Rectangular Column Formwork Systems

Introduction

Rectangular Column Formwork is a key system in modern concrete construction

, designed to shape accurate and durable vertical supports that carry loads efficiently from the superstructure to the foundation. This type of formwork ensures precise dimensions, smooth concrete surfaces, and superior structural integrity, making it indispensable in reinforced concrete column works.

Engineers and contractors prefer rectangular concrete column formwork because it offers high load capacity, easy assembly, and full compatibility with most architectural layouts. It’s the ideal choice for high-rise buildings, commercial centers, industrial facilities, and other heavy-duty projects where precision and reliability are crucial.

At BFS Industries, we manufacture advanced rectangular column formwork systems built for speed, strength, and sustainability. Our steel formwork designs minimize labor time, reduce material waste, and ensure consistent performance on every site — delivering long-term durability and cost efficiency trusted by builders worldwide.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

Rectangular Column Products

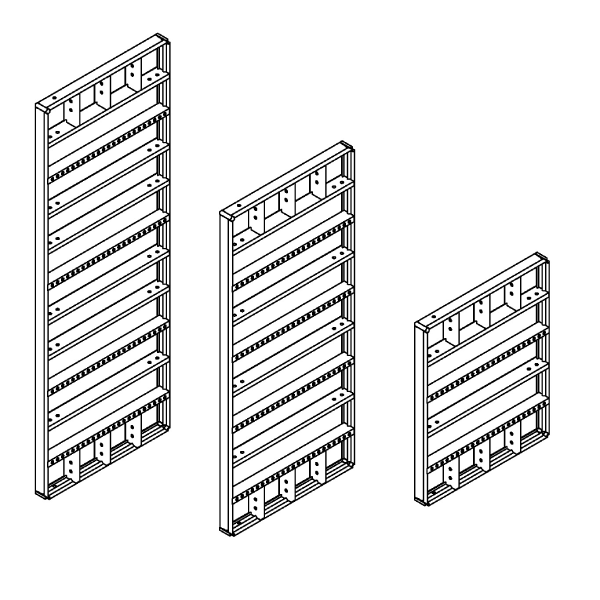

Column ZigFlex Panel

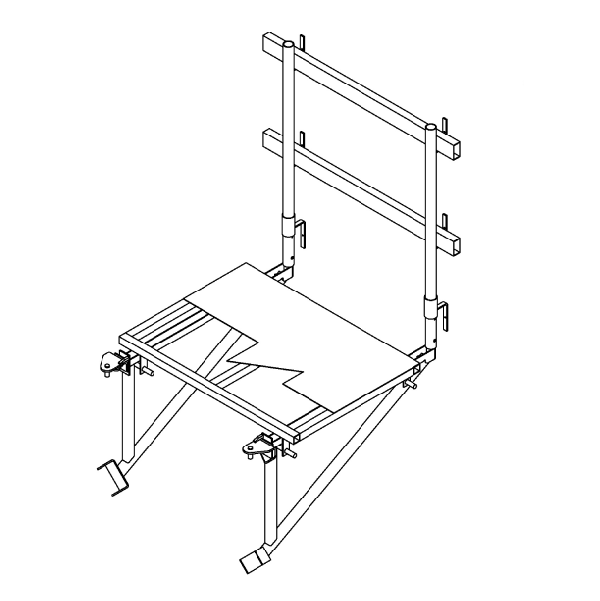

Column ZigFlex Pouring Platorm(shelter)

