Infill Beam & Deck Infill Systems by BFS Industries

Introduction

In today’s fast-paced construction industry, time and cost overruns in suspended slab projects can quickly impact profitability. Traditional formwork systems often add complexity, increase labor demands, and slow progress. BFS Industries redefines this process with precision-engineered infill beam and deck infill systems that accelerate your workflow, improve safety, and ensure a superior concrete finish.

Our advanced deck infill solution, centered around high-performance infill beams, offers a smarter, reusable, and highly efficient alternative for modern slab construction. Designed through extensive research and real-world testing, it delivers unmatched reliability and adaptability.

With BFS Industries, you gain more than a product — you gain a partner in concrete construction innovation. We help you build faster, smarter, and with greater quality, ensuring every project stays on schedule and within budget.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

The BFS Infill Beam and Deck Infill System

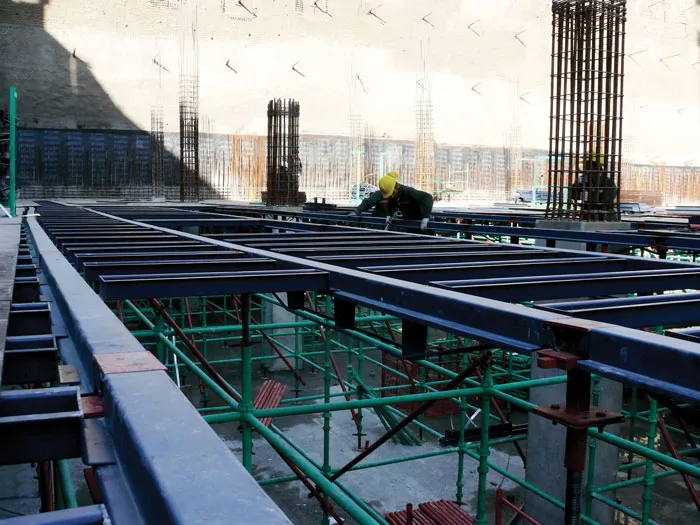

At the heart of any high-performance formwork solution lies a combination of intelligent design, superior materials, and precision manufacturing. The BFS Industries Infill Beam and Deck Infill System embodies these principles, offering a cohesive and meticulously engineered solution for modern infill slab construction. Unlike fragmented systems that require extensive on-site modification and skilled labor for assembly, our system is designed for seamless integration, minimizing guesswork and maximizing productivity. Each component, from the primary decking beams to the secondary infill beams, is optimized to work in concert, creating a secure and dimensionally accurate platform for concrete pouring. This holistic approach ensures that every square meter of your formwork is supported with calculated precision, eliminating inconsistencies and enhancing the overall structural integrity of the final slab, making it an ideal choice for projects demanding the highest standards of quality and performance.

Understanding the core components reveals the ingenuity of the system. The primary decking beams establish the main structural grid, while the infill beam serves as a crucial secondary member, strategically placed between the primary beams to reduce the span of the plywood or formwork panels. This simple yet brilliant design allows for the use of standard-sized plywood sheets, drastically reducing cutting, waste, and the associated labor costs. It ensures a consistently flat and level soffit, which translates to a superior concrete finish and minimizes the need for costly and time-consuming remedial work like grinding or patching. This meticulous attention to detail and functionality is what distinguishes BFS Industries as a leader among beam and slab formwork factories, as we deliver a system that is not only strong and reliable but also intelligently designed to save you time and money at every stage of the construction process.

Understanding the Role of the Infill Beam

The infill beam is the unsung hero of modern slab decking systems, a specialized component engineered to perfect the formwork support grid. Its primary function is to act as an intermediate support for the formwork surface, typically plywood, between the main decking beams. By effectively halving the unsupported span, the infill beam prevents the plywood from sagging under the immense weight of wet concrete, a common issue that can lead to an uneven slab soffit and potential structural imperfections. This ensures a uniformly flat surface, which is critical for achieving architectural specifications and reducing post-pour finishing costs. The strategic placement of infill beams creates a more robust and denser support matrix, distributing the load more evenly across the entire formwork structure and down to the shoring below, thereby enhancing the overall safety and stability of the temporary works.

At BFS Industries, our infill beams are designed for maximum efficiency and ease of use. Manufactured from high-strength, lightweight steel, they are easy for operatives to handle and position, significantly speeding up the formwork erection process. The design incorporates a wide top flange, providing a generous landing area for the plywood sheets, which simplifies placement and helps to seal the joints, preventing grout loss. This feature eliminates the need for complex and wasteful timber infill strips, a common requirement in less advanced systems. The integration of our decking beam and infill beam components creates a comprehensive system that is both intuitive for construction crews and highly effective in producing high-quality light industrial slabs and complex commercial floor systems with unparalleled consistency and speed.

