- Published:

- Written by: B.F.S Industries

When to Remove Concrete Forms From a Slab

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

Remove Concrete Forms From a Slab is a process that requires careful balance between preparation, execution, and patience. Whether the project involves a residential patio or a commercial foundation, pouring a concrete slab is only the beginning—the curing phase that follows is arguably the most critical for the long-term health of the concrete. At the heart of this stage lies the formwork, the temporary molds that hold the liquid concrete in place. The decision of when to remove these forms creates a delicate tension: move too quickly, and the structure may lose its integrity; wait too long, and project efficiency suffers.

The role of formwork extends beyond shaping the slab. It also supports the initial curing process by maintaining consistent temperature and moisture levels, both of which are essential for proper hydration—the chemical reaction that gives concrete its strength and durability. Therefore, the timing of form removal is not merely a logistical choice but a critical factor that determines the final quality and lifespan of the structure.

The risks of poor timing are significant. Removing forms too early can cause cracking, spalling, or surface damage, and in severe cases, even partial or total structural collapse. On the other hand, leaving them in place too long can delay the project, tie up labor and reusable materials, and increase costs. Prolonged contact with certain form materials or improper use of release agents may also lead to cosmetic defects such as discoloration. Striking the right balance between safety and efficiency is therefore paramount for every successful concrete project.

Understanding Concrete Forms in Slab Construction

Concrete forms, also known as shuttering, are temporary molds that hold liquid concrete in a desired shape until it hardens sufficiently to support itself. They are a fundamental part of almost all Concrete Construction, from simple walkways to complex structural elements. The materials and systems used for formwork vary widely depending on the scale and nature of the project.

For smaller, residential projects like patios, sidewalks, or home foundations, wood forms are the most conventional and widely used type. Typically constructed from 2×4 lumber or plywood, these forms are built on-site to the required dimensions. Wooden stakes are driven into the ground to provide support and hold the form boards in place against the immense weight of the wet concrete. A form release agent, such as vegetable oil or a specialized compound, is often applied to the inside faces of the boards to prevent the concrete from sticking, which facilitates a clean and easy removal. While versatile and economical for small jobs, wood forms have limitations, as larger boards can warp, and they are generally not strong enough for heavy-duty construction.

In contrast, manufactured metal forms are the preferred choice for large-scale commercial and industrial structures. These are engineered, reusable systems typically made of steel or aluminum alloys. Their primary benefits are their immense strength, durability, and reusability. They can withstand the high pressures of poured concrete and are precisely engineered to produce clean, consistent finishes with fewer cosmetic defects like “bug holes”. While the initial investment is higher, their ability to be reused hundreds of times makes them cost-effective for major projects.

A more modern and energy-efficient solution, particularly for walls and foundations, is the use of Insulated Concrete Forms (ICFs). These are hollow, rigid blocks made of plastic foam that are assembled on-site. Unlike other formwork, ICFs are designed to remain in place permanently after the concrete is poured. They serve as both the form for the concrete and an integrated, high-performance insulation layer for the finished structure, eliminating the need for form removal altogether.

When discussing Slab Formwork specifically, two main systems are common: conventional and modular. Conventional formwork is a site-built system using wooden beams, facing, and temporary props. Modular formwork, on the other hand, consists of pre-fabricated panels or frames with integrated facing that are supported by props and shoring systems. These systems can be erected and dismantled more efficiently, saving valuable time and labor on large projects.

Why the Timing of Form Removal Matters

The decision of when to remove concrete forms is one of the most critical steps in the entire construction process, directly impacting the final product’s strength, durability, and safety. This is because concrete’s strength is not an immediate, fixed property but a gradual development over time, governed by a complex chemical process.

