Circular Column Formwork Supplier | High Quality Systems

Introduction

BFS Industries stands as a premier circular column formwork supplier, offering world-class systems engineered for precision and durability in demanding concrete construction environments. The necessity of high-performance formwork cannot be overstated, particularly when casting architectural or structural columns that require perfectly smooth, circular geometries. Our circular column formwork systems are designed not just to contain the concrete, but to actively shape it with high accuracy and minimal surface imperfections, significantly reducing post-pour finishing costs. We understand that contractors and engineers demand reliability, speed, and safety, which is why our modular systems for circular formwork columns provide a superior solution compared to traditional, often wasteful, site-built alternatives, guaranteeing optimal results for every vertical pour.

As a trusted partner in large-scale projects, BFS Industries delivers innovative solutions for forming flawless vertical structures, cementing our reputation as a leader in circular concrete column formwork. The construction industry continually seeks methods to enhance both structural integrity and project efficiency, and our engineered formwork addresses both these needs simultaneously. Our product line encompasses various materials and connection methods, ensuring a perfect fit for any project scale, whether you are building a high-rise commercial center or essential public infrastructure. By choosing BFS Industries, construction professionals secure a system that promises maximum reusability, rapid assembly, and the structural integrity necessary for achieving exceptional quality in every circular column formwork application.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

