- Published:

- Written by: B.F.S Industries

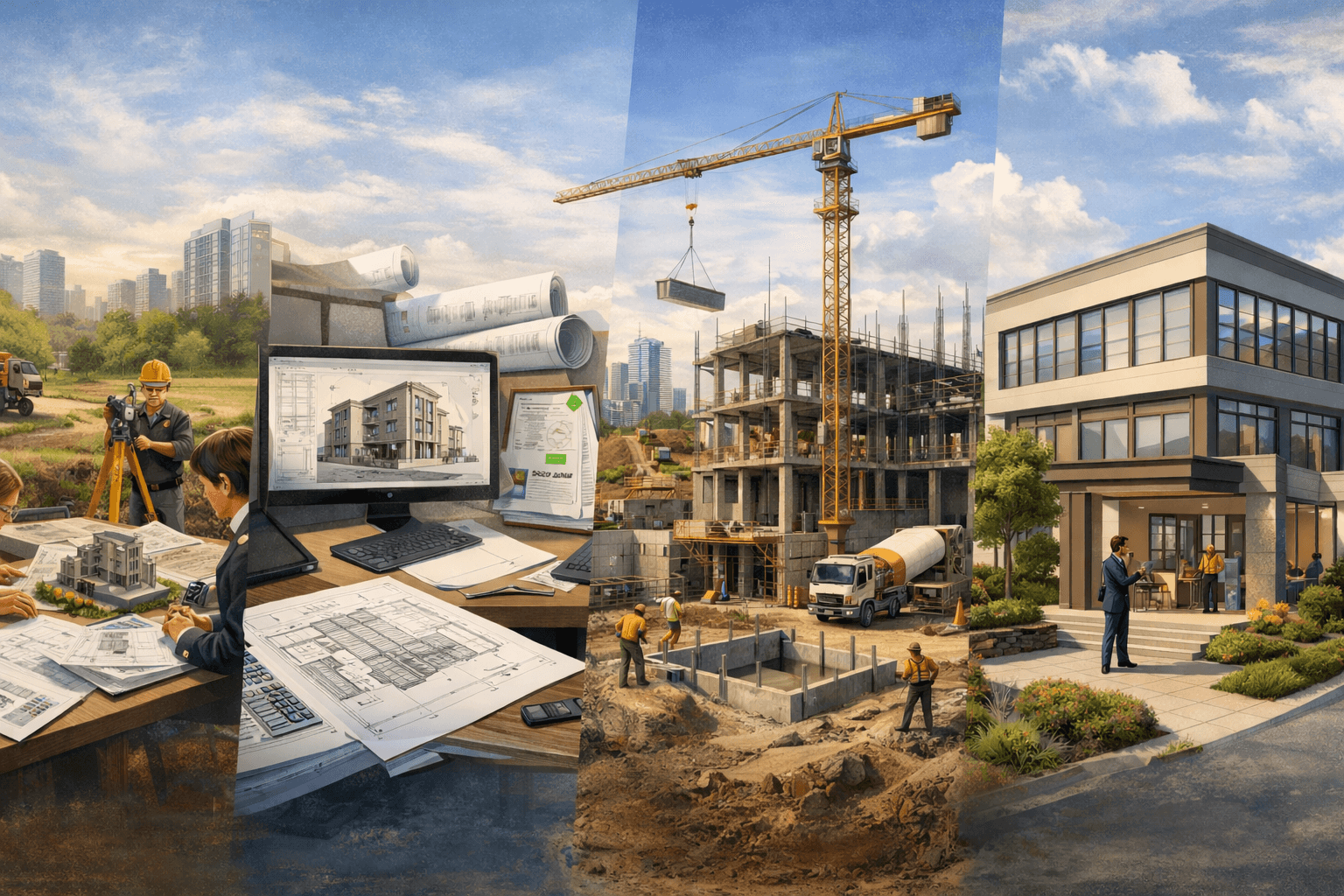

Stages of building construction

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

The successful realization of any built environment, from complex commercial towers to foundational residential structures, relies entirely on the systematic progression through carefully defined Stages of building construction. For civil engineers, project managers, contractors, and aspiring architecture students, a deep, analytical comprehension of this project lifecycle is not merely helpful; it is absolutely foundational to ensuring predictable outcomes. Each phase is intrinsically linked, creating a chain of dependency where the quality of work performed in one stage directly dictates the efficiency, safety, and ultimate success of the next. By establishing clear milestones and rigorous control measures throughout the construction process, project teams can effectively manage critical variables such as cost estimation, adherence to regulatory safety standards, material procurement, and, most importantly, the final quality of the delivered asset. This structured approach is the hallmark of professional construction management, transforming conceptual designs into tangible, durable structures.

Understanding the Stages of Building Construction from Start to Finish

The construction lifecycle is a highly regimented journey, generally moving through four overarching phases: pre-construction, design and permitting, physical construction, and post-construction handover. The comprehensive scope of this process begins long before the first shovel breaks ground, initiating with detailed pre-construction activities that involve critical feasibility studies, conceptual planning, and rigorous budget modeling. Once the initial vision and financial parameters are approved, the design phase formalizes the structure, producing detailed architectural and structural plans that must then navigate the complexities of local and national permitting.