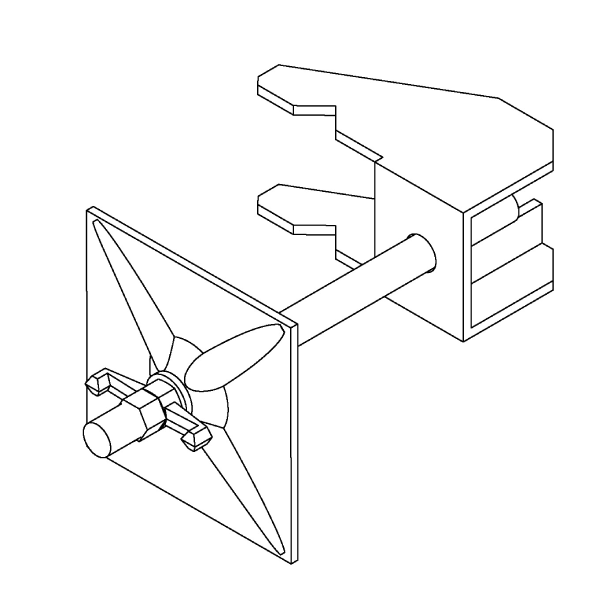

Column ZigFlex Push/Pull Double Prop

Column ZigFlex T-Lock

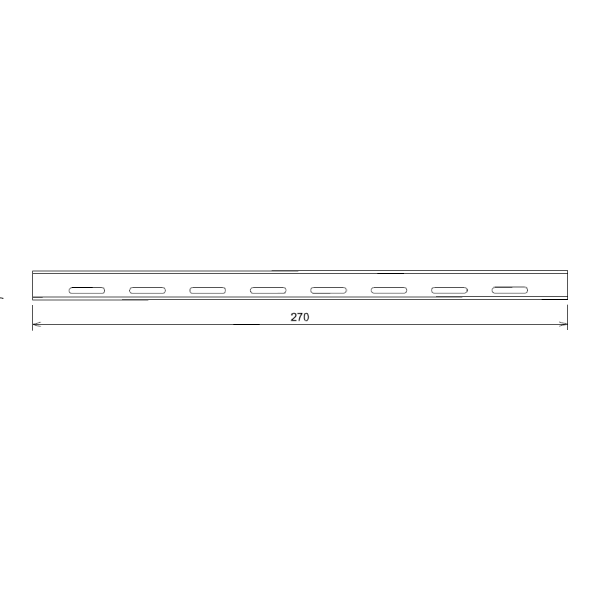

ZigFlex Chamfer strip

What Is a rectangular column formwork?

A rectangular column is a vital vertical structural element with a rectangular cross-section, most commonly built using reinforced concrete and supported by advanced rectangular column formwork during the construction phase. These columns are specifically engineered to carry compressive loads and, when required, to resist bending moments caused by lateral forces such as wind pressure or seismic activity.

In modern concrete construction, rectangular columns are everywhere—from residential apartments and office towers to large-scale industrial facilities and infrastructure projects like bridges and flyovers. Their shape provides excellent alignment with walls, beams, and modular formwork systems, making them the perfect choice for structures with rectangular or grid-based layouts.

