Table Form Systems and Table Formwork for Slab Construction

Introduction

In the fast-evolving construction industry, efficiency, speed, and cost-effectiveness are critical for success, particularly in high-rise, commercial, and large-scale infrastructure projects. Traditional formwork methods, while reliable, often result in delays and increased labor costs due to their time-intensive setup and dismantling processes.

Table form systems, also known as flying table forms or slab table formwork, have emerged as a transformative solution. These systems provide unmatched efficiency, reusability, and adaptability in slab construction, making them ideal for repetitive floor projects.

Leading suppliers and manufacturers of table formwork for slab construction, including assembled table formwork providers, offer customizable solutions that meet the needs of modern contractors and engineering firms. By optimizing setup time, reducing material waste, and supporting rapid construction cycles, table form systems are redefining how concrete slabs are built in contemporary projects.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

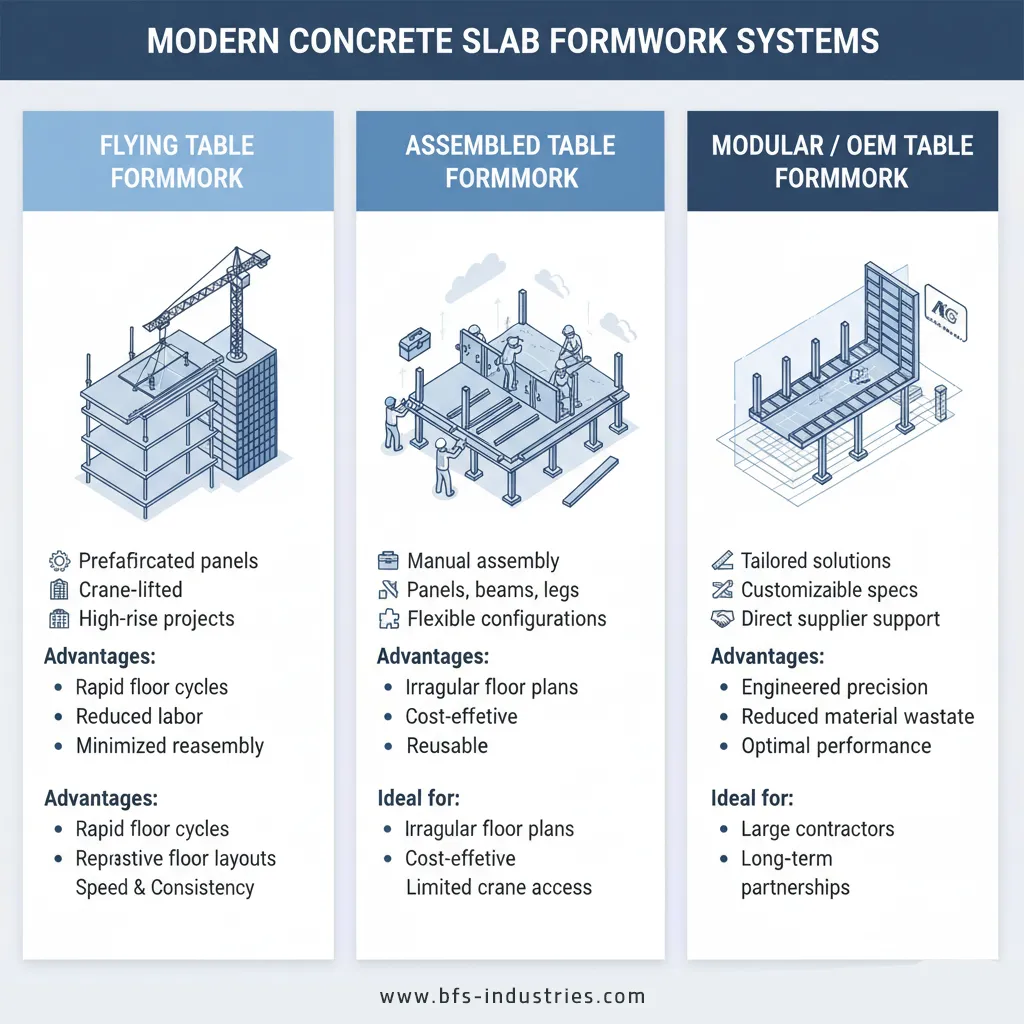

Types of Table Formwork Systems

Table formwork systems have become a cornerstone in modern slab construction, offering faster assembly, higher safety, and greater reusability compared to conventional formwork. These systems come in several types, each designed to meet specific project requirements, site conditions, and contractor preferences. Selecting the right table formwork type can significantly influence construction speed, labor costs, and overall project efficiency.

