concrete slab formwork systems

Introduction

Concrete slab formwork systems represent the backbone of modern structural building, a critical investment that dictates a project’s safety, schedule, and final quality. For construction contractors, engineers, and procurement teams, selecting the right slab formwork system is not merely a purchasing decision—it is a strategic choice that fundamentally impacts profitability and reputation. BFS Industries, a global leader and trusted concrete slab formwork systems manufacturer, delivers innovative, high-performance solutions engineered to meet the demands of fast-paced, high-rise, and large-scale Concrete Construction. We understand that superior formwork for slab construction translates directly into reduced labor costs, accelerated cycle times, and an unparalleled level of finish quality. Partnering with BFS Industries means securing a competitive edge in an increasingly demanding market, ensuring your projects are built faster, safer, and to the highest standards. The long-term return on investment from a premium system far outweighs the minimal savings offered by inferior alternatives, establishing BFS Industries as the definitive choice for professionals seeking performance and reliability.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

Slab Formworks Category

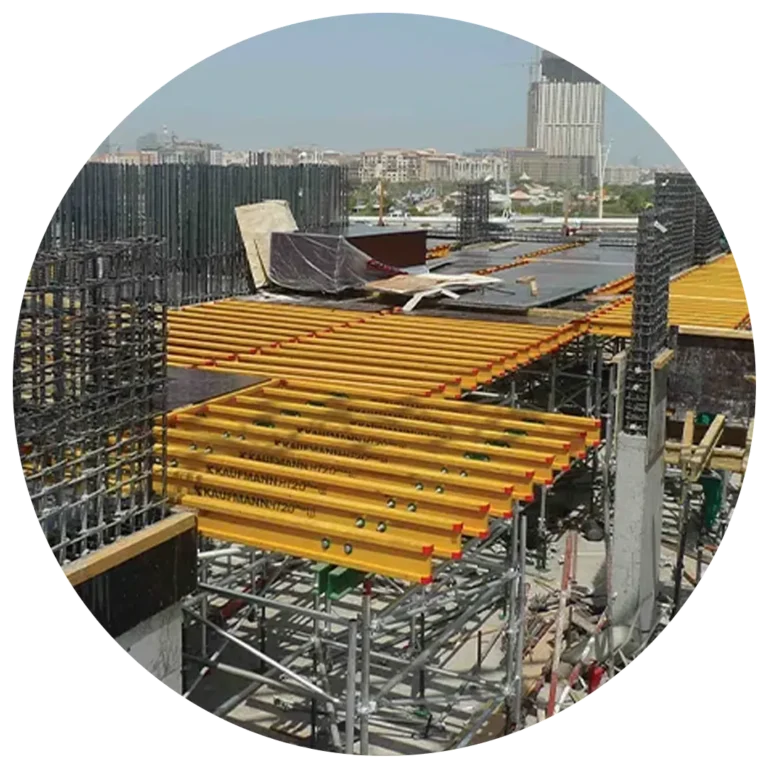

Advanced Concrete Slab Formwork Systems

The global construction industry operates under constant pressure to deliver projects faster while maintaining stringent quality and safety standards. Traditional methods, such as basic timber formwork for concrete slab, often introduce variables that lead to unpredictable labor consumption, excessive material waste, and inconsistent concrete finishes. This reliance on outdated or low-quality slab formwork can erode project margins, delay critical milestones, and even compromise site safety. Modern construction demands engineered solutions that offer predictability and repeatability, which is precisely why high-performance concrete slab formwork is essential for any forward-thinking firm.

The economic consequence of choosing substandard formwork of slab extends well beyond the initial purchase price. Inconsistent surface quality often necessitates costly, labor-intensive grinding and patching after the pour, leading to increased finishing costs and extending the project’s duration. Furthermore, dimensional inaccuracies in the slab can cause fit-up issues with subsequent trades like curtain wall installation or internal partitioning, resulting in expensive rework and potential liquidated damages due to project overruns. BFS Industries’ precision-engineered systems mitigate these financial risks entirely, delivering a near-perfect slab surface and true dimensions right out of the mold, proving that quality concrete slab formwork systems are an investment against future losses.

