Tunnel Formwork System Supplier

Introduction

The landscape of large-scale concrete construction has been fundamentally transformed by high-performance systems designed for speed, repetition, and structural integrity. At the forefront of this evolution is tunnel formwork, a revolutionary method that allows contractors to cast structural walls and slabs simultaneously in a daily cycle. When undertaking vast mass housing schemes, residential block construction, or demanding infrastructure projects, the choice of a reliable tunnel formwork system supplier becomes the single most critical factor in project success, dictating the ultimate pace, quality, and profitability of the build. For over two decades, BFS Industries has specialized in engineering and manufacturing advanced formwork solutions that transcend conventional limitations, establishing ourselves as a trusted global partner in delivering durable, high-cycle tunnel form systems engineered for maximum on-site productivity and long-term asset value. We equip infrastructure developers, mass housing builders, and concrete construction firms with the precise tools necessary to achieve unprecedented construction speeds while ensuring the monolithic strength and superior finish quality that modern specifications demand, confirming our position as the premier choice in the global supply chain.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

Understanding Tunnel Formwork

Tunnel formwork is a highly efficient, panel-based construction system designed for the simultaneous casting of vertical (walls) and horizontal (slabs) concrete elements. This process creates a cellular structure of reinforced concrete, resulting in exceptionally rigid and earthquake-resistant buildings with superior thermal and acoustic performance characteristics. The core mechanism facilitates rapid, repetitive, and reliable cycles, typically allowing for a complete structural unit to be cast and cured every 24 hours, often referred to as “daily-cycle construction.” This speed advantage is particularly critical in large residential developments where thousands of identical or similar units must be constructed within tight deadlines, making tunnel form construction the method of choice for institutional and governmental mass housing initiatives around the world. The system integrates the structural elements into a seamless whole, fundamentally different from traditional beam-and-column methods, which require separate formwork assembly for each element, drastically reducing both material waste and construction time.

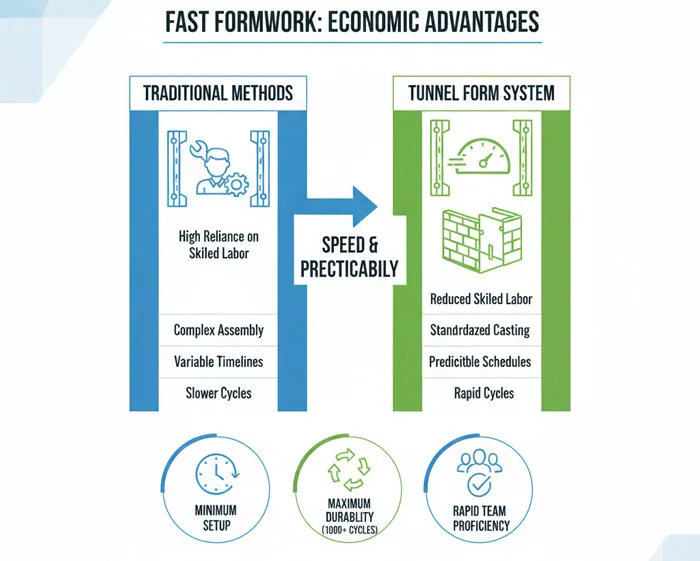

The economic argument for adopting a tunnel form system centers entirely on the speed and predictability it introduces to a project schedule. By reducing the reliance on highly skilled labor for complex assembly and by standardizing the casting procedure, operational variability is minimized, making project timelines more robust and reliable. High-speed projects require systems optimized for minimum setup and maximum durability, where the equipment itself is designed to withstand the rigors of hundreds, often thousands, of cycles. The repetitive nature of the work allows site teams to achieve maximum proficiency quickly, further contributing to the overall speed and quality control. This is the definition of fast formwork in action: a technologically advanced system that leverages repetition to deliver structural stability and rapid economic return, proving its worth over competing slower, and more labor-intensive methods.

