Concrete Column Formwork & Shuttering Systems

Introduction

Column formwork systems are essential components in concrete construction, providing the necessary shape and support for vertical structural elements—especially columns—during the critical phases of concrete pouring and curing. These systems play a vital role in maintaining dimensional accuracy, alignment, and surface quality, while withstanding the lateral pressure of freshly placed concrete. For engineers, architects, and construction professionals, choosing the right column formwork system—such as those offered by trusted manufacturers like BFS Industries—can significantly influence project outcomes in terms of safety, efficiency, cost-effectiveness, and structural performance. In this comprehensive guide, we explore what concrete column formwork is, the different types available, key components, design considerations, installation procedures, and proven best practices, offering you a complete resource to optimize your concrete construction workflow.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

Column Formworks Category

Column Formworks Products

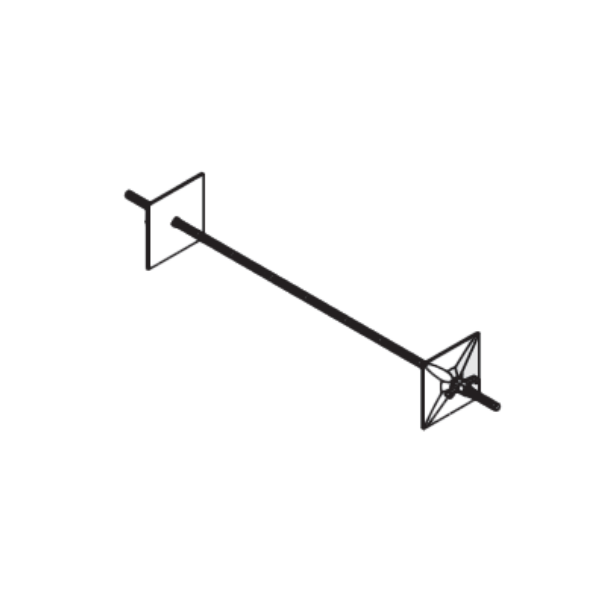

Circular Column Tierod, NUT, Plate

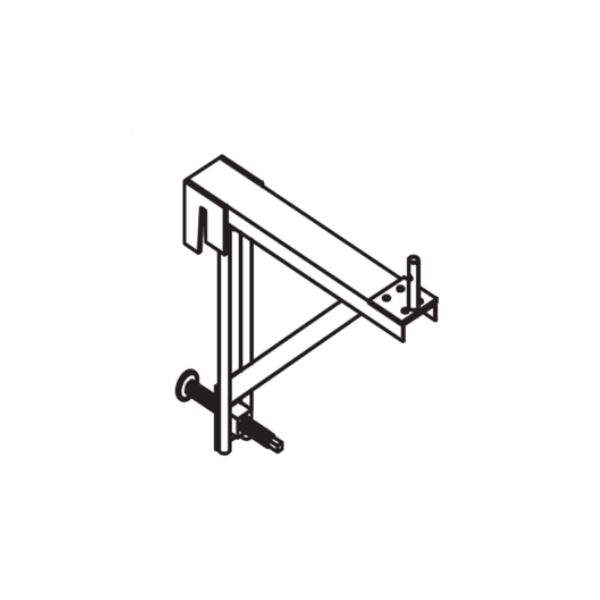

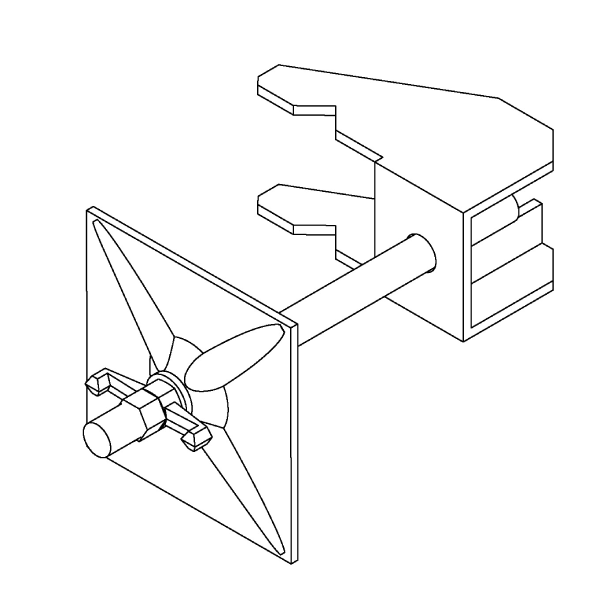

Climbing Circular Column Bracket accessory Pouring Platform

Climbing Circular Column Inclined Push/ Pull Prop

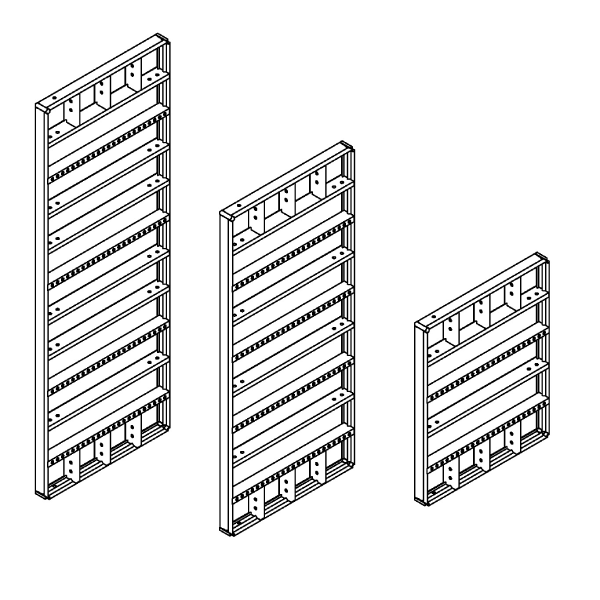

Column ZigFlex Panel

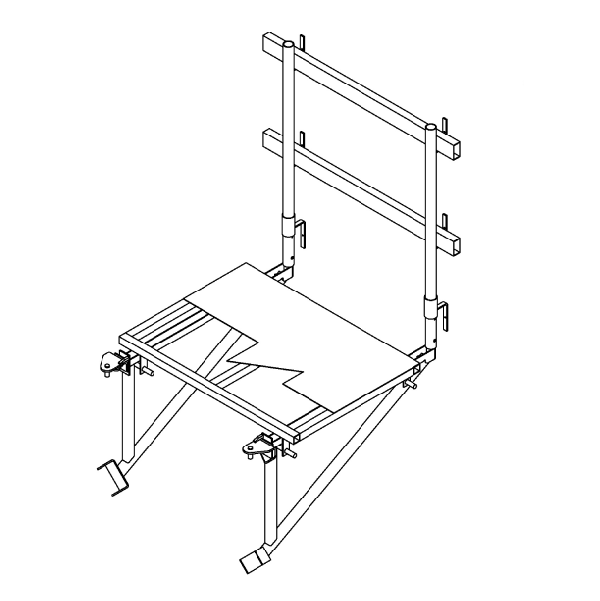

Column ZigFlex Pouring Platorm(shelter)