Flying Table Formwork

Flying table formwork, also known as flying forms, is a prefabricated concrete slab formwork system primarily used in high-rise and multi-story projects. These large table-like panels are lifted and moved to the next floor using cranes, enabling simultaneous concrete pouring and slab finishing. This system offers rapid floor cycle times, reduces labor requirements, and minimizes dismantling and reassembly time between floors. Its high adaptability makes it ideal for repetitive floor layouts in commercial and residential buildings. Flying table formwork is a highly efficient solution for projects where speed and consistency are crucial, making it one of the most reliable concrete slab formwork systems in modern construction.

Assembled Table Formwork

Assembled table formwork, also referred to as modular assembled table forms, is a type of concrete slab formwork system composed of panels, beams, and support legs that are manually assembled on-site. This system is highly flexible and ideal for irregular floor plans, complex geometries, or projects with limited crane access. It allows for customizable configurations to accommodate different slab dimensions and can be reused across multiple projects, making it a cost-effective solution. Compatible with both small and large-scale construction projects, assembled table formwork is often preferred by contractors who require versatile and adaptable concrete slab formwork systems to meet diverse project requirements and challenging site conditions.

Modular / OEM Table Formwork

Modular or OEM table formwork systems are designed for tailored solutions provided directly by manufacturers. These systems can be customized according to project specifications, including slab thickness, panel size, and support structures. Advantages include:

-

Engineered precision for specific project requirements

-

Reduced material wastage and improved structural quality

-

Direct support from OEM suppliers ensures optimal performance and maintenance

Modular and OEM table formwork is particularly valuable for large contractors and engineering firms seeking long-term partnerships with suppliers and highly reliable formwork systems.

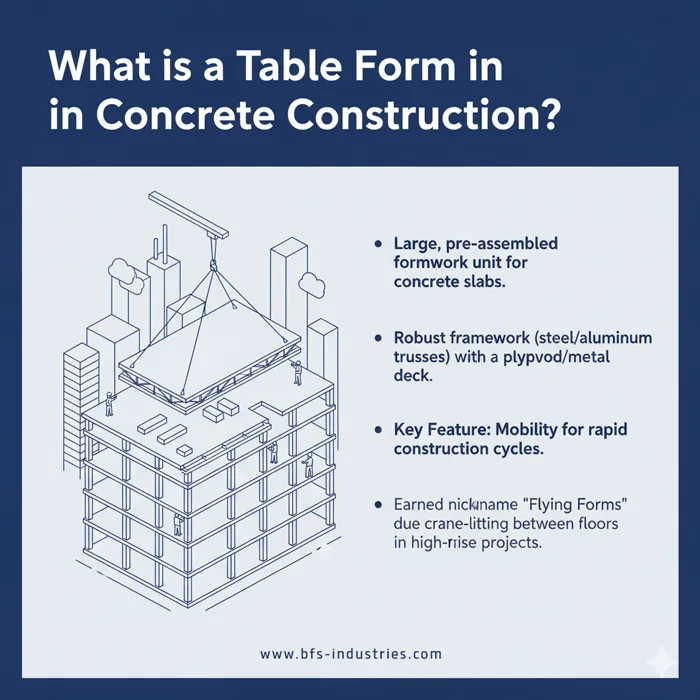

What Is a Table Form in Concrete Construction?