Our Comprehensive Deck Infill Solution

A truly effective formwork system is far more than the sum of its parts. The BFS Industries deck infill solution is a complete, fully integrated system engineered to provide a comprehensive answer to the challenges of suspended slab construction. It begins with our robust primary decking beams, which are designed for optimal strength-to-weight ratios, allowing for wider grid spacing and reducing the total number of vertical supports required. This not only cuts down on material costs but also creates a less cluttered and safer working environment below the deck. The system’s genius lies in the synergy between these primary beams and our precision-manufactured infill beams. This combination allows for a highly adaptable grid that can be configured to suit virtually any slab thickness, bay size, or geometric layout, providing engineers and contractors with ultimate design flexibility.

This adaptability is further enhanced by compatibility with various advanced formwork techniques, including systems analogous to flipper deck formwork, which facilitate early striking. This allows for the removal of the decking panels and infill beams for reuse on subsequent floors, while leaving the primary beams and shoring in place to support the curing slab. This process can dramatically shorten floor-to-floor cycle times, a critical factor in the profitability of multi-story construction projects. Our comprehensive deck infill solution also includes intelligently designed drop heads and support components that ensure rapid, secure assembly and disassembly. As one of the industry’s leading beam slab formwork factories, BFS Industries provides a holistic system that is meticulously engineered to accelerate your project, improve quality, and maximize the return on your investment.

Versatile Applications Across the Construction Spectrum

The true measure of a superior formwork system is its ability to adapt and excel across a diverse range of construction projects, from straightforward structures to complex architectural marvels. The BFS Industries Infill Beam and Deck Infill System is engineered for precisely this kind of versatility. Its modular design and inherent adaptability make it the ideal choice for a wide array of applications, ensuring that no matter the project’s scale or complexity, you have a reliable and efficient solution at your disposal. This system is not a one-size-fits-all product but a dynamic tool that can be configured to meet the specific demands of each unique structure. This flexibility ensures that contractors and developers can standardize on a single, high-performance system for their entire portfolio, simplifying logistics, training, and inventory management while consistently achieving superior results.

The practical applications of our infill slab formwork system are vast and varied. It has been proven time and again in the construction of high-rise commercial office buildings, luxury residential towers, sprawling shopping malls, and critical public infrastructure like hospitals and universities. The system’s ability to create large, open spans with minimal shoring makes it particularly well-suited for projects like multi-story parking garages, where unobstructed space is a key design requirement. Furthermore, its capacity to support heavy loads makes it an excellent choice for the construction of light industrial slabs in warehouses, manufacturing facilities, and data centers, where floor performance is critical. BFS Industries provides a single, cohesive system that empowers construction professionals to tackle any challenge with confidence, delivering quality and efficiency on every project.

High-Rise Commercial and Residential Towers

In the competitive world of high-rise construction, speed is paramount. The ability to complete floor cycles quickly and efficiently translates directly into earlier project completion dates and significant cost savings. The BFS deck infill system is purpose-built for the repetitive nature of multi-story buildings. Its lightweight components and intuitive assembly process allow crews to erect and dismantle the formwork with remarkable speed, dramatically shortening the time required for each concrete pour. For a 40-story tower, shaving just one or two days off each floor cycle can result in finishing the project months ahead of schedule. The system’s design, which often allows for early striking of the infill beams and decking panels, is a game-changer, allowing these components to be “flown” to the next level while the slab continues to cure, maximizing material utilization and workflow efficiency.

Furthermore, the quality of the finished concrete soffit is a major consideration in commercial and residential buildings, where exposed ceilings or direct-applied finishes are common. Our infill beam system ensures a consistently flat and smooth surface, minimizing the need for expensive and labor-intensive plastering or grinding. This not only saves money but also contributes to a higher standard of finish throughout the building. The system’s inherent safety features, providing a stable and fully decked working platform, also reduce the risk of accidents, a critical factor on a busy high-rise site. For developers and contractors specializing in vertical construction, the BFS system offers a clear path to faster, safer, and more profitable projects, making it the definitive choice for infill slab construction at any height.

Industrial Facilities and Warehouses

The construction of industrial facilities, warehouses, and logistics centers presents a unique set of challenges, particularly concerning the floor slab. These structures demand robust, durable, and perfectly level surfaces capable of withstanding the rigors of heavy machinery, high point loads from racking systems, and constant forklift traffic. The BFS Infill Beam and Deck Infill System is ideally suited for creating high-performance suspended light industrial slabs. The system’s ability to provide a rigid and unyielding support platform for the wet concrete is critical in achieving the stringent floor flatness (FF) and floor levelness (FL) numbers required in modern industrial applications. A high-quality slab reduces wear and tear on equipment, improves operational safety, and increases the overall efficiency of the facility.

