- Published:

- Written by: B.F.S Industries

Difference Between Ringlock and Cuplock Scaffolding – A Technical Comparison

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

The complexity and scale of modern construction and industrial projects necessitate scaffolding systems that offer not only safety and stability but also rapid assembly and adaptability. The two leading modular scaffolding solutions dominating the global market are Ringlock and Cuplock. While both fall under the umbrella of system scaffolding, their fundamental design philosophies, connection methodologies, and resulting performance characteristics create a distinct difference between Ringlock and Cuplock scaffolding. For engineers, project managers, and contractors, understanding these technical nuances is paramount to selecting the optimal system that ensures project efficiency, compliance, and structural integrity under various load conditions and complex geometries. This in-depth analysis from B.F.S Industries provides the detailed comparison required to make informed structural decisions.

Introduction to Modular Scaffolding Systems

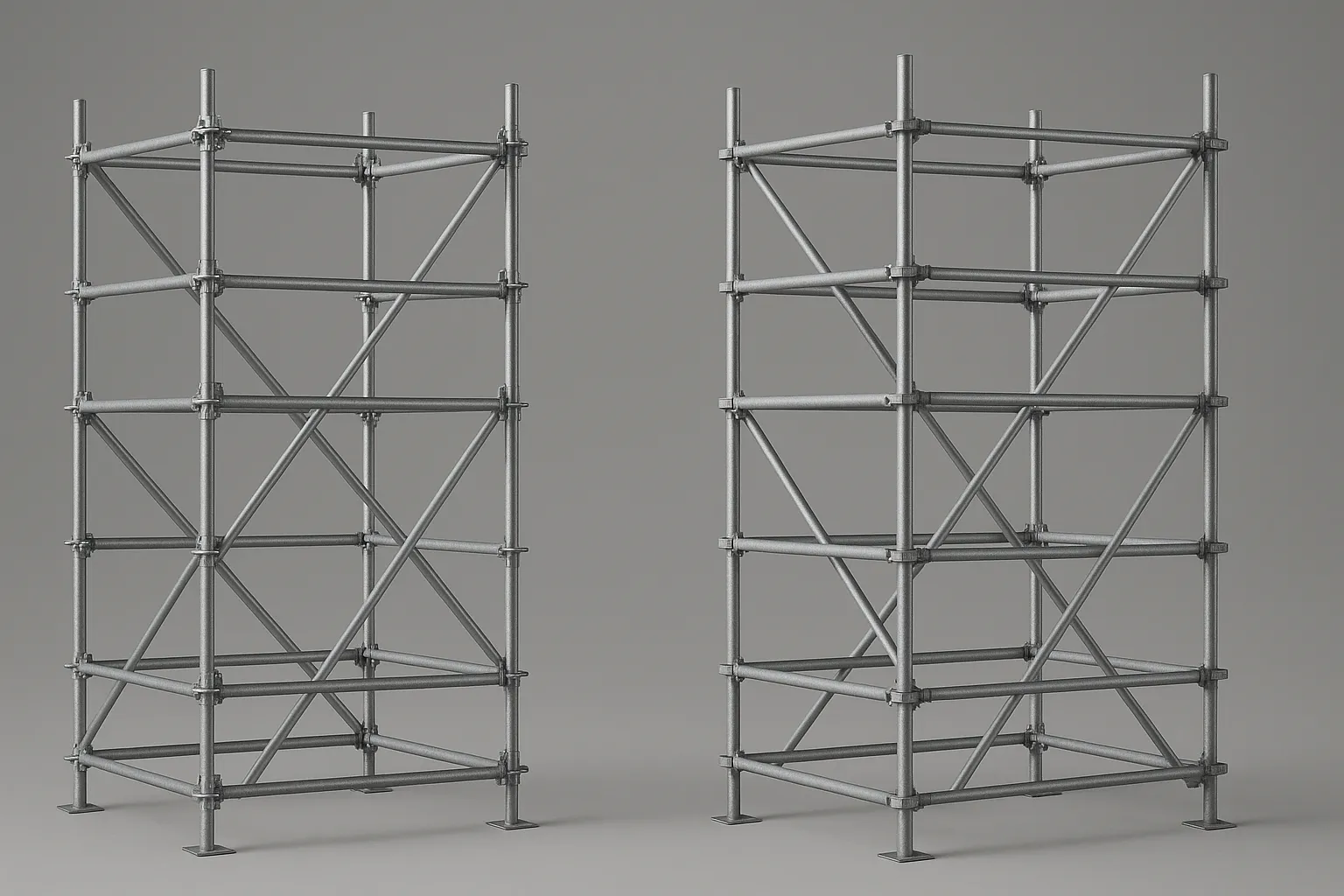

Modular scaffolding represents a significant evolution from traditional tube and fitting scaffolding, offering standardized, pre-engineered components that dramatically reduce erection and dismantling times. These systems, categorized broadly as types of system scaffolding, are designed for repetitive, high-volume use across diverse sectors including construction, oil and gas, shipbuilding, and infrastructure maintenance. The core advantage lies in the system’s ability to establish rigid, predictable structural networks using common vertical and horizontal members connected by proprietary locking mechanisms. This standardization streamlines inventory management, simplifies site training, and ensures consistent quality assurance, making modular solutions the preferred choice for large-scale, long-term projects where speed and safety are critical performance metrics.

What Is Cuplock Scaffolding?

Cuplock scaffolding is one of the earliest and most globally recognized forms of modular system scaffolding, pioneering the concept of rapid component interlocking. Its primary strength lies in its simplicity, robustness, and proven track record across various continents and building codes. The system is characterized by its signature nodal point, which allows for the connection of up to four horizontal members (ledgers) to a single vertical member (standard) in one simple, fast-action locking sequence. This design makes Cuplock incredibly versatile for facade access, masonry work, and forming temporary structures requiring medium to heavy load support, ensuring its continued relevance in the modern construction landscape where reliable load-bearing capacity is consistently demanded.