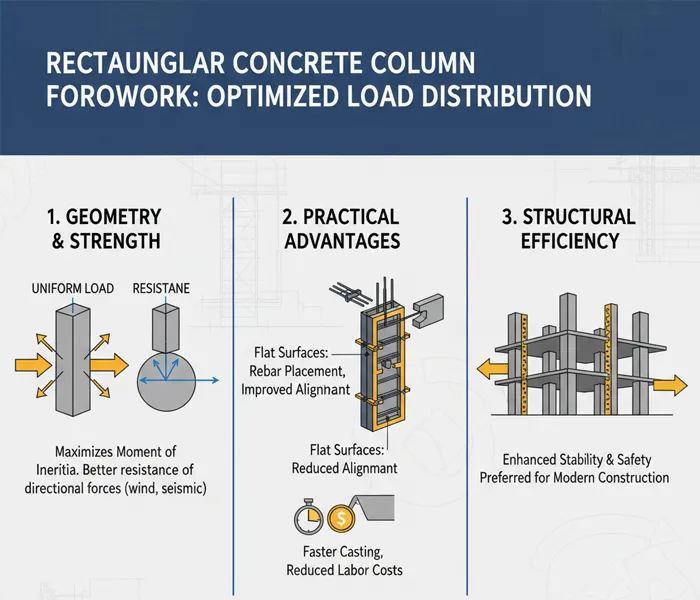

1. Rectangular Column Formwork in Load Distribution

The shape of a column is one of the most important factors influencing its performance, and rectangular Concrete Column Formwork plays a vital role in creating this geometry with precision. The rectangular cross-section provides unique advantages in load distribution compared to circular or square alternatives. Unlike circular columns, which spread loads uniformly in every direction, rectangular columns can be strategically oriented to maximize their moment of inertia in the direction of the primary bending moment.

This property makes them particularly effective in construction scenarios where external forces, such as wind loads, seismic forces, or directional stresses, act more strongly in one axis. By resisting these forces with greater efficiency, rectangular columns enhance both the stability and safety of reinforced concrete structures.

Another practical advantage lies in their flat surfaces, which simplify the placement of reinforcement bars (rebar) and improve alignment during shuttering. Additionally, the use of rectangular column formwork makes the casting process faster and more precise, ultimately reducing construction time and labor costs. For engineers, contractors, and builders, this combination of efficiency, strength, and cost-effectiveness makes rectangular columns a preferred choice for modern concrete construction.

2. Materials Used in Rectangular Column Formwork

The durability and performance of a rectangular column formwork system are strongly determined by the quality of materials and the efficiency of the formwork technology applied. In any concrete construction project, formwork serves as the temporary mold that shapes fresh concrete until it gains sufficient strength to stand independently. For rectangular columns, precision is critical: the formwork must deliver sharp corners, smooth surfaces, and exact dimensions to ensure reliable load-bearing capacity and an aesthetically appealing finish.

Different materials are commonly used in the construction of rectangular column formwork, each with unique benefits. Timber and plywood are often selected for small- to medium-scale projects due to their cost-effectiveness and ease of handling, though their reusability is limited. Steel formwork offers superior durability, dimensional accuracy, and excellent surface finishes, making it particularly valuable in repetitive and large-scale projects such as high-rise buildings. Plastic formwork systems provide another alternative, being lightweight, resistant to moisture, and easy to assemble and dismantle, which makes them ideal for projects where speed and efficiency are priorities.

At BFS Industries, we manufacture high-quality rectangular column formwork solutions that combine strength, durability, and reusability, helping contractors and engineers achieve precision, efficiency, and long-term structural reliability in every concrete project.

3. Types of Rectangular Column Formwork

In concrete construction, formwork—or column shuttering—is the temporary mold that shapes wet concrete until it hardens into a stable structure. For rectangular columns, several materials are commonly used to create effective and precise formwork. Steel formwork is renowned for its durability and strength, providing a smooth finish and withstanding high concrete pressures, making it particularly suitable for large-scale projects where reusable panels offer cost efficiency over multiple pours. On the other hand, plywood formwork is lightweight, affordable, and easy to handle, which makes it a practical choice for smaller projects or when budget constraints are a consideration, although it may require additional maintenance and is generally less durable than steel or aluminum. Aluminum formwork offers a balance between strength and lightness, is corrosion-resistant, and can be reused multiple times, making it ideal for projects that demand rapid assembly and dismantling.

Each type of formwork comes with its own advantages and trade-offs: steel delivers longevity and consistent finishes, plywood provides cost savings and ease of use, and aluminum combines durability with lightweight properties, offering flexibility in high-speed construction projects. Selecting the appropriate material for rectangular column formwork ensures efficiency, structural accuracy, and long-term performance in any reinforced concrete project.