The fundamental principle behind concrete’s hardening is hydration. This is a chemical reaction that occurs when water and cement are mixed. It is not a drying process but a chemical transformation where the cement and water form a strong, paste-like material that binds the aggregates (sand, gravel) together. The forms play a crucial role in this process by keeping the fresh concrete contained and by preventing premature moisture loss, which is essential for the hydration reaction to proceed properly. Without a steady supply of moisture, hydration slows or stops, preventing the concrete from achieving its full potential strength and durability. While concrete theoretically gains strength forever if kept in a moist environment, it achieves approximately 90% of its final, designed compressive strength within the first 28 days.

Beyond chemical and physical development, the timing of form removal is paramount for safety and quality. A concrete slab must gain sufficient strength to withstand its own weight and any subsequent loads it may be subjected to, such as a contractor walking on it or the placement of construction materials. Removing forms before this strength threshold is met can lead to significant structural problems. The most common defects include cracking, spalling (flaking of the surface), and excessive deflection or sagging. In a worst-case scenario, a premature stripping of formwork, particularly for structural elements like slabs and beams, can lead to a partial or total structural collapse.

Factors Influencing the Right Time to Remove Forms

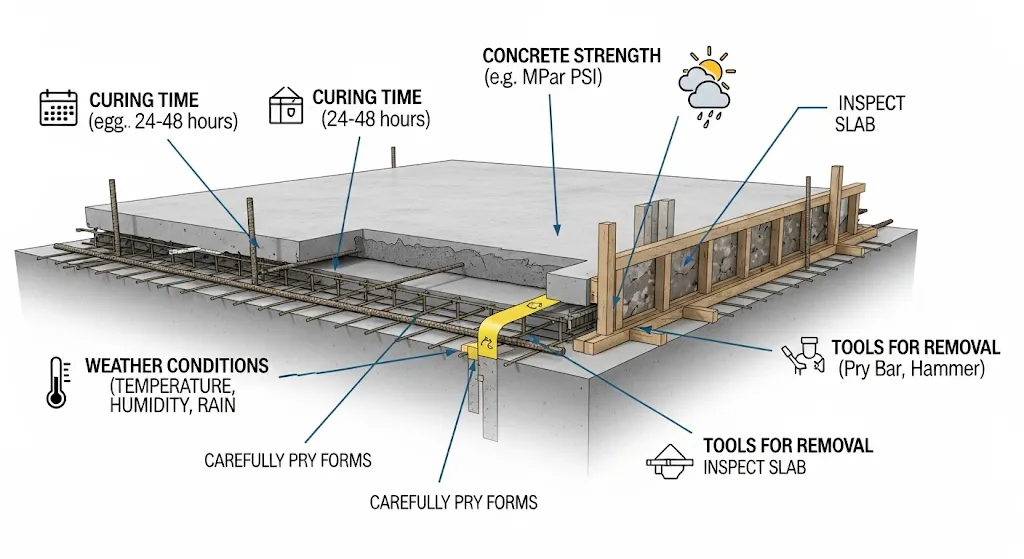

The ideal time to remove concrete forms is not a fixed, universal constant, but rather a decision that depends on a complex confluence of interconnected factors. These factors include the type of concrete mix used, ambient temperature, humidity levels, curing conditions, and the specific structural requirements of the slab or element being cast. Experienced engineers understand that relying solely on a simple, time-based rule of thumb—such as removing forms after 24 or 48 hours—is merely a convenient proxy for a deeper understanding of the underlying engineering principles. In reality, the strength development of concrete follows a dynamic process, influenced by hydration kinetics, chemical composition, and environmental conditions. Therefore, a nuanced assessment, often involving on-site inspections and sometimes even testing the concrete’s early-age strength, is essential to determine the precise moment when forms can be safely removed without compromising structural integrity or surface quality.

Concrete mix and strength gain

The composition of the concrete mix itself is a primary determinant of its strength development. The water-to-cement (w/c) ratio is considered the most critical factor, as a lower ratio generally results in a higher final compressive strength. This is because less water is needed for hydration, resulting in a denser, less porous matrix. The type of cement used is also a major variable; for example, rapid-hardening cement (ASTM C 150 Type III) is designed to achieve high early strength quickly, while ordinary Portland cement (Type I) has a more gradual strength gain curve. The properties of the aggregates—their shape, texture, and size—also influence the mix’s workability and final strength, with angular aggregates typically creating stronger concrete but with a higher water demand. Finally, admixtures can be introduced to the mix to manipulate its properties, such as water reducers to lower the w/c ratio while maintaining workability, or retarders to slow down the setting process in hot weather.