Moreover, the vast, open spaces typical of industrial buildings require a formwork system that can create large, uninterrupted bays with minimal vertical shoring. Our system, combining high-strength primary decking beam and infill beam components, is engineered to maximize spans, thereby reducing the number of props or scaffolding towers needed. This not only accelerates the formwork installation but also provides clearer, safer access for other trades to work concurrently below the deck. The reusability and durability of our steel components also offer a significant advantage over traditional timber-based systems, which degrade over time and contribute to site waste. For industrial projects where performance and longevity are non-negotiable, the BFS system provides the ideal foundation for success.

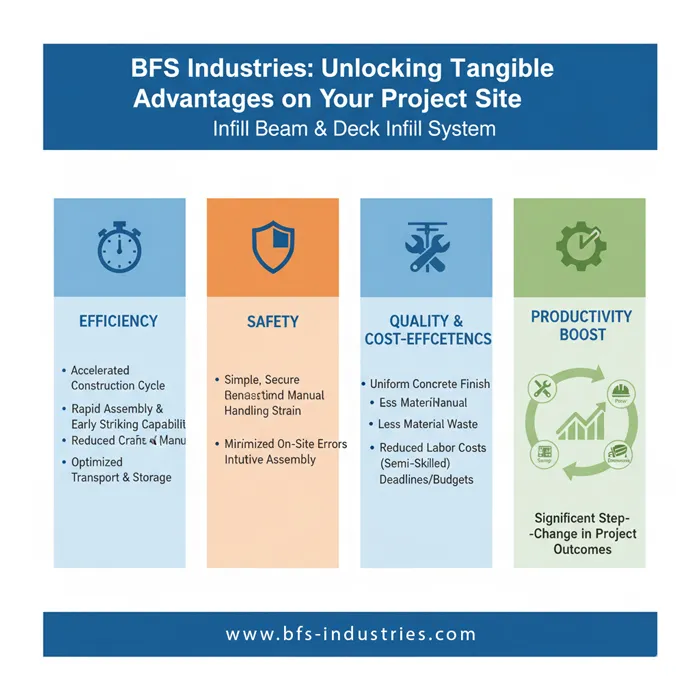

Unlocking Tangible Advantages on Your Project Site

Adopting an advanced formwork system is a strategic decision that should yield tangible, measurable benefits on the ground. The BFS Industries Infill Beam and Deck Infill System is engineered to deliver precisely that, moving beyond theoretical advantages to provide real-world improvements in efficiency, safety, quality, and cost-effectiveness. Choosing our system means investing in a solution that positively impacts nearly every aspect of your slab construction process, from the initial setup to the final concrete finish. These advantages are not marginal; they represent a significant step-change in productivity and project outcomes, enabling construction professionals to meet tighter deadlines and stricter budgets without compromising on quality or safety. Our system is designed by engineers who understand the daily pressures of a construction site and have focused on creating practical solutions to common industry problems.

The core benefits of the BFS system are immediately apparent from the moment it arrives on site. The lightweight, modular components are designed for manual handling, reducing reliance on crane time for all but the largest sections. Assembly is intuitive, with simple, secure connections that can be made by semi-skilled labor, reducing training time and minimizing the potential for errors. This speed of erection is matched by the efficiency of the dismantling process, especially in early-striking configurations. The result is a dramatic acceleration of the entire construction cycle. These on-site efficiencies are complemented by logistical advantages; the components are stackable and designed for optimized transport, reducing shipping costs and minimizing the storage footprint required on a congested project site.

Drastic Reduction in Erection and Stripping Times

Time is the most valuable currency in construction, and our deck infill system is designed to save you a significant amount of it. The entire system is predicated on the principle of efficiency. Unlike traditional timber-and-plywood systems that require extensive on-site measuring, cutting, and nailing, the BFS system utilizes standardized, interlocking components. A small, well-organized crew can assemble a large area of formwork in a fraction of the time, as the placement of each infill beam and decking panel is predetermined by the system’s grid logic. This systematic approach eliminates the guesswork and variability associated with conventional methods, leading to predictable and consistently fast erection cycles. This speed allows for earlier concrete pours, which in turn accelerates the entire project schedule.