How Tunnel Formwork Works: Integrated Wall–Slab Casting

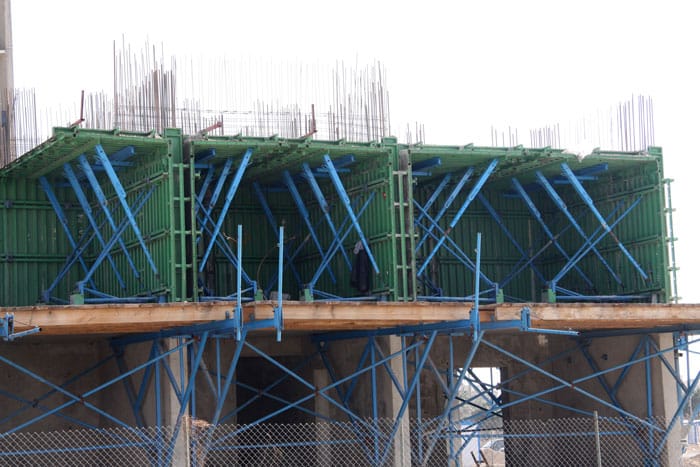

The fundamental principle behind tunnel formwork construction lies in the L-shaped steel components that, when mirrored, create a tunnel-like cavity corresponding to the shape of the wall and the adjacent ceiling or floor slab. These steel molds are placed in sequence along the length of the building floor, forming the full structure of the unit. The system relies on precision engineering; the components must fit together seamlessly to form a leak-proof mold that can withstand the immense hydrostatic pressure of wet concrete. Once the reinforcement is placed within the forms, concrete is poured in a single operation, creating a monolithic structure where the wall and slab are structurally integrated, eliminating cold joints and increasing the overall strength and seismic performance of the building frame. Specialized heating systems, often integrated with the formwork panels themselves, are frequently used to accelerate the curing process, ensuring that the necessary concrete strength for demolding is achieved within the tight 24-hour cycle.

A high-quality tunnel formwork system supplier provides more than just steel panels; they deliver a complete, integrated mechanism for casting. Key tunnel formwork components include the main L-shaped forms, end stop-ends (which define the length of the tunnel), window and door block-outs, and sophisticated stripping mechanisms. The stripping process is engineered to be as swift and non-destructive as possible, typically involving a hydraulic or manual-jack system to slightly retract the formwork from the cured concrete surfaces before the entire unit is rolled out of the finished structure. This controlled demolding is vital for maintaining the finish quality of the concrete and extending the life of the formwork itself. The design must account for tolerances, ensuring that the forms can be easily removed without damaging the freshly cast walls and slabs, a testament to the specialized engineering rigor applied to every piece of concrete tunnel forms provided by BFS Industries.

Why Contractors Prefer Working With a Dedicated Tunnel Formwork System Supplier

Contractors undertaking large-scale repetitive construction projects understand that minimizing variables is the key to maintaining margin and schedule integrity. When working on projects that require hundreds of casting cycles, the durability, dimensional accuracy, and supply chain reliability of the formwork system cannot be compromised. Choosing a dedicated tunnel formwork system supplier like BFS Industries provides a comprehensive level of specialization and engineering support that general formwork vendors cannot match. Our singular focus on high-performance, daily-cycle systems means that every aspect of the product—from the grade of the steel to the release agent compatibility and the stripping mechanism design—is optimized specifically for the demands of the tunnel form construction environment. This dedication ensures the forms deliver consistent results and minimal downtime over thousands of uses, protecting the contractor’s substantial investment in the equipment.

The complexity and capital intensity of tunnel formwork demand a partnership with a supplier that offers not just equipment, but a complete technical service package. This includes initial design customization to meet specific architectural plans, structural analysis to ensure the forms withstand the specified concrete pressures, and on-site training for crew efficiency and safety. The reputation of the contractor is intrinsically linked to the quality of the finished concrete surface, and our systems are designed to deliver a smooth, plumb, and square finish, minimizing the need for subsequent plastering or finishing work. This speed of construction, coupled with the superior quality finish, is a decisive advantage in competitive bidding environments. Furthermore, working with a specialist provides access to immediate, highly relevant technical support for any on-site challenges, guaranteeing that expensive project pauses are mitigated swiftly and effectively, which ultimately is the true value proposition of a leading tunnel formwork manufacturer.