Circular Column Products

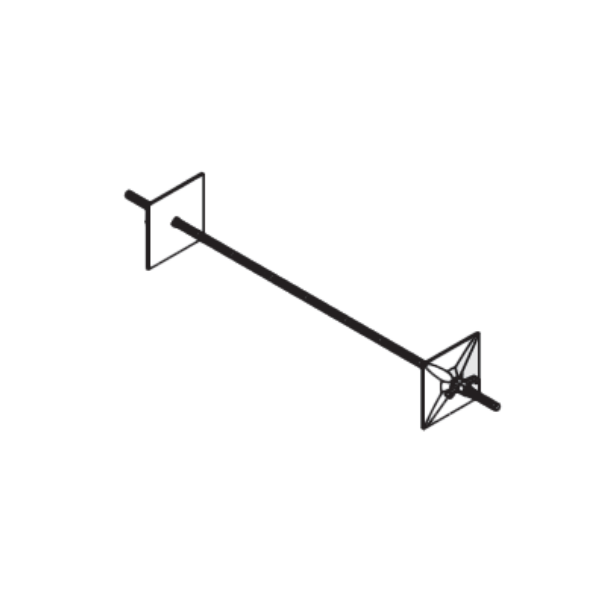

Circular Column Tierod, NUT, Plate

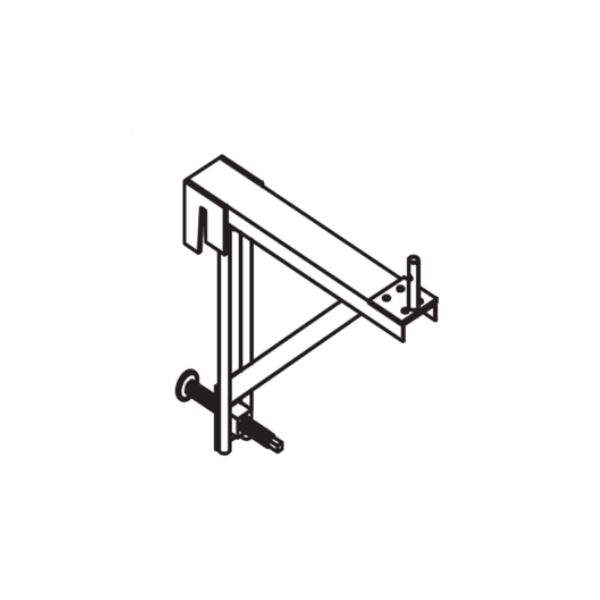

Climbing Circular Column Bracket accessory Pouring Platform

Climbing Circular Column Inclined Push/ Pull Prop

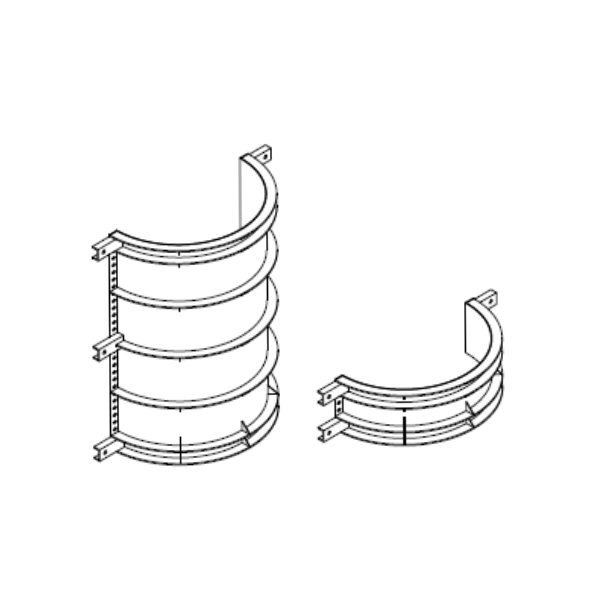

Normal Circular Column Panel

about Our Circular Column Formwork Products

Our circular column formwork systems are the culmination of decades of engineering excellence, focused on delivering modularity, strength, and ease of use to the job site. The core of our offering is a robust, modular design that allows for fast connection and disconnection, dramatically cutting down labor time during assembly and striking. This advanced formwork is capable of handling the intense hydrostatic pressures exerted by fresh concrete, ensuring zero deformation and guaranteeing a precise round column formwork every single time. Furthermore, the high-grade surfaces of our forms are engineered for longevity, allowing for hundreds of reuse cycles, which provides a profound economic advantage over the project lifecycle and solidifies our position as a leading circular column formwork manufacturer.

BFS Industries provides a comprehensive range of components necessary to construct, align, and pour any circular concrete formwork, including specialized accessories for high-rise or climbing applications. We specifically utilize heavy-duty steel circular column formwork in many of our designs, chosen for its unparalleled strength, minimal deflection, and ability to maintain tight tolerances across numerous pours. Our commitment to quality control ensures that every component, from the largest panel to the smallest connection piece, functions perfectly as part of a cohesive system, offering contractors and engineers the confidence that their circular column formwork setup will perform flawlessly under pressure and deliver the specified architectural finish.

Circular Column Tierod, NUT, and Plate

The securing mechanisms are absolutely crucial to the performance of any formwork system, and our circular column shuttering utilizes specially designed tierods, nuts, and plates to manage concrete pressures efficiently. These components provide the necessary clamping force to lock opposing panel segments together, preventing joint leakage and potential blowouts, which are common failure points in lesser formwork. Our tierod system is engineered for simple, high-speed installation and removal, allowing workers to quickly secure and release the circular column formwork while maintaining the high safety standards expected on professional construction sites, ensuring a reliable barrier against concrete stress.

The robust design of the NUT and Plate assembly works in conjunction with the tierods to evenly distribute the intense stress exerted by the fluid concrete mass across the entire circumference of the round column formwork. This meticulous engineering prevents localized stress points that could lead to panel separation or deformation, which is vital for maintaining the column’s perfect circular cross-section. Professionals looking for reliable formwork for circular concrete columns appreciate the ease with which these locking accessories can be inspected and verified for correct tension, providing an extra layer of assurance that the formwork will maintain its structural integrity throughout the pouring and curing process, resulting in a smooth, high-quality finish.

Climbing Circular Column Bracket and Pouring Platform

For high-rise structures, the Climbing Circular Column Bracket is an indispensable element, transforming the standard circular column formwork into an integrated, self-sufficient vertical pouring system. This bracket securely attaches to the previously poured lift, providing a stable, cantilevered working platform for the next pour, eliminating the need for complex external scaffolding systems. The climbing capability significantly accelerates cycle times, as the formwork and platform can be safely raised to the next level in a systematic and organized manner, optimizing productivity and ensuring that the work progresses rapidly up the structure.

Integrated with the climbing bracket is a spacious and secure pouring platform, which dramatically improves worker safety and operational efficiency during the placement of concrete into the circular concrete column formwork. This stable platform provides easy access for placing concrete, managing vibrators, and inspecting the rebar and form alignment before and during the pour. This comprehensive design approach not only provides the structure for the next lift of circular column formwork but also creates a regulated and safe environment for all associated concrete placing and quality control activities, which is non-negotiable for large Concrete Column Formwork projects.

Climbing Circular Column Inclined Push/Pull Prop

The proper vertical alignment of tall columns is a key challenge in construction, and the Climbing Circular Column Inclined Push/Pull Prop is designed to meet this challenge with precision and strength. These adjustable props attach to the formwork and the lower concrete lift, allowing site personnel to make fine, incremental adjustments to ensure the round column formwork is perfectly plumb before concrete placement begins. Maintaining precise verticality is critical for structural stability and for ensuring that the loads are correctly transferred through the column’s axis, making these robust components essential for vertical tolerance compliance on complex projects.