A table form is a large, pre-assembled formwork unit designed specifically for casting concrete slabs. It typically consists of a robust framework made from steel or aluminum trusses, topped with a deck of plywood or metal. The defining feature of a table formwork system is its mobility; it can be easily transported across a construction site or lifted between floors using cranes, enabling rapid construction cycles. This mobility has earned them the nickname “flying forms,” as they appear to “fly” from one floor to the next during high-rise construction

The Rise of Efficient Formwork in High-Rise Buildings

The global surge in urbanization has driven the demand for high-rise buildings, necessitating innovative construction techniques to meet tight schedules and budgets. Slab formwork, particularly modern table form systems, has emerged as a vital solution for efficiently constructing floor slabs. These systems provide a stable and reusable platform that can be quickly assembled and relocated, allowing construction teams to maintain a consistent workflow while minimizing downtime between concrete pours. Industry insights suggest that the use of table forms can reduce formwork-related construction time by up to 50 percent compared to traditional methods, making them indispensable for high-rise projects where both time and cost efficiency are critical. In addition, these systems enhance safety and quality control on-site, ensuring that each slab is formed accurately and reliably, even under the pressures of rapid construction schedules.

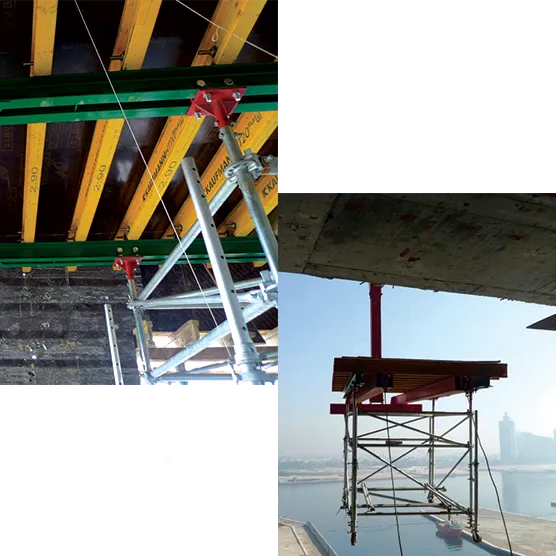

Components and Materials Used in Table Formwork

Table form systems are designed for strength, versatility, and ease of use, with each component contributing to their functionality. Panels, often made of steel, plywood, or aluminum composites, provide a smooth surface for concrete, while beams support the panels and resist bending under heavy loads. Telescopic props ensure stability and precise leveling, and high-tensile connectors secure the assembly during pouring. Together, these components create a durable, reusable system that reduces labor time, enhances safety, and ensures accurate, high-quality concrete slabs in modern construction projects.

Beams, Panels, Legs, and Drop Heads

- Framework (Beams and Trusses): The backbone of the table form, typically made from steel or aluminum, provides the structural integrity needed to support heavy concrete loads. Trusses ensure stability across large spans, often up to 100 square meters

- Panels: The decking surface, usually plywood or metal, where concrete is poured. Plywood is favored for its affordability and ease of replacement.

- Legs or Props: Adjustable supports that allow precise leveling and height adjustment, ensuring the form aligns with the building’s design.

- Drop Heads or Lifting Points: Integrated into the framework, these facilitate easy lifting and positioning by cranes, enhancing the system’s mobility

Material Options: Steel, Aluminum, and Plywood

- Steel: Offers superior strength and durability, ideal for heavy-duty applications in high-rise construction. However, its weight increases crane requirements.

- Aluminum: Lighter than steel, reducing crane loads and simplifying handling, though it may be less durable over extensive reuse.

- Plywood: The most common decking material due to its cost-effectiveness and ease of replacement, though it requires regular maintenance to prevent wear

Benefits of Using Table Form in Slab Construction

Table form systems offer numerous advantages, making them a preferred choice for modern construction projects, especially those that demand high efficiency in concrete casting. Their modular and reusable design allows for rapid assembly and easy adjustment to different floor layouts, significantly reducing construction time. By providing stable and well-supported platforms, these systems enhance worker safety and minimize the risk of structural errors. Additionally, they help lower labor costs and ensure uniform, high-quality slab finishes, making them particularly suitable for high-rise buildings and large-scale developments. The durability and versatility of table form systems also allow contractors to maximize resources, achieving both economic and operational efficiency on complex projects.

Speed and Efficiency in Repetitive Floor Projects

- Rapid Cycling: Table forms can be moved and set up quickly, often within hours, allowing multiple floors to be cast in quick succession. This is particularly beneficial for projects with repetitive floor plans, such as high-rise residential or office buildings.