Quality, Precision, Production Capacity, and On-Site Stability

The manufacturing quality of the formwork components is paramount to the entire system’s performance. BFS Industries maintains rigorous ISO-certified production standards, utilizing advanced robotic welding and CNC machining processes to ensure every panel and component meets micron-level precision requirements. This accuracy is what guarantees the seamless assembly and stripping necessary for daily cycling and prevents concrete leakage or misalignment that would compromise the structural integrity or finish quality of the wall-slab unit. For contractors, our significant production capacity translates directly into project security; we can mobilize and deliver large-volume orders on aggressive schedules to construction sites globally, ensuring that a multi-phase project receives all necessary forms and components precisely when needed to maintain momentum.

On-site stability encompasses both the structural rigidity of the formwork during the pour and the logistical dependability of the supplier. BFS systems are structurally reinforced to handle high rates of concrete placement, minimizing deflection and maintaining dimensional accuracy even under challenging weather or thermal conditions. For the construction firm, relying on experienced tunnel shuttering suppliers also means receiving expert guidance on site logistics, crane deployment, maintenance protocols, and ensuring maximum reuse cycles. Our commitment to supplying robust, durable, and highly precise concrete formwork systems guarantees maximum return on investment. This assurance of both product quality and logistical reliability allows procurement teams and site managers to focus on other critical project areas, secure in the knowledge that their primary structural casting system is entirely dependable and technically superior to off-the-shelf alternatives.

BFS Industries Tunnel Formwork Systems

The BFS Industries tunnel form system represents the pinnacle of modern rapid construction technology, blending advanced material science with intuitive engineering for superior on-site performance. Our systems are characterized by their robust design, exceptional surface finish capabilities, and the seamless integration of stripping mechanisms that maximize the speed and longevity of the assets. The design philosophy is centered on maximizing the volume of concrete cast per working hour while minimizing the effort required for setup and demolding. This is achieved through carefully calibrated component weight, optimized handling points for crane operations, and a highly durable release surface that dramatically reduces adhesion and cleaning time. We are constantly innovating our tunnel formwork to integrate features like specialized thermal blankets and self-compensating jacks, ensuring our clients maintain their competitive edge in high-speed, high-volume markets.

Material Composition, Structural Capacity, and Engineering Specifications

The core of the BFS advantage lies in our materials and engineering specifications. Unlike lighter, less durable alternatives, our tunnel formwork is fabricated primarily from high-tensile, rolled steel plate, specifically chosen for its yield strength and resistance to fatigue after repetitive mechanical stress and thermal cycling. This robust composition ensures the forms retain their precise geometric shape over thousands of reuse cycles, significantly lowering the total cost of ownership for the contractor. All casting surfaces are treated with a specialized coating or finish that not only enhances the concrete’s surface quality but also provides exceptional resistance to abrasion and corrosion, extending the life of the asset far beyond industry norms. Our engineering team meticulously calculates the structural capacity of every component, ensuring they can safely and reliably handle the full hydrostatic load of wet concrete at the specified pour rate, providing an exceptional safety margin and compliance with the most stringent global engineering standards.

Cycle Time Efficiency and Daily Casting Productivity

Optimization of the daily cycle is the ultimate metric for any tunnel formwork system supplier. BFS Industries focuses on three core areas to maximize cycle time efficiency: minimized setup, accelerated curing, and efficient stripping. The forms are designed with minimal connection points and self-aligning features, drastically cutting down the time required for placement and bolting compared to conventional systems. Where heating is employed, our forms are designed for maximal thermal transfer, allowing for faster concrete strength gain. However, the most significant gain is often realized in the stripping phase. Our proprietary stripping mechanisms are engineered for smooth, simultaneous retraction of the form faces, requiring minimal force and protecting the structural integrity of the newly cast concrete. This integrated approach to fast formwork ensures that contractors can consistently maintain a 24-hour cycle, which is essential for projects relying on repetitive tunnel form construction for economic viability and timely handover, thereby securing unparalleled daily casting productivity and site turnover rates that are superior to competing technologies.

