Concrete Formwork Systems Supplier: Engineered Solutions

Introduction

The foundation of any critical infrastructure or monumental high-rise project relies fundamentally on the precision, strength, and efficiency of its temporary molding structure—the concrete formwork systems. For projects that involve extreme hydrostatic pressure, complex geometries, or aggressive construction schedules, such as large-scale dams, deep tunnels, and high-rise cores, standard solutions are simply inadequate. This is where specialized engineering becomes paramount. bfs industries acts as a global, specialized supplier, providing high-performance, custom-engineered formwork solutions designed to manage the immense technical demands of heavy civil concrete construction, guaranteeing safety, accelerated cycle times, and superior surface quality for the world’s most challenging structures.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

concrete formwork systems Category

What Are Concrete Formwork Systems?

Concrete formwork systems represent the essential temporary structure used to contain and mold wet concrete until it hardens and achieves sufficient structural strength to be self-supporting. Far beyond simple wooden molds, modern formwork is a highly technical, engineered system comprised of specialized panels, support components, ties, and connection hardware, all meticulously designed to withstand the dynamic forces exerted by liquid concrete. The correct choice of a formwork system directly influences a project’s timeline, safety record, and overall budget, making the supplier selection a critical commercial decision.

The primary function of formwork is to safely transfer the substantial loads generated by fresh concrete—including static weight, hydrostatic pressure, and construction live loads—to the ground or to supporting structure. A successful formwork system must be robustly engineered to maintain its precise shape and dimensional tolerance throughout the pouring and curing process, ensuring the final structure is geometrically accurate. For large infrastructure projects, like bridges or dams, the system’s reusability and efficiency in cycling from one pour location to the next are key determinants of project profitability and speed.

From Conventional Shuttering to Engineered System Formwork

Historically, concrete shuttering systems relied heavily on labor-intensive, site-built timber assemblies, which, while flexible, offered low reusability and inconsistent dimensional accuracy. The modern evolution has shifted overwhelmingly toward industrialized system formwork, utilizing prefabricated steel formwork systems, aluminum, or composite panels that are meticulously manufactured to exact specifications. These engineered systems, such as Concrete Modular Formwork, significantly reduce on-site labor time, improve safety through integrated access platforms, and ensure high levels of repetition, essential for large, standardized structures.

The transition from conventional to proprietary formwork allows contractors to achieve predictable cycle times, a necessity in competitive construction markets. System formwork is designed for rapid assembly and stripping, minimizing delays between concrete pours. Furthermore, the inherent durability of steel formwork systems and high-quality composite facing material provides hundreds of reuse cycles, amortizing the initial investment over the project’s lifespan. This technical transition is what enables the massive scale and speed seen in modern high-rise and civil projects.

Key Performance Drivers: Speed, Safety, Reusability, and Surface Finish

The selection of a formwork solution is dictated by four main performance drivers that collectively determine project success. Speed, or cycle time, is critical, particularly in high-rise construction where minimizing the time between floors translates directly to reduced overhead and faster project delivery. Specialized systems facilitate this by integrating hydraulic movement and large-area striking mechanisms.

Safety is non-negotiable, and advanced formwork systems incorporate integrated handrail posts, climbing mechanisms, and working platforms to provide secure environments at height or in deep excavations. The third factor, reusability, ensures long-term cost efficiency, reducing waste and material procurement costs across repetitive projects. Finally, the quality of the surface finish (fair-faced concrete) is a function of the formwork facing material and system rigidity, often eliminating the need for subsequent, costly repair or architectural finishes.

Main Types of Concrete Formwork Systems in Heavy Civil Construction

The vast scope of heavy civil engineering necessitates a highly diverse portfolio of concrete formwork systems, ranging from modular, quick-assembly systems for residential slabs to bespoke, heavy-duty travelers used in hydroelectric facilities. Categorization is often based on the structural element being formed and the method of handling or operation. BFS Industries’ expertise lies in supplying the specialized, high-load systems that address the unique challenges of non-standard geometries and high-pour rates found in demanding environments, which require rigorous engineering and specialized design.