- Labor Savings: The pre-assembled nature of table forms reduces the need for extensive on-site labor, as fewer workers are required for setup and dismantling compared to conventional formwork

Cost-Effectiveness and Reusability

- Reusable Formwork: High-quality table forms can be reused hundreds of times, spreading the initial investment across multiple projects and reducing overall costs.

- Reduced Waste: By minimizing the use of disposable formwork materials, table forms contribute to sustainability and lower material costs, aligning with modern environmental standards

Applications of Table Form Systems in Modern Construction

Table form systems are highly versatile, finding applications across various construction sectors due to their adaptability and efficiency. They are widely used in high-rise residential and commercial buildings, where their modular design allows for rapid assembly and consistent slab quality across multiple floors. In large-scale infrastructure projects, such as bridges and parking structures, table forms provide stable platforms that ensure precise concrete casting while reducing labor time. Their flexibility also makes them suitable for complex architectural designs, including irregular floor layouts or buildings with varying slab thicknesses, where traditional formwork would be cumbersome. By enabling reuse across different projects and floors, table form systems contribute to cost efficiency, improved safety, and high-quality finishes, making them an indispensable tool in modern construction practices.

High-Rise and Commercial Projects

Table forms are ideally suited for high-rise construction, where repetitive floor layouts are common. They are widely used in:

- Residential Towers: Enabling rapid construction of identical floor slabs in apartment buildings.

- Office Buildings and Hotels: Supporting large, open floor plans typical of commercial structures.

- Shopping Malls and Airports: Accommodating expansive slab areas with minimal setup time

Use in Residential and Infrastructure Developments

While primarily associated with high-rise projects, table forms are also adaptable for:

- Multi-Story Residential Buildings: Particularly in urban settings where speed is critical.

- Infrastructure Projects: Such as bridge decks, parking garages, and other horizontal structures requiring large, flat slabs

Installation and Dismantling Process of Table Forms

The efficiency of table form systems lies in their streamlined installation and dismantling processes, which are designed to minimize downtime and enhance safety. The installation process typically begins with preparing the work area and positioning the primary support beams, followed by attaching panels in a precise sequence to ensure proper alignment. Telescopic props and adjustable supports are then used to achieve accurate leveling and stability, allowing for safe and uniform concrete pouring. Dismantling is equally efficient: panels and beams are carefully removed in reverse order, minimizing the risk of damage and enabling rapid reuse on subsequent floors or projects. This systematic approach not only reduces labor requirements and project duration but also ensures consistent quality, safety, and operational efficiency, making table form systems a highly practical solution for modern construction workflows.

Industrial & Infrastructure Projects

Table formwork systems are not limited to residential or commercial buildings—they play a crucial role in industrial and large-scale infrastructure projects. These projects often involve wide slabs, long spans, and repetitive structural elements, making conventional formwork inefficient and time-consuming. Table formwork for slab construction provides an optimal solution by offering speed, precision, and reusability across multiple floors or extended work areas.

Key applications in industrial and infrastructure projects include:

-

Bridges and Flyovers: Flying table formwork enables rapid slab casting with uniform quality, minimizing downtime between pours.

-

Power Plants and Industrial Facilities: Assembled and modular table forms provide flexibility for complex layouts and heavy-duty concrete slabs.

-

Warehouses and Logistics Centers: Large-span slabs benefit from high-capacity table form systems, reducing labor and material costs.

-

Transport Hubs and Airports: Modular and OEM table formwork allows contractors to meet tight schedules and strict quality standards.

By leveraging table formwork for slab projects in industrial and infrastructure settings, contractors can achieve faster cycle times, lower labor requirements, and consistent concrete quality. Furthermore, working with reliable suppliers of assembled and modular table form systems ensures smooth project execution and cost efficiency.

Table Formwork Suppliers and Manufacturers

Selecting a reliable supplier or manufacturer of table formwork for slab construction is crucial for the success of any high-rise, commercial, or industrial project. Reputable suppliers offer high-quality, durable, and reusable systems, including flying table formwork and assembled table formwork, tailored to meet diverse project requirements. Working with experienced manufacturers ensures access to technical guidance, proper on-site assembly support, and customizable solutions that optimize efficiency, reduce labor costs, and maintain concrete quality across repetitive slab cycles.

