Buy Pal Scaffolding - Triangle Shoring Systems

Introduction

In modern construction, particularly in heavy civil engineering and large-scale commercial projects, the safe and efficient support of massive concrete structures during their curing phase presents a paramount engineering challenge. This is the domain where Pal Scaffolding, also known widely as Triangle Scaffolding, emerges as a critical structural support system. Engineered specifically for high-load shoring applications, Pal Scaffolding provides an exceptionally robust, rigid, and rapidly assemblable framework that significantly surpasses traditional access scaffolding in load-bearing capacity. Its unique geometry, based on the inherent strength of the triangle, ensures optimal force distribution, making it the preferred solution for supporting thick concrete slabs, deep beams, and complex formwork packages. As a leading supplier of high-performance engineered systems, BFS Industries provides complete Pal Scaffolding solutions designed to meet the rigorous demands of today’s most challenging construction projects, ensuring safety, reliability, and unparalleled project efficiency.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

What Is Pal Scaffolding? A Modern Shoring Solution

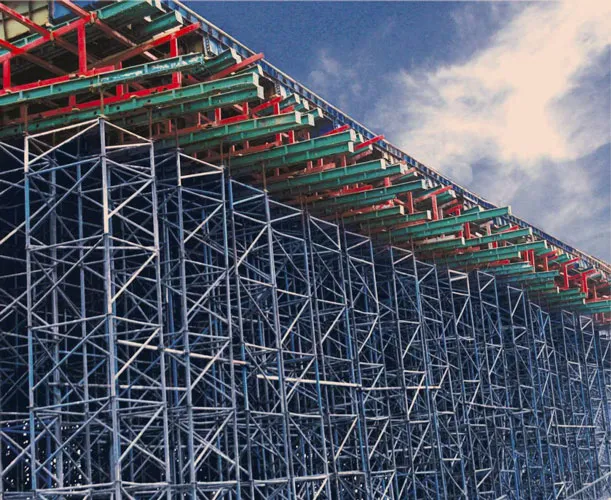

Pal Scaffolding is a specialized, heavy-duty modular shoring system engineered to support immense vertical loads, primarily in Concrete Construction applications. Unlike access scaffolding, which is designed to support workers, tools, and light materials, Pal Scaffolding is a falsework system built to withstand the immense pressures of wet concrete, the weight of the formwork itself, and additional construction or environmental loads. The system is based on prefabricated, welded triangular panels or frames that serve as the primary vertical load-bearing elements. These panels are interconnected with robust bracing to form rigid, high-capacity shoring towers.

These towers can be easily and quickly joined together, both horizontally and vertically, to create a comprehensive support structure capable of covering large areas or reaching significant heights. Its fundamental function is to serve as a temporary structure, transferring the heavy load of a new concrete element—such as a slab, beam, or bridge deck—safely and directly down to a solid foundation. This support remains in place until the new concrete has cured and achieved sufficient compressive strength to be fully self-supporting. The system’s modularity and engineered strength make it an indispensable component for ensuring structural integrity, precision, and safety during the most critical phases of concrete placement.

Understanding the Design and Geometry of Triangle Scaffolding

The core strength and immense capacity of Triangle Scaffolding are derived directly from its fundamental design: the triangle. In structural engineering, a triangle is the most rigid and stable geometric shape, as it cannot be deformed or racked without changing the length of one of its sides. The Pal system harnesses this principle by constructing its main frames from vertical, horizontal, and diagonal steel members that are welded together into fixed triangular panels. These panels, acting as a truss, effectively convert vertical compression forces into a combination of compression and tension along their members, distributing the load efficiently and minimizing the risk of buckling.

When these individual triangular panels are connected side-by-side and braced with horizontal and diagonal tubes, they create a three-dimensional space frame. This truss-like structure provides exceptional stability and minimizes deflection even under substantial loads. The connections between frames are typically made with high-strength, load-bearing pins or bolts, which securely lock the components together. This locking mechanism is critical, as it ensures the entire shoring assembly—whether a single tower or a large, interconnected block—acts as a single, monolithic unit. This unified structure is capable of transferring millions of pounds of force directly and safely to the ground, providing a secure platform for formwork and construction activities above.