BFS Industries recognizes that efficiency is not a luxury; it is a necessity. Our advanced formwork of slab systems are designed to minimize the reliance on skilled carpentry and maximize the speed of assembly and disassembly. By utilizing lightweight yet robust materials and intuitive, modular designs, our systems drastically reduce the time spent on erection and stripping. Furthermore, the inherent stability and high load-bearing capacity of our steel slab formwork solutions provide enhanced safety for the entire site team, allowing project managers to execute complex slab formwork construction with absolute confidence and control, thereby safeguarding both personnel and project schedules.

BFS Industries: Redefining Slab Formwork Efficiency and Safety

BFS Industries has dedicated extensive resources to research and development, creating flexible slab formwork solutions that address the primary pain points of the construction sector. Our proprietary systems are not simply components; they are integrated, meticulously tested tools engineered for high-frequency reuse across multiple projects. This commitment to durability and quality ensures that every contractor receives a long-term asset, reducing lifetime costs associated with constant replacement and maintenance. Our comprehensive approach covers every detail, from the foundational structural design to the ergonomic stripping mechanism, delivering true value.

Our design philosophy centers on maximizing efficiency without sacrificing safety. Each slab formwork system undergoes rigorous testing to meet or exceed international safety standards, providing engineers and site managers with total assurance regarding load capacity and structural integrity. For any serious project manager, the choice of formwork for concrete slab is a decision that affects the entire project risk profile. By selecting a proven, certified system from a leading concrete slab formwork systems supplier like BFS Industries, you mitigate risk, streamline regulatory compliance, and ensure the highest possible level of worker protection across all phases of the concrete pour and cure.

Our modular philosophy is key to our systems’ success. We standardize component sizes (e.g., primary panels, fillers, and drop beams) to a high degree, which dramatically simplifies inventory management and logistics for the contractor. This standardization means fewer unique parts need to be tracked, transported, and stored, allowing crews to rapidly adapt to various slab configurations using the same core components. This interchangeability of our flexible slab formwork significantly reduces the possibility of site error, accelerates training for new personnel, and ultimately ensures that the right component is always available for the next phase of the slab formwork construction, minimizing delays and maximizing flow.

Maximizing Speed with Modular Steel Slab Formwork

The inherent strength and predictable geometry of steel slab formwork offer immense advantages over less durable alternatives. Our steel systems feature pre-engineered modules that lock together rapidly, eliminating the variable and time-consuming cutting, nailing, and adjusting associated with wooden formwork for slab. The standardized nature of our components allows crews to quickly learn and repeat the assembly process, significantly shortening cycle times for multi-story buildings and large commercial complexes where efficiency in slab shuttering is paramount.

By investing in high-quality metal slab formwork from BFS Industries, contractors unlock substantial labor savings. The speed of setup and dismantling dramatically reduces the overall man-hours required for the formwork phase. Moreover, the superior surface finish provided by steel often minimizes the need for extensive post-pour remedial work or finishing. This acceleration of the construction timeline is critical for meeting aggressive deadlines and achieving early handover, reinforcing the value proposition of choosing a premium, high-cycle slab formwork system that integrates seamlessly into your demanding construction schedule. Furthermore, the structural predictability of steel under heavy loads is vastly superior to wood. Steel maintains its engineered load capacity even after repeated exposure to concrete moisture and varying temperatures, whereas timber formwork for concrete slab can degrade or suffer micro-cracks, leading to unpredictable stress points. This inherent reliability is crucial for safety and for maintaining the integrity of the concrete structure during the critical curing process, offering unparalleled confidence to engineers responsible for structural stability.