Durability, Repeated Use, and Steel Panel Longevity

Investing in tunnel formwork is a long-term capital decision, and the durability of the system directly impacts the return on investment. BFS Industries manufactures steel formwork designed for an industry-leading number of reuse cycles, often exceeding 1,500 with proper maintenance. This exceptional longevity is a core differentiator, achieved through the use of heavy-gauge steel, strategic reinforcement at high-stress points, and the highest quality finishing treatments applied by a dedicated tunnel formwork manufacturer. We understand that the construction environment is demanding, and forms are subject to repeated impact and wear; consequently, our design emphasizes robustness and ease of repair. The ability of our system to withstand extensive reuse is crucial for large-scale, multi-year mass housing programs or projects spanning multiple continents, guaranteeing consistent performance from the first pour to the last. This durability translates into lower operational expenditure, reduced replacement costs, and a more sustainable, long-lasting investment for the construction firm.

Applications of Tunnel Formwork Systems

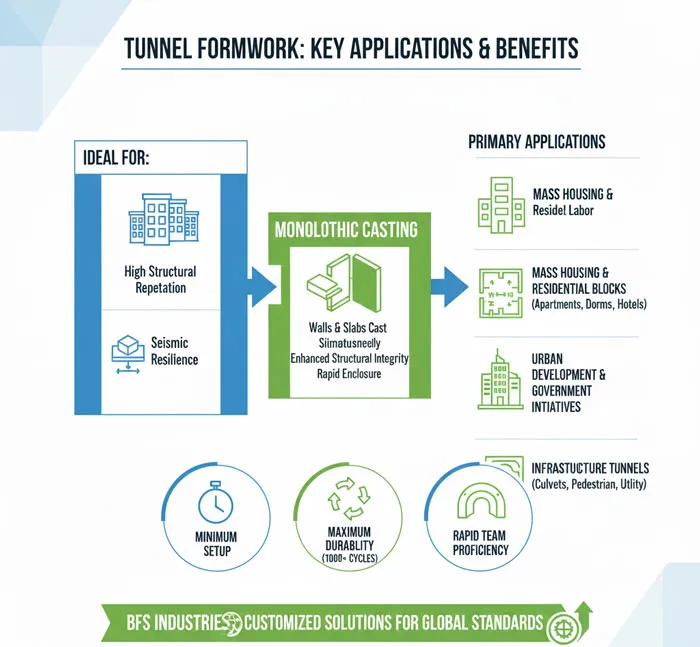

While the concept of using large structural molds is versatile, the economic and technical benefits of tunnel formwork systems are most pronounced in applications characterized by high levels of structural repetition and the need for seismic resilience. The structural integrity achieved by the monolithic casting of walls and slabs is exceptionally well-suited for high-density living spaces where structural performance and speed of enclosure are paramount. Furthermore, the inherent design allows for maximum standardization, simplifying the logistics of material handling and allowing for streamlined finishing trades once the structure is completed, further accelerating overall project timelines. BFS Industries provides customized tunnel formwork solutions engineered to client-specific dimensions and structural requirements, ensuring optimal performance across a diverse range of global construction contexts and compliance standards.

Mass Housing, Repetitive Unit Projects, Residential Blocks, Infrastructure Tunnels

The primary application for tunnel formwork globally remains in mass housing and large-scale residential blocks, where the repetition of unit layouts (e.g., apartment cells, dorm rooms, or hotel suites) allows the daily cycle to realize its full economic potential. The system provides a rapid and cost-effective means of delivering tens of thousands of dwelling units with consistent, high-quality finishes, making it an essential tool for urban development and governmental housing initiatives. Beyond standard residential construction, the principles of monolithic casting are also highly valued in specialized infrastructure projects, particularly in the construction of box culverts and short-span pedestrian or utility tunnels. When considering linear, non-building projects such as road or rail conduits, the specialized requirements are met by dedicated tunnel lining formwork suppliers who apply similar principles of rapid demolding and high-strength steel fabrication to create continuous, durable concrete shells, illustrating the broader applicability of the core tunnel form concept across the built environment. BFS Industries leverages its expertise to support both high-rise residential structure construction and specific infrastructure needs where the speed of tunnel form construction is the decisive factor.