Why Pal Scaffolding Is Widely Used in Concrete Formwork and Civil Projects

Pal Scaffolding sees extensive use in heavy construction precisely because its design directly addresses the industry’s greatest challenges: high loads, complex structures, and aggressive schedules. Its widespread adoption is a direct result of its superior combination of high load capacity, rapid assembly, and structural versatility. For heavy civil projects, such as the construction of bridges, tunnels, and overpasses, it can be assembled into massive shoring towers capable of supporting deep box girders, thick structural slabs, and complex pier caps at significant heights. Its reliability is essential when the cost and safety implications of a formwork failure are catastrophic.

In the commercial sector, Pal Scaffolding is the go-to system for shoring elements that are beyond the capacity of lighter-duty frame or post-shore systems. This includes multi-story parking garages, thick transfer slabs in high-rise buildings (which support the load of columns from upper floors), and the long-span beams required for auditoriums, stadiums, and convention centers. Its modular nature allows it to be adapted to sloping surfaces, complex geometries, and varying elevations. Furthermore, its application extends beyond just slab support; it is frequently integrated with concrete wall formwork systems, providing the necessary lateral bracing and structural support for tall or single-sided wall pours, making it an indispensable and adaptable engineering tool.

Pal Scaffolding vs. Frame and Ringlock Systems

When planning a project, engineers and project managers must often select the most appropriate support system from several options, commonly Pal Scaffolding, traditional frame-and-brace systems, and other modular systems like Ringlock or Cuplock. While all these systems can be used for shoring to some degree, they are engineered for different primary purposes and excel in different applications. Traditional H-frame scaffolding, for instance, is excellent for masonry work and façade access, and can be used for light-duty shoring, but it lacks the high-capacity legs and inherent rigidity of a true Pal system for heavy concrete.

The more relevant comparison is with modular systems like Ringlock and Cuplock. These systems are highly versatile, using a multi-directional “rosette” or “cup” to connect ledgers and diagonals, making them brilliant for creating complex access platforms and shoring in tight or geometrically complex areas. However, the “Cuplock vs Pal Scaffolding” debate in the context of pure, heavy-duty vertical support often favors Pal. Triangle Scaffolding is a specialist. It is designed with one primary goal: to support massive vertical loads with the fewest components and fastest assembly time. For repetitive, large-area shoring tasks, the speed of erecting Pal towers often outpaces the more component-intensive modular systems.

Side-by-Side Comparison: Connection System, Stability, and Cycle Speed

The primary differences between these systems are found in their core components and connection points, which directly influence stability, labor costs, and project cycle speed. Pal Scaffolding utilizes a simple, robust pin or bolt connection on its large, fixed triangular frames. This design results in very few loose components, enabling rapid erection and dismantling. The inherent rigidity of the welded frame provides exceptional stability, especially in tall tower configurations. Ringlock, by contrast, uses a multi-directional “rosette” on its vertical standard, where ledgers and diagonals are connected with a wedge pin. This offers unparalleled flexibility for attaching components at various angles and heights, but with more individual components to manage.

For shoring cycle speed, Pal often has a distinct advantage in large, open slab applications. Because the towers are so rigid, large bays or “tables” of shoring can be pre-assembled on the ground, complete with formwork decking, and then “flown” (lifted by crane) into place. This “flying form” method drastically reduces the labor and time required for each subsequent floor in a multi-story building. While Ringlock can also be ganged, the Pal system’s frame-based design is often considered more robust for these large-scale flying operations.

| Feature | Pal Scaffolding (Triangle) | Ringlock | Frame Scaffolding |

|---|---|---|---|

| Primary Use | Heavy-duty shoring, formwork support | All-purpose: access & shoring | Access, light-duty shoring |

| Key Component | Welded triangular frames | Vertical standard with “rosette” or “cup” | Welded H-frames |

| Connection | High-strength pins or bolts | Wedge pin | Gravity locks & cross braces |

| Load Capacity | Very High | High | Medium |

| Versatility | Good (for shoring) | Excellent (for complex geometry) | Moderate |

| Assembly Speed | Very Fast (for shoring towers) | Moderate | Fast (for simple runs) |

| Loose Parts | Few | Many | Few |

Which System Is Better for Shoring? Engineering Considerations

The engineering decision for the “best scaffolding for shoring” is not absolute but is entirely dependent on the specific project requirements. For projects defined by extreme vertical loads—such as deep transfer beams in a high-rise, thick slabs for industrial facilities, or massive bridge decks—Pal Scaffolding is unequivocally the superior engineered choice. Its design is optimized for one purpose: safely and efficiently transferring massive compression forces to the ground. The high-capacity legs mean that shoring towers can be spaced further apart, reducing material tonnage and the on-site footprint.