Column ZigFlex Push/Pull Double Prop

Column ZigFlex T-Lock

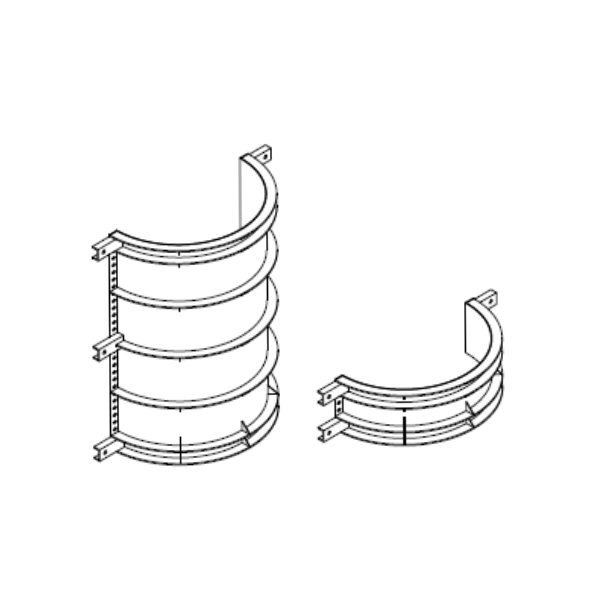

Normal Circular Column Panel

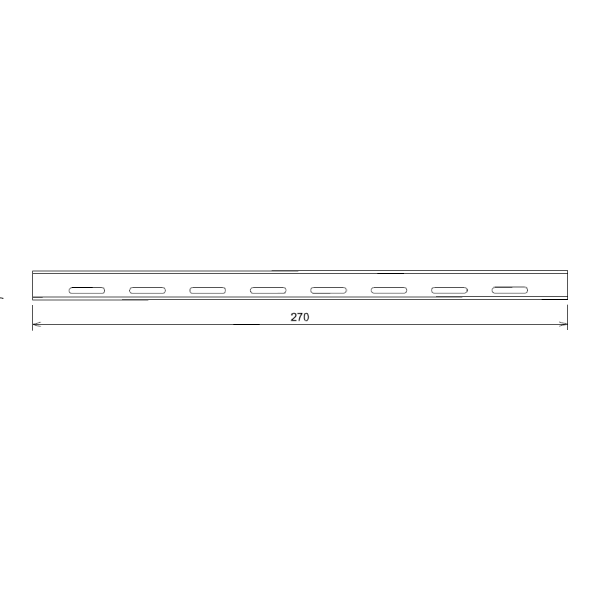

ZigFlex Chamfer strip

What is Concrete Column Formwork & Shuttering? Key Details

Column formwork refers to a temporary or sometimes permanent mold designed to shape and support concrete columns during the construction process. Its primary function is to hold freshly poured concrete in place until it gains sufficient strength and hardens into the intended shape and dimensions. By ensuring proper alignment, verticality, and surface finish, formwork for column plays a vital role in maintaining the structural integrity of vertical load-bearing elements.

These systems are typically constructed from a variety of materials, including timber, steel, aluminum, or durable plastic—each chosen based on project requirements such as load capacity, reusability, and cost. While many column formwork systems are designed to be removed after the concrete cures, some are engineered as permanent formwork, integrating seamlessly into the final structure for added support or insulation.

Today, formwork suppliers in the UAE offer a wide range of innovative column formwork systems to meet the growing demands of fast-paced urban development. Especially in regions like Dubai, where high-rise construction is booming, selecting the right formwork for concrete columns in Dubai is essential for ensuring quality, safety, and efficiency on site.

Why Column Shuttering or Formwork Is Essential in Concrete Construction

Fresh concrete lacks the inherent strength to hold its shape independently, especially when forming complex structures like a circular column formwork. concrete column formwork provides the essential containment needed to shape the concrete accurately, ensuring that both standard and circular columns achieve the precise dimensions, alignment, and surface finish required by the project’s design. Without properly installed formwork, columns may slump, shift out of alignment, or fail to meet critical structural standards—compromising not only the stability of the building but also its overall aesthetics. In addition to shaping the concrete, high-quality formwork systems enhance job site safety by offering stable platforms for workers and minimizing the risk of structural failure during the concrete pouring process. For projects in the UAE, partnering with a formwork specialist in Dubai ensures access to advanced systems and local expertise tailored to regional construction standards.

How Column Shuttering Works

Column formwork and shuttering functions as a mold into which wet concrete is poured. The system must be rigid, watertight, and capable of withstanding the lateral pressure exerted by the concrete, which can be significant in tall columns. Once the concrete reaches sufficient strength (typically after 24–72 hours, depending on the mix and conditions), the formwork is removed in a process called “stripping.” The formwork’s design ensures it can be dismantled without damaging the cured concrete surface.