The Cost-Benefit of Reusable Slab Formwork Solutions

For procurement teams and financial controllers, the move to reusable slab formwork is a clear path to improved bottom-line performance. While the initial investment in high-grade metal or modular systems may be higher than single-use timber, the return on investment through superior reuse cycles is undeniable. Our systems are built from high-strength alloys and treated for maximum durability, offering hundreds of uses with minimal degradation. This drastically reduces the per-use cost of the slab formwork compared to materials that must be discarded after only a few cycles.

The long-term cost savings generated by BFS Industries’ reusable slab formwork extend beyond material costs. Reduced construction waste also translates into lower disposal fees and a smaller environmental footprint, appealing to modern clients focused on sustainability. Our focus on precision engineering ensures that even after numerous uses, the components maintain their exact dimensions and structural integrity, guaranteeing consistent, high-quality results for every concrete slab formwork pour. Choosing durability is not just good business; it’s a commitment to efficiency and environmental responsibility.

To truly understand the value, consider the full life-cycle cost analysis. BFS Industries’ metal slab formwork requires negligible maintenance—a simple cleaning process is typically all that is needed. In stark contrast, wooden formwork for slab requires constant inspection, repair of splintered edges, and replacement of damaged sections, incurring continuous hidden labor and material costs. Moreover, our high-grade steel systems retain significant residual value, acting as a capital asset that can be sold or redeployed with minimal depreciation after a project is complete, fundamentally shifting the cost model from an expense to an investment.

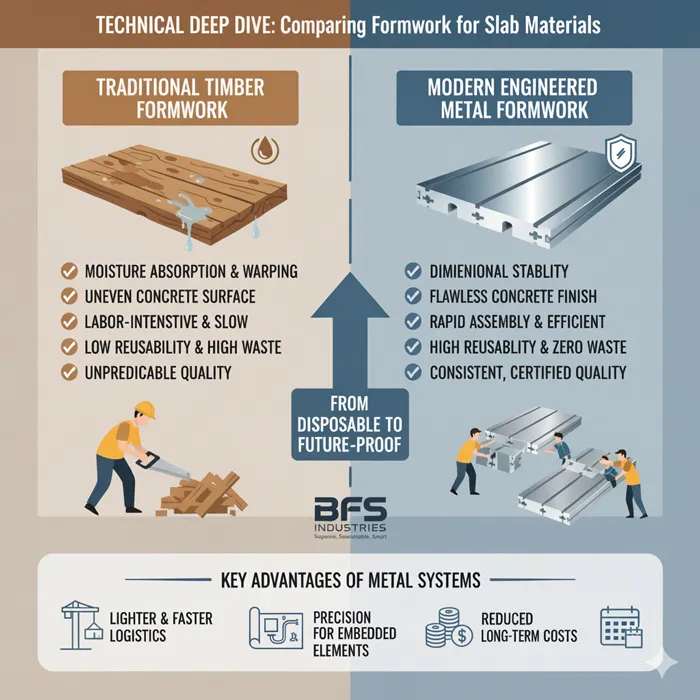

Technical Deep Dive: Comparing Formwork for Slab Materials

Understanding the material science behind slab formwork is key to making an informed procurement decision. The materials used directly influence the system’s weight, lifespan, ease of handling, and the quality of the resulting concrete surface. BFS Industries provides expertise in a range of materials, but we strongly advocate for our engineered metal systems as the superior, future-proof option. This detailed comparison will help construction professionals fully appreciate the strategic shift from traditional methods to advanced modular slab formwork systems designed for modern productivity.

When considering formwork for slab projects, factors like moisture absorption, dimensional stability, and resistance to damage are critical. For instance, while widely available, timber formwork for concrete slab is highly susceptible to swelling and warping when exposed to wet concrete and the elements. This instability directly compromises the flatness and alignment of the finished slab, requiring costly rectifications. Conversely, our engineered formwork maintains its shape precisely, ensuring every concrete slab formwork systems pour meets the tightest tolerances required by contemporary architectural and engineering specifications.