However, if a project requires a single, integrated system to provide both heavy shoring and intricate access platforms—for example, in a power plant boiler or around complex architectural features—a modular system like Ringlock might be the more cost-effective and logical solution. An engineer must evaluate the specific load charts, the required leg spacing (shoring density), the project’s logistics, and the labor skill level. On many large-scale projects, it is common to see a hybrid approach, using a mix of shoring scaffolding systems where Pal is deployed for the heavy lifting and other systems are used for access and lighter support.

Technical Specifications of Triangle

The safe and successful performance of Pal shoring towers is dictated by their precise technical specifications, which engineers must use for all shoring design calculations. These specifications are not universal and vary significantly between manufacturers, making it absolutely critical to source from a reputable, certified supplier like BFS Industries that provides transparent and verifiable load data. Key specifications begin with the dimensions of the triangular panels themselves (e.g., standard heights and widths) and the material properties of the steel tubing.

Material Grades, Dimensions, Diagonal Bracing, and Panel Angles

Diving deeper into the Pal scaffolding components, the vertical and horizontal members of the triangular frames are typically manufactured from high-strength steel tubes. These often range from 48mm to 60mm in outer diameter, with wall thicknesses from 3.0mm to 4.0mm or more for heavy-duty variants. The steel grade is a critical differentiator; a system using S355 (or equivalent) steel has a higher yield strength than standard S235 steel, allowing for a greater load capacity with the same component weight. This reduces the overall tonnage of material required for a project.

The geometry of the frames is fixed, with internal diagonal members welded at precise angles (e.g., 45 or 60 degrees) to create the rigid, non-deformable truss. To create a stable tower, these individual frames are connected by separate diagonal bracing tubes. These braces are essential for providing lateral stability and preventing sway, especially as the shoring height increases. The engineering plan will specify the exact pattern of this “plan bracing” and “elevation bracing” required to ensure the tower acts as a single, stable unit.

Load Capacity, Allowable Deformation, and Safety Factors (EN, OSHA)

The single most critical technical specification for any shoring system is its Pal Scaffolding load capacity. This is typically expressed as a Safe Working Load (SWL) or allowable capacity per vertical leg. Depending on the system’s design (tube diameter, wall thickness, steel grade), this capacity can range from 30 kN to over 60 kN (approximately 3 to 6 metric tons, or 6,700 to 13,500 lbs) per leg. It is crucial to understand that this is not a fixed number; the allowable capacity decreases as the total shoring height increases, due to the increased risk of buckling.

Manufacturers must provide detailed load charts, certified by a third-party engineer, that correlate the allowable leg capacity with the total unsupported shoring height and the specified bracing configuration. Engineers use these charts to design the shoring layout (i.e., the spacing between towers and legs) based on the calculated load of the wet concrete and formwork. This design must then incorporate a significant safety factor as mandated by standards like OSHA (which often requires a 4:1 factor) or EN 12812. Allowable deformation (deflection) is also a key consideration to ensure the formwork remains precisely at the correct elevation when the full concrete load is applied.

Applications of Pal Scaffolding in Heavy Civil and Commercial Projects

The combination of high capacity and modular assembly makes Pal Scaffolding the ideal solution for a wide and demanding range of construction projects. In the commercial building sector, its primary use is for shoring high-load elements that are common in modern, ambitious architecture. This includes thick, reinforced concrete transfer slabs in high-rise buildings—which are designed to support the load of columns from upper floors, allowing for open-plan spaces below—as well as the long-span beams found in auditoriums, shopping malls, and convention centers. It is also the standard for constructing multi-level parking structures, where the entire floor system is designed for heavy, repetitive loading.

