Multi Flex in Concrete Formwork

Introduction

Multi Flex in concrete formwork is a versatile, adjustable formwork system designed to streamline the construction of slabs, beams, and other structural elements. Unlike rigid traditional systems, Multi Flex offers unparalleled adaptability, allowing contractors and civil engineers to tackle complex geometries and diverse project requirements with ease. By combining modular components like beams, props, and panels, Multi Flex in concrete formwork ensures precision, speed, and cost-efficiency, making it a preferred choice in modern construction. This innovative system is particularly valued for its ability to adapt to varying slab thicknesses, irregular layouts, and challenging site conditions. Whether for residential, commercial, or industrial projects, Multi Flex in concrete formwork enhances productivity while maintaining structural integrity. Its reusable and adjustable design aligns with the industry’s push toward sustainable and fast construction techniques.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

Multi Flex – A Reliable Flexible Formwork Company

Multi Flex by BFS Industries represents the new generation of flexible slab formwork systems designed for precision, durability, and speed. As a trusted flexible formwork company, we specialize in providing high-quality solutions for both concrete slab and beam construction.

Our production facilities are equipped with advanced machinery to ensure consistent quality and dimensional accuracy in every component — from H20 beams and steel props to premium plywood panels. This makes BFS Industries not only a flexible formwork manufacturer but also a reliable supplier for contractors and developers seeking efficiency and long-term value.

Whether you need a flexible slab formwork company for large-scale commercial projects or a flexible formwork factory capable of customized solutions, Multi Flex delivers outstanding performance, reusability, and cost-effectiveness. Our systems are designed to reduce installation time, improve site safety, and ensure superior concrete finishes across all types of structures.

Evolution from Traditional to Flexible Formwork Systems

Historically, concrete formwork relied heavily on timber-based systems, which were labor-intensive and time-consuming to assemble. These traditional methods often lacked the flexibility needed for complex designs, leading to inefficiencies and higher costs. The advent of flexible formwork systems like Multi Flex marked a significant shift in construction practices. By introducing modular formwork and reusable components, Multi Flex systems have revolutionized the industry, offering contractors a solution that balances durability, adaptability, and ease of use.

The evolution to Multi Flex in concrete formwork reflects the construction sector’s demand for systems that reduce material waste, optimize labor, and accelerate project timelines. Today, it stands as a cornerstone of modern formwork technology, catering to the dynamic needs of civil engineers and contractors worldwide.

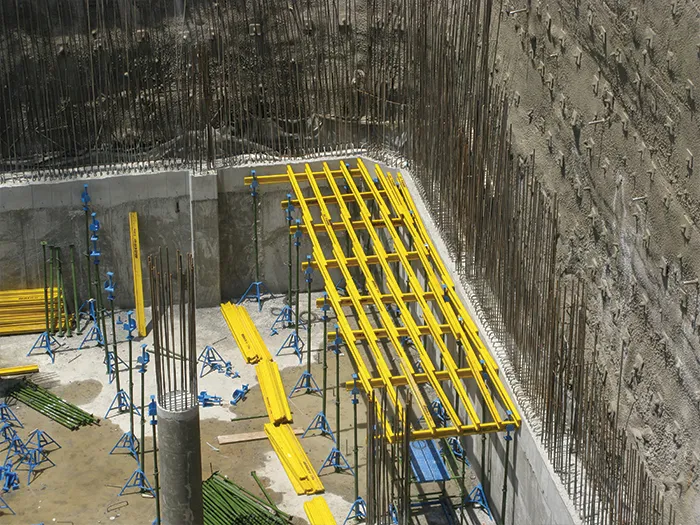

Main Elements: Beams, Props, and Panels

The core of Multi Flex in concrete slab formwork systems lies in its modular components, which include adjustable beams, props, and panels. Beams, typically made of steel or timber, provide the primary framework, supporting the weight of wet concrete during pouring. Props, such as telescopic steel supports, ensure stability and allow for height adjustments to accommodate different slab elevations. Panels, often made from plywood or composite materials, form the surface that shapes the concrete.

These components work together seamlessly, enabling contractors to customize the formwork to suit specific project requirements. The adjustable Slab Formwork system allows for quick reconfiguration, making Multi Flex ideal for projects with non-standard dimensions or intricate designs.

Material Types: Steel, Aluminum, and Plywood

Multi Flex systems leverage a combination of materials to balance strength, weight, and cost. Steel-plywood formwork is a popular choice due to its durability and ability to withstand repeated use. Steel provides the structural backbone, while plywood panels offer a smooth finish for concrete surfaces. Aluminum, though lighter, is often used in projects where portability is a priority, reducing labor costs during assembly and dismantling.