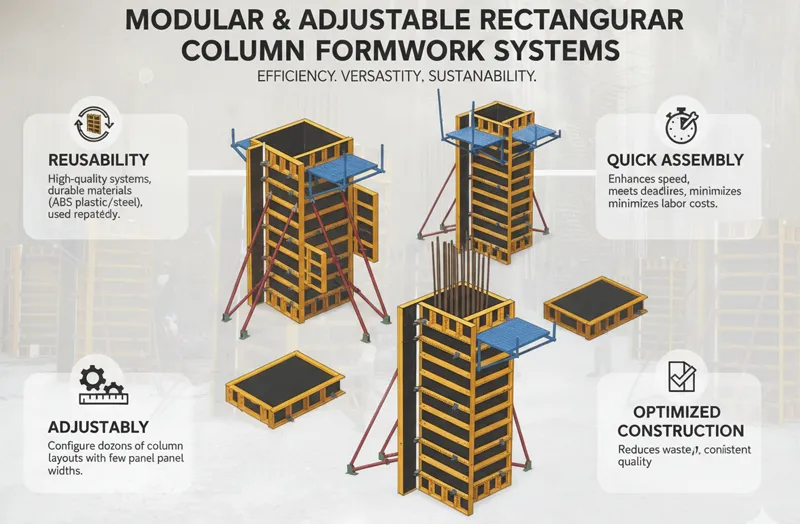

4. Modular and Adjustable Rectangular Column Formwork Systems

In modern construction, the use of Concrete Modular Formwork systems has become increasingly essential for efficiency and versatility. These systems utilize standardized panels that can be configured to create a wide range of rectangular column sizes, significantly reducing the need for custom-built formwork.

One of the primary advantages of modular Concrete Formwork is reusability; high-quality systems, often made from durable materials like ABS plastic or steel, can be used repeatedly across multiple projects, delivering both cost savings and sustainability benefits. Another key benefit is adjustability, as innovative systems allow contractors to configure dozens or even hundreds of column layouts using just a few panel widths, meeting diverse project requirements without compromising structural accuracy.

Additionally, the quick assembly and disassembly of these Concrete Modular Formwork systems enhance construction speed, enabling projects to adhere to tight deadlines while minimizing labor costs.

For builders, engineers, and contractors, employing modular rectangular column Concrete Formwork not only optimizes the construction of vertical concrete columns but also reduces material waste, improves site safety, and ensures consistent quality in every project. These advanced systems represent a modern approach to achieving precision, efficiency, and sustainability in reinforced concrete construction.

5. Reinforcement Rectangular Column Formwork

Reinforcement serves as the backbone of any rectangular column, providing the structural strength needed to withstand both compressive and tensile forces encountered during the life of a building. Proper design and placement of reinforcing steel (rebar) within the rectangular column formwork are critical for ensuring the column’s stability, durability, and load-bearing capacity. Engineers must carefully consider factors such as the column’s dimensions, load requirements, and expected environmental stresses, including wind, seismic forces, and other lateral loads. Integrating reinforcement correctly within high-quality formwork systems not only enhances the structural performance of the column but also ensures precise alignment, smooth concrete surfaces, and a long-lasting, aesthetically pleasing finish. At BFS Industries, our rectangular column formwork solutions are designed to accommodate optimal reinforcement placement, helping contractors achieve both safety and efficiency in every reinforced concrete project.

6. Reinforcement Layout in Rectangular Column Formwork

The reinforcement layout is a critical aspect of designing rectangular columns, directly influencing their structural strength and stability. In these columns, longitudinal steel bars are placed at the corners and, for larger columns, along the sides to resist compressive loads and bending moments. Surrounding these vertical bars, transverse ties encircle the longitudinal reinforcement, preventing buckling and confining the concrete to enhance its compressive strength. The shape of these ties is usually square or rectangular, and their spacing follows the applicable design codes to maintain safety and stability.

The reinforcement ratio, which refers to the amount of steel relative to the overall concrete area, is carefully managed to facilitate construction while ensuring strength and durability. Adequate concrete cover protects the steel from corrosion, fire, and other durability concerns. Proper placement of reinforcement within high-quality rectangular column formwork ensures not only structural reliability but also smooth, well-finished concrete surfaces, making the columns both safe and aesthetically pleasing. At BFS Industries, our formwork solutions are designed to support optimal reinforcement layouts, enabling contractors to achieve high-precision, efficient, and long-lasting reinforced concrete columns in every project.