In the heavy civil domain, Pal Scaffolding’s applications are even more robust and visually impressive. It is used to create the extensive temporary structures, or falsework, needed to construct cast-in-place concrete bridges, highway overpasses, and viaducts. Its ability to be assembled into towers of significant height and structural integrity makes it suitable for supporting bridge decks high above ground, water, or active roadways. In infrastructure, its reliability is non-negotiable, and its performance is critical to the project’s success.

Concrete Slab Shoring and High Load-Bearing Floors

The most frequent and widespread application for Pal scaffolding is for concrete slab support, especially in instances where the slab thickness, span, or required elevation exceeds the capacity of lighter-duty shoring systems like post shores or standard frame scaffolding. For example, in the construction of an industrial warehouse or manufacturing plant designed to support heavy machinery, or a data center with a high live load, the concrete slabs may be 300mm (12 inches) thick or more. This creates a massive dead load of wet concrete that must be supported perfectly.

A scaffold pal system provides a dense grid of high-capacity support legs, ensuring the formwork remains perfectly level and stable as thousands of pounds of concrete are poured and vibrated. This same system can be seamlessly integrated to provide lateral support for slab-edge beams or adjacent concrete wall formwork, creating a single, unified shoring structure. The adjustable screw jacks at the top and bottom of the Pal towers are critical in this application, allowing for micro-fine alignment of the entire formwork package to guarantee a flat, level, and accurate final concrete surface.

Infrastructure Projects: Bridges, Tunnels, and Industrial Plants

In large-scale infrastructure, Pal shoring towers demonstrate their full engineering potential. For cast-in-place bridge construction, they are assembled on foundations or barges to support the complex, often curved or superelevated formwork for bridge piers, massive pier caps, and the main deck segments themselves. Their high rigidity and fully braced design are crucial for resisting not only the vertical load of the concrete but also lateral loads from wind, water currents, or construction activities, especially at significant heights.

In tunnel construction, customized Pal systems are used to support the heavy, arched, or box-section formwork for casting the tunnel linings. In the industrial sector, such as in the construction of power generation facilities, petrochemical refineries, or LNG plants, Pal Scaffolding is used to support the construction of heavy concrete foundations, pedestals, and support structures for turbines, reactors, and other massive equipment. These applications often require high-capacity shoring to be assembled in congested areas with complex logistics, a challenge for which the modular Pal system is well-suited.

Advantages of Choosing Pal Scaffolding

The widespread adoption and continued specification of Pal Scaffolding by leading engineering firms and contractors stem from a clear and compelling set of advantages. These benefits directly impact project timelines, budgets, and, most importantly, site safety. The primary advantage is its exceptional strength-to-weight ratio. The engineered triangular frames provide immense load capacity while remaining relatively lightweight, allowing them to be handled by workers or ganged into large units and flown by crane. This efficiency translates directly into significant material and labor savings.

Because each leg can support a higher load, fewer vertical supports are needed to shore the same area compared to lighter-duty systems. This reduction in the number of components (or “shoring density”) simplifies site logistics, reduces the assembly footprint, and minimizes tripping hazards, contributing to a cleaner and safer work environment. Furthermore, the system’s inherent rigidity and stability provide a secure working platform and reliable support, giving engineering teams and site crews confidence in the falsework’s performance under load. This psychological assurance, backed by certified engineering, is an invaluable asset on any high-risk construction project.

Fast Assembly, High Rigidity, Reusability, and Cost Efficiency

The design of Triangle Scaffolding is optimized for speed and efficiency. With fewer, more robust components and simple, secure pin-and-lock connections, assembly and dismantling times are significantly reduced compared to more complex modular systems. A small, well-trained crew can erect or strip large areas of Pal shoring in a single shift. This rapid cycling is a major cost-saver, allowing for more aggressive project schedules. The high rigidity achieved through the welded truss design means that tall towers can be erected with minimal deflection, a critical factor for maintaining the precise elevations required by formwork.

