soil bearing capacity at a moderate depth is sufficient to support the structure’s total load without excessive or differential settlement. The selection of a shallow foundation depends heavily on the uniformity of the underlying soil and the distribution of the structural loads, requiring meticulous site investigation and careful calculation of bearing pressure to ensure long-term stability.

Strip Footings and Wall Foundations: Lateral Load Distribution

Strip footing systems are continuous foundations designed to support linear loads, typically beneath load-bearing walls. They are essential for distributing continuous loads over a wider area, thereby reducing the intensity of stress transmitted to the soil. Crucially, they play a significant role in managing lateral loads, such as those induced by wind or seismic activity, by providing continuous resistance and distributing shear forces along the length of the wall base.

Reinforcement Detailing for Strip Footings

Accurate reinforcement detailing for foundations is vital in strip footing construction to control crack formation and provide necessary tensile strength, especially in resisting bending moments and shear forces. Longitudinal reinforcement (main bars) is typically placed at the bottom to counteract positive moments, while stirrups or shear reinforcement are used to manage vertical shear stresses. Proper concrete cover, usually $75\text{ mm}$ minimum for foundations in contact with the ground, must be strictly maintained to prevent corrosion and ensure long-term structural resilience.

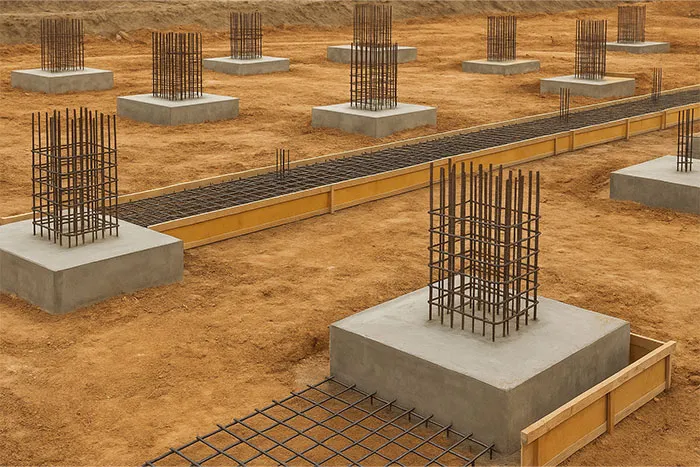

Isolated Pad Footings: Concentrated Load Transfer

Isolated pad footing foundations are square, rectangular, or circular pads designed to support individual, concentrated point loads, such as those transmitted by columns. They are the go-to solution for framed structures where loads are delivered to discrete points. The size of the pad is determined by dividing the column’s total factored load by the safe soil bearing capacity of the soil. Their design is focused on resisting the punching shear forces concentrated directly beneath the column, which often necessitates shear reinforcement cages or deep footing dimensions.

Assessing Differential Settlement in Pad Footing Systems

While uniform settlement across an entire structure is often tolerable, foundation settlement control is critical to prevent differential settlement, which occurs when adjacent footings settle at different rates or magnitudes. Differential settlement induces secondary stresses in the superstructure (beams and slabs) that can lead to visible cracking and structural failure. Mitigation strategies involve meticulous soil compaction, careful sizing of adjacent footings to equalize soil pressure, and, in severe cases, the use of grade beams to tie the isolated pads together, effectively bracing the foundation system.

Mat and Raft Foundations: Load Spreading Across Large Areas

Raft foundation or mat foundation design involves a single, continuous, heavily reinforced concrete slab extending over the entire footprint of the structure. This type is selected when soil bearing capacity is very low, when the structure’s column loads are so close together that individual footings would overlap, or when the structure requires extensive basement waterproofing. The mat acts as a rigid diaphragm, minimizing differential settlement and ensuring that the structural load is uniformly spread across the maximum possible area.

Construction Challenges and Concrete Pouring Methods for Mat Foundations

The construction of large mat foundation design slabs presents unique logistical and technical challenges. Temperature control during the hydration process is crucial; large concrete pours generate significant heat, which can lead to thermal cracking if not managed. Specialized Concrete pouring methods, such as continuous pour strategies using multiple concrete trucks and cooling pipes embedded in the slab, are often required. For quality, our bfs industries partners specify precise concrete specifications and slump tolerances to ensure uniform strength and ease of placement across the massive area.