Weather and temperature conditions

Temperature has a profound effect on the rate of the hydration reaction. In warm weather, the reaction accelerates, causing the concrete to set and gain early strength more quickly. Conversely, cold temperatures slow the reaction dramatically, prolonging the setting and strength-gain period. A contractor pouring on a hot day might be able to remove forms sooner due to this rapid initial strength gain. However, a deeper understanding of concrete chemistry reveals a crucial trade-off. While high temperatures accelerate early strength development, they can lead to a lower long-term compressive strength. This is because the rapid hydration process creates a less uniform, more porous internal structure. A study showed that concrete cured at 12°C achieved a compressive strength 13% higher than that cured at 40°C after two years, demonstrating that a slower, more deliberate curing process can result in a more durable final product. This principle highlights why project planners must consider not just the short-term schedule but the long-term integrity of the structure.

Slab thickness and design

The mass and dimensions of a concrete element directly affect its curing time and strength gain. Thicker slabs and larger structural members like beams and arches take longer to cure and gain sufficient strength compared to thinner slabs or vertical elements. This is due to the larger volume of concrete, which generates more heat from the exothermic hydration reaction. This heat needs time to dissipate evenly without causing thermal stress cracks. The design of a member is also critical; vertical elements like walls and columns primarily resist compressive and shear forces, and can be stripped relatively early, as they only need to support their own weight. Horizontal members like slabs and beams must resist bending and deflection under their own weight, requiring much greater strength before forms can be safely removed.

Type of cement used

As mentioned, the type of cement is a primary factor in the rate of strength gain. Different types of cement are formulated to achieve specific properties and setting times. This is why professional standards provide different timeframes based on the cement type. The American Concrete Institute (ACI) recommends minimum curing times to achieve 70% of a concrete’s designed strength based on the cement type.

- Type I (Ordinary Portland Cement): The most common type, typically requires 7 days to reach a significant portion of its strength.

- Type II (Moderate Sulfate Resistant Cement): Slower-setting, requiring around 10 days.

- Type III (Rapid Hardening Cement): Gathers strength very quickly, often allowing for form removal in just 3 days.

- Type IV & V (Low Heat & High Sulfate Resistant): These cements are designed for very slow hydration and require the longest curing period, typically 14 days or more.

Curing methods and site practices

The forms themselves act as a critical curing method, known as formwork curing, by preventing moisture loss from the concrete. This is particularly effective for thick concrete elements where the heat of hydration is significant. Other common practices complement this, such as spraying water or using wet coverings like hessian, which are applied to the concrete surface after the forms are removed to continue the hydration process. The application of membrane curing compounds, which form an impermeable seal on the concrete surface, is another popular method to trap moisture and ensure adequate curing.

Recommended Time Frames for Removing Forms

While a quick answer might suggest a specific number of days, the true standard is based on a fundamental engineering principle: the concrete must achieve a strength of at least twice the stress it will be subjected to at the time of form removal. The time-based guidelines published by organizations like the American Concrete Institute (ACI) and British Standards (BS EN) are practical estimates for achieving this strength under normal conditions with ordinary Portland cement. For a successful project, it is essential to understand both the general timeframes and the underlying strength requirements.

