Ringlock Scaffolding System

Introduction

The ringlock scaffolding system engineered by BFS Industries represents the apex of modern modular construction access and support technology, designed specifically to address the demanding requirements of high-load, high-rise, and complex industrial projects worldwide. This innovative system moves beyond the limitations of traditional scaffolding approaches by leveraging a proprietary rosette-based connection that facilitates rapid, omni-directional assembly with unparalleled structural rigidity. As the construction sector evolves towards greater efficiency and enhanced safety, the BFS Ringlock platform offers a definitive solution, ensuring structural integrity under extreme vertical and horizontal loads, dramatically reducing erection and dismantling times, and providing complete compliance with the most stringent global safety standards. Our dedication to precision manufacturing ensures that every component contributes to a safe, reliable, and cost-effective solution, making this system the optimal investment for any major infrastructure or commercial development that prioritizes performance and worker safety.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

ringlock scaffolding system Products

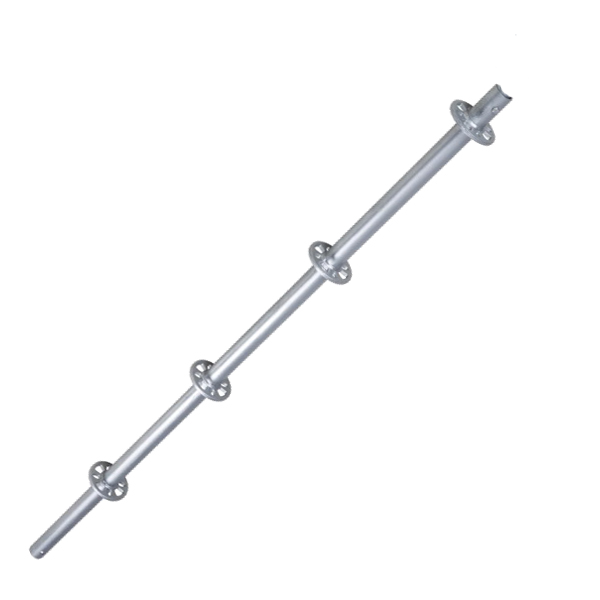

Ringlock Standard

Ringlock Ledger

Ringlock Radial

Ringlock Diagonal Brace

Ringlock GS Spigot Connector(SC)

What Is Ringlock Scaffolding?

Ringlock scaffolding is a widely adopted, highly advanced modular ringlock scaffolding system defined by its speed, versatility, and exceptional strength, distinguishing it significantly from older pipe and fitting systems. At its core, the system utilizes vertical members (Standards) that feature circular metal discs, known as Rosettes, welded at uniform intervals (typically every 0.5 meters). These rosettes are the defining characteristic, providing up to eight connection points for ledgers and diagonal braces, all converging at a single node. This multi-directional capability allows construction crews to easily conform the scaffold structure to complex architectural geometries, including curved facades, circular tanks, and irregular work surfaces, which would be prohibitively difficult and time-consuming with conventional scaffolding methods. The robust, factory-welded joints and high-strength steel composition ensure structural performance and longevity, making it the system of choice for contractors seeking reduced material handling costs and superior operational efficiency across diverse job sites.

The fundamental advantage of the ring lock scaffolding design lies in its inherent structural stability and simplicity of operation, qualities that translate directly into reduced labor requirements and increased project profitability. The wedge-locking mechanism—where a forged steel wedge on the Ledger or Brace slots into the rosette and is secured with a hammer blow—creates a friction-grip connection that instantly transmits loads to the vertical standard. This rapid, positive connection system eliminates the need for loose, cumbersome fasteners like bolts and couplers, thereby removing the potential for human error associated with unevenly tightened components. Furthermore, the standardization and interchangeability of BFS Ringlock components simplify logistics and inventory management; all standards, ledgers, and braces are manufactured to exacting tolerances, guaranteeing perfect fit-up every time. This precision engineering not only enhances safety and load distribution but also ensures maximum system reusability over a prolonged service life, providing an outstanding return on investment for large-scale construction firms and scaffold hire companies alike.