The inclined geometry of the push/pull prop provides stability in both compression and tension, which is necessary to counteract any external forces, such as wind loads or accidental bumps, that might shift the circular column shuttering during the critical setup and pouring phases. Constructed from heavy-gauge, durable materials, these props are designed for continuous reusability and can sustain extreme loads, which speaks to the technical superiority offered by BFS Industries as a key circular column formwork supplier. They are indispensable tools for achieving the high standards of alignment required for modern, load-bearing circular formwork columns in multi-story construction.

Normal Circular Column Panel

The Normal Circular Column Panel forms the primary shell of the formwork system, characterized by its durable construction and meticulous attention to surface finish quality. Each panel is engineered to tight radius tolerances, ensuring that when two or more segments are joined, they form a perfect, seamless circular cross-section, which is vital for both the structural integrity and the aesthetic appeal of the final column. These panels are modular and interchangeable, allowing the same inventory to be rapidly configured to cast columns of varying diameters simply by changing the combination of segments, increasing site flexibility and reducing overall equipment holding costs for any circular column formwork manufacturer.

The superior surface of our steel circular column formwork panels is treated to prevent concrete adhesion, which not only facilitates easy stripping but also results in an exceptionally smooth, uniform, and void-free concrete surface finish. This reduced porosity minimizes the need for extensive grinding or plastering, offering significant labor and time savings on site. The efficiency and quality delivered by the BFS Normal Circular Column Panel makes it the preferred choice for contractors aiming for rapid cycle times and demanding a high-quality, architecturally exposed finish on their formwork for circular concrete columns, reflecting our dedication to excellence.

What Is a Circular Column and Where Is It Used?

A circular column is a reinforced concrete structural member characterized by its perfectly round cross-section, serving primarily to transfer compressive loads from slabs, beams, or roofs down to the foundations. Structurally, the circular profile offers enhanced resistance to forces from any direction, especially torsional and seismic loads, due to the continuous nature of its geometry and superior confinement of the internal reinforcement cage. This inherent structural efficiency, combined with its unique aesthetic appeal, makes the circular column a popular and technically advantageous choice in a wide array of modern construction projects that require robust and visually appealing vertical support. The essential requirement for creating these structures is, of course, a reliable and precise circular column formwork system to mold the fluid concrete into its perfect shape.

Circular columns are ubiquitously deployed across many sectors of the built environment, showcasing their versatility and functional elegance. They are common in underground parking garages, where the round shape can minimize visual obstruction and facilitate easier vehicle movement compared to sharp-cornered square columns. Furthermore, they feature prominently in public spaces such as airport terminals, convention centers, and lobbies, where their smooth geometry contributes to an open, refined architectural aesthetic. In heavy engineering and infrastructure, such as elevated highway piers, bridge supports, and massive retaining structures, the high-performance attributes of the circular column make it the design of choice, which in turn necessitates robust and high-quality Concrete Column Formwork.

Structural and Aesthetic Roles of Circular Column Formwork

The role of circular column formwork is dual: it must simultaneously manage the rigorous structural demands of concrete placement and achieve the exacting aesthetic finish required by architects. Structurally, the formwork must be rigid enough to prevent bulging or shifting under the massive hydrostatic pressure of the concrete, ensuring a precise diameter that guarantees the designed load-bearing capacity and proper confinement for the rebar. This high level of dimensional accuracy is fundamental to the structural performance of the column, which relies on a uniform cross-section to distribute load effectively and prevent localized stress concentrations, making the selection of reliable circular column formwork a key project decision.

Aesthetically, the circular shape is often chosen to soften harsh structural lines and introduce a sense of flow and modernity into a building’s design, demanding a flawlessly smooth and continuous surface finish. The quality of the circular concrete formwork material directly translates to the quality of the exposed concrete surface; a high-quality internal face means a beautiful, uniform texture free of seams, tie-holes, or blemishes. BFS Industries excels in providing circular formwork columns that meet these architectural demands, enabling designers to realize their vision of smooth, elegant vertical elements without incurring excessive post-treatment costs to correct surface flaws left by inferior, non-specialized formwork systems.