Beyond standard metallic surfaces, BFS Industries offers specialized contact surfaces tailored for specific architectural requirements. This includes using high-density phenolic resin coatings on formwork panels where an exceptionally smooth, non-porous, and water-resistant surface is needed to achieve a ‘fair-faced’ concrete finish. These specialty surfaces are integral to our flexible slab formwork offering, allowing architects and engineers to specify unique aesthetic qualities without compromising the speed or structural integrity provided by the underlying steel slab formwork structure. We provide the tools to elevate the concrete finish from a purely structural element to a key feature of the final building design.

From Timber Formwork for Concrete Slab to Modern Metal

The history of slab formwork construction is rooted in the use of wood, a material that, while accessible, presents significant limitations in a high-efficiency environment. Timber formwork for concrete slab requires substantial manual labor for cutting, assembly, and on-site modification, introducing variables and human error into the process. The repetitive nature of this work is slow and often results in a porous or uneven surface finish, necessitating additional time and cost for grinding or leveling.

BFS Industries offers a compelling alternative: modular metal slab formwork that is designed for minimal setup and maximum reusability. Our systems feature components pre-cut and pre-finished in our state-of-the-art facilities, eliminating the need for costly on-site fabrication and reducing material waste to almost zero. This shift from labor-intensive, disposable wooden formwork for slab to highly efficient, capital-intensive reusable slab formwork is the definitive sign of a contractor serious about optimizing project delivery and achieving best-in-class results in Concrete Construction.

The logistical advantages of switching to metal slab formwork are profound. Unlike heavy timber materials that require considerable crane time and dedicated labor for movement across the site, our lightweight aluminum and galvanized steel panels significantly reduce the load on tower cranes, freeing up critical lifting capacity for other trades. Furthermore, the compact, stackable design of our modular components means fewer trucks are required for transport and storage, resulting in reduced site congestion, lower fuel costs, and fewer disposal trips—all critical factors in reducing the total operational expense of slab formwork construction.

Why Metal Slab Formwork Surpasses Traditional Wooden Formwork for Slab

The choice between traditional wooden formwork for slab and modern metal slab formwork comes down to predictability and longevity. Wood naturally degrades with moisture, and its physical properties are inconsistent, leading to constant variance in load-bearing capacity and component life. This lack of reliability poses inherent risks on large structures where stability and consistent performance are non-negotiable requirements for successful slab formwork construction.

In contrast, BFS Industries’ metal slab formwork is manufactured under strict quality controls, offering guaranteed strength, durability, and a flawless concrete contact surface. The smooth, non-porous finish of the metal eliminates the grain imprints and surface imperfections commonly left by wood, resulting in a superior aesthetic and structural finish straight out of the form. For high-profile projects where the exposed concrete is part of the final design, our metal slab formwork provides the quality and certainty that simply cannot be achieved with traditional timber formwork for concrete slab systems.

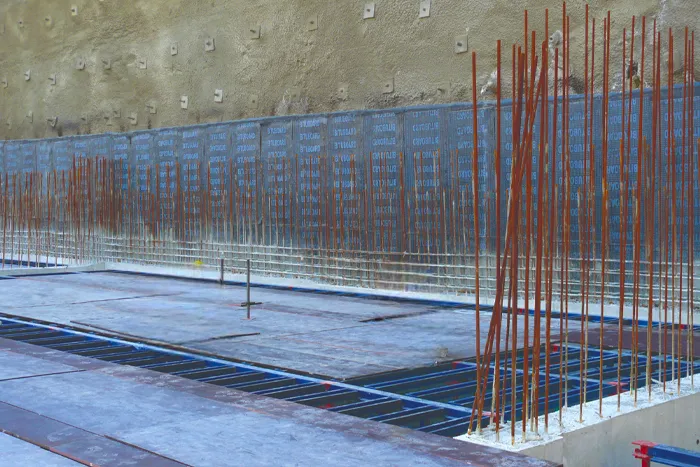

A less obvious, but equally crucial, advantage lies in the integration of embedded elements. Modern slabs often contain complex networks of electrical conduits, plumbing pipes, and precise rebar cage arrangements. Our steel slab formwork systems feature dedicated, repeatable attachment points and pre-punched sections that allow for secure and highly accurate placement of these embedded components. This level of precision is virtually impossible to replicate consistently with site-fabricated wooden formwork for slab, where manual cutting and measurement inevitably lead to variations and compromise the structural integrity or serviceability of the final concrete element.