The choice of materials in Multi Flex in concrete formwork depends on project scale, budget, and environmental conditions. For instance, steel is favored for heavy-duty industrial applications, while aluminum suits smaller-scale or time-sensitive projects. Plywood, with its versatility, remains a staple for achieving high-quality concrete finishes.

Flexibility and Adaptability in Complex Projects

One of the standout features of Multi Flex in concrete formwork is its adaptability. The system’s modular design allows it to conform to a wide range of structural configurations, from curved slabs to irregular beam layouts. This flexibility makes it an excellent choice for projects with unique architectural designs or challenging site conditions. Civil engineers can adjust the system on-site, reducing the need for custom-built formwork and minimizing delays.

Time-Saving and Reusability Benefits

Multi Flex systems are engineered for efficiency. Their reusable formwork components significantly reduce material costs over time, as contractors can use the same system across multiple projects. The quick assembly and disassembly process further accelerates construction timelines, aligning with fast construction techniques that prioritize speed without compromising quality. For contractors, this translates to lower labor costs and faster project delivery, enhancing overall profitability.

Additionally, the durability of Multi Flex components ensures they withstand the rigors of repeated use, making them a sustainable choice for environmentally conscious construction firms like Bozorgmehr Industrial Group.

Use in Slab and Beam Construction

Multi Flex in concrete formwork excels in slab and beam formwork applications. Its adjustable props and beams allow for precise alignment, ensuring uniform load distribution and high-quality concrete finishes. Whether constructing flat slabs, ribbed slabs, or complex beam structures, Multi Flex provides the versatility needed to achieve structural integrity and aesthetic precision.

Suitability for Residential, Commercial, and Industrial Buildings

The adaptability of Multi Flex makes it suitable for a wide range of construction projects. In residential buildings, it supports the creation of floors and structural elements with varying dimensions. For commercial projects, such as office towers or shopping centers, Multi Flex in concrete formwork accommodates large spans and heavy loads. In industrial settings, its robust design handles the demands of warehouses, factories, and infrastructure projects, ensuring durability and safety.

Step-by-Step Assembly Process

Installing Multi Flex in concrete formwork involves a systematic process to ensure accuracy and safety. The steps include:

- Site Preparation: Clear and level the site to ensure a stable base for the formwork.

- Prop Installation: Position telescopic props at designated intervals, adjusting their height to match the slab or beam specifications.

- Beam Placement: Install primary and secondary beams, securing them to the props to form the framework.

- Panel Installation: Lay plywood or composite panels over the beams to create the concrete mold.

- Reinforcement and Pouring: Add reinforcement bars and pour concrete, ensuring proper vibration to eliminate air pockets.

- Curing and Stripping: Allow the concrete to cure, then carefully dismantle the formwork for reuse.

This streamlined process minimizes errors and ensures a high-quality finish, making Multi Flex a favorite among contractors.

Safety Considerations and Best Practices

Safety is paramount when working with Multi Flex in concrete formwork. Contractors should ensure props are securely anchored and beams are properly aligned to prevent collapse. Regular inspections of components for wear and tear are essential to maintain structural integrity. Workers must be trained in proper assembly techniques and equipped with personal protective equipment (PPE) to mitigate risks.

Multi Flex vs Traditional Timber Formwork

Traditional timber formwork, while cost-effective for small projects, lacks the durability and flexibility of Multi Flex systems. Timber is prone to warping and requires extensive labor for customization, increasing project timelines. In contrast, Multi Flex in concrete formwork offers reusable components and quick assembly, making it more efficient for large-scale or complex projects.

Multi Flex vs Modular Panel Systems

Modular panel systems, such as those made from pre-fabricated steel or plastic, are rigid and less adaptable to non-standard designs. Multi Flex, with its adjustable formwork system, provides greater versatility, allowing contractors to modify configurations on-site. While modular systems may be faster to install for repetitive tasks, Multi Flex excels in projects requiring customization.

Common On-Site Issues and How to Avoid Them

Despite its advantages, Multi Flex in concrete formwork can present challenges. Misalignment of props or beams can lead to uneven concrete surfaces, which can be mitigated through precise measurements and regular checks during installation. Overloading components beyond their capacity is another issue, which can be avoided by adhering to manufacturer guidelines and load ratings.