Types of Column Formwork & Shuttering Systems

Column formwork and shuttering systems come in a wide range of materials, designs, and configurations—each tailored to meet specific construction needs and project constraints. The choice of formwork can significantly influence factors such as installation speed, surface finish, structural accuracy, and cost-efficiency. Understanding the distinct features and benefits of each type is essential for selecting the most suitable system. Below, we explore the most common types of column formwork used in today’s construction industry.

Column Steel Formwork & Shuttering

Steel shuttering is renowned for its exceptional strength, durability, and ability to withstand high concrete pressures—often reaching 80 kN/m² in advanced systems. This makes it an ideal choice for large-scale commercial or industrial projects where structural demands are higher and consistency is critical. One of the key advantages of steel formwork is its high reusability, which offsets the initial investment over multiple uses, especially in projects with repetitive column designs. Many steel systems also feature adjustable or modular components, providing flexibility to accommodate various column dimensions and geometries. However, due to its weight, steel formwork typically requires cranes or specialized lifting equipment for installation and removal, which can increase labor and equipment costs. Despite this, its long-term performance, precision, and resilience make it a reliable solution for demanding construction environments.

Circular vs. Rectangular Column Formwork: Which to Choose?

Column formwork & shuttering can be circular or rectangular, depending on the architectural design and structural requirements of the project. B.F.S Holding offers reliable and efficient solutions for both types, helping construction teams meet performance, safety, and aesthetic standards.

Circular column formwork or shuttering typically consists of two semi-circular units that join together to form a complete mold. These systems are designed to handle concrete pressure effectively without the need for additional ties, thanks to their balanced load distribution. Circular formwork is ideal for creating smooth, curved surfaces, making it a great choice for decorative columns or structural elements like bridge piers.

Rectangular column formwork or shuttering, offered by B.F.S Holding, includes foldable and adjustable panels that simplify assembly and allow for quick adaptation to different column sizes. This type of formwork is commonly used in residential, commercial, and industrial construction projects due to its versatility and ease of use.

Key Components & Parts of Concrete Column Formwork

A formwork for column or shuttering system is made up of several key components, each playing an essential role in ensuring the system’s overall functionality, structural integrity, and on-site safety. Understanding these components is crucial for proper installation, efficient use, and achieving high-quality results in concrete column construction. Below, we’ll explore the main elements that make up a typical column shuttering system and their specific functions.

Column Formwork Suppliers & Manufacturers

At B.F.S Industries, we are one of the leading column formwork suppliers and manufacturers in the Middle East, offering a complete range of concrete column formwork systems for circular, rectangular, and custom shapes.

Our production facilities in Dubai, UAE, are equipped with advanced fabrication technologies that ensure high precision, durability, and modular compatibility for every project.

Whether you need standard column formwork panels, custom steel formwork, or full modular shuttering systems, BFS provides engineered solutions that guarantee fast installation and long-term reliability. We also supply essential accessories such as tie rods, wing nuts, plates, clamps, and brackets — all designed to integrate seamlessly with our column formwork systems.

If you are looking to buy concrete column formwork directly from the manufacturer, contact our sales team for detailed specifications, pricing, and technical support.

Panels & Form Faces of Column Formwork

Panels are the primary surface elements of a column formwork and shuttering system, directly responsible for shaping the concrete as it sets. These panels, often referred to as form faces, are made from materials such as plywood, steel, or plastic—each influencing the final appearance and surface quality of the column. For instance, steel form faces are known for delivering smooth, uniform finishes with minimal surface imperfections, making them ideal for exposed architectural concrete. In contrast, plywood panels are more cost-effective and easier to handle but may require additional surface treatment or lining to achieve a high-quality finish. The choice of panel material plays a crucial role in both the aesthetic outcome and overall efficiency of the formwork system.