Key Components and Engineering Design

The efficacy of the BFS ringlock scaffolding system stems from its five primary components, each designed for maximum structural performance and seamless integration. These elements include the vertical Standards (or verticals), horizontal Ledgers (or horizontals), Diagonal Braces, Base Jacks, and Decking Units. The Standards are the load-bearing backbone, typically fabricated from high-grade steel tubing with the critical rosette connections. Ledgers connect the standards horizontally, providing the necessary bracing and support for the working platforms. Diagonal Braces are essential for lateral stability and anti-sway resistance, especially at height or under dynamic loads. The engineering philosophy behind the entire system ensures that forces are distributed uniformly through the rosette joint and down the standards, maximizing the system’s high-load capabilities while minimizing material weight relative to its strength. Every piece is engineered to work synergistically, creating a rigid lattice structure that remains stable regardless of complexity or height.

The intelligent modular design inherent in the BFS modular ringlock scaffolding solution means the system can be adapted for both simple façade access and complex shoring scaffolding systems applications. Unlike older systems that require bespoke components for corner or angle changes, the flexibility of the rosette connection allows for angular configurations ranging from 0° to 360° at every joint, using only standard ledgers and braces. This adaptability drastically simplifies planning and inventory requirements, reducing downtime associated with sourcing specialized parts. Moreover, all components are manufactured with a hot-dip galvanized finish, providing superior protection against corrosion, rust, and environmental degradation, thereby maintaining structural integrity and appearance even in harsh industrial or marine environments. This commitment to durability and functional design ensures that the BFS Ringlock system maintains its structural performance and extends its service life far beyond the capabilities of inferior coated or painted systems.

Rosette Connection and Ledger System

The rosette connection is arguably the most critical and innovative feature of the ring lock scaffolding system, acting as the structural node where up to eight components can securely meet. Each rosette is a robust, precision-welded steel disc with equally spaced openings, ensuring that when ledgers or braces are attached, the load transfer geometry is optimized. This design prevents localized stress points and ensures that vertical load-bearing capacity is consistently maintained, even when supporting platforms on multiple sides and at various angles. The simplicity of the connection—achieved by inserting the component’s forged steel end into the rosette opening and securing it with a single, captive wedge—is what facilitates the system’s reputation for rapid assembly and dismantling. This mechanical advantage significantly contributes to labor savings and quicker project turnaround times compared to labor-intensive tube and clamp arrangements.

The Ledger system works in direct conjunction with the rosette, providing the horizontal connection that defines the bay size and supports the working deck. BFS Industries Ledgers are designed with a reinforced profile to handle both the weight of workers and materials and the lateral forces exerted on the scaffold. The design ensures a positive lock when the wedge is hammered home, eliminating play in the joint and guaranteeing maximum rigidity. The standard ledger lengths available (ranging from 0.73m to 3.07m) offer the flexibility required to adapt the scaffold footprint to nearly any configuration while maintaining structural predictability. This standardized interface across the entire system means that components are completely interchangeable, providing a logistical benefit that reduces confusion on site, minimizes the risk of using incorrect parts, and accelerates the overall scaffolding erection process, reinforcing the system’s reputation for efficiency.

Diagonal Braces, Standards, and Decking Units

The integrity of any high-rise or high-load scaffold structure relies heavily on effective lateral bracing, which in the BFS ringlock scaffolding system is provided by the Diagonal Braces. These braces are essential for triangulation, converting the cube-like scaffold bays into rigid structural units capable of resisting wind loads, seismic activity, and lateral forces imposed by material hoists or internal movements. Each diagonal brace is equipped with the same wedge-locking head as the ledgers, allowing it to connect to the rosettes at vertical levels. This method ensures that the bracing is integrated directly into the load-bearing standards, maximizing the stiffness of the structure. The consistent use of high-strength steel in the manufacture of these ring lock braces ensures that stability is not compromised, even at extreme heights or when the scaffold is used in demanding applications like heavy shoring scaffolding systems for concrete work.