Real-World Applications and Projects

The Multi Flex formwork system has proven its reliability and versatility across a wide range of concrete construction projects. From high-rise residential towers to industrial slabs and commercial beam structures, contractors around the world rely on BFS Industries as a flexible slab formwork company that delivers efficiency, safety, and long-term performance.

In large-scale developments, Multi Flex ensures accurate leveling, easy handling, and consistent concrete finishes — even in complex floor geometries. As one of the trusted flexi formwork companies in the Middle East and beyond, BFS has supported numerous infrastructure and real estate projects with advanced flexible formwork and shoring systems.

Our experience as a flexible slab shuttering company allows us to adapt to different site conditions and project scales. Each Multi Flex setup can be easily customized to match varying slab thicknesses, beam spans, and support loads. This flexibility makes it an ideal choice for contractors, developers, and construction companies seeking to enhance productivity while maintaining structural quality.

Maintenance and Storage Tips for Longevity

To maximize the lifespan of Multi Flex components, proper maintenance is crucial. After each use, clean panels and beams to remove concrete residue, and inspect props for signs of damage. Store components in a dry, covered area to prevent rust or warping, particularly for steel-plywood formwork. Regular lubrication of adjustable parts ensures smooth operation and extends usability.

Looking for a trusted flexible formwork manufacturer or supplier for your next concrete project?

BFS Industries delivers professional-grade Multi Flex systems designed to optimize your construction workflow — combining strength, flexibility, and cost-efficiency.

As an experienced flexible formwork company and factory, we provide tailored solutions to meet the exact requirements of your slab and beam structures.

Contact our engineering team today to receive technical guidance, customized quotations, and expert support for your ongoing or upcoming projects.

Conclusion: Why BFS Is a Leading Flexible Formwork Manufacturer

BFS Industries stands out as one of the leading flexible formwork manufacturers, trusted by construction professionals for delivering durable, efficient, and adaptable systems.

Our Multi Flex formwork system combines high load capacity, easy assembly, and long-term reusability — making it an essential choice for modern slab and beam construction.

Through continuous innovation, precise engineering, and strict quality control, BFS ensures every component meets international safety and performance standards.

Contractors choose BFS not only as a flexible slab formwork company, but as a long-term partner that supports them from design consultation to on-site implementation.

As the construction industry continues to evolve toward smarter, more sustainable solutions, BFS Industries remains committed to advancing flexible formwork technology that saves time, reduces costs, and guarantees superior concrete results — project after project.

Frequently Asked Questions About Multi Flex in Concrete Formwork

What is Multi Flex in Concrete Formwork, and how does it differ from traditional formwork systems?

Multi Flex in concrete formwork is a flexible, modular formwork system designed for constructing slabs, beams, and other structural elements. Unlike traditional timber formwork, which is rigid and labor-intensive, Multi Flex uses adjustable components like beams, props, and steel-plywood panels. This adjustable formwork system allows for greater adaptability to complex designs, faster assembly, and reusability, making it ideal for modern, fast construction techniques.

What are the main advantages of using Multi Flex systems, and why do contractors choose BFS as a flexible formwork company?

Multi Flex in concrete formwork offers several benefits, including flexibility for irregular or complex structures, time savings due to quick assembly, and cost-efficiency from reusable formwork components. Its adaptability suits residential, commercial, and industrial projects, while the durable materials, such as steel and plywood, ensure high-quality concrete finishes and long-term reliability.

Can Multi Flex be used for both slab and beam construction, and what makes it different from other flexible formwork manufacturers?

Yes, Multi Flex is highly versatile and excels in slab and beam formwork applications. Its adjustable props and beams allow contractors to configure the system for various slab thicknesses and beam layouts, ensuring precise alignment and structural integrity. This makes it a preferred choice for projects requiring customized formwork solutions.

How do I ensure the safety and longevity of Multi Flex formwork components supplied by a reliable flexible formwork supplier?

To ensure safety, always follow manufacturer guidelines for load capacities and proper assembly of Multi Flex in concrete formwork. Regular inspections for wear and tear, secure anchoring of props, and worker training are critical. For longevity, clean components after use, store them in a dry environment to prevent rust or warping, and lubricate adjustable parts to maintain functionality.

How does Multi Flex compare to modular formwork systems offered by other flexible slab formwork companies?

Multi Flex in concrete formwork offers greater flexibility than modular panel systems, which are often pre-fabricated and less adaptable to non-standard designs. While modular systems may be faster for repetitive tasks, Multi Flex’s adjustable formwork system is ideal for unique or complex projects. Its reusable components also reduce long-term costs, making it a cost-effective choice for contractors prioritizing versatility.