Comparison With Other Industrial Formwork Systems

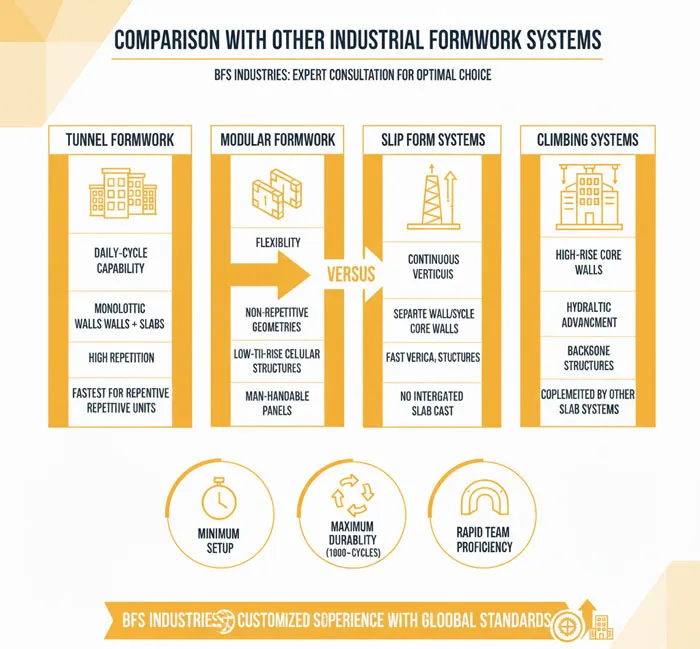

Understanding the strategic advantage of tunnel formwork requires a clear comparison with other major concrete formwork systems available on the market. While systems like modular formwork offer flexibility and climbing systems address verticality, none can match the simultaneous casting speed and monolithic structural outcome provided by the tunnel form method in the appropriate context. The selection of the correct system is a procurement decision based on structural typology, desired cycle time, and required finish quality, and BFS Industries provides expert consultation to guide clients toward the optimal choice for their specific project brief, leveraging our vast experience with multiple formwork technologies. The comparison highlights not just the technical specifications but the fundamental economic difference delivered by the daily-cycle capability of the tunnel form.

Tunnel Formwork vs Modular Formwork vs Slipform vs Climbing Systems

Tunnel formwork, as a fast formwork solution, differentiates itself from modular formwork primarily through its scope. Modular systems, while offering exceptional flexibility for non-repetitive structures and complex geometries, require separate cycles for walls and slabs, making them inherently slower for repetitive cellular structures. Modular systems use smaller, man-handleable panels and are excellent for custom commercial builds, whereas the tunnel form uses large, integrated, crane-handled L-forms for daily monolithic casting. Conversely, Slip Formwork Construction is optimized for linear, continuous vertical structures like silos, bridge piers, or tall core walls, moving continuously rather than in discrete daily cycles. Slip forming, though fast vertically, does not integrate the slab and wall casting simultaneously in the same manner as the tunnel form. Finally, the self climbing formwork system is designed explicitly for high-rise buildings, facilitating the construction of high core walls and perimeter structures by vertically advancing itself using hydraulics. While climbing systems achieve vertical speed, they are structurally distinct and generally used to form the backbone of a high-rise structure, which is then complemented by floor slabs formed by other means. Tunnel form is superior for low-to-mid-rise cellular structures where the majority of the concrete is cast simultaneously in a repetitive horizontal slice.

Buying Tunnel Formwork Systems: Key Criteria for Selecting the Right Supplier

When procurement engineers finalize the decision to utilize tunnel formwork, the subsequent selection of the tunnel formwork system supplier becomes paramount. This choice goes far beyond the initial purchase price of the steel forms; it involves assessing the supplier’s capacity to deliver technical assurance, global logistics, and responsive support that will ensure the high-capital equipment operates continuously and effectively for the project’s duration. A capable supplier is one who acts as an extension of the engineering and logistics teams, not merely a manufacturer of goods, focusing on long-term asset performance rather than transactional sales. For major infrastructure developers and mass housing builders, this technical partnership is what safeguards project timelines and final structural quality.

Technical Support, Certification, Production Speed, and Global Delivery

The criteria for evaluating a tunnel formwork supplier must emphasize post-sale support and manufacturing pedigree. Certifications are critical; a supplier must demonstrate adherence to international quality management standards (e.g., ISO 9001) and possess engineering teams proficient in major international building codes. BFS Industries excels in this area, providing comprehensive technical documentation and site supervision services to ensure optimal implementation of the tunnel form construction system. Furthermore, production speed is directly linked to project mobilization; a supplier with robust, high-volume manufacturing capabilities is essential to ensure that a large batch of custom forms can be delivered on schedule, regardless of the project’s global location. Our established international logistics network and experience in large-scale equipment dispatch and customs navigation guarantee timely delivery and setup support across continents, making BFS Industries the preferred choice for multinational construction and development companies seeking reliable tünel kalıp solutions globally.