Materials and Formwork Systems for Circular Columns

A variety of materials are used in the construction of circular column formwork, each offering distinct benefits in terms of cost, finish, and reusability, but high-quality steel circular column formwork often provides the best balance of longevity and precision. Steel systems, like those manufactured by BFS Industries, offer exceptional durability and can be reused hundreds of times, making them the most cost-effective option for projects with repetitive column pours. The rigidity of the steel guarantees a consistent diameter and roundness over its long lifespan, delivering a high-quality finish and requiring minimal maintenance when properly cared for between uses on site.

The sophistication of circular formwork columns is defined by the system’s ability to adapt to varying project specifications, including different heights and diameters. Our formwork systems are designed for modularity, featuring segment sizes that can be combined to achieve a wide range of column diameters, which greatly simplifies inventory management for the contractor. Furthermore, for forming specialized round column formwork in complex configurations, such as tapering columns or those with integrated capital sections, BFS Industries provides custom engineered solutions, ensuring that every unique project requirement is met with a specialized, high-performance, and site-ready circular column formwork solution.

Advantages of Using Circular Concrete Column Formwork

The deployment of purpose-built circular concrete column formwork systems offers a host of significant advantages over traditional, ad-hoc methods, leading directly to reduced project timelines and lower overall costs. The pre-engineered nature of these systems ensures that assembly is straightforward, requiring less skilled labor and significantly less time than constructing a custom circular form on site, accelerating the project schedule considerably. The speed of both assembly and the subsequent striking process are key factors in minimizing cycle times between concrete pours, which in turn allows for faster completion of the structural frame, providing a distinct competitive edge to the construction firm utilizing efficient concrete slab formwork systems and complementary column systems from BFS.

Beyond speed, the quality and reusability of professional circular column formwork systems provide a powerful economic incentive for construction companies. The high-grade surfaces and robust connections of our systems mean that the resulting concrete columns require minimal, if any, remedial work, saving on labor and materials post-pour. Moreover, the inherent durability of our steel formwork ensures hundreds of reuse cycles, amortizing the initial investment over multiple projects. This high reusability factor drastically reduces the material wastage that is typical with single-use systems, aligning project execution with sustainable practices while simultaneously lowering the per-use cost of the circular column formwork.

Strength, Load Distribution, and Earthquake Resistance

From a pure structural mechanics perspective, circular concrete columns are inherently efficient, and this efficiency is maximized when poured using precise circular column shuttering. The round cross-section provides optimal distribution of compressive stress without the stress concentration points that occur at the corners of square columns, leading to superior axial load capacity for a given cross-sectional area. The continuous perimeter of a circular column is also superior in providing confinement to the core concrete and the longitudinal reinforcement, particularly under the extreme forces encountered during seismic events.

This superior confinement afforded by the circular concrete column formwork is critical because it enhances the ductility and energy absorption capacity of the column, which are essential properties for earthquake-resistant design. The precise dimensional accuracy delivered by BFS Industries’ round column formwork ensures that the rebar cage is perfectly centered and confined, allowing the concrete to perform optimally under lateral forces. Therefore, choosing a high-quality circular column formwork manufacturer like BFS Industries is not just a decision about aesthetics or efficiency; it is a foundational choice for structural robustness, longevity, and enhanced life safety in seismically active regions.

Aesthetic Value in Modern Architecture

The seamless curve and smooth finish produced by high-quality circular formwork columns contribute a significant aesthetic value that is highly sought after in contemporary architectural design. Circular columns offer a visual softness and elegance that contrasts beautifully with the linear forms of walls and beams, often serving as defining architectural elements in public atriums, lobbies, and exterior facades. The absence of sharp corners makes the structures feel less imposing, promoting a sense of openness and accessibility within a modern, refined space, which is often a critical element of the design brief for high-end commercial projects.

Achieving this signature aesthetic requires formwork with extremely tight tolerances and a perfectly non-porous surface, which is exactly what our circular column formwork provides. Any imperfections in the formwork, such as visible seams or bulging joints, would immediately compromise the intended visual effect, necessitating costly and time-consuming patching. By utilizing the best formwork for circular concrete columns from BFS Industries, construction teams can guarantee a consistent, flawless, fair-faced concrete finish that is ready to be showcased immediately upon stripping, eliminating subsequent finishing processes and delivering the clean, elegant aesthetic that architects demand.