The Standards, or vertical members, are the load-bearing heart of the modular ringlock scaffolding system, defining its height and supporting all vertical loads. BFS Industries manufactures standards from premium steel, ensuring the highest yield strength and resilience. The continuous placement of rosettes every half-meter allows for precise platform height adjustments and flexible planning. Complementing these load-bearing standards are the Decking Units, which form the actual working platforms. Our decking is typically made from galvanized steel or reinforced aluminum, often featuring anti-slip surfaces for enhanced worker safety. These units are designed to slot securely between the ledgers, minimizing gaps and eliminating trip hazards. The precision of the ringlock system components ensures that the standards, braces, and decking units fit together seamlessly, making the BFS system a safe, reliable, and expertly engineered access solution.

Technical Specifications and Load Capacities

Understanding the technical specifications and load capacities is paramount for construction planning and safety compliance. The BFS Industries ringlock scaffolding system is meticulously engineered to meet and exceed global standards, offering predictable and superior performance under varied environmental and load conditions. The system utilizes Standards typically fabricated from 48.3mm OD (Outer Diameter) high-strength steel tubing, with wall thicknesses calibrated to handle extreme axial compression. The inherent strength of the rosette-wedge connection means that vertical loads are efficiently transferred through the center of the standard. This optimization enables our ringlock platform to achieve classification ratings that support heavy-duty work applications, making it suitable for masonry, concrete finishing, and industrial maintenance where simultaneous high material and personnel loads are common.

Our commitment to safety and engineering excellence is evidenced by the certified ringlock scaffold load capacity ratings we provide. When properly assembled according to our guidelines, the system is classified for various duty levels, including heavy-duty (up to 6.8 kN/m² or 150 psf). The actual capacity of the scaffold bay is a function of the bay size (ledger length) and the height of the structure, which is why rigorous engineering calculations are mandatory for every project. The BFS Ringlock system’s ability to operate as a high-capacity ringlock load bearing scaffolding structure, capable of supporting significant vertical and horizontal forces, allows it to serve as robust support for formwork and heavy structural elements. We recommend incorporating a detailed technical review, which is available upon request, to determine the exact component requirements and load factors specific to your project’s unique demands.

Image Recommendation: A high-quality, professional photograph or detailed technical drawing illustrating a standard Ringlock bay under load, highlighting the rosette connection and the standards.

| Component | Material | OD (mm) | Wall Thickness (mm) | Finish | Max. Design Load (kN/Leg) |

|---|---|---|---|---|---|

| Standard (Vertical) | High-Grade Steel (S355/Q345) | 48.3 | 3.2 – 4.0 | Hot-Dip Galvanized | Up to 60 kN |

| Ledger (Horizontal) | High-Grade Steel | 48.3 | 2.5 – 3.2 | Hot-Dip Galvanized | Up to 15 kN/m |

| Diagonal Brace | High-Grade Steel | 48.3 | 2.5 | Hot-Dip Galvanized | N/A (Lateral Stability) |

| System Rosette | Forged Steel | N/A | N/A | Hot-Dip Galvanized | Integrated |

Step-by-Step Assembly and Installation Procedure

The assembly of the BFS ringlock scaffolding system is characterized by a streamlined, highly intuitive process, significantly reducing the complexity and time typically associated with scaffold erection. The procedure begins with establishing a stable foundation, utilizing Base Jacks placed on firm ground or sill plates, ensuring precise vertical leveling. Following this, the first lift of Standards is erected, interconnected by the Ledgers to establish the primary bay dimensions. This initial step is simplified by the speed of the wedge connection, which requires only a hammer to secure the components, eliminating the torque-wrenching required by traditional systems. Subsequent lifts are then added by joining the next Standard section to the top of the previous one using integral spigots, maintaining vertical alignment and continuity of the rosettes.