This critical phase ensures the design is compliant with all relevant codes and is structurally sound. The main physical work, which includes site preparation, foundation laying, and structural framing, progresses systematically toward the building enclosure, followed by the integration of mechanical, electrical, and plumbing (MEP) systems. Finally, the project concludes with finishing works, rigorous system testing, final inspections, and the official handover, demonstrating a complete and seamless project sequencing that guides the building from its initial abstract concept right through to occupancy.

Why Construction Projects Depend on Clear and Sequential Stages

Dividing a large-scale construction project into clear and sequential stages is an engineering and managerial necessity rooted in principles of complexity control, resource management, and risk mitigation. This segmentation allows project managers to apply appropriate managerial controls, quality assurance checks, and safety protocols precisely when they are most effective. For instance, the foundation stage requires an entirely different skill set, set of equipment, and safety regime compared to the interior finishing stage, and treating them as one monolithic task would introduce unacceptable levels of workflow coordination risk. By breaking the work into defined phases, such as the substructure, superstructure, and enclosure, budgeting becomes more accurate, enabling precise cost tracking against earned value at each milestone.

Furthermore, staged completion facilitates better scheduling logic, preventing trade conflicts, such as interior plastering beginning before essential conduit work is finished. This systemic approach is also crucial for quality control, where checks and sign-offs at the conclusion of one stage (like the concrete strength testing after the slab pour) provide the necessary assurance before the next stage can commence safely and efficiently, thereby minimizing costly rework and ensuring regulatory compliance across the entire project scope.