Column Formwork Bracing & Support Systems

column formwork bracing is a critical component in any column formwork system, ensuring stability and structural integrity during the concrete pouring process. Vertical braces are used to prevent the formwork from tilting or shifting, while horizontal braces help maintain proper panel alignment, especially under lateral pressure from fresh concrete. In addition to bracing, falsework—such as adjustable props or scaffolding—provides temporary support to hold the formwork securely in place until the concrete has fully cured. High-performance formwork systems are often designed to withstand substantial loads without the need for additional shoring, improving efficiency and reducing setup complexity on-site. Proper bracing and support are essential for both safety and the accurate formation of concrete columns.

Important Details of Concrete Column Formwork

Ties and clamps play a vital role in securing opposing formwork panels, preventing them from spreading apart under the lateral pressure of freshly poured concrete. These components help maintain the column’s exact dimensions and structural integrity during the curing process. In addition to these core fasteners, various accessories—such as spacers for maintaining uniform gaps, leveling devices for precise alignment, and lifting lugs for safe transportation and positioning—enhance the accuracy, safety, and efficiency of formwork installation. Advanced formwork systems may also include integrated ladders and working platforms, providing secure access for workers during setup, inspection, and pouring activities. Together, these elements contribute to a safer and more streamlined construction process.

Column Formwork Details to Consider

When selecting formwork for concrete construction, it’s important to consider integrated safety features that can significantly improve both on-site efficiency and worker protection. Elements such as guardrails, access platforms, and bond breakers—specialized chemicals that facilitate easy formwork removal—play a crucial role in streamlining the construction process while minimizing risks. These built-in safety and performance enhancements not only support smoother operations but also contribute to higher-quality results in any concrete construction project.

Column Shuttering Design Considerations

Designing column formwork and shuttering is a critical step in any concrete construction project, requiring a careful balance between structural integrity, on-site safety, and practical execution. A well-thought-out design ensures that the formwork can withstand concrete pressure, maintain alignment, and allow for efficient installation and removal. In the following sections, we’ll explore the key considerations that influence effective column formwork design.

Structural Load and Pressure Handling

Column shuttering must be designed to withstand the significant lateral pressure exerted by freshly poured concrete, which can reach 80 kN/m² or more depending on the height and rate of the pour. High-performance systems, such as those offered by BFS Industries, are engineered to handle extreme pressures—sometimes exceeding 120 kN/m²—ensuring stability and dimensional accuracy throughout the pouring process. In addition to concrete pressure, the formwork design should also consider external loads, including wind forces, equipment vibrations, and other dynamic factors present on active construction sites. Proper structural analysis and component selection are essential to ensure safety and performance under these demanding conditions.

Accurate Sizing and Positioning

Precise sizing and positioning of column formwork or shuttering are essential to meet both architectural intent and structural requirements. Accurate alignment ensures that columns connect seamlessly with beams, slabs, and other structural elements, maintaining the integrity and functionality of the overall design. Adjustable formwork systems, such as those offered by BFS Industries, allow for on-site fine-tuning, making it easier to adapt to real-world conditions and layout variations. Any misalignment during setup can result in serious structural inconsistencies, aesthetic defects, or costly delays due to rework—highlighting the importance of precision in the formwork installation process.

Safety in Design and Execution

Safety is a top priority in any concrete construction project, and formwork systems must be designed with worker protection and structural stability in mind. A well-designed column formwork setup should include stable working platforms, fall protection systems, and safe, convenient access for personnel during all phases of construction. Adhering to established safety standards—such as ACI 347 (Formwork for Concrete)—helps ensure both the structural integrity of the formwork and the well-being of workers on-site. Incorporating integrated safety features like guardrails, ladders, and secure access points not only enhances protection but also reduces the need for external scaffolding, streamlining setup and improving overall efficiency.

Concrete Column Formwork Installation Process

Proper installation of column formwork is essential to guarantee the structural integrity, dimensional accuracy, and overall safety of concrete columns. A well-executed installation not only ensures that the formwork performs as intended under load, but also helps prevent issues such as misalignment or surface defects. The process typically involves several critical steps, each of which must be carried out with precision and attention to detail. In the following sections, we’ll outline the key stages involved in the correct installation of column formwork.