The following table provides a synthesis of typical timeframes for form removal based on different structural elements, drawing from standard industry guidelines.

| Structural Element | General Guideline (Time) | ACI 347 (Time) | IS/BS Standards (Time) |

|---|---|---|---|

| Vertical Walls & Columns | 1 to 2 days | 24 to 48 hours | 24 to 48 hours |

| Slabs (soffit with props left under) | 3 to 4 days | 3 to 4 days | 3 days |

| Beam Soffits (props left under) | 7 days | 7 to 10 days | 7 days |

| Props to Slabs | 7 to 14 days | 7 to 14 days | Up to 4.5m span: 7 days. Over 4.5m span: 14 days |

| Props to Beams & Arches | 14 to 21 days | 10 to 14 days | Up to 6m span: 14 days. Over 6m span: 21 days |

For residential projects, the 24 to 48-hour rule of thumb is often sufficient for simple, non-load-bearing slabs like patios or sidewalks, especially if the weather has been favorable. However, homeowners are always advised to err on the side of caution and wait longer if there is any doubt. For commercial and industrial projects, the timeline is not a matter of guesswork but is dictated by specific, engineered project specifications. Formwork removal is a precisely planned process that relies on in-situ strength testing rather than just a clock and calendar.

Step-by-Step Process for Safe Form Removal

A successful form removal process involves much more than simply pulling off the molds; it requires careful preparation, a gentle touch, and a thorough post-removal inspection to ensure the structural integrity and surface quality of the concrete. Proper preparation begins well before the forms are removed, including confirming that the concrete has achieved sufficient strength, that curing conditions have been maintained, and that any supporting props or bracing are ready to be adjusted safely. The act of removing the forms itself demands a delicate balance—too forceful, and the concrete may crack or chip; too slow, and the process may become inefficient or risk disturbing partially cured sections. Once the forms are removed, a meticulous post-removal inspection is crucial. This involves checking for surface defects, ensuring alignment and levelness are within acceptable tolerances, and addressing any imperfections immediately, whether through minor patching, finishing, or additional curing. Each of these steps contributes to a smooth, successful process that preserves both the strength and the aesthetic quality of the concrete structure.

Pre-checks before removal

Before any form is touched, a careful assessment must be made. For a basic residential project, a visual inspection is often the first step. If the concrete has hardened and slightly pulled away from the forms, it’s a good visual indicator that it has set sufficiently. For commercial or high-stakes projects, the visual check is just the beginning. The engineer or contractor will need to verify the in-place strength of the concrete to ensure it meets project specifications.

Several professional methods are used for this verification:

- Test Cylinders: The most common method involves preparing test cylinders from the same concrete batch and curing them under the same conditions as the slab. These cylinders are then tested for compressive strength in a laboratory at various ages (e.g., 7 days and 28 days).

- Maturity Method: This modern, highly accurate technique uses wireless sensors placed directly within the concrete. The sensors record the concrete’s temperature history, and a maturity equation is used to calculate the in-situ strength in real-time, allowing for precise, data-driven decisions on form removal.

- Non-Destructive Tests (NDT): Methods such as the rebound hammer (ASTM C805) or ultrasonic pulse velocity (ASTM C597) can provide an estimate of surface hardness, which can be correlated to strength. These are less accurate than the maturity method but provide a quick, on-site assessment.

Best practices during removal

The actual removal process should be performed with care to avoid damaging the new concrete surface. The process begins with removing all external supports, such as stakes and kickers, and any fasteners like nails or screws. Gently tapping the boards along the top and side with a hammer can help break any remaining adhesion and loosen them. A wooden wedge or pry bar should be used carefully to separate the formwork from the slab, with extreme caution to avoid gouging or chipping the delicate concrete edges. A professional will follow a specific sequence for multi-element projects, starting with vertical members (walls, columns) before moving to horizontal soffits, and leaving all props in place until the structural member can support its own weight and any applied loads.

