Manhole Forms: High-Quality Factory-Made Solutions

Introduction

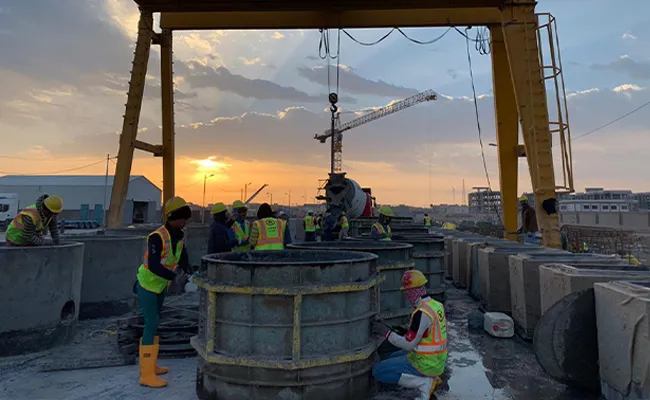

Our high-quality, factory-manufactured manhole forms are engineered to provide exceptional durability, precision, and efficiency for all your sewer and utility infrastructure needs. Designed with advanced materials and cutting-edge production techniques, these manhole formworks ensure consistent performance even in the most demanding construction environments.

Whether you are an experienced contractor seeking robust and reliable manhole form systems or a newcomer looking for easy-to-install and cost-effective solutions, our products cater to a wide range of project specifications. By prioritizing quality, innovation, and client satisfaction, our manhole forms seamlessly integrate into your workflow, accelerating project timelines and minimizing labor and material costs.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

1. What Are Manhole Forms?

Manhole forms play a critical role in modern construction by offering the necessary structural framework to build secure access points within underground utility systems. These essential tools ensure precise shaping and durability, facilitating safe and efficient installation and maintenance of sewer, drainage, and electrical networks.

For professionals engaged in manhole construction, a thorough understanding of formwork types, materials, and design specifications is vital to choosing the optimal solution that meets project demands, enhances workflow efficiency, and guarantees long-term reliability.

1.1. Definition and Purpose of Manhole Forms

Manhole forms, also referred to as manhole formwork, are specialized molds or frameworks designed to shape and support concrete during the construction of manholes. Depending on the application, these forms may be reusable or single-use, playing a crucial role in forming cylindrical or rectangular access points for sewer, utility, and drainage networks.

Functioning as a temporary or permanent framework, manhole forms securely hold wet concrete in place until it fully cures, ensuring exact dimensions and maintaining structural integrity. For those new to the field, manhole forms can be likened to the “cookie cutters” of underground infrastructure—they precisely define the shape and strength of the manhole, enabling easy maintenance and inspection access.

Our factory-manufactured manhole forms are engineered with high precision, utilizing advanced materials designed to withstand the demanding conditions of concrete pouring and curing. By selecting our premium-quality manhole forms for sale, you invest in reliable tools that enhance your construction workflow, reduce errors, and guarantee durable, long-lasting results.

1.2. Importance in Sewer and Utility Construction

In sewer and utility construction, manhole forms are indispensable for creating safe, efficient, and code-compliant infrastructure. They provide the structural foundation for durable access points that enable routine inspections, cleaning, and repairs without interrupting surface activities or daily operations.

Without reliable and precise manhole formwork, projects face risks such as structural failures, water leaks, and expensive rework—all of which can cause significant delays and increase costs. For seasoned construction professionals, the priority is selecting forms that comply with rigorous engineering standards like ASTM and local building regulations. Meanwhile, beginners benefit from understanding how these forms directly impact the overall durability and safety of underground systems.

Our prefabricated manhole forms, including those offered by B.F.S Industries, are engineered to enhance project performance by ensuring watertight seals and superior corrosion resistance. This results in reduced maintenance expenses and extended service life of your infrastructure. Whether you are installing new sewer lines or upgrading existing utilities, integrating our high-quality manhole forms streamlines your workflow and improves efficiency.

2. Types of Manhole Forms We Manufacture

We provide an extensive selection of manhole forms, meticulously crafted to meet the varied requirements of modern construction projects. Our product lineup ranges from durable precast sewer manhole forms to advanced fiberglass solutions, all manufactured under strict factory conditions to guarantee uniform quality and reliable performance.

This diverse offering ensures that whether your project demands strength, lightweight materials, or specialized design features, you can rely on our manhole forms to deliver optimal results every time.

2.1. Precast Manhole Forms

Precast manhole forms are specifically engineered for off-site fabrication, enabling the casting of concrete manholes in a controlled factory setting before being transported to the construction site. These forms are ideal for large-scale projects where consistency and uniformity are paramount. Their modular design allows for straightforward assembly and disassembly, enhancing operational efficiency.

Manufactured from robust steel or reinforced composite materials, precast manhole forms facilitate the production of sewer manholes that are durable, precise, and ready for immediate installation upon arrival. Key advantages include significant reductions in on-site labor requirements and accelerated project timelines, making them the preferred solution for major infrastructure developments. If you are looking for manhole forms for sale that emphasize accuracy, durability, and speed, our precast manhole forms offer unmatched performance and value.