Safety Guidelines: A key aspect of the BFS installation protocol emphasizes safety and compliance at every step. Firstly, all ground conditions must be inspected by a competent person, ensuring adequate bearing capacity. Secondly, ringlock scaffold load capacity must never be exceeded, and scaffold tags (Green/Yellow/Red) should be utilized to communicate status. Thirdly, Fall Protection (harnesses, lanyards) is mandatory when working at heights, particularly when installing guardrails on the new lift. Fourthly, bracing is critical: Diagonal Braces must be installed immediately after the ledgers for a given bay to provide the essential lateral stability before any further vertical progression. Lastly, proper storage and handling of the ring lock scaffolding components are vital; damaged components must be quarantined, and hot-dip galvanized finishes must be protected to ensure longevity and structural performance. Adherence to these strict guidelines ensures both worker safety and the structural integrity of the final access platform.

Advantages of the BFS Ringlock Scaffolding System

The adoption of the BFS ringlock scaffolding system provides substantial competitive advantages to contractors and construction managers, particularly those focused on large-scale and long-duration projects. The inherent geometric efficiency of the rosette connection allows for quicker adaptation to varying construction needs without compromising the structural integrity of the final assembly. This modularity means fewer component types are needed on-site, simplifying logistical planning and reducing the likelihood of construction delays due to missing parts. Beyond mere speed, the system’s design contributes directly to a cleaner, more organized site environment, as the lack of loose fasteners and redundant connections streamlines material flow. Furthermore, the robust, all-steel construction, finished with a comprehensive hot-dip galvanization process, translates to lower lifetime replacement and maintenance costs, presenting a clear financial benefit over painted or electro-plated alternatives.

From a business perspective, choosing the BFS scaffolding ringlock system represents a strategic investment in long-term efficiency and worker well-being. The system’s superior design and ease of use significantly reduce the training time required for scaffolding crews, allowing for faster mobilization and productivity gains. The positive locking action of the wedge connection provides immediate, visible confirmation of a secure joint, simplifying site supervision and increasing crew confidence in the scaffold’s stability. Compared to older, heavier systems, the optimized weight-to-strength ratio of our modular ringlock scaffolding components allows for higher stacking density during transport and storage, lowering logistics costs per project. Ultimately, the rapid assembly, dependable strength, and minimized component count position the BFS Ringlock solution as the most advanced and economically rational choice for modern construction access needs.

High Load-Bearing Strength and Durability

The core technical advantage of the BFS ringlock scaffolding system is its certified capacity for high-load applications, which far surpasses the limits of many conventional frame or tube-and-clamp setups. This capability is achieved through the use of premium, high-yield steel in the Standards and Ledgers, combined with the structural efficiency of the rosette connection that disperses axial loads evenly across the structure. This makes it an ideal choice for heavy-duty requirements, such as supporting material hoists, temporary heavy equipment, or acting as a falsework structure in complex concrete pours. The durability is further secured by a comprehensive hot-dip galvanization process, which applies a thick, uniform coating of zinc to every component, providing a self-healing barrier against rust and abrasion. This finish ensures a service life of 20 years or more, even in harsh, corrosive environments common in large-scale Concrete Construction sites or coastal industrial facilities.

Quick Installation and Reduced Labor Cost

The speed of erection is one of the most compelling economic arguments for adopting the BFS ring lock scaffolding solution. The proprietary rosette connection allows a single scaffolder to connect up to eight components with only a hammer, eliminating the tedious, time-consuming process of positioning and tightening multiple couplers required by traditional systems. This streamlined workflow can translate to a 40% to 50% reduction in labor hours for assembly and dismantling when compared to pipe and fitting scaffolding. For major high load ringlock scaffold projects that span several months or years, these labor savings become a significant driver of overall project profitability. The standardized component lengths also aid in pre-planning, where material allocation can be calculated precisely, avoiding over-ordering or time lost due to component shortages, thereby reinforcing the cost-saving benefits inherent in the modular design.