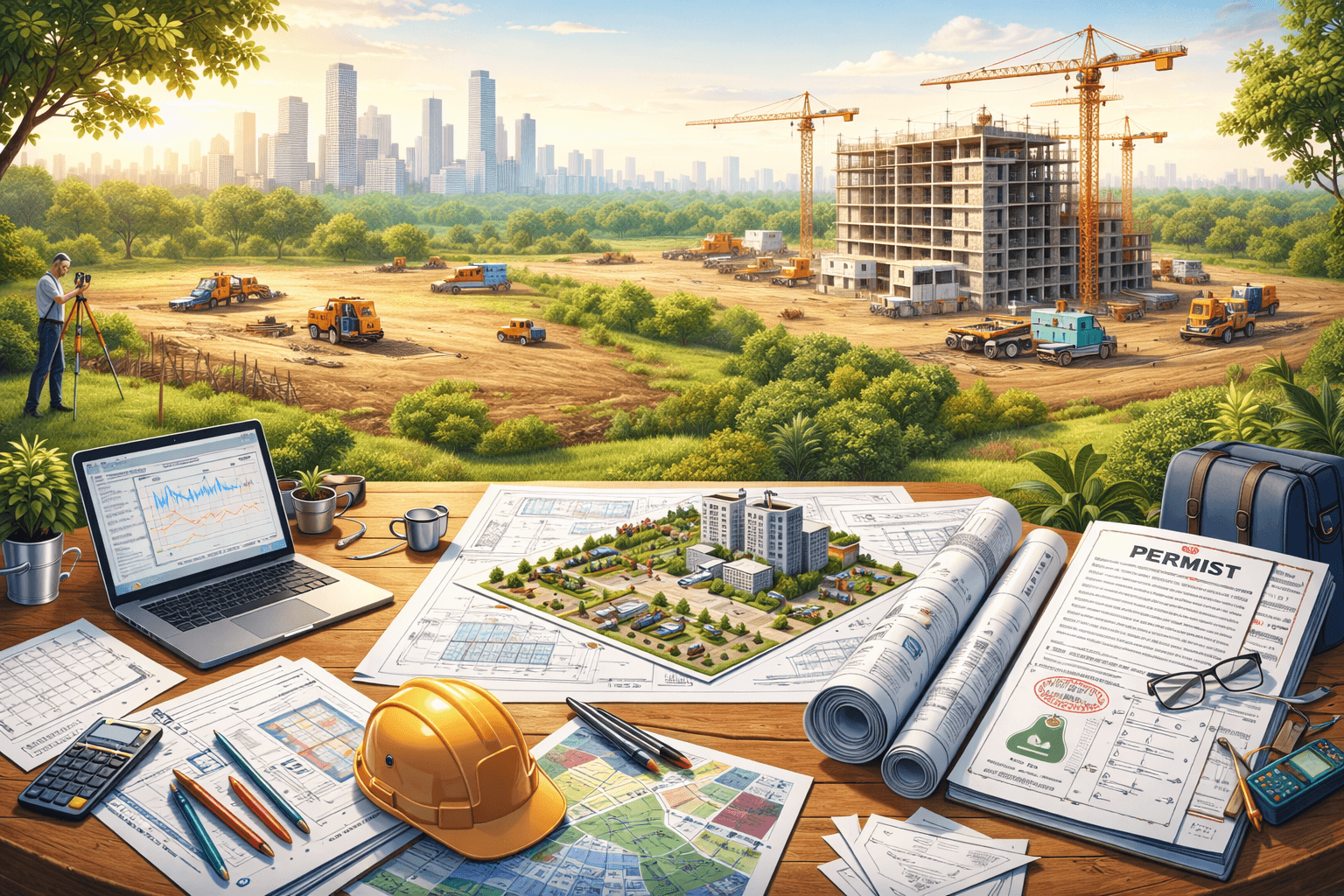

Pre-Construction Stage: Planning, Land Acquisition, Budgeting, and Scheduling

The pre-construction stage serves as the project’s strategic blueprint, arguably exerting the greatest influence over its ultimate success or failure. This phase initiates with the client articulating their needs, leading to conceptual planning and preliminary feasibility studies, which often include crucial land acquisition and site evaluation processes. This is where the initial client–contractor dialogue takes place, setting expectations and defining project scope.

The core output is a robust budget development plan that incorporates initial material decisions, project scheduling, and early procurement strategies. Accurate cost estimations and detailed scheduling models are painstakingly developed during this period, factoring in potential risks and market volatility. The professionalism and depth of planning carried out here are paramount, as every detail, from site logistics to resource availability, is considered. A failure to accurately scope and budget at this early juncture inevitably creates cascading problems, leading to unforeseen expenses, protracted delays, and major defects that surface later during the physical building phase, emphasizing that prevention through planning is far superior to corrective action on site.

The Role of Design Development and Permits in the Construction Timeline

Following the initial planning and budgetary approval, the design development phase translates the concept into constructible realities. This involves the collaborative efforts of architectural teams, structural engineers, and MEP consultants to produce highly detailed drawings, specifications, and building models. This stage is fundamentally important for ensuring legal approval and structural safety, as all designs must undergo rigorous compliance checks against local, state, and national building codes.