Furthermore, Pal Scaffolding is built for extreme durability. Manufactured from high-grade, often hot-dip galvanized steel, the components are exceptionally resistant to the harsh conditions of a construction site, including physical impacts and weathering. This high reusability over dozens of projects and many years provides a very low total cost of ownership. While the initial purchase price may be higher than light-duty frames, the long-term return on investment— factoring in labor savings, durability, and reusability—makes it a highly cost-efficient shoring solution for professional contractors.

Why Contractors Prefer Pal Scaffolding for Repetitive Slab Cycles

In the construction of multi-story buildings, such as high-rise offices, residential towers, or hotels, contractors overwhelmingly prefer Pal Scaffolding for its unmatched efficiency in repetitive slab cycles. The system is ideally suited for being pre-assembled into large shoring “tables” or “bays.” These units, which consist of multiple Pal towers braced together and topped with the formwork decking (e.g., stringers, joists, and plywood), can support an entire section of a concrete slab.

After the concrete on one level has cured to a sufficient strength, these large table units are lowered using the screw jacks, rolled horizontally to the building’s edge (often on specially designed casters or rollers), and then “flown” by crane to the next floor to be reset. This method, known as “flying forms,” is the pinnacle of shoring efficiency. It drastically cuts down on the labor required for dismantling and re-erecting the shoring for each new slab. This ability to move large, intact sections of the shoring system is a key operational advantage and a primary reason Pal is favored over systems that must be disassembled piece by piece.

Pal Scaffolding Price Guide and Buying Tips

Determining the Pal Scaffolding price is not as simple as a per-piece cost; it is a complex calculation based on the specific requirements of a project. The system is typically quoted based on the total tonnage of steel required, or sometimes as a cost per square meter (or square foot) of the area to be shored at a specific height. When requesting a quote, a supplier will need to know the total area, the shoring height, and the load requirements (e.g., the thickness of the concrete slab) to calculate the required amount of equipment.

When buying, it is crucial for contractors to look beyond the initial purchase price and consider the total cost of ownership. This includes the system’s durability, its reusability, and the significant labor savings it offers through faster assembly and dismantling. A cheaper, non-certified, or lower-grade system may fail prematurely, require more components (a denser grid) to support the same load, or lack the necessary engineering certification, ultimately costing more in labor, time, and risk. Always request certified load data, weld quality reports, and quality assurance documentation from any potential supplier.

Price Factors: Steel Grade, Height, Thickness, Certification, and Market Conditions

Several key variables directly influence the final procurement price of a new Pal Scaffolding system. The most significant factor is the raw material. Higher-grade steel, such as S355, and thicker tube walls (e.g., 3.5mm vs. 3.0mm) will increase the cost but provide superior load capacity and durability. The surface finish is another major factor: a hot-dip galvanized finish provides the best possible corrosion protection and longest lifespan, but at a higher cost than a standard painted or powder-coated finish.

The required shoring height dictates the total number of components needed, including extra frames and a higher quantity of diagonal bracing, which increases the total package cost. Certified systems that have undergone expensive, independent third-party testing to meet EN or OSHA standards will command a premium over non-certified products. Finally, global market conditions, including the price of steel, and international shipping and logistics costs, can introduce significant volatility to procurement budgets.

Choosing Between New and Used Pal Scaffolding

Contractors, especially those looking for the best scaffolding company for shoring solutions, must often decide between investing in new or purchasing used equipment. New Pal Scaffolding, sourced directly from a reputable manufacturer like BFS Industries, provides the ultimate peace of mind. It guarantees full certification, a manufacturer’s warranty, and pristine components with no unknown history of being overloaded, dropped, or damaged. This is by far the safest and most reliable option for high-risk, heavy-load applications.

Used Pal Scaffolding can offer significant initial cost savings, but it carries substantial risks. Buyers must conduct an extremely thorough inspection of every single component. This means checking for any signs of damage, such as bent or dented tubes, cracked welds, excessive or deep rust, and damaged or missing connection pins. It is essential to verify the original manufacturer and ensure that the certified load data for that specific system is still available and applicable. Any used equipment should ideally be inspected and recertified by a qualified professional engineer before being deployed on a job site to ensure it is still safe for use.