Definition and Background of Cuplock Scaffolding

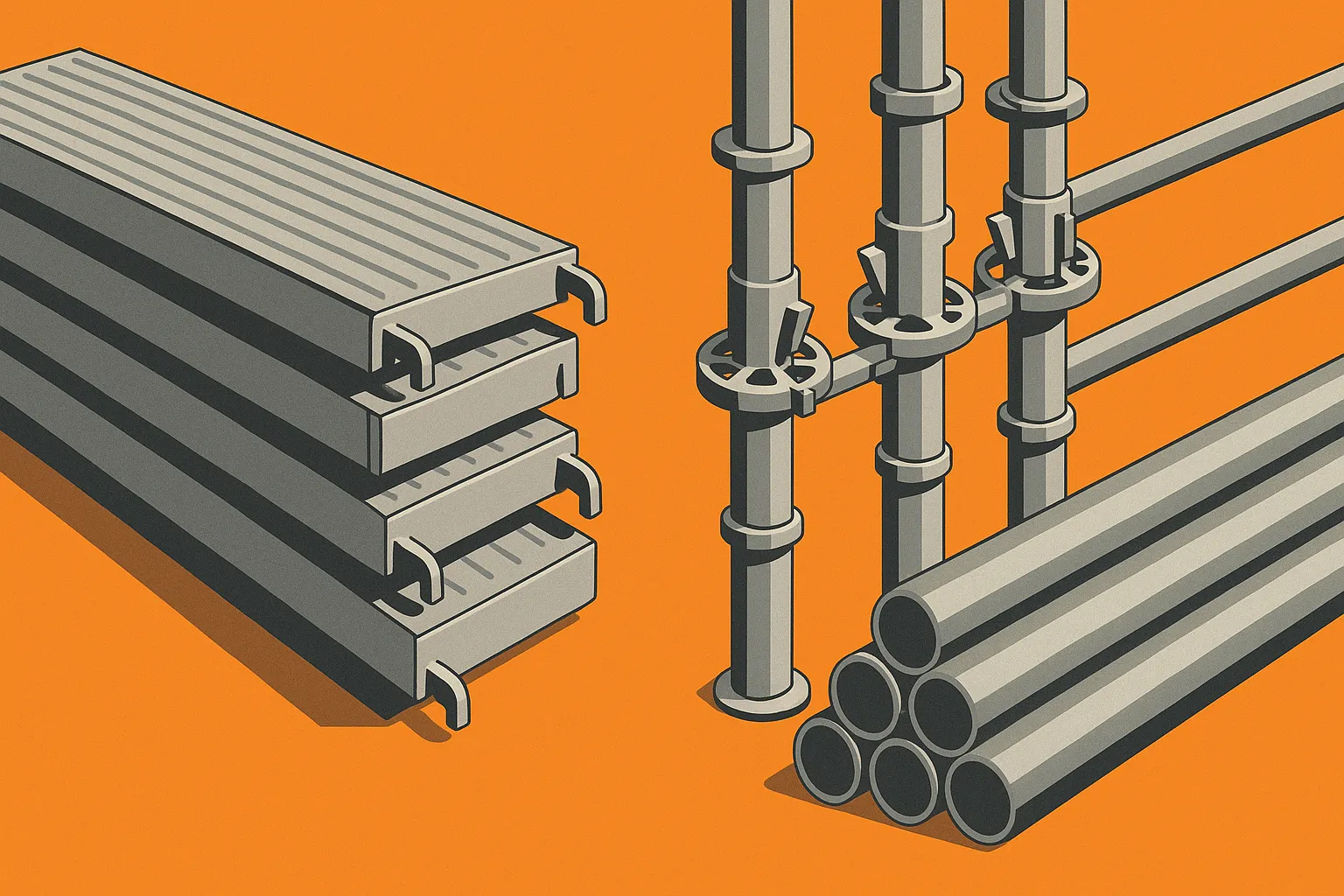

Introduced in the early 1970s, Cuplock was developed to address the limitations of traditional scaffolding, primarily the labor-intensive assembly and disassembly process. The system’s name derives directly from its connection method: the “cup” mechanism. It features a lower fixed cup welded to the standard at regular intervals (typically 500mm or 1000mm) and a movable upper cup. The simplicity of the connection has made it a foundational solution, particularly favored in regions where ease of training and straightforward application trump geometric complexity. It remains a cost-effective and structurally sound choice for straightforward linear structures and shoring applications. For a deeper understanding of its specific components and technical drawings, refer to the documentation for the cuplock scaffolding system.

Main Components and Connection Mechanism of Cuplock

The central components of the Cuplock system include the standards (verticals), ledgers (horizontals), and transoms. The connection mechanism is ingeniously simple: the end blades of the ledgers and transoms are positioned around the fixed lower cup. The movable upper cup is then slid down and rotated, locking the blade ends securely in place within the cup. A hammer blow seals the connection, ensuring rigidity and positive load transfer. This simple, two-piece locking action allows workers to swiftly attach ledgers at any angle within the cup’s circumference. This system’s connection point is designed to resist uplift and twisting forces effectively, making it a reliable choice for maintaining system rigidity.

Advantages and Limitations of Cuplock Scaffolding

The primary advantages of Cuplock include its proven durability, excellent load-bearing capabilities—especially when used in conjunction with double-standard shoring configurations—and its reduced number of loose components compared to tube and fitting. The speed of the Cuplock assembly can be significantly higher than traditional methods, resulting in considerable labor cost savings. However, its major limitation stems from the fixed 90-degree angle of the cup’s face, which, while versatile for general access, limits the immediate creation of acute or obtuse angles without specialized bracing components. Additionally, the vertical interval of the nodal points means that platform levels are restricted to specific heights, offering less flexibility than newer systems for complex architectural facades.

What Is Ringlock Scaffolding?

Ringlock scaffolding represents the next generation of modular system scaffolding, distinguished by its superior flexibility, high density of connection points, and optimized design for modern, non-linear construction. It is engineered for greater adaptability to curved structures and complex industrial environments. The core of the system is the “Ring,” a circular rosette welded to the standard at regular intervals, providing up to eight connection points. This feature allows for multidirectional bracing, providing exceptional stability and the ability to conform to intricate geometries that are difficult or impossible to achieve efficiently with a traditional Cuplock system.