Applications in Construction Projects

The robust versatility of circular column formwork allows it to be efficiently employed across virtually every sector of the construction industry, from residential developments to the largest governmental infrastructure initiatives. Its adaptability to various heights and diameters means that a single system can be utilized for both internal structural supports in a parking deck and as visually exposed elements in a high-end retail facility. This wide applicability is a testament to the sophisticated engineering of modern circular column formwork manufacturer systems, which are designed to be rapidly deployed, reconfigured, and reused, making them an invaluable asset for contractors managing diverse project portfolios and demanding deadlines.

BFS Industries takes pride in supplying circular column formwork systems that are robust enough to handle the immense scale and technical complexity of large-scale construction, while remaining efficient enough for smaller commercial and industrial applications. Whether the requirement is for dozens of identical columns poured in rapid succession or a few uniquely sized structural elements, our modular circular formwork columns provide a tailored yet standardized solution. This comprehensive support across different construction scales and complexities is further complemented by our full range of solutions, including high-performance concrete wall formwork systems for completing the entire structural envelope with BFS quality.

Residential, Commercial, and Industrial Projects

In the commercial and industrial sectors, the demand for high-strength, durable columns is paramount, and circular column formwork from BFS Industries is a key enabler for rapid structural erection. Large-scale industrial warehouses and distribution centers utilize circular columns for their excellent load-bearing capacity and resilience, offering maximized floor space efficiency. In commercial high-rises, the rapid cycle time associated with our engineered circular concrete formwork is crucial for meeting aggressive deadlines, ensuring that successive floors are ready for follow-on trades as quickly as possible, thus optimizing the entire construction workflow and project profitability.

For multi-family residential construction and large parking structures, the superior finish and structural integrity provided by reliable round column formwork is consistently preferred. Parking structures, in particular, benefit from the continuous surface of the circular column, which minimizes damage from vehicle contact compared to sharp corners. Furthermore, in all these environments, the system’s reusability means the initial investment in circular column formwork quickly yields returns through repeated use across multiple phases or projects, proving that quality formwork is an asset that appreciates in value due to its exceptional performance and longevity on the job site.

Infrastructure Projects: Bridges, Pillars, and More

Infrastructure projects represent some of the most challenging environments for formwork, requiring systems that can handle extreme heights, massive concrete volumes, and harsh environmental conditions, making robust steel circular column formwork essential. Bridge piers and highway support pillars often feature large-diameter circular cross-sections to maximize stability and resistance to lateral forces like wind and water currents. Our heavy-duty circular column formwork is specifically designed to manage the immense hydrostatic pressure generated by pours that can extend to significant heights, guaranteeing that the final pillar maintains its perfect geometry and structural capacity.

BFS Industries supplies specialized climbing and customized circular column formwork systems that meet the unique demands of forming massive infrastructure elements like overpass supports, viaduct pillars, and utility structures. These systems integrate advanced safety features and high-capacity bracing to ensure worker security and structural stability during the pour of often complex and voluminous concrete lifts. The ability of our formwork for circular concrete columns to consistently deliver a high-quality surface finish is also beneficial for infrastructure, as a smoother, less porous concrete surface enhances the durability and resistance of the structure to long-term exposure to weather and environmental degradation.

How to Form a Circular Column: Step-by-Step Guide

The process of forming a concrete column using high-quality circular column formwork follows a structured and highly efficient methodology, beginning long before the first piece of formwork is assembled on the site. Initial steps involve meticulous preparation, including establishing the exact location and verticality of the column base and ensuring that the foundation is clean and level to receive the formwork. Once the base is prepared, the circular column formwork panels are staged, and the reinforcement cage is accurately placed and secured within the column footprint, ready for the formwork enclosure to be constructed around it, setting the stage for a precise concrete pour.

The subsequent steps focus on assembly, alignment, and final readiness, where the engineered simplicity of the round column formwork system truly shines, accelerating the cycle time dramatically. The modular segments are quickly secured around the rebar cage using the dedicated tierod and clamping mechanisms, and the verticality is verified using the push/pull props to ensure the column is perfectly plumb. Before pouring, a final inspection is mandatory to confirm all connections are secure, all joints are sealed, and all safety platforms are in place. This systematic approach, leveraging the reliability of BFS circular column formwork, ensures that the concrete pour will be successful, yielding a structurally sound and aesthetically superior column.

Formwork Setup and Reinforcement Placement

The initial phase of circular column formwork setup involves carefully setting the first segment of the form on the pre-marked base, which acts as the reference point for the column’s final position and diameter. Following this, the pre-fabricated reinforcement cage is lifted and lowered into the formwork area, where it must be accurately supported and positioned using spacers to ensure the required concrete cover is maintained uniformly around the entire circumference. This uniform cover is vital for protecting the steel from corrosion and ensuring the column’s fire rating, emphasizing the need for precise placement facilitated by the clear access provided during the initial circular column formwork setup.