7. Common Standards for Rectangular Column Formwork

Designing rectangular columns requires adherence to established industry standards, such as those provided by the American Concrete Institute and Eurocode, which offer detailed guidelines for reinforcement placement, load calculations, and safety considerations. These standards ensure that rectangular column formwork accommodates both structural integrity and building requirements. Columns can be fabricated in a wide range of dimensions and heights to suit different types of buildings, from small residential structures to large commercial or industrial facilities. Specialized projects may require larger or taller columns, and the formwork must be capable of supporting the concrete throughout the curing process while maintaining precise shape, alignment, and smooth surfaces. Following these common standards and selecting appropriately sized rectangular column formwork ensures both safety and efficiency in construction projects of any scale.

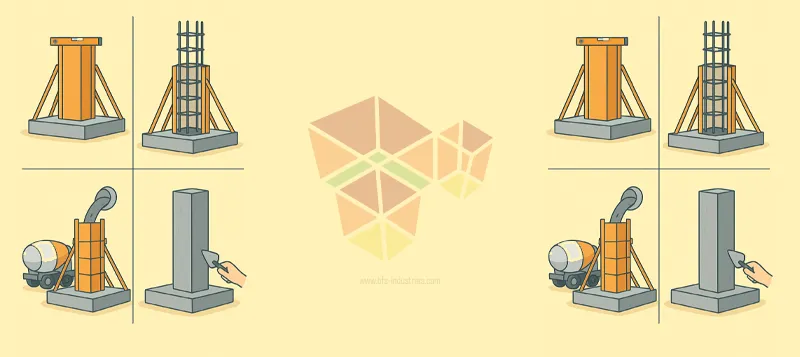

8.Step-by-Step Process of Rectangular Column Casting

Constructing a rectangular column demands careful planning, precision, and adherence to a systematic process to ensure both structural integrity and high-quality results. Using properly designed rectangular column formwork, contractors can achieve accurate dimensions, smooth surfaces, and secure reinforcement placement, which are essential for the column’s load-bearing capacity and durability. Each step, from setting up the formwork to placing concrete and finishing the surface, plays a critical role in achieving a strong and reliable reinforced concrete column. By following a structured casting process, construction teams can minimize errors, improve efficiency, and maintain consistent quality across all projects.

8.1. Formwork Setup and Alignment for Rectangular Columns

Proper setup and alignment of rectangular column formwork are crucial for achieving accurate and structurally sound columns. The process begins with careful planning of the column layout, marking the precise locations based on structural drawings to ensure correct placement within the building grid. Once the layout is defined, the formwork panels—whether plywood, steel, or aluminum—are assembled and carefully aligned. It is essential that the formwork is plumb, properly braced, and securely fixed to resist the pressure of fresh concrete during pouring. Additionally, applying form release agents helps ensure that the formwork can be removed cleanly without damaging the concrete surface. A stable base is also prepared to support the formwork, providing a solid foundation that maintains alignment and structural accuracy throughout the casting process.

8.2. Concrete Casting and Finishing for Rectangular Columns

After proper reinforcement placement within the rectangular column formwork, concrete is poured carefully to ensure structural integrity. The longitudinal bars and transverse ties must be correctly positioned, with adequate concrete cover to protect the steel and maintain durability. Concrete is poured from the bottom, using chutes or pumps, to prevent segregation and ensure uniform distribution within the formwork. During pouring, mechanical vibrators are used to eliminate air pockets and achieve proper compaction, resulting in a dense, strong, and uniform column.

Once the concrete has gained initial strength, curing is applied using wet coverings or curing compounds to maintain moisture and facilitate proper hydration, which enhances the long-term strength and durability of the column. After sufficient curing, the formwork is carefully stripped, ensuring that the concrete surface remains smooth and undamaged. When executed correctly, this systematic process produces robust, precise, and reliable rectangular columns suitable for a wide range of building applications.