2.2. Fiberglass Manhole Forms

Fiberglass manhole forms are distinguished by their exceptional combination of light weight and high strength, making them ideal for projects demanding corrosion resistance and easy handling. Produced from premium-grade fiberglass reinforced with specialized resins, these forms offer outstanding resistance against chemicals, moisture, and environmental degradation, significantly outperforming traditional materials in longevity.

Particularly suitable for coastal and industrial environments—where exposure to harsh elements is frequent—fiberglass manhole forms reduce shipping costs thanks to their lighter weight and simplify installation processes on-site. For construction professionals looking for versatile and durable manhole form solutions, our factory-produced fiberglass forms provide a dependable, low-maintenance alternative that improves overall project productivity and efficiency.

2.3. Cast-in-Place (Pour-in-Place) Manhole Forms

Cast-in-place manhole forms, also known as pour-in-place systems, are assembled directly at the construction site, allowing concrete to be poured and cured in its permanent position. This approach offers unparalleled customization, making it ideal for projects with unique site conditions such as irregular terrain, varying depths, or complex geometries.

Constructed from durable materials like aluminum or steel panels, these forms create a seamless, monolithic structure that minimizes joints and reduces the risk of leaks. Their adaptability ensures superior integration with existing underground utilities and infrastructure.

For specialized requirements, our range of cast-in-place manhole forms, including innovative Special Formworks, guarantees structural integrity, efficiency, and cost-effectiveness. Elevate your manhole construction process by choosing our premium solutions designed to meet the most demanding site conditions.

2.4. Prefabricated Manhole Forms

Prefabricated manhole forms are fully assembled at our factory and delivered ready for immediate installation, significantly streamlining the construction workflow. These forms feature pre-engineered components such as adjustable risers and base molds, enabling rapid setup and ensuring consistent, high-quality results across multiple uses.

Ideal for urban projects where space and time are limited, prefabricated manhole forms offer reusability and reduce material waste while improving dimensional accuracy. Their precise manufacturing process guarantees seamless integration with site conditions, minimizing delays and labor costs. Investing in our prefabricated manhole forms means choosing efficiency, durability, and precision. Explore our comprehensive range of factory-produced manhole forms for sale and benefit from advanced, hassle-free solutions tailored to your project needs.

3. Features and Specifications of Our Manhole Forms

Our manhole forms are meticulously engineered to surpass industry standards. By utilizing premium materials and advanced designs inspired by modern concrete formwork systems principles, they ensure outstanding performance and long-lasting durability in your construction projects. These features make our forms not only compliant with today’s technical and operational demands but also reliable under the most challenging and extended conditions. Below, we provide a detailed overview of the key specifications and capabilities that empower you to make the best-informed choice.

3.1. Material Quality and Durability

At the core of our manhole forms is a commitment to using top-quality materials, including high-strength steel, advanced fiberglass composites, and corrosion-resistant alloys, ensuring outstanding durability and performance. These robust materials are engineered to endure repeated use, harsh weather conditions, and chemical exposure, significantly prolonging the lifespan of both the forms and the finished manholes.

For example, our fiberglass forms excel in resisting rust and environmental degradation, while steel-based forms deliver unparalleled structural strength and stability. By prioritizing material quality, we reduce the need for frequent replacements and minimize long-term maintenance costs, making our manhole formwork an ideal, reliable choice for the most demanding construction projects.

3.2. Dimensions and Design Standards

Our manhole forms conform to industry-standard dimensions, starting from 48-inch diameters for shallow installations to custom sizes exceeding 120 inches, tailored to meet deep utility requirements. All designs strictly follow ASTM C478 and AASHTO specifications to ensure safety, reliability, and compatibility.

Equipped with features such as adjustable heights and tapered profiles, these forms accommodate a wide range of pipe sizes and configurations. Whether your project calls for round, square, or eccentric shapes, our manhole forms provide precise engineering and craftsmanship, guaranteeing optimal fit, structural integrity, and seamless integration into your construction workflow.

3.3. Compliance with Construction Codes

All our manhole forms fully comply with crucial construction regulations, including OSHA safety standards, EPA environmental guidelines, and relevant local building codes. This rigorous adherence guarantees that your projects meet all legal and regulatory requirements, helping you avoid costly fines and project delays.

Our factory production processes incorporate stringent testing for load-bearing capacity and watertight integrity, ensuring that every form delivers reliable performance and safety. This commitment provides confidence and peace of mind for both experienced professionals and newcomers in the construction industry.

4. Advantages of Using Our Factory-Made Manhole Forms

Selecting our factory-made manhole forms offers a multitude of advantages, including superior quality control, consistent performance, and durable construction. These benefits translate into faster project completion, reduced labor costs, and minimized material waste. With precision-engineered designs and stringent factory testing, our forms deliver reliability that contractors can trust.

Discover why leading construction professionals prefer our manhole forms as the smart, cost-effective solution to elevate project efficiency and ensure long-term success.