Once the reinforcement is in place, the remaining circular column shuttering panels are brought in and rapidly assembled around the cage, using the proprietary connection hardware to lock them tightly together. Attention to detail at this stage is crucial, particularly at the joints, where proper sealing prevents slurry leakage which can lead to unsightly surface blemishes or a structurally compromised column. The entire assembly must then be braced using the inclined push/pull props, allowing the site team to adjust the form to achieve perfect vertical alignment, a non-negotiable step before the concrete pouring phase can commence on any complex formwork for circular concrete columns project.

Concrete Pouring, Compaction, and Stripping

The concrete pouring stage requires careful execution and monitoring to ensure a high-quality, dense final product that is free of voids or internal flaws. Concrete must be placed in controlled layers, with each layer systematically compacted using mechanical vibrators to fully eliminate trapped air and achieve maximum density. During this process, personnel must continuously monitor the circular concrete formwork for any signs of movement or leakage, as the dynamic hydrostatic pressure increases rapidly with the column height, requiring the robust design of the BFS system to withstand the immense forces.

After the concrete has reached the required curing strength, the final and equally important stage is the stripping of the round column formwork, which must be conducted carefully to avoid damaging the fresh concrete surface. The modular nature of the BFS system, including easily removable tierods and clamps, facilitates a fast and clean stripping operation, minimizing labor time and protecting the valuable formwork components for immediate reuse. This rapid demounting of the circular column formwork is a primary factor in accelerating overall project schedules, allowing subsequent construction activities to begin quickly while maintaining the integrity and reusability of the forming system.

Common Challenges and Solutions

Working with vertical concrete structures inherently presents a number of unique technical challenges, and forming perfectly round columns with circular column formwork is no exception, requiring specialized equipment and expertise. Common issues on site include maintaining absolute verticality over tall pours, managing the extreme hydrostatic pressure of fluid concrete, and preventing slurry leakage at panel joints which leads to surface imperfections. Traditional or low-quality formwork often exacerbates these problems, leading to significant delays and expensive remedial work, but BFS Industries’ engineered systems are specifically designed to anticipate and successfully mitigate these typical site difficulties, providing confidence to construction professionals.

The solution to these pervasive site challenges lies in the precision manufacturing and robust connection technology embedded in every piece of our circular column formwork. Our panels are built with extremely tight tolerances to ensure flawless joint alignment, and our heavy-duty tierod systems are rated to handle pressures far exceeding standard industry requirements, virtually eliminating the risk of formwork failure or bulging. Furthermore, the integrated alignment tools and climbing systems ensure that even the tallest columns can be erected and maintained at perfect plumb with simple, mechanical adjustments, providing a reliable and superior alternative to struggling with inferior, makeshift solutions on site.

Alignment, Support, and Form Pressure

Achieving and maintaining perfect vertical alignment is arguably the most critical and challenging aspect of circular column formwork erection, especially for structures exceeding one story in height. Any deviation from plumb can compromise the structural integrity of the column and create alignment problems for connecting beams and Concrete Construction elements on upper floors. Our solutions incorporate the Inclined Push/Pull Props, which are adjustable down to the millimeter, allowing site teams to quickly correct for minor shifts caused by accidental impacts or ground movement, thereby guaranteeing that the column maintains its design-specified vertical axis throughout the pouring and curing process.

The tremendous hydrostatic pressure exerted by newly poured concrete necessitates a formwork system with exceptional lateral strength, especially when using high-slump mixes in deep pours. BFS formwork for circular concrete columns features strategically placed reinforcement ribs and heavy-duty, high-tensile connection components designed to absorb and distribute this pressure uniformly across the entire form surface. This superior design capability ensures that the circular column formwork will not deform, bulge, or fail catastrophically under load, which is essential for both worker safety and the achievement of the column’s intended final geometry and structural performance.

Avoiding Honeycombing and Ensuring a Smooth Finish

Honeycombing, a structural defect characterized by voids and rock pockets in the concrete, is typically caused by insufficient vibration, improper concrete mix, or slurry leakage from the circular column shuttering, and it must be actively avoided. To mitigate this risk, BFS circular concrete formwork is engineered with exceptionally smooth, non-porous contact surfaces that minimize friction and promote the smooth flow of concrete during placement and compaction. The sealed, high-tolerance joints prevent the cement slurry from leaking out, which is a common cause of rock pockets and honeycombing near the form face, ensuring a dense and structurally sound surface layer.