Precision Engineering and Safety Standards Compliance

Precision engineering is the foundation of the BFS scaffolding ringlock system, ensuring not only efficiency but, most importantly, compliance with stringent global safety standards such as those set by ANSI, OSHA, and EN 12810. Every component, including the critical forged wedge on the ledgers and the rosette connection itself, is manufactured to exact tolerances, guaranteeing a perfectly secure, friction-grip joint every time. This manufacturing accuracy is crucial for maintaining the structural calculation assumptions regarding load distribution and stability. The built-in safety features, such as the immediate, visible lock provided by the wedge and the standardization of bay dimensions, inherently reduce the risk of on-site errors that could compromise structural integrity. This dedication to precision ensures the BFS Ringlock system is not merely compliant, but sets a benchmark for safe, reliable access and working platforms across the construction industry.

Applications of Ringlock Scaffolding System

The versatility of the ringlock scaffolding system allows it to excel in a diverse range of construction and industrial applications where conventional systems often prove inadequate or inefficient. Its modularity and high load capacity make it the premier choice for projects that demand structures capable of handling extreme vertical loads while conforming to complex or irregular structural geometries. From supporting the installation of heavy mechanical equipment in industrial refineries to providing access for maintenance on curved storage tanks, the modular ringlock scaffolding platform adapts with unparalleled ease. Moreover, its ability to integrate seamlessly with other construction technologies, such as advanced lifting systems and weather protection enclosures, further expands its utility, positioning it as an all-in-one solution for both primary access and auxiliary structural support on any major project.

The rapid and flexible assembly also makes it a powerful tool in time-critical infrastructure projects, where speed of mobilization is essential. The standardized nature of the ring lock scaffolding components means that large inventories can be maintained and deployed quickly to multiple sites, a logistical advantage for scaffolding ring lock system company operators and major contracting firms. Whether providing perimeter access for glazing installation on a high-rise tower or creating a complex access gantry over public roads, the system’s structural predictability ensures engineers can rapidly certify the structure’s safety. This adaptability across different environments—from dense urban centers to expansive industrial sites—underscores the BFS Ringlock system’s value as a universal scaffolding solution.

High-Rise Construction and Industrial Projects

In high-rise and extensive industrial construction, the stability and speed of the ringlock scaffolding system are non-negotiable requirements. For towering commercial buildings, the system provides a continuous, highly rigid perimeter access platform essential for facade work, cladding, and window installation. The consistent bay size and rapid erection process minimize the time the scaffold is required on site, accelerating the overall construction schedule. Similarly, in heavy industrial settings, such as power plants, petrochemical facilities, or maritime structures, the system’s hot-dip galvanized finish is vital for protection against harsh chemical and atmospheric corrosion. Furthermore, the high-load capacity enables it to support heavy maintenance tasks, including boiler repairs, tank internal lining, and pipework replacement, positioning it as the indispensable choice for complex Concrete Construction and facility maintenance projects globally.

Formwork Support, Shoring, and Access Solutions

Beyond external access, the BFS ringlock scaffolding system is widely utilized in structural applications as robust falsework. Its high-capacity Standards and triangulated bracing allow it to serve as a superior shoring scaffolding systems solution for supporting heavy-duty loads during the pouring and curing of concrete slabs, bridges, and large structural beams. By integrating the ringlock components with specialized concrete wall formwork and slab formwork systems, contractors can create flexible, adjustable, and supremely strong temporary support structures. This capability minimizes the need for separate shoring inventory, maximizing the utility of the ringlock components. Moreover, the system’s adaptability extends to creating suspended scaffolds, stair towers for safe vertical access, and even temporary grandstands or public access ramps, showcasing its comprehensive utility across all facets of site management and structural support.