Domestic suppliers provide fast delivery, local technical support, and on-site training for contractors and labor teams, ensuring smooth project execution. International exporters and OEM partners deliver modular, precision-engineered table formwork suitable for complex geometries and long-span slabs. Collaborating with trusted suppliers guarantees both scalability and compliance with safety and quality standards, making it easier for contractors to complete projects on time and within budget.

Table Formwork Pricing and Availability

The cost of table formwork for slab construction varies depending on the type, material, size, and manufacturer. Steel table formwork is generally suited for heavy-duty, high-rise projects due to its strength, while aluminum systems offer lighter weight and easier handling for rapid construction cycles. Modular or plastic table formwork options are often more cost-effective and flexible, making them ideal for smaller-scale or repetitive floor projects. Project location, required volume, and customization also influence the overall pricing of these systems.

Availability depends on geographic location, supplier networks, and production capacity. Leading manufacturers, including domestic suppliers and international OEM partners, provide timely delivery and technical support to ensure smooth project execution. For specialized projects, premium brands may offer enhanced quality, modularity, and on-site assistance. Contacting authorized suppliers with project specifications is the best way to determine the most suitable and cost-efficient table formwork solution.

Step-by-Step Assembly Workflow

- Preparation: Assemble the table form on the ground or a lower floor to reduce working at height.

- Transportation: Use a crane to lift the form to the desired floor level.

- Adjustment: Level the form using adjustable legs to align with the building’s grid.

- Sealing: Seal joints to prevent concrete leakage.

- Reinforcement: Place steel reinforcement as per the structural design.

- Casting: Pour concrete evenly across the deck.

- Curing: Allow the concrete to cure until it reaches sufficient strength.

- Stripping: Lower the form to break the bond with the concrete, then roll it out using built-in rollers or skids.

- Relocation: Lift the form to the next location or store it for future Lifting, Stripping, and Safety Considerations

- Lifting: Ensure cranes have adequate capacity and lifting points are correctly identified to prevent accidents.

- Stripping: Use hydraulic jacks or drop heads to ease the form away from the cured concrete, avoiding damage to the slab.

- Safety: Implement edge protection, harnesses, and regular equipment inspections to ensure worker safety

Table Form vs Conventional Slab Formwork

Comparing table forms to conventional slab formwork highlights their clear advantages in efficiency, cost, and safety. Unlike traditional slab formwork, which often requires extensive scaffolding, individual panel placement, and significant labor time, table form systems are modular, reusable, and quicker to assemble, allowing for faster floor cycles and reduced project duration. They provide stable and well-supported platforms, minimizing the risk of errors during concrete casting and ensuring uniform slab quality. Additionally, the reuse potential of table forms leads to lower material costs and reduced labor expenses over multiple floors or projects. This combination of speed, safety, and cost-effectiveness makes table form systems a preferred choice in modern construction, particularly for high-rise buildings and large-scale developments, where efficiency and reliability are paramount.

7. Key Differences in Setup and Efficiency

| Aspect | Table Form | Conventional Formwork |

| Setup Time | Pre-assembled, quick setup (hours) | Built on-site, time-consuming (days) |

| Reusability | Reusable for multiple pours | Often disposable or requires reassembly |

| Labor Requirements | Minimal labor due to prefabrication | High labor for assembly and dismantling |

| Efficiency | Fast cycling for repetitive floors | Slower, less suited for repetitive tasks |

When to Use Table Forms Over Traditional Methods

- Repetitive Slabs: Best for projects with identical floor plans, such as high-rise buildings.

- Time-Sensitive Projects: Ideal when deadlines are tight, as table forms significantly reduce construction time.

- Large-Scale Projects: The initial investment is justified by cost savings over multiple uses

Challenges in Using Table Form and How to Overcome Them

While table forms offer significant benefits, they come with challenges that require strategic planning and careful management. One common issue is the heavy initial investment in acquiring modular panels, beams, and props, which can be mitigated by planning reuse across multiple floors and projects to maximize cost efficiency. Another challenge is the requirement for skilled labor to correctly assemble, level, and secure the forms, which can be addressed through training programs and clear operational guidelines. Space constraints on crowded construction sites may also limit maneuverability, necessitating efficient site organization and proper sequencing of installation and dismantling. Additionally, handling irregular floor plans or non-standard slab dimensions can complicate assembly, but the inherent flexibility of table form systems, along with adjustable components, allows these obstacles to be overcome. By anticipating these challenges and implementing proactive solutions, contractors can fully leverage the efficiency, safety, and quality benefits that table form systems provide.