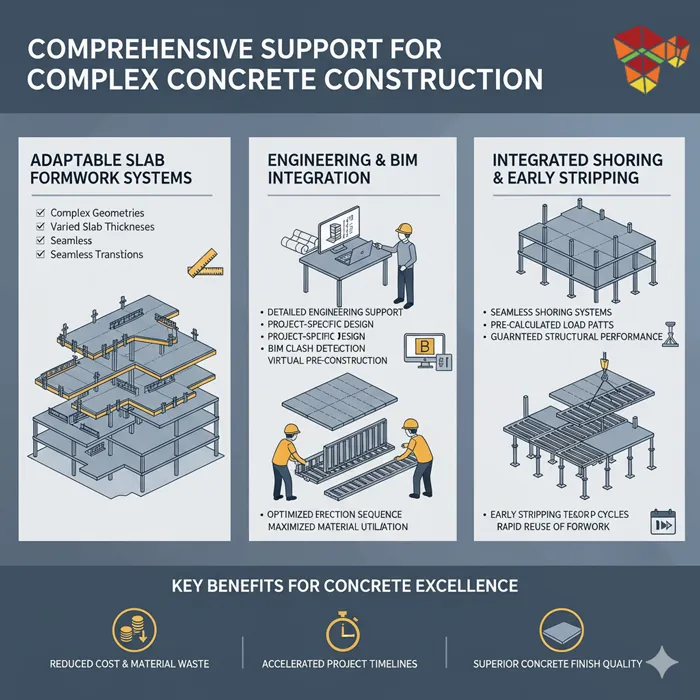

Comprehensive Support for Complex Concrete Construction

Modern construction projects are rarely simple, often involving complex geometries, varied slab thicknesses, and demanding timelines. The requirement for a truly adaptable concrete slab formwork system is greater than ever before. BFS Industries designs its products to be flexible and highly compatible, allowing seamless transition between different structural elements and phases of work. This adaptability is critical for engineers and project managers facing the challenge of constructing intricate, multi-level designs requiring coordinated use of different slab formwork solutions.

Our commitment extends beyond providing components; we offer detailed engineering support and project-specific design consultations. Before a single piece of slab formwork leaves our facility, our engineers work directly with your team to model the optimal solution for your specific site challenges. This ensures that the supplied formwork of slab maximizes material utilization, minimizes component counts, and optimizes the erection sequence. This upfront planning is a core benefit of partnering with a professional concrete slab formwork systems company like BFS Industries, guaranteeing the most efficient and cost-effective slab formwork details are integrated into your project execution plan.

We actively leverage Building Information Modeling (BIM) to integrate our slab formwork system into your project’s virtual environment long before physical construction begins. Our in-house BIM specialists create detailed, constructible models that optimize the formwork layout, detect potential clashes with rebar or mechanical, electrical, and plumbing (MEP) systems, and simulate the entire erection and stripping sequence. This virtual pre-construction validation eliminates guesswork, reduces expensive field modifications, and provides the project team with crystal-clear slab formwork details and assembly plans, leading to faster, more accurate execution.

Seamless Integration with Shoring Scaffolding Systems

Successful concrete pouring is a unified process that relies heavily on the synchronized performance of both the slab formwork and the underlying support structure. BFS Industries excels in providing integrated solutions where our concrete slab formwork systems are perfectly matched to our advanced shoring scaffolding systems. This synergy eliminates compatibility issues, simplifies planning, and ensures that the total system—from the ground support to the contact surface—operates as one cohesive, load-bearing unit.