Overview and Design Evolution of Ringlock Systems

Ringlock scaffolding emerged as an evolution to enhance the modularity and load distribution characteristics of system scaffolding. Its design addresses the need for faster erection, greater flexibility in structure configuration, and improved load transfer efficiency. The system’s multi-directional capability allows it to be used not only for straight facade access but also for circular tanks, spheres, and highly complex industrial plant environments. The standardized nature of the wedges and the rosette ensures a tight, high-strength connection every time. To review the specific technical details and assembly guides, refer to the official documentation for the ringlock scaffolding system.

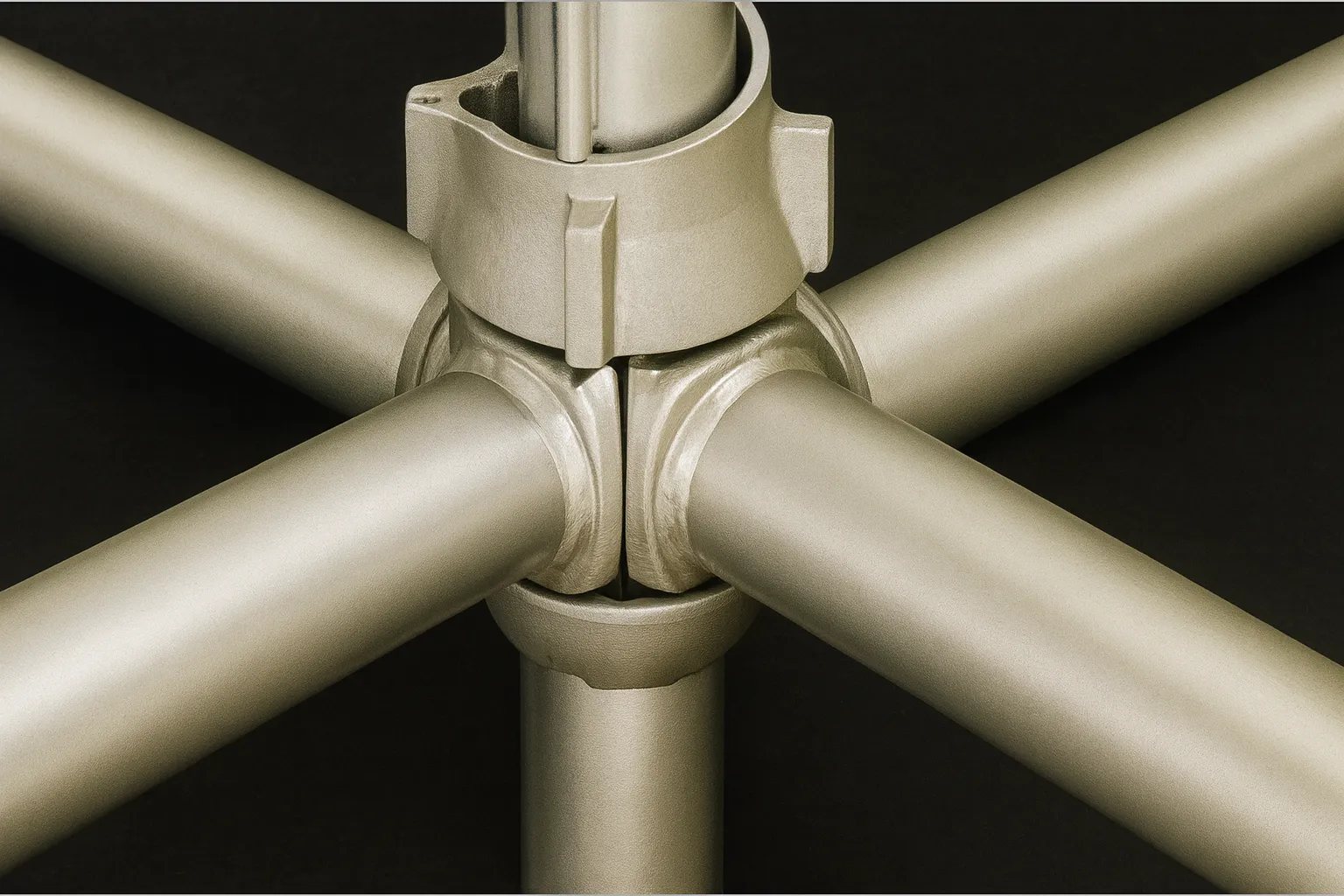

Key Components and Locking Mechanism of Ringlock

The main components are the standards (verticals) featuring the welded rosette, the ledgers (horizontals) with wedge-end connectors, and the diagonal braces. The Ringlock mechanism uses a fixed rosette (the “Ring”) with eight holes—four smaller for 90-degree connections and four larger for angled bracing. The ledgers and diagonal braces utilize a captured wedge that fits into the rosette holes. A hammer is used to drive the wedge down, tightly clamping the component ends to the standard. This mechanism creates a highly rigid joint capable of transferring bending moments and shear forces effectively, resulting in a more structurally efficient and robust scaffold assembly, crucial for high-stress applications.

Advantages and Limitations of Ringlock Scaffolding

The core advantage of Ringlock is its eight connection points, enabling full 360-degree versatility and the ability to integrate diagonal bracing in multiple planes, which significantly enhances lateral stability. This multi-directional connection dramatically reduces the need for specialized accessories when dealing with curved or irregular structures, saving time and component costs. Furthermore, the inherent design often results in higher permissible safe working loads compared to Cuplock for the same component weight, which is beneficial for heavy construction. A common limitation, however, is the initial cost investment, which can be higher than Cuplock, though this is frequently offset by reduced labor costs and long-term versatility, particularly on projects involving non-standard architecture.

Ringlock vs Cuplock – Design and Connection Differences