Transportation, Handling, and On-Site Adjustments

Transportation: Table formwork for slab, including flying and assembled table forms, are large and heavy, requiring robust cranes and carefully planned access routes. Proper logistical planning ensures smooth movement between storage areas, assembly points, and casting locations.

Handling: Workers must be trained in correct lifting, moving, and assembly techniques to prevent damage to the formwork and ensure on-site safety. Using designated handling tools and following manufacturer guidelines improves efficiency and reduces the risk of accidents.

On-Site Adjustments: Modular and assembled table formwork systems allow for quick adaptation to irregular slab shapes, drop beams, or cantilevered sections. Working with reliable suppliers ensures that adjustments can be made efficiently, maintaining project timelines and structural quality.

Maintenance and Storage Tips for Longevity

- Regular Inspections: Check for wear, damage, or concrete buildup after each use to maintain performance.

- Cleaning: Clean forms thoroughly to prevent concrete residue from affecting future pours.

- Storage: Store in a dry, covered area to protect against weather damage, extending the lifespan of the forms

High-Quality Table Form Systems for Concrete Construction by B.F.S Industries

Table form systems have revolutionized concrete construction by providing a fast, safe, and efficient method for casting large floor slabs. These modular platforms allow for repetitive use across multiple floors, significantly reducing construction time and labor costs. The system’s adaptability makes it ideal for high-rise buildings, where precision, speed, and reliability are critical.

B.F.S Industries is a leading supplier and manufacturer of high-quality table form systems. With extensive experience in the industry, B.F.S Industries delivers durable, customizable, and safe solutions that meet the demands of modern concrete construction projects. Their products ensure consistent performance, enabling contractors to achieve both efficiency and structural accuracy on every project.

Conclusion: Why Table Form Systems Are Essential in Modern Construction

Table form systems have become a cornerstone of modern concrete construction, particularly for high-rise and large-scale projects. Their ability to enhance concrete casting efficiency, reduce labor costs, and improve safety makes them indispensable for engineers, contractors, and builders. By addressing challenges through proper planning, training, and maintenance, table forms can deliver superior project outcomes, meeting the demands of today’s fast-paced construction industry. As urbanization continues to drive the need for efficient building solutions, table form systems will play an increasingly vital role in shaping the skylines of tomorrow.

Frequently Asked Questions (FAQs) About Table Form Systems in Concrete Construction

What is a table form system, and how does it work in concrete construction?

A table form system is a pre-assembled formwork unit used for casting concrete slabs, primarily in high-rise buildings. It consists of a framework, decking, and adjustable supports. Once the concrete cures, the table form is lowered, rolled out, and lifted to the next floor using a crane, enabling rapid and efficient slab construction.

What are the main advantages of using table formwork over traditional formwork?

Table formwork offers faster setup and dismantling, reusability for multiple pours, and reduced labor costs. Its pre-assembled design and mobility make it ideal for repetitive floor layouts, cutting construction time by up to 50% compared to conventional slab formwork methods.

What types of projects are best suited for table form systems?

Table forms are ideal for high-rise residential and commercial buildings, such as towers, hotels, and office complexes, where repetitive floor plans are common. They are also used in infrastructure projects like parking garages and bridge decks, where large, flat slabs are required.

What materials are commonly used in table form systems, and why?

Table forms typically use steel or aluminum for the framework due to their strength and durability, with plywood or metal for the decking. Aluminum is lighter, easing crane loads, while steel is more robust for heavy-duty applications. Plywood is cost-effective and easily replaceable.

What challenges should be considered when using table form systems?

Challenges include transportation and handling due to the large size of table forms, requiring robust cranes and clear site access. Maintenance is also critical to prevent wear and ensure longevity. Proper training, regular inspections, and strategic logistics can overcome these issues effectively.