Once the design package is finalized, obtaining the necessary permits and regulatory approvals becomes the critical path item. This permitting process is non-negotiable; it serves as a formal, documented confirmation from statutory bodies that the proposed structure is structurally feasible, adheres to safety standards, and is legally sanctioned for construction. Delays in design sign-off or permit issuance can significantly impact the overall construction timeline, halting the progression of mobilization and site works, underscoring why meticulous documentation and proactive engagement with regulatory agencies are essential for maintaining the project schedule.

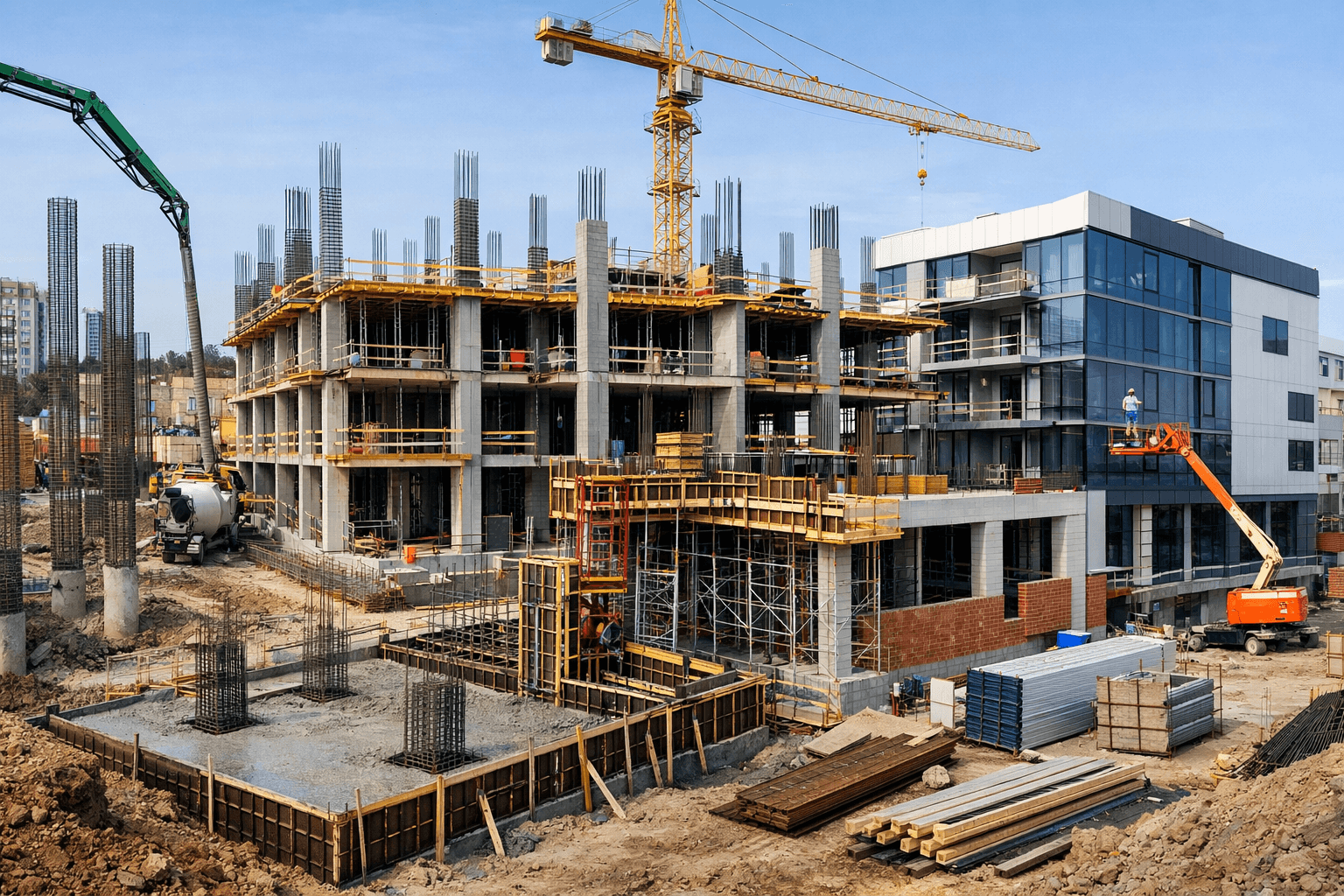

Construction Stage: Site Preparation, Foundation, Structural Frames, and Building Enclosure

The physical construction stage begins with mobilization, wherein equipment, personnel, and temporary facilities are brought to the site. The initial active steps involve thorough site clearing, where any existing structures or vegetation are removed, followed by precise excavation to prepare the ground for the substructure. The foundation work, whether shallow footings or deep piles, is the first and most critical element, as it transfers the structure’s load safely to the underlying soil.

Following the foundation, the construction proceeds to the superstructure framing, which involves erecting the primary structural elements—columns, beams, and slabs—often utilizing concrete or steel, or a combination thereof. This phase is characterized by the intensive use of forming materials, the management of which is a key technical challenge; professional construction practices must thoroughly address issues like what is formwork in concrete before proceeding. The exterior of the building then rapidly progresses toward the building enclosure, incorporating masonry work, curtain walls, roof installation, and exterior finishes, all sealed with a systematic waterproofing plan. For detailed planning of the core framing components, resources like a Shuttering Material List are invaluable for ensuring all necessary elements are accounted for before construction begins on site.

How Formwork, Concrete Placement, and Quality Control Shape the Early Structure

The successful execution of the early structural phases hinges on the precision of temporary structures, specifically formwork systems. Formwork must not only resist the hydrostatic pressure of wet concrete but also ensure the final dimensions and alignment of the structural members are within acceptable tolerances. For instance, the specialized systems used for the construction of Concrete Column Formwork require careful engineering to guarantee verticality and finish. The process of placing and curing the concrete itself requires strict adherence to industry best practices, making the implementation of a comprehensive concrete pouring checklist an indispensable quality control measure. This ensures factors like slump, temperature, vibration, and curing time are correctly managed to achieve the specified design strength.