Understanding the difference between the main types—namely vertical structures (walls and columns) and horizontal structures (slabs and beams)—is the first step in optimizing a project’s concrete strategy. The loads, lateral pressures, and tolerances vary significantly between these elements, demanding equally distinct formwork approaches. Advanced systems integrate these vertical and horizontal components seamlessly, often incorporating multi-use panels and adaptable connection hardware to streamline the entire structural frame process.

Wall, Core, and Concrete Column Formwork Systems

Vertical elements such as shear walls, core walls, and columns are critical load-bearing components requiring precise alignment and high pressure resistance. Concrete Column Formwork solutions typically involve reusable, adjustable steel or fiberglass molds designed for quick locking and stripping. These systems ensure consistent column diameters and rapid cycling for projects with high repetition.

For continuous or tall vertical pours, panelized concrete wall formwork systems are used, often backed by heavy-duty steel walers to manage the substantial hydrostatic loads of deep or fast pours. High-rise projects heavily rely on inner and outer core wall formwork systems, which are typically designed to climb or self-climb (as discussed later) to minimize crane dependency and accelerate the tower’s central spine construction.

Slab Formwork, Shoring Towers, and Concrete Shuttering Systems

Slab formwork, also known as deck formwork, is responsible for forming the horizontal floor plates of a structure and managing the dead load of the wet concrete, as well as the equipment and personnel live loads. These systems include everything from lightweight Concrete Modular Formwork systems, which can be easily hand-set for lower-height applications, to heavy-duty primary beam systems supported by advanced shoring scaffolding systems.

The load management is often delegated to sophisticated shoring scaffolding systems or tower-based shoring, which are engineered structures designed to transfer enormous forces down through multiple levels. BFS Industries provides integrated slab formwork and shoring solutions that prioritize fast erection and dismantling, often incorporating drop-head systems that allow the main formwork panels to be struck and reused quickly while the temporary shore support remains in place to ensure concrete maturity.

Specialized Systems: Dams, Tunnels, and Vertical Cores

The realm of heavy civil construction presents challenges that exceed the capabilities of even standard system formwork. Dams, tunnels, and deep foundations require formwork engineered not just for pressure and speed, but for highly unique geometries, massive single-pour volumes, and often challenging on-site logistics. These applications demand collaboration with a specialized concrete formwork systems supplier capable of bespoke design and fabrication.

These projects often feature significant non-vertical or non-standard curved elements. For example, the inner lining of a tunnel requires a traveling arch-shaped system, while the construction of a dam may involve massive, adjustable panels that must accommodate changes in wall thickness and inclination. These systems are defined by their structural rigidity and their integrated mechanisms for movement, which are essential for achieving the required tolerances and pour cycles efficiently in a challenging environment.

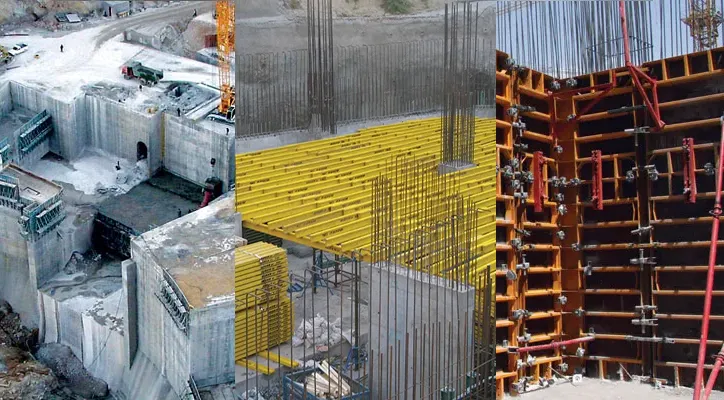

Dam Formwork: High-Load, Curved and Inclined Structures

The construction of concrete dams—whether gravity, arch, or buttress—involves forming massive, often curved or inclined walls that must withstand extreme hydrostatic pressure, potentially for weeks, before the concrete sets. Dam formwork is characterized by its exceptionally heavy-duty construction, typically utilizing robust steel formwork systems capable of handling the highest lateral loads encountered in construction.

These formwork systems are frequently designed as large, self-supporting units or travelers, enabling the entire assembly to be repositioned to the next pour location via crane or an integrated rail/hydraulic system. Specialized dam formwork must include sophisticated anchor systems to secure the panel against uplift and lateral movement, as well as integrated inspection and access platforms, ensuring the safety and quality control necessary for such critical infrastructure projects.