This deep integration offers project managers a streamlined procurement and execution path. By sourcing both the formwork for concrete slab and the shoring scaffolding systems from a single, expert concrete slab formwork systems manufacturer like BFS Industries, you benefit from pre-calculated load paths, standardized assembly instructions, and guaranteed structural performance. Our sales-oriented approach ensures that we don’t just sell products; we sell complete, optimized construction solutions that save time and enhance safety during the critical concrete curing phase, a significant advantage in large-scale Concrete Construction.

A key benefit of this seamless design is the facilitation of the ‘early stripping’ or ‘flying formwork’ technique. Our integrated formwork and shoring components are engineered with release mechanisms that allow the slab formwork contact panels to be removed safely after the concrete has achieved minimal strength, while leaving a temporary propping system (reshores) in place to support the full curing load. This enables the rapid reuse of the expensive formwork panels for the next level above, accelerating the floor-to-floor cycle time, which is the single biggest determinant of speed in high-rise Concrete Construction.

Achieving Excellence in Concrete Construction

Excellence in Concrete Construction requires more than robust material; it demands a strategic approach to planning, execution, and material management. Our concrete slab formwork systems are designed to be a centerpiece of this strategy, enabling faster cycle times and providing consistently high-quality results. The high dimensional accuracy and rigidity of our metal slab formwork directly contribute to a reduction in concrete consumption by minimizing over-pour and waste, which provides a tangible cost-saving benefit for contractors and clients alike.

BFS Industries’ expertise in slab formwork construction allows us to guide our clients toward best practices that yield maximum return. From selecting the optimal panel size for a specific project to designing highly efficient slab shuttering sequences, we offer the technical know-how that transforms good projects into exceptional ones. Our solutions are used globally, demonstrating our capability to handle the most demanding specifications and environmental conditions, confirming our status as a premium global concrete slab formwork systems exporter focused on delivering concrete excellence every time.

Our engineering capability extends far beyond standard flat slabs. We provide specialized flexible slab formwork for intricate structural elements such as drop panels, column heads, waffle slabs, and band beams, all crucial for large-span or post-tensioned Concrete Construction. These specialized forms are often customized, yet they retain the modularity and quick-strip features of our standard systems. This means that even the most architecturally challenging slab formwork details can be executed with production-line efficiency, ensuring that complex designs do not translate into significant time or cost penalties on site.

Maximizing Site Efficiency: Speed, Safety, and Quality

The competitive edge in construction today is defined by operational efficiency—the ability to move quickly and safely without compromising the final product. BFS Industries’ concrete slab formwork systems are explicitly engineered to enhance this efficiency through rapid-assembly features, superior component longevity, and simplified handling. Our systems are the choice of leading contractors because they understand that productivity on site begins with the quality of the tools they use, and our flexible slab formwork is second to none in ease of use and adaptability.

We place a major emphasis on the training and deployment of our slab formwork systems. For large projects, this includes on-site consultation and support to ensure that your teams achieve peak assembly speeds immediately. This holistic support model differentiates BFS Industries from commodity providers. We ensure your investment in our advanced reusable slab formwork is realized rapidly through streamlined processes and reduced learning curves, effectively minimizing non-productive downtime and maximizing the speed at which you can complete the formwork of slab tasks. This focus on site performance is the cornerstone of our sales proposition.

One of the most critical safety benefits of our pre-engineered systems is the reduction of site hazards caused by ‘ad-hoc’ modifications. When working with timber formwork for concrete slab, crews are constantly cutting, nailing, and adjusting materials on scaffolds, creating trip hazards, falling debris, and inconsistent structural integrity. Our standardized, modular steel slab formwork eliminates the need for this precarious site fabrication. The components arrive ready-to-use, minimizing elevated work and maximizing the safety of the entire assembly process, ensuring full compliance with OSHA and other stringent regional safety requirements.