Safety Considerations for Concrete Column Formwork

Ensuring safety in concrete column formwork is critical during both installation and dismantling phases. Improper setup, insufficient bracing, or premature removal of formwork can lead to serious structural failures and site hazards.

At B.F.S Industries, we follow international safety standards and best practices to guarantee the stability and alignment of each column during casting.

Key safety considerations include:

-

Proper Bracing and Alignment: Each column formwork must be firmly braced to resist concrete pressure during pouring.

-

Quality Fasteners and Ties: Always use tested and approved tie rods, nuts, and clamps to prevent blowouts.

-

Load Distribution: Ensure the supporting scaffold or base structure can handle the total load of the wet concrete.

-

Inspection Before Pouring: Check all panels, joints, and connections before concrete placement.

-

Safe Removal Timing: Never remove column formwork before concrete achieves sufficient strength (as per project specifications or standards like ACI or BS).

Adhering to these safety measures minimizes the risk of deformation, leakage, and structural instability, ensuring the quality and longevity of concrete columns.

Site Preparation for Concrete Column Formwork

Before installation, the site must be leveled and column positions marked accurately. This ensures proper alignment and prevents issues during pouring. Inspect the ground for stability and correct any uneven surfaces.

Assembling Concrete Column Formwork

Formwork assembly involves connecting panels and braces according to the manufacturer’s instructions. Modular systems, like Fast-Form, allow for quick assembly with minimal tools. Ensure all components are securely fastened and aligned.

Bracing & Securing Column Formwork

Bracing is a critical component in column formwork installation, as it prevents unwanted movement or shifting during the concrete pouring process. Both vertical and horizontal braces must be installed according to engineering specifications to maintain the correct alignment and withstand lateral pressure. Additionally, the formwork should be securely anchored to the ground or to adjacent structural elements to ensure full stability under load. Some advanced formwork systems, such as those offered by BFS Industries, are designed for crane-lifted assembly, allowing for faster and safer installation—especially on large or complex construction sites. Proper bracing not only enhances structural accuracy but also contributes significantly to overall site safety.

Pouring & Curing Concrete Column Formwork

Concrete should be poured at a controlled and consistent rate to prevent excessive lateral pressure on the column formwork, which could lead to bulging, misalignment, or even formwork failure. Throughout the pouring process, the system should be closely monitored to detect any signs of movement, deformation, or leakage that could compromise the integrity of the column. Once pouring is complete, the concrete must be allowed to cure properly—typically for 3 days , depending on environmental conditions and the mix design. It’s essential to follow the manufacturer’s guidelines before stripping the formwork to ensure the concrete has gained sufficient strength and to avoid damaging the column’s surface or structure.

Bracing Techniques for Column Formwork & Shuttering Stability

Effective bracing is essential for maintaining the stability and alignment of column formwork throughout the concrete pouring and curing process. Without proper bracing, even a well-designed formwork system can shift or collapse under pressure, leading to structural defects, safety hazards, and costly project delays. In the following sections, we’ll explore the key principles and best practices for implementing reliable bracing in column formwork systems.

Preventing Movement During Pouring

Secure anchoring and continuous monitoring during the concrete pouring process are essential to maintain the stability of column formwork and prevent movement or failure. Anchors should be torque-verified and installed according to the manufacturer’s specifications to ensure they can withstand both internal and external forces. Proper brace placement is also crucial, as incorrect positioning can compromise the system’s integrity. Avoid overloading the formwork with excessive concrete or placing heavy equipment nearby during the pour.

Common Bracing Mistakes to Avoid:

-

Insufficient Bracing: One of the most frequent causes of collapse or misalignment. Always follow the manufacturer’s bracing guidelines for safe and stable installation.

-

Improper Anchoring: Using substandard or poorly installed anchors can lead to failure under pressure. Choose high-quality, tested anchors and verify their performance.

-

Ignoring Wind Loads: Especially in tall or exposed formwork setups, wind can create significant lateral forces. Always account for local wind conditions in the design and bracing layout.