The time savings are equally dramatic during the stripping phase. The system is designed for rapid and safe dismantling. In early-striking applications, specially designed drop heads allow the main support grid to be lowered by a few inches, releasing the plywood panels and infill beams for removal without disturbing the primary shoring supporting the curing infill slab. This means that a single set of decking components can be used to construct multiple floors in rapid succession, a process that is simply not possible with traditional formwork. This ability to cycle formwork materials faster is a key driver of profitability on multi-story projects, drastically reducing the total amount of equipment required on site and maximizing the return on investment for the contractor.

Superior Concrete Finish and Quality

The quality of the final concrete finish is a critical benchmark for any construction project, directly impacting aesthetic appeal, client satisfaction, and follow-on trade costs. The BFS Infill Beam and Deck Infill System is engineered to produce a superior, Class 1 soffit finish, pour after pour. The system’s rigidity and the precise placement of each infill beam create an exceptionally stable and flat platform. This prevents the plywood from deflecting under the heavy load of wet concrete, eliminating the subtle waves and undulations that are common with less robust systems. The result is a smooth, level ceiling that often requires no remedial work, allowing for direct application of paint or textured finishes and significantly reducing the time and expense associated with plastering or grinding.

This commitment to quality extends to the very design of our components. The wide top flange on our infill beams provides excellent support for the edges of the plywood sheets, creating tight, sealed joints. This meticulous design prevents grout leakage, a common problem that leads to unsightly fins and blemishes on the concrete surface that must be manually removed. By delivering a consistently high-quality finish, our system not only enhances the final product but also accelerates the subsequent phases of construction. Interior finishing trades can start their work sooner in a cleaner environment, contributing to an overall faster and more efficient project timeline. For construction professionals who take pride in the quality of their work, the BFS system is an invaluable asset.

The BFS Industries Partnership: More Than Just a Supplier

In an industry where project success hinges on the reliability of every component and the expertise of every partner, choosing a formwork supplier is a critical decision. At BFS Industries, we understand that you are not just buying steel; you are investing in a crucial part of your project’s success. That is why we have built our business around the concept of partnership. We position ourselves as more than just a name on a purchase order; we are your dedicated ally, committed to providing not only a superior infill beam and deck infill system but also the comprehensive support needed to ensure its optimal performance on your site. This partnership approach is woven into the fabric of our company, from our rigorous manufacturing standards to our responsive and knowledgeable technical support team.

We believe that our responsibility begins long before our products arrive at your gate and continues long after the concrete has cured. This philosophy sets us apart from other beam and slab formwork factories that may focus solely on volume and transactions. Our goal is to build long-term relationships based on trust, reliability, and shared success. We invest the time to understand the unique challenges and requirements of your project, allowing us to provide tailored solutions and expert advice that add real value. When you choose BFS Industries, you gain access to a wealth of industry experience and a team that is genuinely invested in helping you achieve your construction goals faster, safer, and more cost-effectively.

Unwavering Commitment to Quality and Durability

Quality is not just a buzzword at BFS Industries; it is the fundamental principle that guides our entire operation. Every infill beam, decking beam, and accessory that leaves our state-of-the-art manufacturing facility is a testament to this commitment. We begin by sourcing only the highest-grade steel from certified mills, ensuring that the raw materials possess the strength and resilience required for the demanding construction environment. Our manufacturing processes utilize advanced robotics for welding and precision-cutting, guaranteeing dimensional accuracy and consistency across every single component. This eliminates the on-site issues of ill-fitting parts that can plague lower-quality systems, ensuring a smooth and rapid assembly process for your crew.

To protect your investment and ensure a long service life, our components undergo a rigorous finishing process. We offer hot-dip galvanization, a superior corrosion protection method that provides a durable, resilient coating capable of withstanding years of harsh site conditions, transportation, and storage. This meticulous attention to manufacturing excellence and durability means our deck infill system can be reused dozens, if not hundreds, of times, delivering an exceptional return on investment over the life of the equipment. Our adherence to stringent international quality control standards gives you the peace of mind that you are using a system that is not only efficient but also built to last, providing reliable performance project after project.

Expert Engineering and On-Site Support

A superior product realizes its full potential only when it is applied correctly. That is why BFS Industries provides an unparalleled level of engineering and technical support to our clients. Our team of experienced formwork designers and engineers is available to collaborate with your project team from the earliest stages of planning. We can assist with developing the most efficient formwork layouts, creating detailed component lists, and providing crucial technical data to ensure seamless integration with your overall structural design. This proactive support helps to identify potential challenges before they arise, optimizing material usage and developing a clear, actionable plan for your site team, which is a cornerstone of effective infill slab construction.