Ensuring an architecturally smooth, fair-faced finish is a primary objective for many projects utilizing round column formwork, and our high-quality materials are designed to deliver this finish consistently. The non-stick properties of the form face ensure that the concrete releases cleanly upon stripping, leaving a flawless surface that often requires no further cosmetic treatment, saving substantial time and cost. By providing superior steel circular column formwork that is both structurally sound and aesthetically refined, BFS Industries helps contractors meet the highest standards of architectural finish while reducing the total lifecycle cost of the column.

Circular Column vs Square Column

The decision between a circular and a square column is often dictated by a balance of structural efficiency, architectural intent, and integration with the surrounding structural system. Structurally, the circular column formwork yields a profile that provides superior confinement to the core concrete, making it exceptionally resilient under seismic loads and biaxial bending, which is beneficial in high-risk areas. Conversely, a square column simplifies connections to orthogonal elements like walls and beams and fits neatly into corners, offering better spatial integration within rectangular room layouts, though it requires a different approach to circular column formwork supplier considerations if the design is later altered.

From a structural efficiency standpoint, for a given cross-sectional area, the circular shape generally requires less longitudinal reinforcement and less concrete to carry the same axial load compared to a square column, primarily due to the superior lateral confinement provided by the circular stirrups. However, square columns can sometimes be more advantageous in maximizing usable space, as they can be completely concealed within a wall, whereas a protruding round column formwork always remains an exposed element. The choice ultimately depends on balancing the structural engineering benefits with the aesthetic and space-planning objectives of the specific project, which is why BFS Industries offers both high-performance circular column formwork and square column systems.

Structural Performance and Space Utilization

The superior structural performance of a circular column stems largely from the continuous confining pressure exerted by the helical or circular ties on the core concrete, which significantly enhances the column’s ductility and ultimate load capacity. This enhanced confinement, which is perfectly formed by our high-precision circular formwork columns, means the column can absorb more energy before failure, making it the preferred choice for major infrastructure and high-rise structures in seismic zones. The continuous curve of the circular column formwork also distributes stresses uniformly, whereas square columns can experience stress concentrations at the sharp, less-confined corners under specific loading conditions.

Regarding space utilization, square columns possess an obvious advantage in structures with orthogonal layouts, as they can be readily integrated into dividing walls or property lines, maximizing usable floor area. However, while a round column formwork may protrude, its continuous, corner-less surface can actually facilitate smoother traffic flow in areas like parking garages, minimizing the risk of vehicle damage. Therefore, when evaluating circular column formwork versus square formwork for a project, engineers must weigh the superior seismic and structural efficiency of the round shape against the spatial economy and ease of architectural integration offered by the square profile in a given Concrete Construction environment.

Cost, Formwork, and Labor Considerations

The initial formwork investment is often higher for high-quality circular column formwork systems than for standard square column forms, due to the complex curvature and precision manufacturing required to create a flawless curve. However, this initial cost is quickly offset by the system’s exceptional reusability, superior surface finish, and significantly reduced labor costs for striking and finishing work, making it a sound long-term economic choice. The pre-engineered, modular nature of BFS circular concrete formwork means that assembly is often faster and less prone to on-site errors than customized square forms, which often require extensive bracing and corner treatment.

When factoring in labor costs, the reduced surface area that requires finishing on a circular column, compared to the four faces of a square column, can lead to measurable savings in plastering or grinding time. Furthermore, the specialized clamping and tying systems used in modern circular column formwork are designed for rapid dismantling, accelerating the overall pour cycle time compared to traditional systems. BFS Industries provides detailed technical consultation to help contractors perform a comprehensive cost-benefit analysis, demonstrating how the efficiency, quality, and durability of our steel circular column formwork provide a superior return on investment over the lifecycle of a large-scale project.

Why Choose BFS Industries for Circular Column Formwork?

Choosing BFS Industries as your circular column formwork supplier means partnering with a global leader committed to delivering systems that define project quality and efficiency. Our reputation is built on an unwavering commitment to engineering excellence, utilizing only the highest-grade materials to construct robust, high-tolerance circular column formwork that withstands the most challenging site conditions. We don’t just supply equipment; we provide fully integrated formwork solutions backed by comprehensive technical support and decades of experience in formwork for circular concrete columns across diverse international markets, offering peace of mind to project managers and construction engineers.