Ringlock vs Other Scaffolding Systems

When evaluating temporary access solutions, the choice of scaffolding system is critical to project timelines, budget, and safety outcomes. The BFS ringlock scaffolding system is specifically engineered to outperform older, less sophisticated alternatives by offering a synergistic combination of structural strength, assembly speed, and geometric flexibility. While other systems may offer cost savings on initial material purchase, the long-term operational costs associated with labor, maintenance, and slow mobilization often negate these savings. Ringlock’s design minimizes loose parts, simplifies training, and guarantees connection integrity, factors which collectively result in superior operational efficiency and a significantly lower Total Cost of Ownership (TCO) over the lifespan of the assets compared to more conventional methods.

The key differentiation lies in the rigidity and load transmission characteristics of the joint. Older systems rely on external fasteners (couplers or cup/wedge connections) that can be susceptible to uneven torque application or movement over time. The modular ringlock scaffolding system’s integrated rosette and captive wedge create a positive, friction-grip connection that instantly solidifies the structure with minimal effort. This inherent stability and consistency in connection strength are impossible to replicate with systems that rely on numerous external, non-integrated components. By choosing the BFS Ringlock system, contractors are not just acquiring materials; they are investing in a proven engineering system designed for maximum productivity and safety compliance in today’s demanding high-performance construction environment.

Ringlock vs Cuplock Scaffolding

The primary distinction between the ringlock scaffolding system and Cuplock scaffolding lies in the connection node’s design and load-bearing efficiency. Cuplock utilizes a fixed bottom cup and a sliding top cup that secures up to four horizontal members using a captive blade end. While Cuplock is also a modular system and offers considerable speed advantages over tube and clamp, the Ringlock rosette connection is functionally superior for complex configurations and higher loads. The Ringlock rosette provides up to eight connections, enabling greater flexibility for diagonal bracing and complex angular structures without the need for additional, specialized fittings. Furthermore, the BFS Ringlock system often achieves higher structural ratings due to the more direct and concentric transfer of vertical loads through the standard, minimizing eccentricity at the joint. For heavy-duty ringlock load bearing scaffolding applications and geometrically challenging facades, Ringlock consistently proves to be the more robust and adaptable choice.

Ringlock vs Tube & Clamp Systems

The comparison between the ring lock scaffolding system and the traditional Tube & Clamp (or fitting) system highlights the evolution of scaffolding technology. Tube & Clamp requires two components (a tube and a fitting/coupler) for every single connection point, meaning every ledger and brace requires at least two separate couplers that must be manually torqued. This method is highly labor-intensive, slow, and dependent on the skill and diligence of the scaffolder to ensure consistent joint strength. The BFS Ringlock system, conversely, uses a single, integrated wedge for connection, reducing the number of connection components by over 80%. Moreover, Ringlock’s standards feature pre-set connection points, eliminating the need for measurement and plumb-line adjustments at every level, a major source of error and delay in Tube & Clamp setups. The result is a structure that is faster to erect, inherently safer due to standardized connections, and geometrically more reliable under high loads.

Quality Assurance, Surface Finish, and Safety Certifications

BFS Industries is committed to delivering the highest quality in every component of our ringlock scaffolding system, underpinned by a rigorous Quality Assurance (QA) program that controls every stage of the manufacturing process. All materials are sourced from certified suppliers and undergo stringent metallurgical testing to confirm the required yield and tensile strengths of the high-grade steel. Our fabrication facilities utilize advanced robotic welding and precise jigging to ensure every rosette is perfectly positioned and every component conforms to the required dimensional tolerances for seamless integration. The final protective layer—the hot-dip galvanized finish—is applied according to ISO 1461 standards, providing a thick, durable, and highly corrosive-resistant coating. This finish is critical, providing superior longevity compared to painted or pre-galvanized alternatives, directly reducing the maintenance expenditure for the owner.