Tunnel Formwork and Tunnel Lining Formwork Systems

Tunnel construction requires specialized tunnel formwork designed to cast the arch, invert (floor), and side walls simultaneously or sequentially, creating the final tunnel lining formwork structure. The primary solution is the tunnel traveler or tunnel shield formwork, a massive, wheeled steel carriage that supports the arch and wall forms.

These systems are hydraulically operated to smoothly strip the lining and advance to the next section of the tunnel, dramatically accelerating the cycle time for the concrete lining process. BFS Industries supplies custom steel formwork systems for tunnels that accommodate different cross-sectional shapes (circular, horseshoe, square) and various lining thicknesses, providing the structural integrity and smooth surface finish required for both road and rail tunnel projects.

Self-Climbing and Slipform Systems for High-Rise and Continuous Pour Projects

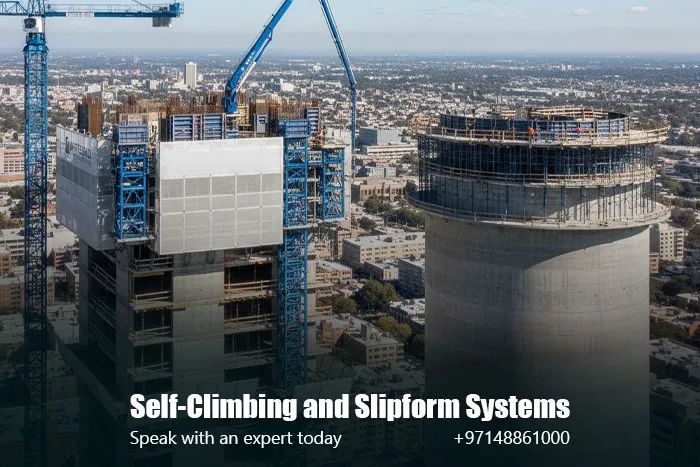

For high-rise towers and concrete structures with significant continuous vertical repetition, the efficiency of standard crane-handled formwork rapidly diminishes due to lifting time and wind-related delays. This necessity spurred the development of advanced automated formwork solutions—specifically, self-climbing and slipform systems—which drastically reduce reliance on tower cranes for relocation. These systems are essential tools for achieving the speed required to meet the demands of modern metropolitan development.

Both the self climbing formwork and slip formwork technologies are designed for continuous or semi-continuous concrete placement, minimizing cold joints and maximizing construction speed. While self-climbing systems move incrementally up the structure using integral hydraulic jacks, slipform systems move vertically during the pour itself. This focus on vertical repetition allows projects to achieve optimal cycle times, often completing a new level or segment every few days.

Self-Climbing Formwork Systems for Cores, Elevator Shafts, and Shear Walls

A self climbing formwork system is the preferred method for constructing the central core, elevator shafts, and shear walls of tall buildings. The system uses a series of hydraulic jacks that climb up vertical guide rails or sacrificial anchors embedded in the previously poured concrete. This independent movement frees up the main tower crane for other critical tasks like lifting steel or materials.

The complete system includes the large-area formwork panels, working platforms, concrete placing booms, and weather protection screens, all moving upward as a single unit. This centralized system provides a permanently safe, enclosed working environment, independent of height and weather, leading to highly consistent cycle times and safer, faster climbing formwork for high-rise building construction.

Slipform and Continuous Pour Concrete for Silos, Towers, and Dams

Slip formwork is a form of continuously moving formwork used for structures requiring a uniform cross-section over a great height, such as silos, water towers, chimneys, and concrete gravity dams. Unlike self-climbing systems, which move incrementally, slipform moves vertically, usually at a slow, continuous rate, while the concrete is being placed.

This continuous movement necessitates extremely fast-setting concrete and precision control, allowing the freshly placed concrete to cure just enough to hold its shape as it emerges from the bottom of the traveling formwork system. Slipform formwork supplier teams must manage the complex mechanical, hydraulic, and structural systems involved, ensuring zero interruptions in the pour process to prevent cold joints and structural flaws in the finished structure.