9. Benefits of Rectangular Columns in Construction

Rectangular columns provide several advantages that make them a preferred choice in modern concrete construction. Their shape allows for efficient load distribution and seamless integration with walls and beams, optimizing structural performance. They are easy to construct using standardized rectangular column formwork, which ensures accuracy, smooth surfaces, and consistent quality. Additionally, rectangular columns are versatile, suitable for a wide range of building types, from residential and commercial structures to large industrial facilities. Their design also simplifies reinforcement placement and reduces construction complexity, making them both cost-effective and reliable for contractors and engineers alike.

9.1. Construction Ease and Stability of Rectangular Columns

The flat surfaces of rectangular columns simplify formwork setup, making construction faster and reducing labor and material costs compared to circular columns. Their shape allows engineers to align the column with the primary load direction, optimizing material usage while maintaining structural stability. Additionally, rectangular columns are robust and resistant to buckling, making them ideal for a wide range of building types, particularly low- to mid-rise structures. Using well-designed rectangular column formwork ensures accurate dimensions, proper reinforcement placement, and a smooth, high-quality finish, contributing to both construction efficiency and long-term durability.

9.2. Rectangular Columns with Beams and Walls

Rectangular columns naturally integrate with beams and walls thanks to their flat surfaces, making connections and load transfer more efficient. This inherent compatibility simplifies the design and construction of framed structures, ensuring a cohesive and stable structural system. Using high-quality rectangular column formwork allows for precise alignment, smooth surfaces, and accurate placement, enhancing both structural performance and construction efficiency.

10. Challenges and Solutions for Rectangular Columns

Although rectangular columns offer numerous benefits, certain challenges can emerge during construction. Issues such as improper formwork alignment, inaccurate reinforcement placement, and difficulties in achieving smooth concrete surfaces can affect structural performance and aesthetics. By using high-quality rectangular column formwork from reputable formwork column manufacturers, following standardized construction procedures, and implementing proper quality control measures, these challenges can be effectively managed, ensuring durable, precise, and reliable columns for any building project.

10.1. Form Pressure and Finish in Rectangular Columns

During construction, wet concrete exerts considerable pressure on rectangular column formwork, which can cause bulging or leakage and compromise the column’s shape and finish. Using high-strength formwork systems, such as steel or modular plastic panels, reinforced with proper bracing and sealed joints, helps prevent these issues. Regular inspection during pouring ensures the formwork remains stable.

Achieving a smooth surface finish can also be challenging, especially with plywood formwork, which may result in imperfections. Choosing steel or aluminum formwork, or using form liners with plywood, enhances surface quality. Applying release agents further ensures clean removal of the formwork, maintaining the precise and aesthetically pleasing appearance of the column.

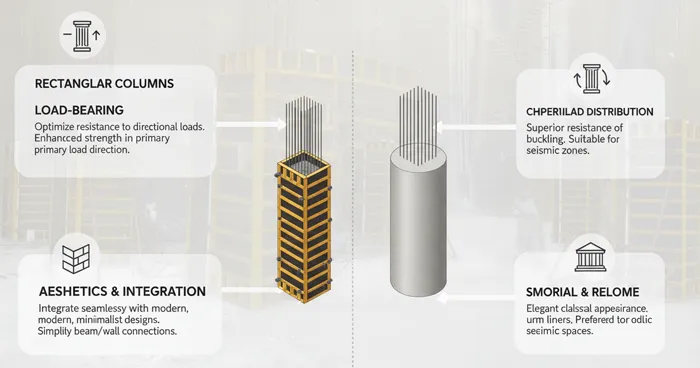

11. Rectangular vs Circular Columns: Key Differences

Understanding the differences between rectangular and circular columns is essential for selecting the most suitable type for a construction project. Rectangular columns offer flat surfaces that simplify formwork, reinforcement placement, and integration with beams and walls, while circular columns provide uniform load distribution in all directions. By consulting a reliable formwork for concrete columns manufacturer, project teams can ensure the selection and use of high-quality formwork systems. Considering these factors ensures optimal structural performance, construction efficiency, and material usage.