Deep Foundations: Addressing Poor Soil and High Structural Loads

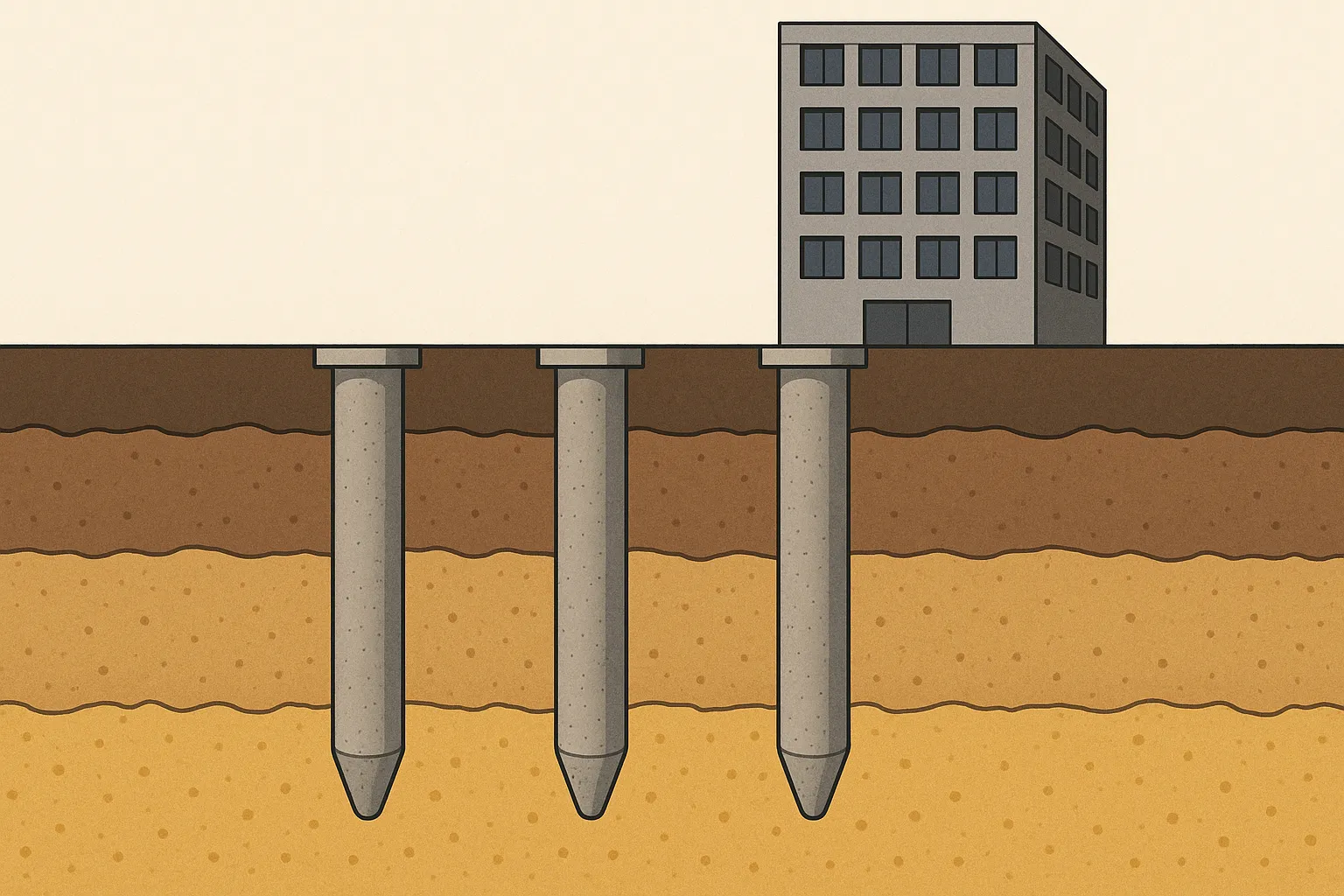

Deep foundations are employed when the near-surface soil layers lack sufficient soil bearing capacity or when the structural loads are extremely high, necessitating the transfer of the load through weak, compressible soil layers down to a stronger stratum or rock deep below the surface. These foundation types derive their support from either end-bearing on a competent layer or by developing significant skin friction along their perimeter with the surrounding soil.

Pile Foundations: End-Bearing vs. Friction Piles

Pile foundation systems consist of slender, columnar elements driven or bored into the ground. They are categorized based on their load-transfer mechanism. End-bearing piles transfer their load primarily through their tip onto a strong, incompressible layer, such as rock or dense gravel. Conversely, friction piles rely on the shear resistance developed along the entire surface area between the pile shaft and the surrounding soil (skin friction) to support the load. Often, a pile will act as a combination of both, utilizing whatever resistance is available.