How to Select the Right Concrete Formwork System

Choosing the optimal concrete formwork systems is a sophisticated exercise in value engineering, moving beyond simple cost comparison to evaluating the total cost of ownership, including labor, crane time, and cycle acceleration. The decision process requires a careful analysis of the project’s technical specifications, logistical constraints, and commercial goals. An incorrect formwork choice can lead to significant delays, budget overruns, and compromised safety, underscoring the necessity of expert consultation.

The primary objective is to select a system that balances initial material cost against operational efficiency and reusability. For a high-repetition tower, the higher initial investment in a self climbing formwork system quickly pays for itself through reduced crane time and predictable, fast cycle times. Conversely, a one-off basement wall pour may better suit a less capital-intensive, manhandled system. BFS Industries leverages deep experience to guide clients through this critical technical and financial assessment.

Technical Criteria: Loads, Geometry, Repetition, and Crane Strategy

Several technical criteria drive the selection of a high performance concrete formwork solution. The structural loads—specifically the lateral pressure from the fresh concrete, which increases with the rate of pour—dictate the required strength of the system’s walers and ties. Complex, curved, or variable geometries (as found in dam formwork and tunnel formwork) necessitate custom steel formwork systems that can be finely tuned or articulated.

The repetition rate is another key factor: projects with 100+ uses of the same panel justify heavy-duty, durable systems, while low-repetition projects favor lighter, more flexible Concrete Modular Formwork. Crucially, the site’s crane strategy plays a major role; systems that are hydraulic (self-climbing) or traveler-based (tunnel systems) are chosen specifically to de-couple the formwork cycle from the increasingly congested tower crane schedule.

Comparing Dam, Tunnel, Self-Climbing, Slipform, and Modular Systems

A direct comparison highlights why no single formwork system can serve all construction needs; each is optimized for a specific set of constraints related to scale, geometry, and cycle speed.

| Feature | Modular Wall Systems | Self-Climbing Formwork | Slipform Formwork | Dam Formwork | Tunnel Formwork |

|---|---|---|---|---|---|

| Primary Use Case | Low/Mid-rise walls, foundations | High-rise cores, shear walls | Silos, chimneys, towers, gravity dams | Arch/Gravity Dam faces | Tunnel lining, vaults |

| Cycle Speed | Fast, crane-dependent | Very Fast, self-powered, regular | Continuous, fastest possible vertical speed | Moderate, heavy crane/traveler needed | Fast, hydraulic traveler-driven |

| Geometry Focus | Simple, rectilinear | Rectilinear, consistent core shape | Constant cross-section/tapering | Complex curves, heavy inclination | Curved arch, circular/horseshoe |

| Crane Dependence | High (for panel movement) | Low (only for initial set-up/dismantle) | None (system is fully integrated) | High (for massive resets) | Low (system moves on rails) |

| Load Capacity | Medium/High | High | High/Extreme | Extreme Hydrostatic | High Arch Load |

The table clearly shows that systems like self climbing formwork system are highly specialized tools for vertical repetition, while the engineered rigidity of dam formwork or the mobility of tunnel lining formwork supplier systems addresses large-scale infrastructure.

Benefits of Working with a Specialized Concrete Formwork Systems Supplier

Engaging a specialized concrete formwork systems supplier like BFS Industries transitions the client relationship from a simple material purchase to a strategic partnership focused on constructability and risk mitigation. General suppliers may offer standard catalogue products, but specialized firms focus on integrating the formwork design with the specific challenges of heavy civil and high-rise projects, offering a significant competitive edge to the contractor.

A technical supplier provides expertise that goes beyond product supply, offering value engineering services that can identify opportunities for labor reduction, improved safety, and optimization of the concrete curing cycle. This partnership is particularly vital when dealing with complex geometries, such as those found in demanding “system formwork for tunnels and dams” projects, where off-the-shelf solutions are functionally impossible or prohibitively inefficient.

Engineering Support, Design Optimization, and Value Engineering

The value proposition of BFS Industries begins with deep engineering support. Our teams utilize advanced 3D modeling and structural analysis software to pre-design every formwork arrangement, accounting for project-specific constraints like wind loading, seismic forces, and crane reach. This upfront design optimization often identifies material savings and workflow efficiencies that outweigh the cost of the system itself.

Value engineering is implemented by scrutinizing the construction methodology, suggesting alternatives like a move from crane-set forms to a self climbing formwork solution where cycle time is paramount. This specialized guidance helps clients avoid potential on-site failures and delays by guaranteeing the system’s structural adequacy and operational alignment with the project’s critical path.