12. Differences in Load-Bearing and Aesthetics

Rectangular columns are designed to optimize resistance to directional loads, offering enhanced strength and stability in the primary load direction due to their shape. In contrast, circular columns distribute material uniformly, providing superior resistance to buckling and making them more suitable for seismic zones or structures with unpredictable load patterns. From an aesthetic perspective, rectangular columns integrate seamlessly with modern, minimalist architectural designs, while circular columns are often preferred for their elegant, classical appearance in open spaces or exposed structures. Choosing the right column type ensures both structural performance and visual harmony in any project.

13. Cost, Labor, and Formwork Considerations

| Aspect | Rectangular Columns | Circular Columns |

|---|---|---|

| Formwork Cost | Lower due to simpler, flat-sided forms | Higher due to complex, curved forms |

| Labor | Easier and faster to construct | More labor-intensive formwork setup |

| Material Efficiency | Efficient for directional loads | May require less material for same load |

| Reusability | Modular systems highly reusable | Reusable but less common |

Rectangular columns generally offer cost and labor savings, while circular columns may be more material-efficient in certain scenarios.

14. Conclusion: Why Rectangular Columns Remain a Standard in Modern Construction

Rectangular columns continue to be a cornerstone of concrete construction due to their practicality, cost-effectiveness, and structural versatility. Their flat surfaces simplify construction, formwork setup, and reinforcement placement, while their shape allows efficient handling of directional loads and seamless integration with beams and walls. Although circular columns offer advantages in uniform load distribution and seismic resistance, the simplicity, reliability, and efficiency of rectangular columns make them the preferred choice for residential, commercial, and industrial projects. Advancements in modular formwork systems and reinforcement techniques further enhance their performance, ensuring that rectangular columns remain essential in shaping modern, durable, and aesthetically pleasing structures.

Rectangular Columns in Concrete Construction

What is a rectangular column, and where is it used?

A rectangular column is a vertical structural element with a rectangular cross-section, made of reinforced concrete, designed to transfer compressive loads from floors, beams, or roofs to the foundation. It is widely used in residential, commercial, and industrial buildings, as well as infrastructure projects like bridges, due to its compatibility with rectangular building layouts.

What are the advantages of rectangular columns compared to circular columns?

Rectangular columns are easier and more cost-effective to construct due to their simpler, flat-sided formwork. They align well with beams and walls, making them ideal for grid-based designs. Additionally, they can be oriented to efficiently resist directional loads, such as wind or seismic forces, compared to circular columns, which offer uniform load distribution but require more complex formwork.

What types of formwork are best for rectangular columns?

Common formwork materials include steel, plywood, and aluminum. Steel formwork provides durability and a smooth finish, ideal for large projects. Plywood is cost-effective for smaller projects but less durable. Aluminum offers a balance of strength and lightweight properties. Modular formwork systems, such as reusable plastic or steel panels, are increasingly popular for their flexibility and efficiency.

How can a smooth surface finish be achieved for rectangular columns?

Achieving a smooth finish requires high-quality formwork, such as steel or aluminum, and the use of form release agents to ease stripping. Proper bracing prevents formwork bulging, and adequate vibration during concrete pouring eliminates air pockets. For plywood formwork, using form liners can enhance the surface quality.

What are the common challenges in constructing rectangular columns, and how can they be addressed?

Challenges include formwork pressure causing leaks or bulges and achieving a consistent surface finish. These can be addressed by using robust formwork materials (e.g., steel or modular systems), ensuring proper bracing and sealing of joints, and applying curing techniques to maintain concrete quality. Regular inspection during pouring also helps maintain structural integrity.