Inspection after removal

Immediately after the forms are removed, the concrete surface must be inspected for any defects that may have occurred during the pour or removal. Timely repairs are crucial, ideally within 24 hours of stripping the forms, to ensure the long-term integrity and appearance of the slab. The following table outlines common defects and their recommended repair methods.

| Defect | Description | Repair Method |

|---|---|---|

| Honeycombing | Voids or air pockets on the surface where the concrete mixture failed to fill a space, leaving behind exposed aggregates. | Chip out the affected area to create a solid, keyed hole with perpendicular or undercut edges. Fill with a mortar patch, applied in thin layers, with a rough finish on each layer to ensure a proper bond. |

| Rock Pockets | Similar to honeycombing, a larger void with loose aggregates. | Chip out the area completely and shape it with sharp edges to allow for a keyed patch. Pack with a non-shrink grout or concrete patch, ensuring each layer is well-compacted. |

| Bulges/Ridges | Uneven concrete surfaces caused by forms bulging under pressure or concrete seeping through form joints. | Chip off the excess concrete and rub the area with a grinding stone to create a smooth, level surface. |

| Bolt/Tie Holes | Small, circular voids left behind by form ties. | Fill with small amounts of non-shrink grout, mixed as dry as possible, and carefully packed into place. |

| Stripping Damage | Cracks, chips, or spalling caused by the form removal process itself. | For small chips, a thin layer of mortar can be applied and troweled to match the surrounding surface. For more significant damage, follow the procedure for honeycombing or rock pockets. |

Common Mistakes to Avoid

Success in a concrete project often comes down to avoiding common pitfalls.

Removing forms too early is arguably the most dangerous mistake. It directly risks the structural integrity of the concrete, which is at its most vulnerable in the first few days of curing. This can result in structural collapse, as seen in the infamous case of the 2000 Commonwealth Avenue apartment building failure, where premature formwork removal was identified as a key procedural concern. The desire to accelerate a project schedule must never outweigh the fundamental requirement for the concrete to gain adequate strength.

Delaying removal unnecessarily is a mistake of a different nature. While it does not harm the concrete to leave the forms on for an extended period, it ties up a contractor’s valuable labor, equipment, and reusable materials. For commercial projects with tight schedules and budgets, this can result in significant opportunity costs and project delays. For residential projects, leaving wood forms on for too long can even lead to discoloration of the concrete if chemicals from the wood or form release agents bleed into the surface.

Ignoring curing requirements is a final, critical error. The hydration process does not stop the moment the forms are removed. Proper post-removal curing, whether through wet curing, membrane compounds, or sheeting, is essential to allow the concrete to continue its strength gain and achieve its designed durability and long-term properties. A contractor who views form removal as the end of the curing process is compromising the final quality of their work.

Case Studies and Real-Life Examples

The principles of formwork removal are best understood through real-world applications and cautionary tales.

For a residential slab, a typical DIY project demonstrates the standard timeline. The initial site preparation and form setting can take a couple of days. The concrete is then poured and finished, often a long day of work. The forms are typically removed 24 to 48 hours later, once the concrete is solid enough to support foot traffic. A common issue for DIYers is concrete “slough off,” or overspill, that hardens under the forms due to uneven grade The simplest solution is to backfill with dirt to hide the spill, but a more meticulous approach involves carefully chipping off the excess concrete and then finishing the surface with a mortar patch.

In commercial and industrial projects, the stakes are much higher. A prime example is the collapse of the Commonwealth Avenue building. A detailed investigation found that a combination of flawed design and procedural concerns, including the premature removal of formwork, contributed to the catastrophic failure. This serves as a powerful reminder of why adherence to engineering standards and a focus on safety are non-negotiable on a large scale.

In contrast to historical failures, modern high-rise construction illustrates how technology and engineering allow for faster but still safe form removal. A study on the use of aluminum formwork systems in high-rise buildings demonstrates how engineers use finite element analysis and evaluate factors like “punching shear capacity” to determine the earliest possible time for form removal. The use of engineered, reusable formwork allows for a rapid construction cycle while ensuring the concrete has reached the necessary strength to support itself and subsequent loads. This highlights how the balance between efficiency and safety can be achieved through advanced planning and a scientific approach.