Advantages of Using Modular and Reusable Formwork

Modular and reusable formwork systems have transformed modern construction by offering clear advantages over traditional, single-use methods. Their standardized components, ease of assembly, and high reusability make them ideal for improving efficiency, reducing material waste, and lowering labor costs—especially in large-scale or repetitive concrete projects. In the following sections, we’ll explore the key benefits and practical applications of modular formwork systems in detail.

Cost-Effectiveness

While the initial investment in reusable formwork systems—such as those made from steel—may be higher than that of traditional materials, the long-term cost benefits are significant. These systems are particularly advantageous in large-scale concrete or steel structure projects, where durability, precision, and repeatability are essential. By eliminating the need for single-use materials, reusable formwork helps reduce waste and recurring expenses. For example, steel formwork can be reused up to 300 times, according to some manufacturers, making it an efficient and cost-effective solution for repetitive construction tasks.

Time-Saving on Large Projects

ZIG-FLEX formwork systems are engineered for quick assembly and disassembly, significantly reducing labor time and improving overall job site efficiency. Their standardized, easy-to-handle components make them especially valuable in large-scale projects with repetitive column designs, such as commercial buildings, high-rise developments, and bridge construction. By streamlining installation and removal, modular systems help accelerate construction schedules while maintaining precision and safety.

Environmental Benefits

Reusable formwork minimizes waste compared to timber or cardboard systems. Many modular systems, like Fast-Form, are made from recyclable materials, reducing environmental impact and aligning with sustainable construction practices.

Common Mistakes in Concrete Column Formwork & How to Avoid Them

Avoiding common pitfalls is essential for achieving a successful formwork installation and producing high-quality concrete columns. Even well-designed systems can fail if misused or improperly assembled, leading to structural defects, safety hazards, or costly delays. In the following section, we’ll highlight some of the most frequent mistakes and how to prevent them through proper planning, execution, and adherence to best practices.

Inadequate Bracing

Insufficient bracing is one of the leading causes of formwork failure, often resulting in structural damage, safety risks, and costly project delays. To ensure formwork stability and overall column integrity, it’s crucial to follow the manufacturer’s bracing guidelines precisely, while also adapting the setup to meet site-specific conditions. On construction sites exposed to high winds, uneven ground, or frequent equipment movement, additional bracing should be incorporated to reinforce the system and maintain alignment throughout the concrete pouring and curing process. Taking these precautions not only protects workers and structures but also ensures consistent, high-quality results.

Incorrect Form Alignment

Misaligned formwork can lead to columns that are out of plumb, uneven, or incorrectly sized—compromising both structural integrity and aesthetic quality. To avoid these issues, it’s essential to use leveling devices and precisely verify all measurements during the assembly process. Regular checks throughout setup help ensure that the formwork aligns with design specifications, preventing costly rework and ensuring a high-quality finish.

Delayed Stripping of Formwork

Leaving formwork in place for too long can complicate the removal process and potentially damage the finished concrete surface. Over time, formwork materials may bond too tightly with the concrete, leading to chipping or surface defects during stripping. To prevent this, always follow recommended stripping times based on the concrete’s curing rate and strength—typically 3days. Adhering to these guidelines ensures clean removal, protects surface quality, and maintains structural integrity.

Choosing the Right Concrete Column Formwork & Shuttering

Selecting the appropriate formwork system is a critical decision that depends on a range of project-specific factors, including column size, shape, structural load, repetition, budget, and site conditions. The right choice can greatly influence construction speed, safety, cost-efficiency, and the overall quality of the finished structure. In the following sections, we’ll explore the key considerations that guide effective formwork selection for concrete column construction.

Factors to Consider When Buying Column Formwork

When choosing a column formwork system, budget, size, and reusability are key considerations. For small-scale or one-off projects, timber formwork offers a cost-effective solution. However, for larger projects or repeated use, steel or aluminum systems provide better long-term value due to their durability and high reusability. Projects involving large columns benefit from high-capacity systems, such as steel formwork, which can withstand greater pressure. Meanwhile, modular formwork systems are ideal for sites that require multiple pours, offering efficiency, precision, and reduced labor time across repeated cycles.