How to Install Pal Scaffolding: Step-by-Step Process

The installation of Pal Scaffolding is a systematic, engineering-led process that must be performed by trained, certified assembly crews under the direct supervision of a competent person. The entire process begins not with the scaffold itself, but with its foundation. The ground, or the concrete slab on which the shoring is being built, must be level, compacted, and certified as capable of supporting the immense, concentrated loads from the shoring legs. Sills (timber or steel) or sole plates are laid down first to distribute the leg load over a wider area.

The assembly then begins by laying out the adjustable base jacks according to the shoring plan’s “footprint” and setting them to a base elevation. The first level of triangular frames is then connected to the base jacks, creating the base of the shoring tower. From this foundation, crews work upwards, adding subsequent levels of frames and locking them in place with the connecting pins. The key to how Pal scaffolding works safely is ensuring the tower remains perfectly plumb (vertical) and square at every stage, with all bracing installed as the tower is built.

Pre-Assembly Checklist and On-Site Inspection Requirements

Before a single component is assembled, a rigorous pre-assembly and inspection process is mandatory for site safety. First, all Pal scaffolding components delivered to the site must be inspected for damage. Any frames with bent or dented tubes, any braces with damaged ends, or any components with cracked welds or excessive corrosion must be immediately quarantined and removed from use. The connection pins and bolts must be checked for straightness and proper fit.

The job site itself must be inspected to ensure the foundation is adequate and all potential hazards (like overhead power lines or underground utilities) are identified and mitigated. The shoring design plans, which must be prepared and stamped by a professional engineer, must be on-site and reviewed in detail with the assembly crew. This plan details the required tower locations, leg spacing, maximum height, bracing requirements, and the safe working load of the designed system. No deviation from this engineered plan should ever be allowed without the formal written approval of the design engineer.

Assembly, Vertical Alignment, Bracing, and Final Locking

As the Pal shoring towers are erected level by level, maintaining vertical alignment is critical. A spirit level, and often a plumb line or laser, must be used continuously to ensure the tower is not leaning. Even a slight angle out of plumb can dramatically reduce a leg’s load capacity and introduce dangerous lateral forces. As the tower gains height, horizontal and diagonal bracing must be installed immediately, as per the engineered drawings. This bracing is what connects individual frames into a rigid, stable structure. Often, this bracing also links multiple towers together to create a fully stable, monolithic shoring block.

Once the tower reaches the required height, the U-head jacks (or flat-head jacks, depending on the application) are installed. These are then adjusted to the final precise elevation to support the formwork’s primary beams (stringers). A final, comprehensive inspection must be conducted by the competent supervisor. This involves checking that every single pin is securely locked, all required braces are in place, and all screw jacks at the base and top are properly seated and bearing load before any formwork or concrete load is applied.

Certifications and International Standards

Shoring and falsework systems are among the most safety-critical components on a construction site. A failure can be catastrophic, leading to project collapse, loss of life, and massive financial and legal consequences. Because of this high risk, the design, manufacture, and use of these systems are governed by stringent national and international standards. In the United States, OSHA (Occupational Safety and Health Administration) regulations provide strict guidelines for the design, erection, and inspection of all scaffolding and shoring.

While OSHA does not “approve” or “certify” specific brands, it mandates that the system must be designed by a qualified person and be capable of supporting its own weight and at least four times the maximum intended load to be applied. In Europe, the primary standard is EN 12812 (Falsework – Performance requirements and general design). This comprehensive standard provides a detailed framework for the structural design, testing, and certification of shoring systems like Pal Scaffolding. Reputable manufacturers worldwide will design and test their products to meet or exceed these standards, often involving third-party testing to validate their published load charts.

OSHA, EN 12812, EN 12810, and Load Testing Requirements

EN 12812 is the key standard for falsework design, outlining the complex structural calculations, load combinations, and safety factors that engineers must use. It is often used in conjunction with related standards like EN 12810 (Facade scaffolds made of prefabricated components), which details standards for materials, component testing, and quality control during the manufacturing process. Compliance with these rigorous EN standards is not a simple paper exercise; it requires extensive and destructive physical load testing.