BFS Industries stands out as a specialized circular column formwork manufacturer by offering bespoke services alongside our standardized product lines, ensuring that every unique project dimension and structural requirement can be met. From providing custom-diameter round column formwork segments to engineering specialized climbing systems for unique structural designs, our flexibility is unmatched in the industry. Our commitment to client success extends far beyond the sale, encompassing site training, logistics planning, and ongoing technical consultation, a dedication that underscores why so many global firms entrust their most complex vertical construction challenges to BFS Industries.

Conclusion

The successful execution of modern structural projects relies on high-performance vertical forming systems, and the BFS Industries circular column formwork represents the pinnacle of efficiency, durability, and structural precision. Our comprehensive, modular systems for circular column formwork ensure that contractors can rapidly achieve flawless, aesthetically superior circular columns while significantly reducing overall labor and material costs associated with post-pour finishing. By minimizing cycle times and maximizing reusability, our specialized circular column formwork supplier solutions directly contribute to improved profitability and faster project completion, making them an indispensable asset for forward-thinking construction firms globally.

BFS Industries is dedicated to being more than just a circular column formwork manufacturer; we are a strategic partner providing technical consultation and globally proven reliability for every phase of your vertical concrete pour. Our robust, engineered systems—from the core panels to the specialized climbing props—are designed for demanding environments, ensuring safety and quality from the foundation to the final lift. We invite construction professionals, engineers, and project managers seeking the highest quality circular concrete formwork to elevate their next project. Contact BFS Industries today for detailed pricing, technical consultation, or to discuss customized circular column formwork solutions that guarantee your project ranks among the best in class.

Frequently Asked Questions About Circular Columns in Concrete Construction

What is the typical lifespan and reusability of BFS circular column formwork?

The lifespan of BFS Industries’ circular column formwork is engineered for superior longevity, especially for our robust steel circular column formwork products. With proper maintenance, these systems are designed to withstand hundreds of reuse cycles, significantly lowering the formwork cost per pour and providing excellent return on investment across multiple projects. The high-strength materials and protective coatings ensure that the form face maintains its smooth, non-porous quality even after extensive use, consistently delivering the high-quality concrete finish that contractors and architects expect from premier circular formwork columns.

This high level of reusability is a key factor in project economy, dramatically reducing material consumption and waste compared to single-use or wood-based alternatives. Our engineering team provides detailed guidance on cleaning, handling, and maintenance procedures to maximize the lifespan of the circular column formwork, ensuring its structural integrity and surface quality remain optimal for years of service. Investing in BFS systems is therefore an investment in sustainable, long-term construction assets that enhance efficiency and quality throughout their operational life.

What diameter and height limitations apply to BFS circular column formwork?

BFS Industries provides one of the most versatile ranges of circular column formwork systems on the market, capable of handling column diameters ranging from small, non-structural sizes up to massive, several-meter-wide infrastructure piers. Our modular design allows for the precise combination of panel segments to achieve virtually any required diameter, ensuring that our clients are not limited by rigid, fixed-size formwork inventory. If a required diameter is not covered by our standard range, our in-house engineering team can quickly design and manufacture custom segments to meet the exact specifications of the most specialized projects.

Regarding height, our circular column formwork systems are designed to accommodate columns of virtually unlimited height, utilizing our advanced climbing and re-shuttering mechanisms for multi-lift pours. The strength of our forms is calculated to withstand the full hydrostatic pressure of a single, continuous pour up to standard floor heights, and our climbing systems efficiently manage the sequential pouring of extremely tall structures like bridge pylons. We always recommend engaging with our technical consultants to specify the precise system and component configuration, including bracing and alignment props, required for any column exceeding standard dimensions.

How can I ensure a smooth finish on a circular column?

To achieve a smooth finish, use high-quality formwork (e.g., steel or coated plastic), apply a release agent to prevent concrete sticking, ensure proper vibration during pouring to eliminate air pockets, and cure the concrete adequately to avoid cracks or surface defects.

What are the common challenges in forming circular columns?

Key challenges include maintaining proper alignment, supporting formwork against concrete pressure, and avoiding honeycombing. These can be addressed by using robust, adjustable formwork systems, precise leveling, and thorough compaction during pouring.

Are circular columns more expensive to construct than square columns?

While circular column formwork can be more costly due to its specialized nature, modular systems reduce long-term costs through reusability. Additionally, circular columns often require less material and can save on labor, potentially offsetting initial expenses compared to square columns.