Specialized Piling Techniques for Restricted Sites (Micropiles)

In urban environments or sites with restricted access, the use of traditional large-diameter piles is often impractical. Micropiles (or mini-piles) provide an effective alternative solution. These small-diameter bored piles (typically less than 300 mm) are installed by drilling and grouting through a hollow steel casing. Micropiles are particularly suitable for underpinning existing structures, stabilizing slopes, or strengthening foundations in areas with limited headroom, enabling structural reinforcement without the need for extensive excavation.

Pier and Caisson Foundations: Large Diameter Deep Support

Piers and caissons are large-diameter deep foundations constructed by excavation and often extending down to bedrock. Piers are generally constructed in situ by excavating a shaft, installing reinforcement detailing for foundations, and filling it with concrete. Caissons (or drilled shafts) are similar but use a cylindrical casing (often steel) that is sunk into the ground as excavation proceeds, acting as the formwork and sometimes remaining permanently in place. They are preferred for massive loads and large bridge supports where deep, substantial bases are required.

Utilizing Concrete Column Formwork for Pier Construction

The construction of concrete piers often requires specialized Concrete Column Formwork systems, particularly for the portion above the excavation or water table. These forms, often made of robust steel or modular panels, must be capable of withstanding the immense hydrostatic pressure of the wet concrete. Our integrated approach utilizes precision-engineered formwork to ensure the pier maintains the exact cylindrical or rectangular geometry required, preventing any eccentricity in the load path that could compromise the pier’s capacity.

Combined Pile-Raft Foundation (CPRF) Systems

A Combined Pile-Raft Foundation (CPRF) is an integrated solution where the load is shared between the piles and the raft (or mat). This sophisticated concrete foundation types system is typically reserved for critical structures—such as very tall high-rise buildings or those founded on highly compressible soils—where minimizing settlement is a priority. The piles stiffen the raft and reduce the total settlement, while the raft distributes the load and mobilizes the soil beneath it.

Foundation Settlement Control in CPRF Systems

In CPRF, the primary objective of foundation settlement control is to manage the overall stiffness of the system. This involves meticulous prediction of the interaction between the piles, the raft, and the soil. Instrumentation is often installed during construction to monitor immediate and long-term settlement. The design goal is a total settlement that is within tolerance and, crucially, a differential settlement that is nearly zero, ensuring the structural frame remains level and unstressed.

Specialized Foundation Solutions and Advanced Formwork Integration

Beyond the conventional shallow and deep systems, foundation engineering often requires specialized solutions to address challenging geological conditions, high water tables, or complex loading scenarios such as seismic activity or dynamic machinery loads. The effectiveness of these specialized designs is inextricably linked to the quality and precision of the concrete formwork systems used in their construction.

Foundation Design for High-Rise Structures

High-rise construction often mandates deep basements, which require innovative foundation strategies. These foundations must not only carry the massive vertical loads but also resist significant overturning moments from lateral forces. This often involves very deep raft foundation or CPRF systems combined with engineered temporary earth retention systems (e.g., diaphragm walls) to support the deep excavation walls.

Application of Tunnel Formwork Systems in Basements

While typically used for repetitive wall and slab construction in residential sectors, integrating the efficiency of a tunnel formwork system supplier into the basement and foundation walls of high-rise projects can provide significant advantages. By using large, robust steel forms for the basement perimeter walls and core structures, the system offers excellent concrete finish quality and rapid cycle times, enabling the transition from foundation construction to superstructure erection with optimized speed and precision.

The Role of Concrete Formwork Systems in Foundation Quality

The choice of concrete formwork systems directly impacts the strength, durability, and alignment of the finished foundation element. Poor formwork can lead to honeycombing, leakage of cement paste (resulting in weak spots), and geometrical misalignment. High-performance formwork systems provided by bfs industries ensure a liquid-tight seal, maintain dimensional accuracy under high hydrostatic pressure, and contribute directly to the specified quality of the concrete foundation types.

Specification and Tolerances for Foundation Formwork

For critical foundation elements, design specifications mandate extremely tight tolerances. This includes strict limits on plumbness (vertical alignment), levelness, and sectional dimensions. Formwork systems must be specified to prevent concrete leakage and maintain an impeccable surface finish (FS-1 or better) where required for elements like exposed basement walls. Proper shuttering and alignment are non-negotiable for foundations, as correcting sub-standard work post-pour is often impossible or prohibitively expensive.