The most critical factor influencing the performance, erection speed, and versatility of these systems is the design of their central nodal connection. The difference between ringlock and cuplock scaffolding at the node defines the fundamental application strengths of each system. The Cuplock system, with its two-piece cup, is inherently faster for simple, straight runs but is geometrically restrictive. Conversely, the Ringlock system’s rosette, with its eight attachment points, provides unparalleled multidirectional capacity and a higher concentration of structural connections per square meter, enabling far greater adaptability to diverse site conditions and reducing the reliance on additional bracing components.

Locking Mechanism and Assembly Process

The Cuplock locking mechanism involves placing up to four ledger blades into the fixed cup and securing them by sliding the upper cup down and tapping it with a hammer. This one-step action is fast for linear work, but the locked angle is primarily 90 degrees. The Ringlock locking mechanism involves inserting the ledger’s wedge into the rosette hole and driving the wedge with a hammer, clamping the ledger end to the standard. While this is also a simple hammer action, the eight-hole rosette allows ledgers and braces to be connected at various angles (45°, 90°, 135°), vastly increasing configuration flexibility. In pure speed tests for long, straight facade runs, Cuplock often holds a slight advantage, while Ringlock excels in any scenario requiring complex geometry or multi-plane bracing.

Flexibility and Modularity in Construction Applications

Modularity in scaffolding refers to the system’s ability to be constructed and deconstructed rapidly with minimal specialized tooling and its capacity to adapt to various construction tasks. Both are modular systems, but Ringlock offers superior structural flexibility. The high number of connection points in Ringlock allows for the integration of safety measures and structure reinforcement—like guardrails and diagonal braces—at more frequent intervals, increasing the system’s inherent safety factor and structural redundancy. Cuplock is highly effective for rectilinear applications, while Ringlock’s design makes it the modern choice for circular, sloped, and complex architectural designs, providing unmatched adaptation without compromising structural integrity.

Load Capacity and Stability Comparison

When assessing ringlock vs cuplock scaffolding, the critical engineering consideration is their performance under load. Both systems are designed for heavy-duty applications, but the method by which they transfer forces differs due to the connection geometry. The high-density, multi-directional connectivity of the Ringlock rosette generally allows for superior performance in complex loading scenarios, whereas Cuplock’s robustness makes it an exceptionally strong choice for high-rise, uniform vertical loads, particularly when configured for shoring scaffolding systems. Both systems must be engineered and erected in strict accordance with the manufacturer’s specifications and local load calculation standards.