Since the structural integrity of the entire building depends on these components, systematic quality control, including regular cube testing and non-destructive examination, must be integrated into the workflow. The professional management of these elements—from the engineering of the formwork system to the precise execution of the pour—is what differentiates a structurally robust building from one plagued by early-life defects.

MEP Systems, Interior Works, and Final Finishes

Once the structural frame is completed and the building enclosure, including the roof and exterior walls, is secured and watertight, the focus shifts internally to the installation of mechanical, electrical, and plumbing (MEP) systems. These critical infrastructure components—which include HVAC ducts, piping, wiring, fire suppression lines, and conduits—are meticulously routed through the structure before walls and ceilings are permanently sealed.

Following the rough-in of the MEP systems, interior construction progresses rapidly toward finishing. This includes the installation of insulation, drywall, and plastering, followed by the placement of fixed architectural elements such as flooring, window frames, door systems, and interior woodwork. The later stages involve applying decorative coatings, installing light fixtures, sanitary fixtures, and all other final detailing. This progression requires careful sequencing; for example, painting or delicate floor finishes must only occur after all heavy, disruptive installations, such as the setting of large air handling units, have been safely completed to prevent damage and costly rework.

Why Coordination of MEP and Finishing Stages Determines Project Efficiency

The coordination between the MEP systems and the architectural finishing trades is often the single greatest determinant of efficiency and the potential for costly rework in the later construction phases. The space within walls, ceilings, and service shafts is a finite resource, and installations must be sequenced precisely to avoid interference and conflicts. Poor sequencing, such as installing a major duct run that prevents the installation of a ceiling grid or requires complex rerouting of electrical conduits, directly translates into delays and significant budget overruns. Project managers must use advanced coordination tools, such as Building Information Modeling (BIM), to virtually resolve clashes before they manifest physically on site.