Concrete Column Formwork Price & Suppliers

The cost of column formwork can vary depending on several factors such as material type, condition (new or used), and included accessories. While new column formwork is generally priced within a certain range per square meter, many contractors also consider used options to reduce upfront costs. Materials like steel, aluminum, and plastic offer long-term value thanks to their durability and reusability, making them a smart investment despite the initial expense. Timber may seem more affordable, but it typically has a shorter lifespan and limited resale potential. One of the advantages of purchasing quality column formwork is that it often retains its value—making resale or reuse a viable option once a project is complete. Some sets may also come bundled with helpful extras like access ladders, guardrails, or falsework, which can slightly raise the total cost but enhance efficiency and safety on-site. Ultimately, investing in column formwork is a strategic choice that can offer both immediate construction benefits and long-term financial returns.

B.F.S Industries is a top brand among shuttering systems suppliers.

Among the top brands in shuttering systems, B.F.S Industries stands out as a leading supplier of column formwork, modular vertical systems, steel frames, and scaffolding. With a strong focus on durability, precision engineering, and reusable design, B.F.S Industries delivers high-performance formwork solutions tailored to a wide range of construction needs — from small projects to large-scale infrastructure developments.

Final Thoughts and Recommendations

Column formwork systems play a vital role in concrete construction, providing the necessary support and shape for columns while ensuring both structural integrity and aesthetic quality. Available in various materials—such as timber, steel, aluminum, concrete, and modular systems—each type caters to specific project requirements. These systems consist of key components including panels, bracing, and ties, all designed to handle concrete pressure, maintain alignment, and ensure worker safety. Effective installation involves site preparation, accurate assembly, proper bracing, and controlled concrete pouring. Attention to detail—such as avoiding common issues like insufficient bracing or misalignment—is critical for success. Modular and reusable formwork systems offer significant advantages, including cost savings, time efficiency, and environmental sustainability. Ultimately, selecting the right formwork system depends on factors like budget, project scale, and reusability goals.

Concrete Columns Formwork Factory – About BFS Industries

At BFS Industries, we operate as a specialized concrete columns formwork factory, delivering durable, precision-engineered solutions for construction projects worldwide. With advanced manufacturing facilities and strict quality control, our formworks ensure perfect alignment, high load-bearing capacity, and long service life. We produce a wide range of column formwork systems suitable for various project scales, from small commercial builds to large-scale infrastructure developments. Our factory’s commitment to innovation, on-time delivery, and competitive pricing makes us a trusted partner for contractors and developers seeking reliable formwork solutions.

Frequently Asked Questions (FAQ)

What’s the distinction between formwork and shuttering in construction?

Although the terms formwork and shuttering are often used interchangeably on-site, there’s a subtle technical difference. Shuttering typically refers to the vertical molds or panels that hold wet concrete, whereas formwork is a broader term encompassing the complete temporary structure used to shape and support poured concrete until it sets.

When is it safe to strip column system formwork?

Column molds are generally removed after about 24 to 48 hours, depending on several variables. These include the type and strength of the concrete mix, the surrounding temperature, and overall humidity. Cooler weather or slower-curing mixes may require additional time before stripping.

What are the essential parts of a column formwork system?

formwork for concrete columns setup usually includes several key elements: vertical panels to shape the column, walers for horizontal reinforcement, strongbacks for vertical bracing, and tie rods to keep the system aligned and stable under pressure.

How can formwork failures be avoided?

To minimize the risk of collapse or failure, it’s vital to ensure the formwork is properly engineered, assembled using durable materials, and securely fastened. Monitoring curing times and removing the molds only when the concrete has gained sufficient strength is also essential.

What’s the difference between column and wall formwork?

concrete column formwork is designed for vertical, cylindrical columns, while wall formwork is used for large, flat surfaces like walls. The installation methods and materials may differ.