Why BFS Industries Is a Trusted Tunnel Formwork System Supplier

BFS Industries has built its global reputation as a trusted tunnel formwork system supplier on an unwavering commitment to engineering superiority, manufacturing precision, and end-to-end project partnership. We view every project, from smaller residential blocks to multi-thousand-unit housing schemes, as a collaboration requiring bespoke technical solutions rather than a standardized product delivery. Our integrated approach—where design, fabrication, and site support are managed internally—ensures that the final system is perfectly optimized for the client’s concrete mix design, curing methods, and specific site constraints, guaranteeing that the tunnel formwork components function in perfect harmony. We pride ourselves on the documented success and durability of our systems in some of the most challenging construction environments worldwide, demonstrating our capacity to deliver quality and performance consistently.

Manufacturing Excellence, Custom Engineering, and End-to-End Project Support

Our manufacturing facilities employ the latest in fabrication technology, ensuring every panel of tunnel formwork is a masterpiece of precision engineering, ready for immediate, high-cycle use. This commitment to manufacturing excellence means reduced site modifications and faster initial assembly for the client. The greatest value, however, comes from our custom engineering capabilities. We don’t just sell standard tunnel forms; we custom-design the entire system, including non-standard forms, specialty block-outs, and custom striking gear, to integrate seamlessly with the specific architectural blueprints. Our end-to-end project support begins at the schematic design phase and extends through on-site crew training, initial pour supervision, and long-term maintenance planning. This holistic service model, provided by BFS Industries, ensures that the contractor maximizes the system’s daily casting potential and achieves the highest possible return on their investment in our high-performance tunnel form construction solutions.

Conclusion: Upgrade Your Project Performance With BFS Tunnel Formwork Systems

In the high-stakes environment of mass-scale concrete construction, time, quality, and structural integrity are non-negotiable pillars of project success. The adoption of a high-cycle tunnel formwork system is the strategic decision that delivers these pillars simultaneously, providing an unmatched speed advantage for repetitive building structures. However, the performance of this system is directly proportional to the expertise and reliability of its supplier. BFS Industries stands as a globally recognized, technically advanced tunnel formwork system supplier, delivering systems that are engineered not just for strength, but for thousand-cycle durability and optimal daily productivity. Our commitment to precision manufacturing, custom design integration, and comprehensive on-site support ensures that your investment translates into predictable, profitable, and rapid construction outcomes, setting a new benchmark for structural quality and project efficiency.

Final Summary and Call to Action for Procurement Teams

The operational efficiencies delivered by the BFS Industries tunnel formwork system offer a decisive competitive advantage in the high-volume construction market, providing superior quality, faster cycle times, and robust longevity compared to alternative formwork methods. We invite all procurement engineers, infrastructure developers, and concrete construction firms to engage with our specialist team to explore how our custom-engineered solutions can be adapted to meet the unique specifications and aggressive schedules of your next major project. Do not settle for generic equipment; partner with the tunnel formwork system supplier that guarantees manufacturing excellence and project success. Contact BFS Industries today to schedule a consultation and receive a detailed technical proposal outlining the performance advantages and investment returns our advanced formwork can deliver for your most demanding construction challenges.

FAQ: Tunnel Form System

1. Is Tunnel Form construction more expensive than traditional methods?

Initially, yes. The formwork investment is high, but faster construction and reduced labor costs make it cost-effective for large projects.

2. How long does it take to build a floor using the Tunnel Form system?

With proper planning, a 24-hour cycle per floor is achievable, meaning an entire building can be completed in weeks rather than months.

3. Can Tunnel Form be used for custom-designed buildings?

It is best suited for repetitive layouts. While modifications are possible, complex designs may require additional work.

4. How many times can the formwork be reused?

High-quality steel or aluminum formwork can be reused up to 500 times, depending on maintenance.

5. Is the Tunnel Form system earthquake-resistant?

Yes! The monolithic structure enhances strength, making buildings more resistant to seismic activity.