Furthermore, the finishing crews, responsible for aesthetics and user experience, must wait for the full sign-off from the technical teams to ensure concealed systems, like pipes and wiring, are fully tested and functional before they are covered by drywall or ceiling panels. This integrated, multi-disciplinary approach to scheduling and execution is an industry best practice designed to deliver the project efficiently and on time without compromising the quality of either the functional systems or the final aesthetics.

Post-Construction Stage: Inspection, Handover, and Long-Term Maintenance

The post-construction stage marks the transition from building site to operational facility. This phase begins with rigorous system testing and commissioning, where all MEP components—from elevators and fire alarms to ventilation systems—are confirmed to operate according to the design specifications. A key step is the walkthrough, conducted by the client, project manager, and architect, resulting in a formal “punch list” of minor defects, imperfections, or incomplete items. Dedicated teams then work quickly and systematically to resolve this punch list.

The formal handover protocols follow, which involve transferring operational manuals, warranties, and crucial documentation to the building owner or facilities management team. This process also includes training the owner’s personnel on the proper operation and maintenance of the complex installed systems. Comprehensive documentation and transparent performance evaluation are paramount, ensuring that the client receives a building that is not only complete but also fully understood in terms of its operational needs and long-term requirements.

Ensuring Durability and Building Performance After Completion

Long-term durability and sustained building performance are not accidental outcomes; they are the direct result of a proactive, post-handover strategy centered on maintenance, monitoring, and periodic inspections. Even the highest-quality construction will degrade without systematic lifecycle management. Maintenance protocols, which are defined during the handover process, dictate the schedule for inspecting critical components like the roof membrane, HVAC units, and foundation drainage systems.

Monitoring the performance of the building, especially its energy consumption and indoor air quality, provides data-driven feedback that can identify issues before they become catastrophic failures. Periodic professional inspections are essential to catch structural and material deterioration early. These practices are crucial not just for preserving the aesthetic and functional value of the asset but, fundamentally, for long-term structural safety. By embracing a lifecycle perspective, where maintenance is viewed as an investment rather than an expense, building owners ensure the structure remains safe, efficient, and compliant throughout its entire intended lifespan.

Conclusion

Understanding the discrete and sequential stages of building construction is the fundamental principle that underlies all successful projects in the built environment. This professional knowledge, encompassing everything from initial conceptual planning and meticulous design development to the structural phase, MEP installation, and final handover, empowers project stakeholders to achieve exceptional results. Proper planning in the pre-construction phase prevents costly surprises, while rigorous quality control applied during the foundation and framing stages secures the building’s structural integrity.

Managing the complex coordination between technical systems and architectural finishes ensures a swift and efficient close-out. Companies such as BFS Industries, by adhering to these structured processes and engineering standards, demonstrate how a disciplined approach can elevate project outcomes. Ultimately, mastering this staged workflow is crucial for effectively managing timelines, optimizing the deployment of resources, and guaranteeing that high standards of quality and safety are maintained without exception. Every step, when executed with professional diligence, contributes to the creation of a structurally sound and reliable structure that will serve its occupants for decades to come.

FAQs

1. What are the main stages of building construction?

The main stages include pre-construction planning, design and permitting, physical construction, and post-construction handover.

2. Why is construction divided into clear and sequential stages?

Dividing construction into stages helps control cost, manage time efficiently, reduce risks, and maintain quality and safety throughout the project.

3. What happens during the pre-construction stage?

The pre-construction stage focuses on feasibility studies, budgeting, scheduling, land evaluation, and defining the project scope.

4. How do design development and permits affect the construction timeline?

Proper design and timely permits ensure code compliance and structural safety, preventing delays or work stoppages during execution.

5. What is included in the post-construction stage?

Post-construction includes final inspections, system testing, defect correction, project handover, and maintenance documentation.