Foundational Case Study: Mega-Project Implementation by BFS Industries

This case study demonstrates the integrated approach required for selecting and executing complex concrete foundation types in challenging environments, illustrating the critical nature of meticulous planning and execution. The project involved the construction of a large industrial complex built on an old river flood plain, presenting a substantial geotechnical challenge.

Project Overview and Geotechnical Challenges

The site investigation indicated highly variable subsurface conditions, consisting of several meters of compressible silty clay underlain by dense bedrock at an approximate depth of 25 m. The low and inconsistent bearing capacity of the upper soil layers rendered a conventional shallow foundation unsuitable for the heavily loaded industrial structures. In addition, the presence of a high groundwater table further increased the potential for long-term settlement and heightened the risk of liquefaction under dynamic loading conditions.

Design Selection and Execution (Integrated Raft and Pile System)

To mitigate the significant risk of differential settlement, the project engineers, in collaboration with BFS Industries, adopted a Combined Pile-Raft Foundation (CPRF) system—an advanced integration of two complementary concrete foundation types. Bored cast-in-place piles were installed to a depth of approximately 25 m, reaching the underlying bedrock to function as end-bearing elements. These piles were subsequently integrated with a 2 m-thick reinforced concrete mat foundation, forming a unified structural system. This hybrid configuration ensured optimal load distribution: the piles provided deep, stable bearing resistance, while the raft uniformly redistributed residual loads across the surface, thereby enhancing long-term settlement performance. The construction of the thick, heavily reinforced raft slab required the use of high-strength steel formwork systems to maintain precision and structural integrity during casting.

Critical Checklist for Concrete Foundation Selection and Planning

Selecting the appropriate concrete foundation types is a multi-disciplinary process that requires adherence to a structured decision-making process. This checklist provides a framework for project managers and engineers to ensure all critical factors are accounted for prior to the start of excavation.

Pre-Construction Decision Matrix

Critical decision-making begins with a thorough evaluation of the project requirements and site constraints. This includes obtaining a detailed geotechnical report, accurately defining all dead, live, wind, and seismic loads, and assessing site access for heavy equipment required for deep foundation installation (e.g., pile drivers). Cost sensitivity and construction schedule also factor heavily into the final selection, as deep foundations are significantly more expensive and time-consuming than shallow foundations.

| Factor | Description & Impact on Selection | Recommended Action |

|---|---|---|

| Soil Bearing Capacity | Ultimate stress the soil can safely carry. Low capacity necessitates deep foundations. | Geotechnical report and laboratory testing. |

| Total Structural Load | Total weight of the building. Heavy loads necessitate deep/mat systems. | Structural analysis and load calculation report. |

| Water Table/Hydrostatic Pressure | High water tables affect excavation, require dewatering, and influence buoyancy control. | Pumping tests, permanent drainage plan, or buoyant resistance design. |

| Differential Settlement Risk | Likelihood of uneven sinking. High risk points to raft foundation or CPRF. | Analysis of soil compressibility and required foundation settlement control. |

| Adjacent Structures | Proximity to existing buildings impacts vibration limits and requires lateral support. | Monitoring plan and use of specialized techniques like micro-piling. |

Managing Reinforcement Detailing and Concrete Specification

The integrity of any concrete foundation hinges on precise material specification. The project team must ensure that reinforcement detailing for foundations—including bar size, spacing, splice lengths, and concrete cover—aligns perfectly with the structural engineer’s drawings. Furthermore, the concrete mix itself must be specified for aggressive environments, such as those exposed to sulfates or chlorides, and must meet minimum strength and durability criteria. Quality control involves slump testing on-site and curing measures to achieve the design strength efficiently.

Comparative Analysis of Major Concrete Foundation Types

Engineers weigh the advantages and disadvantages of various concrete foundation types against project-specific criteria. The ultimate goal is to find the most cost-effective and construction-efficient system that guarantees long-term structural performance.