Performance Under Vertical and Lateral Loads

Vertical load capacity in both systems is primarily determined by the wall thickness and yield strength of the steel standards. However, Ringlock’s ability to accept diagonal bracing at virtually any joint significantly enhances its resistance to lateral (wind) loads and minimizes sway. The eight-way connection distributes forces more uniformly across the node, reducing stress concentration. Cuplock also offers high vertical capacity, often favored for heavy-duty slab support (shoring), but typically requires dedicated cross-bracing and a more stringent approach to verticality checks to ensure robust lateral stability, particularly at significant heights or in high-wind environments.

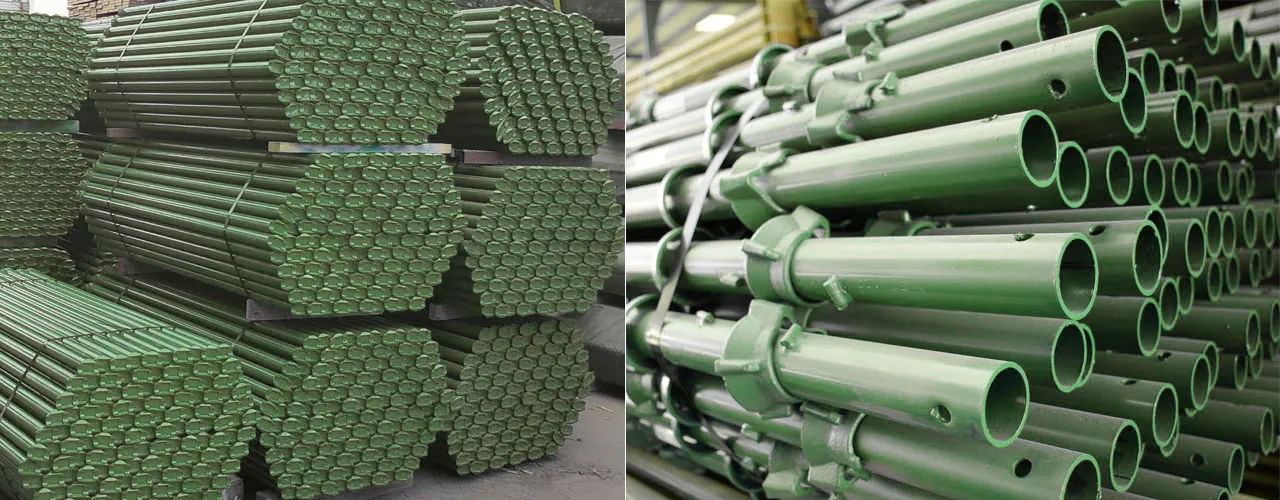

Durability and Material Specifications

Both Cuplock and Ringlock manufactured by BFS Industries are constructed from high-grade structural steel (typically galvanized or painted) to maximize longevity and resistance to corrosion and mechanical damage. The durability of the system is often more dependent on the quality of the galvanization and site handling protocols than the locking mechanism itself. Cuplock, being a proven, long-standing design, is renowned for its resilience in harsh industrial environments. Ringlock components are often subject to tighter manufacturing tolerances due to the precision required for the wedge connection, which contributes to its perceived quality and long-term service life when properly maintained and stored.

Applications of Cuplock and Ringlock Scaffolding Systems

The appropriate selection between Ringlock and Cuplock should be guided by the project’s specific requirements regarding structural geometry, required access height, and imposed loading conditions. While both systems are versatile, their intrinsic design characteristics lend themselves to different optimal applications. Cuplock remains the benchmark for simple, high-load-bearing applications, while Ringlock has become the industry standard for projects demanding maximum geometric adaptability and construction speed.

Cuplock Scaffolding in Building and Industrial Projects

Cuplock scaffolding is the workhorse of the industry, widely utilized for traditional building construction where the structure is primarily rectilinear (e.g., residential facades, commercial buildings, and medium-rise structures). Due to its inherent robustness and fewer connection points to inspect, it is also frequently used in industrial plants for straightforward access platforms and boiler maintenance. Critically, Cuplock excels as a shoring system—providing temporary support for concrete slabs, beams, and formwork—where its high vertical load capacity and simple, rapid assembly make it a preferred, reliable solution for structural support applications.