Practical Tips for Builders and DIY Homeowners

Regardless of the project’s scale—whether it is a small residential patio, a mid-sized commercial floor, or a large industrial foundation—there are a few key takeaways that can help ensure a successful form removal process. These guiding principles include understanding the concrete’s curing progress, monitoring environmental conditions such as temperature and humidity, and planning the removal sequence carefully to prevent undue stress on the structure. By paying attention to these factors, construction teams can minimize the risk of surface damage, cracking, or structural weakness, while also optimizing efficiency and safety on site. Even in projects of vastly different sizes, adhering to these fundamental considerations lays the groundwork for a smooth and reliable form removal experience.

Recommendations for contractors

For professional builders, the goal is to balance efficiency with unwavering quality. This can be achieved through advanced practices:

- Implement Strength Testing: Rely on data, not just time. Utilize modern tools like wireless maturity sensors (ASTM C1074) to get real-time, in-situ strength readings. This allows for the safest and most efficient form removal, potentially accelerating project timelines by a day or two per cycle without compromising the structure.

- Invest in Reusable Forms: Choose high-performance, durable formwork materials like steel, aluminum, or recycled plastic sheets over traditional wood.

- While the initial investment may be higher, these materials can be reused dozens or even thousands of times, reducing material waste, procurement cycles, and long-term costs.

Simple checklist for non-professionals

For the DIY homeowner, a simple, step-by-step approach is best. Use this checklist to ensure all critical steps are covered:

- Check Local Codes: Confirm any specific requirements or waiting periods mandated by your local building authority.

- Wait the Minimum Time: A general rule is to wait at least 24 to 48 hours for a basic slab, or longer if weather conditions were not ideal.

- Observe the Concrete: Look for visual cues, such as the concrete slightly pulling away from the forms.

- Gather Your Tools: Have a hammer, a pry bar or wooden wedge, and a stiff brush ready.

- Remove Forms Gently: Start with the fasteners and external supports before gently prying the boards away from the slab, being careful not to chip the edges.

- Begin Post-Removal Curing: As soon as the forms are off, begin the post-removal curing process by covering the slab with a plastic sheet or applying a curing compound to prevent moisture loss.

Conclusion

The successful removal of concrete forms is a testament to the confluence of timing, chemistry, and sound engineering judgment. The central principle that governs this process is not an arbitrary number of hours or days, but the concrete’s ability to achieve sufficient strength to withstand the stresses it will face. The recommended timeframes provided by industry standards are invaluable guidelines, but they are most effective when understood as a proxy for this core strength requirement.

For contractors and builders, this means leveraging technology and a deep understanding of material properties to make data-driven decisions that balance project efficiency with safety. For homeowners and DIY enthusiasts, it means exercising patience and following a clear checklist, erring on the side of caution to protect the integrity of their work. Ultimately, proper formwork removal is not just about finishing a project; it is about building a structure that is safe, durable, and built to last.

Frequently Asked Questions (FAQs)

What happens if forms are removed too early ?

Removing forms prematurely can lead to several problems, including cracking, spalling, and deformation of the concrete. In the worst-case scenario, it can cause structural instability or a catastrophic collapse, as the concrete has not yet achieved the necessary strength to support its own weight and any external loads.

Can forms be reused after removal ?

The reusability of forms depends entirely on their material. Engineered forms made of steel, aluminum, or plastic are specifically designed for multiple uses and can be cleaned and stored for future projects. However, wood forms used for structural applications, particularly those exposed to the high pH and alkalinity of fresh concrete, should not be reused for load-bearing purposes. The concrete can degrade the wood, and the stripping process can cause unseen damage, reducing its strength and creating a significant safety risk if used in a new structural application.

How to know if concrete is strong enough ?

The most reliable way to determine if concrete has gained sufficient strength is through a compressive strength test. This can be done by testing laboratory-cured cylinders taken from the same pour or by using modern, non-destructive methods like wireless maturity sensors that provide real-time data on the in-situ concrete strength.

Are removal times different in hot and cold weather ?

Yes, ambient temperature significantly impacts concrete curing. High temperatures accelerate the hydration reaction, leading to faster early strength gain and allowing for earlier form removal. Conversely, cold temperatures slow the reaction, requiring forms to be left in place for a much longer period.