Our dedication to safety is validated by a comprehensive suite of international safety certifications. The BFS ringlock scaffolding system is compliant with major global standards, including European Standard EN 12810/12811, Australian/New Zealand Standard AS/NZS 1576, and the American ANSI/SSFI standards. These certifications are not merely stamps; they represent independent, third-party verification of the structural analysis, load testing, and manufacturing quality of our system. For ringlock scaffold exporters like BFS Industries, providing fully certified systems is essential for smooth importation and immediate use on international construction sites. We provide full technical documentation and certification papers with every major order, giving our clients the confidence that they are utilizing a system that meets the highest standards of engineering and worker safety globally.

Why Choose BFS Industries for Ringlock Systems?

Choosing BFS Industries means partnering with a recognized leader in the global scaffolding ring lock system company landscape, one dedicated not just to manufacturing, but to the safety and efficiency of your projects. Our decades of experience in the scaffolding and formwork industry afford us a deep understanding of complex construction challenges, allowing us to deliver not just products, but engineered solutions. We leverage advanced manufacturing techniques to produce superior-quality, hot-dip galvanized ringlock scaffolding system components that maximize structural performance and minimize lifetime costs. Unlike many general suppliers, BFS Industries offers comprehensive project support, including initial engineering consultation, detailed material lists (BOMs), assembly training, and dedicated post-sale support.

Our global footprint and established network of distribution allow us to function efficiently as reliable ringlock scaffold exporters, delivering large volumes of high-quality material on time, anywhere in the world. We offer competitive pricing combined with uncompromising quality assurance, ensuring our clients receive the best possible value proposition. By integrating advanced logistics and maintaining substantial inventory levels, we minimize lead times, allowing contractors to mobilize quickly and stay on schedule. When you choose BFS Industries, you gain access to a partner whose commitment to innovation, quality, and comprehensive customer support ensures that your investment in the modular ringlock scaffolding system is the most secure and profitable decision for your construction needs.

Conclusion: Investing in the Future of Safe and Efficient Construction

The ringlock scaffolding system from BFS Industries is more than just a set of components; it is a meticulously engineered, safety-certified, and globally proven solution designed to enhance project efficiency, reduce labor costs, and ensure worker protection in the most challenging construction environments. By leveraging the superior strength of the rosette connection and the longevity of hot-dip galvanization, this system offers a significant technical and economic advantage over legacy scaffolding methods. We encourage project managers, procurement specialists, and engineers to explore the full capabilities of our system, particularly for high-rise, industrial, and heavy-duty shoring applications. Investing in the BFS Ringlock platform is an investment in the future—one that guarantees compliance, maximizes performance, and establishes a new benchmark for safety and modularity in the construction industry.

Frequently Asked Questions (FAQ) About Ringlock Scaffolding

What Is the Ringlock System Scaffold?

Ringlock scaffolding is a modular scaffolding system that uses a unique rosette (ring) locking mechanism to securely connect the vertical and horizontal components. This system is widely used in construction due to its versatility, strength, and quick assembly, making it ideal for complex and large-scale projects.

How does Ringlock scaffolding compare to traditional scaffolding?

Ringlock scaffolding is more efficient and secure than traditional scaffolding systems. Its rosette locking mechanism allows for faster and easier assembly and disassembly, while its robust design enables it to support heavy loads with excellent stability. Additionally, Ringlock scaffolding requires fewer components, making it more convenient to transport, store, and manage on construction sites.

Is Ringlock scaffolding suitable for all types of construction?

Yes, Ringlock scaffolding is highly versatile and can be used in a wide range of construction projects, from residential buildings to large-scale commercial and industrial sites. Its modular design and flexibility allow it to adapt easily to various building shapes, heights, and structural requirements.

Is Ringlock scaffolding more expensive than traditional scaffolding?

While the initial investment in Ringlock scaffolding may be higher than traditional systems, the savings in labor costs, faster assembly times, and the long-term durability of its components often make it a more cost-effective and efficient option in the long run.

How long does Ringlock scaffolding last?

Ringlock scaffolding is designed to be durable and long-lasting. With proper maintenance and care, it can be used for many years, offering a reliable and safe platform for construction workers on a variety of projects.