Ringlock Scaffolding in Infrastructure and High-Rise Construction

Ringlock is increasingly favored for high-complexity, high-rise, and infrastructure projects. Its multi-directional capability makes it essential for circular infrastructure like storage tanks, cooling towers, and bridge piers. In high-rise construction, Ringlock’s ease of integrating internal stair towers and its superior lateral stability often make it the choice for perimeter access and mast climber support. Furthermore, in the shipbuilding industry, Ringlock is used extensively to contour the complex hull and interior shapes, providing a safe, adaptable working platform that minimizes the need for custom-fabricated components.

Safety and Compliance Standards

Regardless of the system chosen, adherence to stringent safety and compliance standards is non-negotiable. Both Ringlock and Cuplock, when manufactured and used correctly, meet the highest global safety benchmarks. Safety performance is ultimately dictated by the correct engineering, erection, and inspection protocols employed on site, ensuring the scaffold is always maintained within its designated safe working load (SWL) limits and configuration parameters.

OSHA and EN12810 Compliance for System Scaffolding

BFS Industries ensures that both its Ringlock and Cuplock systems are manufactured and tested to comply with major international regulatory bodies. In the United States, this means meeting the stringent standards set by OSHA (Occupational Safety and Health Administration) for structural integrity and safe access. Internationally, compliance with EN 12810 (European Standard for Facade Scaffolding) and AS/NZS 1576 (Australian/New Zealand Standard) is mandatory. These certifications guarantee that the system components meet minimum design loads, material specifications, and performance requirements, providing contractors with assurance of their system’s reliability.

Inspection and Maintenance Considerations

Effective inspection and maintenance are crucial for maximizing the service life and safety of any modular scaffolding. Due to the differing locking mechanisms, inspection points vary slightly. For Cuplock, inspectors must verify the upper cup is fully seated and the connection is tight. For Ringlock, the focus is on confirming that the wedge is fully driven home and that the wedge plate is flush against the rosette. Both systems require regular component checks for deformation, corrosion, and damage to ensure that the tight tolerances necessary for their interlocking actions are maintained, thereby preventing potential structural failure and maximizing operational lifespan.

Cost and Efficiency Comparison

While initial purchase price is a factor, the true cost analysis for scaffolding systems must incorporate long-term factors: labor efficiency, speed of erection, component longevity, and transport volume. Often, a system with a higher initial cost can result in a lower total cost of ownership (TCO) due to reduced labor time and greater reusability, a key consideration when weighing ringlock vs cuplock scaffolding for fleet investment.

Assembly Time and Labor Efficiency

Ringlock generally provides a greater overall labor efficiency due to its superior adaptability and fewer specialized components required for non-standard applications. Studies often show that Ringlock can reduce overall erection time by 30-40% compared to traditional systems in complex or multi-level environments. Cuplock remains highly efficient for linear, repetitive work. However, when complex angles, curved access, or extensive internal reinforcement are needed, the Ringlock system’s superior nodal design allows for quicker problem-solving on-site, minimizing labor bottlenecks and accelerating project schedules significantly.

Long-Term Investment and Maintenance Costs

The initial investment for Ringlock is typically higher than for Cuplock. However, because Ringlock components are highly standardized and fewer specialized items are needed for complex configurations, the inventory management becomes simpler and the utilization rate of components higher. Cuplock’s proven durability often translates to lower maintenance needs, particularly for rough site conditions. Ultimately, the long-term investment depends on the fleet’s primary use: if the projects are varied and complex, Ringlock offers a better return on investment through reduced labor and greater versatility; if projects are high-volume, repetitive, and rectilinear, Cuplock provides a highly cost-effective and dependable solution.