Quality Control, Safety Compliance, and Lifecycle Cost Advantages

Quality control is integral to a specialized supplier’s mandate. Steel formwork systems and other components are manufactured under strict quality standards to ensure precise fit and finish, which translates directly to superior concrete surfaces and reduced post-pour repair costs. This attention to quality is essential for aesthetic finishes and demanding structural tolerances.

Safety compliance is embedded into the formwork design, including built-in access, guardrails, and secure tie-off points, which exceeds general construction safety requirements, especially for climbing formwork for high-rise building applications. Furthermore, our systems offer exceptional durability and high reusability rates, driving down the lifecycle cost per use compared to lower-quality or disposable formwork alternatives.

BFS Industries as Your Concrete Formwork Systems Partner

BFS Industries has established itself as a premier global concrete formwork systems supplier, specializing in the robust, technically demanding solutions required for major infrastructure and landmark projects. Our brand is synonymous with engineered reliability, particularly in sectors requiring high-load capacity and advanced cycling mechanisms, such as hydroelectric plants, transportation tunnels, and super-tall structures.

We offer a vertically integrated service, encompassing initial consultation, bespoke formwork design, manufacturing, and comprehensive on-site technical support. By focusing on high performance concrete formwork, we empower our partners—from large multinational contractors to specialized local builders—to tackle the most complex concrete challenges with maximized efficiency and minimized risk, setting us apart from traditional concrete formwork suppliers.

Product Portfolio: Dam Formwork, Tunnel Systems, Self-Climbing and Slipform

Our specialized product portfolio is built around the needs of the heavy civil sector. We supply ruggedized dam formwork travelers designed to handle massive hydrostatic pressures and accommodate complex wall inclinations. Our tunnel formwork systems include hydraulic travelers capable of rapid cycling for kilometers of continuous lining pours, ensuring high output and consistent quality.

For vertical construction, our suite of systems includes advanced self climbing formwork platforms for building cores and proprietary slip formwork solutions for continuous pour structures like towers and storage facilities. We also complement these advanced solutions with versatile systems like Concrete Column Formwork and slab systems, providing a fully integrated site solution that maximizes component synergy and operational efficiency.

Global Supply, OEM Capabilities, and Project-Proven References

BFS Industries maintains global supply chain capabilities, allowing us to deliver complex concrete formwork systems to remote or challenging project sites worldwide with reliability and speed. As a strategic partner, we offer extensive OEM (Original Equipment Manufacturer) services, collaborating directly with major construction firms to customize formwork components and integrate them seamlessly into their existing fleet.

Our reputation as a trusted slipform formwork supplier and dam formwork manufacturer is underscored by a deep portfolio of project-proven references across continents. These references validate our ability to deliver highly specialized, high-load solutions on time and on budget, establishing bfs industries as the partner of choice for contractors seeking unparalleled engineering expertise and guaranteed formwork performance.

Frequently Asked Questions (FAQs)

1.What type of formwork is best for my project?

The choice depends on project size, complexity, budget, and specific requirements. For large projects, metal (steel, aluminum) or plastic formwork is often more cost-effective due to reusability. For smaller projects, timber or plywood might suffice, offering flexibility and lower initial costs.

2.How do I calculate the cost of formwork?

Costs include materials, labor, and sometimes rental fees. For reusable formwork, initial costs are higher, but they can be spread over multiple uses, reducing overall project cost. Consider maintenance and storage costs, to assess long-term savings.

3.What safety precautions should I take when working with formwork?

Ensure proper design and bracing to handle concrete weight, use appropriate personal protective equipment (PPE), and follow manufacturer’s instructions. Regular inspections for defects are crucial, to prevent accidents.

4.How do I properly remove formwork without damaging the concrete?

Wait until the concrete achieves sufficient strength, typically a few days to a week, depending on curing conditions. Remove carefully from top to bottom, using tools that avoid scratching or chipping, to maintain surface integrity.

5. What are the common mistakes to avoid in formwork installation?

Mistakes include inadequate bracing, using low-quality materials, improper alignment, and premature removal. Ensuring proper design, following manufacturer guidelines, and conducting regular inspections can prevent structural failures and rework costs.