This support extends directly to the project site. We offer comprehensive training for your crews, ensuring they understand the proper assembly, safety, and dismantling procedures for the infill beam system. Our field technicians can be available to supervise the initial erection, providing hands-on guidance to ensure the system is being used to its maximum potential. This commitment to knowledge transfer empowers your team to work more efficiently and safely, minimizing the learning curve and maximizing productivity from day one. This level of partnership—from initial design to final implementation—ensures you extract the maximum value from your investment in the BFS formwork solution, making us a true partner in your success.

Build Faster, Smarter, and Stronger with BFS Industries

In today’s demanding construction landscape, the choice of your formwork system is a strategic decision that reverberates throughout the entire lifecycle of your project. Opting for a solution that is slow, wasteful, or unreliable means accepting compromised timelines, inflated budgets, and unnecessary risks. The BFS Industries Infill Beam and Deck Infill System offers a definitive alternative—a path to superior efficiency, quality, and profitability. By integrating our advanced, reusable, and easy-to-use system into your workflow, you are not merely pouring concrete; you are building a reputation for excellence, reliability, and on-time delivery. Our system is the catalyst that enables you to take on more complex projects, bid more competitively, and ultimately grow your business with a foundation of proven performance.

The time to elevate your construction standards is now. Move beyond the limitations of traditional methods and embrace a solution engineered for the future of Concrete Construction. Let us show you how the strategic implementation of our infill beam technology can transform your floor slab construction process, turning a traditionally challenging phase into a streamlined, predictable, and highly efficient operation. We invite you to connect with our team of experts to discuss the specific needs of your upcoming project. Allow us to demonstrate the tangible benefits and significant return on investment that our premier concrete slab formwork systems can bring to your company. Contact our technical sales team today for a no-obligation consultation, detailed product specifications, or a customized quote. Build with confidence. Build with BFS Industries.

Frequently Asked Questions About Deck and Infill Beam Systems

What Is a Deck and Infill Beam System and How Does It Work?

A deck and infill beam system is a structural floor system that combines corrugated steel decking with infill beams (typically steel or concrete) and a reinforced concrete slab to create a robust, load-bearing platform. The steel deck serves as permanent formwork and tensile reinforcement, while infill beams distribute loads to primary beams or columns. This system leverages composite action between the steel and concrete to optimize load distribution, making it ideal for long-span applications in commercial and industrial buildings. The result is a lightweight, efficient structure that enhances construction speed and structural performance.

What Are the Key Advantages of Deck and Infill Beam Systems Compared to Traditional Slab Systems?

Deck and infill beam systems offer several advantages over traditional solid concrete slab systems. By using steel decking as permanent formwork, they reduce the volume of concrete needed, lowering material costs and dead loads. This leads to smaller foundation requirements and cost savings. Additionally, the system allows for longer spans without additional columns, providing greater architectural flexibility for open floor plans. The prefabricated nature of the steel deck and infill beams also speeds up installation, making it a cost-effective and time-efficient solution for modern construction projects.

What Are the Main Design Considerations for Deck and Infill Beam Systems?

Designing a deck and infill beam system requires careful attention to structural loads, span lengths, and deflection limits. Engineers must account for dead, live, and dynamic loads to ensure the system can support the intended use of the building. The span length influences the size and spacing of infill beams, with longer spans requiring deeper beams or additional reinforcement to control deflection. Integration with the reinforced concrete slab is also critical, requiring proper shear connectors and reinforcement detailing to achieve composite action and prevent cracking. Adherence to standards like AISC or Eurocode ensures safety and performance.

In What Types of Projects Are Deck and Infill Beam Systems Most Commonly Used?

Deck and infill beam systems are versatile and widely used in commercial, industrial, and residential construction. They are particularly popular in high-rise office buildings, retail centers, and warehouses due to their ability to support long spans and heavy loads while maintaining open floor spaces. The system is also compatible with precast and composite construction, making it suitable for modular or rapid-build projects. Additionally, it is often used in retrofitting projects to strengthen existing floors or adapt them to new loading requirements, showcasing its adaptability across various applications.

What Are the Common Challenges in Deck and Infill Beam Systems and How Are They Addressed?

Common challenges in deck and infill beam systems include vibration control and managing construction tolerances. Long spans can lead to floor vibrations, which may affect occupant comfort or equipment performance. Engineers mitigate this by optimizing beam stiffness, adjusting spacing, or incorporating damping systems. Construction tolerances are another concern, as misalignment of beams or decking can compromise structural integrity. This is addressed through precise installation techniques, such as laser leveling, and thorough coordination between design and construction teams to ensure material compatibility and proper integration of the composite deck system.