Detailed Comparison Table – Ringlock vs Cuplock

| Feature | Cuplock Scaffolding System | Ringlock Scaffolding System |

|---|---|---|

| Nodal Connection | Fixed Lower Cup & Movable Upper Cup | Welded Rosette (Ring) |

| Connection Points | Up to 4 components per node | Up to 8 components per node |

| Connection Angles | Primarily 90 degrees | Multi-directional (45°, 90°, 135°, etc.) |

| Optimal Geometry | Linear, Rectangular, Shoring | Curved, Circular, Complex Geometries |

| Assembly Speed (Linear) | Generally slightly faster | Highly fast and efficient |

| Assembly Speed (Complex) | Slower, requires more accessories | Fastest, due to 8-way connection |

| Load Transfer | Excellent vertical load transfer (Shoring strength) | Superior lateral and complex load distribution |

| Components | Standards, Ledgers, Transoms, Cups | Standards, Ledgers, Diagonal Braces, Rosettes |

| Primary Use | General facade access, Heavy-duty shoring, Linear industrial | Infrastructure, High-rise, Shipbuilding, Complex industrial |

Which Scaffolding System Should You Choose?

The decision between a Cuplock and a Ringlock system must be based on a detailed engineering assessment of the project’s scope, duration, and geometrical demands. If your firm frequently engages in high-volume, straight-run construction, heavy vertical shoring, or projects requiring an extremely robust and established system, Cuplock remains an unmatched, cost-effective, and efficient choice. Conversely, if your projects involve complex curved surfaces, significant height, multi-plane bracing requirements, or if minimizing labor time on intricate scaffold setups is the primary goal, Ringlock’s superior flexibility and advanced nodal design make it the clear technical winner. Choosing the right system is a strategic investment that directly impacts project profitability and site safety.

Conclusion – Optimize Your Scaffolding with BFS Industries

Selecting the appropriate system from the array of types of system scaffolding is a foundational step in successful project execution. Whether the preference leans toward the tried-and-true robustness and shoring capacity of Cuplock, or the multi-directional adaptability and rapid assembly of Ringlock, the underlying commitment must be to quality, compliance, and material integrity. As a trusted manufacturer and supplier of both Cuplock and Ringlock systems, B.F.S Industries provides meticulously engineered, internationally compliant components, ensuring that contractors and engineers have access to the optimal solution for every structural challenge. Partner with us to leverage our expertise and optimize your construction and industrial access requirements with the highest safety and efficiency standards.

FAQ (Frequently Asked Questions)

What is the main difference between Ringlock and Cuplock scaffolding?

The main difference lies in the connection node. Cuplock uses a two-piece cup mechanism that allows for up to four connections at primarily 90-degree angles. Ringlock uses a rosette (ring) with eight connection holes, enabling up to eight multi-directional connections (e.g., at 45, 90, and 135 degrees), offering superior geometric flexibility and load distribution for complex structures.

Which scaffolding system has a higher load capacity?

Both systems are engineered for heavy-duty loads. Cuplock is exceptionally strong for high, uniform vertical loads, often making it the preferred system for temporary shoring. Ringlock, due to its multi-directional bracing capabilities and higher number of connections, often demonstrates superior resistance to lateral loads and better overall structural efficiency in complex, three-dimensional configurations, allowing for higher permissible safe working loads in those specific scenarios.

Which is faster to assemble, Ringlock or Cuplock?

In general, Ringlock is faster to assemble, especially in projects involving complex structures, curves, or multiple bracing requirements, due to its eight-way connection point, which minimizes the need for specialized accessories. For simple, long, straight façade runs, Cuplock can be marginally faster initially, but Ringlock maintains a significant labor efficiency advantage across the overall project lifespan due to its superior adaptability.

Is Ringlock scaffolding more durable than Cuplock?

Both Ringlock and Cuplock, when manufactured using high-quality galvanized steel as provided by BFS Industries, are highly durable. Ringlock components require higher manufacturing precision for the rosette and wedge, contributing to its robust design. Cuplock, as an older, simpler system, is globally known for its resilience and ability to withstand prolonged use in harsh industrial environments. Durability ultimately depends on material quality and proper site maintenance.

How does BFS Industries supply modular scaffolding systems?

BFS Industries supplies both Ringlock and Cuplock modular scaffolding systems as complete component sets, manufactured and tested in compliance with international standards such as OSHA and EN 12810. We offer full technical support, engineering consultation, and logistics services to ensure contractors receive the optimal, high-quality, and structurally sound system tailored to their specific project requirements.