Design Innovation: Reducing Component Count and Labor

A key feature of our advanced concrete slab formwork systems is the intelligent reduction in the total number of unique components required for any given design. Traditional slab formwork can require dozens of different small pieces, leading to confusion, slow assembly, and high component loss. BFS Industries’ modular systems utilize fewer, more multi-functional components. This simplification significantly reduces labor time and decreases the likelihood of assembly errors, directly benefiting your schedule and budget for complex slab formwork details.

Furthermore, our commitment to innovation extends to the materials themselves. By using lightweight, high-tensile strength alloys for our metal slab formwork, we reduce the physical strain on workers and often eliminate the need for mechanical lifting equipment during certain phases of the slab formwork construction. This ergonomic advantage is a major selling point for safety-conscious project managers, demonstrating that choosing a leading concrete slab formwork systems company can dramatically improve both productivity and on-site well-being.

Our patented ‘drop-head’ system is a prime example of labor-saving innovation built into our reusable slab formwork. This mechanism allows a single crew member to lower the formwork panels rapidly without needing to disassemble the entire shoring tower, effectively separating the stripping process from the reshoring process. This innovation not only drastically cuts the labor time required for stripping but also protects the panels from damage during removal, extending their service life exponentially. Such design features showcase our understanding of on-site ergonomics and operational efficiency, driving unmatched productivity in slab shuttering.

The BFS Advantage: Global Supply Chain and Quality Assurance

When selecting a long-term concrete slab formwork systems supplier, global reach, manufacturing capability, and stringent quality control are paramount. BFS Industries stands out as a world-class concrete slab formwork systems manufacturer with a robust, integrated supply chain that spans continents, including substantial operations supporting the supply of high-quality china concrete slab formwork systems. This global presence ensures reliable, high-volume delivery capacity, crucial for contractors undertaking multiple large-scale projects simultaneously.

Our quality assurance is built on total control over the manufacturing process. From raw material sourcing to final finishing, every component of our slab formwork system is meticulously inspected and tested. We welcome stringent quality audits and certification requirements, offering our clients complete transparency and confidence in the product they are receiving. For procurement teams looking for a reliable, OEM concrete slab formwork systems partner who guarantees product consistency and compliance with the most rigorous international standards, BFS Industries is the logical and superior choice.

To guarantee this consistency globally, BFS Industries maintains compliance with major international standards, including ISO 9001 for Quality Management and region-specific certifications such as the European EN standards and various American Society for Testing and Materials (ASTM) requirements. Every component of our metal slab formwork is traceable back to its source batch and material certificate. This rigorous documentation ensures that when you purchase from BFS Industries, you are not just getting a product; you are receiving a fully certified, compliant, and documented concrete slab formwork system that will satisfy the strictest regulatory body on any project site, anywhere in the world.

Global Partnership: A Reliable Concrete Slab Formwork Systems Supplier

In today’s interconnected construction market, consistency of supply, regardless of the project location, is a non-negotiable requirement. As a leading concrete slab formwork systems supplier, BFS Industries maintains extensive stock and production agility, ensuring that project delays due to material shortages are a thing of the past. Our logistics network is optimized for fast, efficient delivery to any site, whether you need standard steel slab formwork or highly customized flexible slab formwork. We understand the cost of delays and are structured to prevent them.

Our deep experience as concrete slab formwork systems exporters means we are experts in navigating the complexities of international trade, documentation, and on-site delivery requirements. We simplify the procurement process for global construction giants, acting as a single point of accountability for all formwork for slab and shoring scaffolding systems needs. By partnering with BFS Industries, you gain access to a reliable, scalable supply of high-quality metal slab formwork and expert support, positioning your firm for competitive success in any market.

We offer comprehensive logistics management that includes handling customs clearance, managing local import duties, and providing documentation in compliance with local regulatory bodies, reducing the administrative burden on your procurement team. Furthermore, for clients engaged in multi-year international projects, we offer transparent strategies for managing currency fluctuations and guaranteeing supply chain continuity, ensuring the cost of your concrete slab formwork systems remains predictable and protected against external economic volatility. This end-to-end service is essential for complex, cross-border Concrete Construction projects.