Foundation Type Comparison Table

This table provides a high-level technical comparison, focusing on the applicability, complexity, and primary benefits of the most common foundation systems.

| Foundation Type | Primary Load Transfer | Typical Application | Relative Cost & Complexity | Key Advantage |

|---|---|---|---|---|

| Strip Footing (Shallow) | Soil Bearing | Load-bearing walls, simple structures, good soil. | Low | Simple to construct; rapid execution. |

| Pad Footing (Shallow) | Soil Bearing | Columns in framed structures, good soil. | Low | Direct load transfer; minimal concrete volume. |

| Raft Foundation (Shallow/Intermediate) | Soil Bearing (Spread) | Low soil bearing capacity, high structural loads, basements. | Medium | Excellent foundation settlement control; acts as a basement slab. |

| Pile Foundation (Deep) | End-Bearing and/or Friction | Highly variable or weak surface soils; heavy structures. | High | Transfers loads to competent deep strata; predictable load capacity. |

| Caisson/Pier (Deep) | End-Bearing | Massive structural loads (e.g., bridges, skyscrapers). | Very High | Exceptional load capacity; reduced vibration compared to driven piles. |

Interpreting the Data for Optimal Foundation Selection

The selection process is iterative: if the structural load is high and the soil bearing capacity is low, the designer must move from the lower-cost shallow options (strip/pad) to higher-cost, more complex options (raft/pile). The key metric is the ratio of the structure’s weight to the soil’s capacity. When that ratio is high, deep or extensive mat foundation design systems are mandatory. The cost of concrete formwork systems and reinforcement detailing for foundations increases exponentially as complexity rises.

Frequently Asked Questions (FAQs) on Foundation Engineering

As expert tunnel formwork system supplier and construction partners, we often address complex questions regarding foundation design and execution.

What is the most critical factor influencing the choice of concrete foundation types?

The most critical factor is the geotechnical report and the resulting safe soil bearing capacity. This information dictates whether a shallow system is adequate or if a deep foundation (like a pile foundation or caisson) is required to bypass weak soil layers. The second most critical factor is the total magnitude of the load being transferred.

How do engineers achieve foundation settlement control in deep foundation systems?

Foundation settlement control in deep systems is achieved through precise design and testing. For friction piles, this means confirming the design load through load tests (e.g., Static or Dynamic Load Tests). For end-bearing piles, it involves ensuring the pile tip is adequately seated on the load-bearing stratum (e.g., rock) and verifying the stability of the surrounding soil to prevent consolidation settlement. In CPRF systems, settlement is controlled by tuning the stiffness ratio between the raft and the piles.

When should a strip footing be chosen over a series of pad footings?

A strip footing is chosen when the load is continuous, such as under a thick load-bearing wall, or when the underlying soil is weak but uniform, and distributing the load across a long, continuous line is preferable. Pad footing is chosen when the load is concentrated at discrete points (columns) and the soil is strong enough to support the resulting high-pressure areas efficiently.

What are the main challenges in reinforcement detailing for foundations?

The main challenges in reinforcement detailing for foundations include managing the high density of steel (especially in thick raft foundation or pile caps), ensuring adequate concrete cover against corrosive ground conditions, and coordinating the placement of dowel bars to connect the foundation to the vertical structure (Concrete Column Formwork). Accuracy is essential to prevent rebar congestion that impedes proper concrete placement.

Why is BFS Industries focused on both formwork and foundation selection?

At bfs industries, we recognize the inseparable link between foundation design and construction execution. While the foundation type is a design choice, the quality of its execution relies entirely on superior concrete formwork systems and controlled Concrete pouring methods. As a premier tunnel formwork system supplier, our focus is on providing high-precision systems that support the structural engineer’s design intent, ensuring that the chosen concrete foundation types perform as intended throughout the life of the structure.

Conclusion: Engineering Resilience from the Ground Up

The successful implementation of any construction project, from mid-rise residential buildings to complex industrial plants, rests on the meticulous selection and flawless execution of the concrete foundation types. We have detailed the technical considerations, from managing soil bearing capacity in shallow foundations to the complex load transfer mechanisms of deep foundations. Whether the solution is a basic strip footing or an advanced mat foundation design system utilizing sophisticated reinforcement detailing for foundations, the outcome must be structural resilience.

The next generation of construction demands integrated solutions where design specifications for foundation settlement control are met with high-performance construction tools. As your partner in advanced construction, bfs industries delivers not only expert consultation on system selection but also the high-precision concrete formwork systems that guarantee the quality and longevity of every foundation pour. We invite you to collaborate with our team to optimize your next project, ensuring that your structure is built on the most solid ground possible. Let us know if you’d like to dive deeper into the specifics of a particular pile foundation design or review the tolerances for our high-precision formwork.