This testing involves taking components and fully assembled shoring towers and loading them to failure in a controlled laboratory environment. This destructive testing is the only way to validate the theoretical calculations and establish the system’s true ultimate capacity, from which the Safe Working Load (SWL) is derived. Sourcing Pal Scaffolding from a supplier that provides transparent, third-party load testing reports compliant with these EN standards is the best way for a contractor to perform due diligence and ensure that the material being used on their site is high-quality, reliable, and, above all, safe.

Why Choose BFS Industries for Pal Scaffolding?

When sourcing a safety-critical system as robust as Pal Scaffolding, the supplier you choose is as important as the product itself. BFS Industries distinguishes itself as a premier, engineering-focused partner for the construction industry’s most demanding projects. We are not simply a distributor; we are a solution provider. We understand that shoring is not a one-size-fits-all commodity. Our team works directly with our clients’ project managers and engineering teams to provide the optimal shoring system for their specific application, backed by comprehensive technical data, certified load charts, and full compliance with all relevant international safety standards.

Our primary commitment is to our clients’ success. This means delivering a product that is unequivocally safe, demonstrably reliable, and highly efficient to use on site. We help our clients stay on schedule and on budget by providing a system that assembles quickly, performs flawlessly under load, and is durable enough to last for years. This focus on long-term value and partnership is why we are considered one of the best scaffolding company for shoring solutions in the industry.

Manufacturing Quality, Load Testing and After-Sales Service

Our reputation is built on a foundation of uncompromising manufacturing quality. The Triangle Scaffolding supplied by BFS Industries is manufactured in state-of-the-art, ISO 9001-certified facilities. We use only high-grade, certified steel from reputable mills, and our automated and robotic welding processes ensure consistent, full-penetration, high-integrity welds on every single frame.

This commitment to quality extends to our comprehensive after-sales service. We provide full documentation, including load charts and assembly manuals, and offer responsive technical assistance to our clients’ teams. We partner with our clients to ensure the safe, correct, and successful deployment of our shoring systems from the first pour to the final project completion. When you choose BFS Industries, you are investing in a system and a partner you can trust.

Frequently Asked Questions (FAQ) About Pal Scaffolding

What is the maximum load capacity of Pal Scaffolding?

The Pal Scaffolding load capacity is not one single number; it varies significantly by manufacturer, component specification (steel grade, tube thickness), and, most importantly, the shoring configuration. A typical heavy-duty leg can have a Safe Working Load (SWL) between 30 kN and 60 kN (approx. 3 to 6 metric tons or 6,700-13,500 lbs). However, this allowable capacity decreases as the shoring height increases. You must always consult the manufacturer’s specific, certified load charts for your exact configuration.

What is the difference between Pal Scaffolding ?

The main difference is their design and primary purpose. Pal Scaffolding (or Triangle Scaffolding) uses pre-welded, rigid triangular frames designed almost exclusively for heavy-duty vertical shoring. It is a specialist system. Cuplock and Ringlock are more versatile modular systems. They use a multi-directional “rosette” or “cup” connection point, making them excellent for both shoring and creating complex access scaffolding, such as for industrial maintenance or around curved structures.

How high can you build Pal shoring towers?

Pal shoring towers can be built to significant heights, often exceeding 20-30 meters (65-100 feet) or more, as seen in the construction of tall bridge piers. However, as the height increases, the towers must be extensively braced, both internally and by lacing multiple towers together into a larger, stable block. Furthermore, the allowable load per leg will decrease with height, as specified in the manufacturer’s load charts. All tall shoring structures must be designed by a qualified professional engineer.

Is Pal Scaffolding the same as Triangle Scaffolding?

Yes, the terms “Pal Scaffolding,” “Triangle Scaffolding,” and “Tri-Frame Scaffolding” are generally used interchangeably within the construction industry. They all refer to this heavy-duty shoring system that is based on pre-fabricated, welded triangular frames as the main load-bearing component.

Can Pal Scaffolding be used for regular access scaffolding?

While it is technically possible, it is highly inefficient, costly, and not recommended. The components are much heavier, larger, and more cumbersome than standard access scaffolding systems (like Frame scaffolding or lightweight modular systems). Pal is an engineered shoring system designed to handle massive vertical loads; it is not designed for creating light-duty working platforms for personnel.