Why Partner with BFS Industries, the Leading Manufacturer

Choosing BFS Industries means choosing a comprehensive partner, not just a vendor. As a premier concrete slab formwork systems manufacturer, we offer unparalleled technical consultation, customized system design, and the assurance of a product engineered for peak performance and longevity. We are dedicated to providing the most advanced, safest, and most cost-effective slab formwork systems available on the market today, helping you move away from inefficient methods like wooden formwork for slab and into the profitable era of engineered construction.

Our commitment to innovation ensures that our clients are always equipped with the latest advancements in slab formwork details and technology. We continuously integrate feedback from construction contractors and project managers globally to refine our products, solidifying our reputation as a trusted concrete slab formwork systems company. Whether your next project requires robust steel slab formwork for a high-rise core or highly adaptable reusable slab formwork for multi-story residential buildings, BFS Industries provides the quality, experience, and scale you need to succeed.

Ultimately, the choice of a concrete slab formwork system is a reflection of your company’s commitment to quality and efficiency. When comparing the perceived initial cost of our premium systems against the long-term, total value of ownership—including minimized rework, accelerated cycle times, reduced labor hours, lower waste disposal fees, and extended product lifespan—the return on investment from BFS Industries is unmatched. We don’t just supply equipment; we supply the foundation for your next profitable and successful construction project. Trust the proven advantage of a global leader.

Final Decision: Secure Your Future with BFS Industries

The decision to upgrade your concrete slab formwork systems is the decision to upgrade your construction capability, safety profile, and profitability. For construction contractors, engineers, and procurement specialists dedicated to achieving maximum efficiency and the highest quality in Concrete Construction, the choice is clear: BFS Industries offers the superior technology, integrated solutions, and global support necessary to outperform the competition. Our advanced slab formwork systems drastically reduce labor requirements, accelerate cycle times, and guarantee the precision and finish quality your demanding projects require. We eliminate the unpredictability of traditional methods and provide the certainty of engineered excellence. Do not let outdated slab shuttering systems compromise your project deadlines or your reputation. Take the critical step towards unparalleled construction efficiency today. We strongly encourage you to contact BFS Industries directly to discuss your specific project needs, request a detailed quote, or schedule a consultation with one of our formwork engineering specialists. Call us or reach out via our contact form now to secure the strategic advantage that only a leading global concrete slab formwork systems supplier can provide, and let us partner with you to engineer your project’s success from the ground up.

FAQs on Slab Formwork

What is slab formwork?

Slab formwork refers to the temporary structures used to shape and support concrete slabs during the curing process. It helps ensure that the concrete maintains the desired shape and dimension until it hardens sufficiently.

Why is slab formwork important in construction?

Slab formwork is critical because it:

- Provides support for freshly poured concrete slabs until they gain enough strength.

- Ensures accurate dimensions and smooth finishes.

- Helps manage the distribution of loads during the curing process.

What are the different types of slab formwork?

Common types of slab formwork include:

- Timber Formwork: Cost-effective and easy to work with, often used for small projects.

- Steel Formwork: Durable, reusable, and suitable for larger projects.

- Aluminum Formwork: Lightweight and easy to handle, ideal for repetitive projects.

- Plastic Formwork: Often used for smaller applications and has good resistance to chemical damage.

- Modular Formwork: Pre-fabricated units that can be quickly assembled on-site.

How is slab formwork installed?

Installation of slab formwork typically involves:

- Planning and designing the formwork layout.

- Preparing and gathering necessary materials and tools.

- Setting up the formwork according to the design specifications.

- Ensuring all components are securely fastened and leveled before concrete pouring.

What key factors should be considered for slab formwork?

Key factors include:

- The load-bearing capacity of the formwork.

- Accessibility for cleaning and maintenance.

- The ability to withstand weather conditions.

- Ease of assembly and disassembly.