4.1. Superior Quality Control

Factory manufacturing enables rigorous quality control processes, where each manhole form is thoroughly inspected for defects to guarantee uniformity and dependable performance. Producing forms in a controlled environment significantly reduces common errors found in on-site fabrication, ensuring that the final products are stronger, more consistent, and better suited for demanding construction conditions.

4.2. Faster Installation and Time Savings

Our manhole forms are specifically designed for fast and easy assembly, cutting installation time by up to 50% compared to conventional methods. This enhanced efficiency shortens overall project durations and significantly lowers labor expenses, enabling contractors to increase annual project capacity and improve profitability.

4.3. Cost Efficiency and Reusability

Our manhole forms feature reusable designs that significantly reduce material costs over time, with certain models capable of supporting hundreds of concrete pours. This longevity, combined with minimized waste and low maintenance requirements, delivers excellent return on investment (ROI). As a result, these forms represent a highly economical choice for projects with tight budgets, without compromising quality or performance.

4.4. Enhanced Safety on Site

Safety features like reinforced edges and ergonomic handles minimize risks during handling and pouring. By reducing on-site hazards, our forms promote a safer work environment, complying with industry safety protocols.

5. Applications of Manhole Forms in Sewer and Utility Construction

Our manhole forms are engineered to perform exceptionally across a wide range of applications, providing dependable support and precise construction for vital infrastructure projects. Trusted by leading tunnel lining formwork suppliers, their robust design and adaptability ensure consistent results, meeting the rigorous demands of modern engineering standards.

5.1. Sewer Manholes

For sewer systems, our manhole forms are meticulously engineered to create durable and resilient access points capable of withstanding high flow rates and substantial structural loads. These access points are critical components in municipal wastewater management, providing reliable entry for inspection, maintenance, and repair activities. The robust construction of our forms ensures long-term performance under continuous pressure from both fluid dynamics and environmental stresses, preventing leaks and structural failures. By integrating advanced materials and precise engineering, our manhole forms help municipalities maintain efficient, safe, and compliant sewer infrastructure that supports urban sanitation and public health.

5.2. Inspection Chambers

Inspection chambers built using our high-quality manhole formwork provide convenient access for monitoring utility lines, helping to identify and resolve potential problems before they escalate. Just as Jersey Barrier Molds are designed to deliver durable and reliable safety barriers on roadways, our manhole forms ensure robust, long-lasting structures that support efficient maintenance and protect critical infrastructure.

5.3. Underground Utility Access

In underground utility installations, our manhole forms provide safe and durable access points for electrical, telecommunications, and water systems. Designed to withstand environmental pressures and frequent use, these forms ensure the long-term functionality and integrity of critical infrastructure, enabling easy maintenance and minimizing service disruptions.

6. Manhole Formwork vs. Precast Manholes: Which Is Right for Your Project?

Choosing the most suitable method between manhole formwork and precast manholes depends on the specific requirements of your construction project, including factors like site conditions, timeline, and customization needs. Additionally, integrating Concrete Column Formwork can play a vital role in ensuring structural stability in vertical elements connected to your manhole systems. In this overview, we’ll break down the key considerations, benefits, and best use cases of each solution to guide you toward the optimal decision for your project’s success.

6.1. Comparing Advantages and Limitations

Manhole formwork excels in on-site customization, making it ideal for unique or complex projects that demand tailored solutions. This approach offers potential cost savings but typically requires more labor and longer setup times. In contrast, precast manholes deliver fast installation and consistent factory-quality results, though they offer limited flexibility and can incur higher transportation expenses.

Our manhole formwork is particularly effective in adaptable and specialized scenarios, while precast manholes are best suited for standardized, repetitive builds. Understanding these differences helps you select the most efficient and cost-effective option for your specific project needs.

6.2. Factors to Consider in Your Selection

Carefully evaluate your project’s size, schedule, budget constraints, and site-specific factors before choosing between manhole formwork and precast options. When facing tight deadlines, precast manholes often provide the fastest delivery and installation. Conversely, for projects requiring customization and adaptability, formwork—especially when coordinated with an experienced tunnel formwork system supplier—offers greater flexibility and tailored solutions.

To ensure the best match for your manhole construction needs, consult with our experts who can guide you toward the most efficient and cost-effective solution tailored to your unique project parameters.

7. How to Choose the Right Manhole Form for Sale

Choosing the perfect manhole form for your construction project is a critical decision that impacts both the efficiency and quality of your work. Several key factors must be considered, including the type of materials used, the dimensions and shapes required, the specific site conditions, and the overall project scope and budget. Understanding these variables helps you select a form that not only fits your technical needs but also optimizes cost-effectiveness and durability. This comprehensive guide will walk you through the crucial aspects to evaluate, empowering you to make an informed choice that aligns perfectly with your project goals and ensures long-term success.

7.1. Size and Dimension Considerations

Carefully assess the necessary depth, diameter, and pipe connection types for your manhole construction. Our manhole forms accommodate a wide range of specifications—from standard 4-foot diameters to fully customizable sizes—ensuring a precise fit tailored to your project’s unique requirements. This flexibility guarantees seamless integration with existing infrastructure and enhances overall system performance.

7.2. Material Choices

When choosing manhole forms, consider the specific environmental conditions of your project site. Fiberglass forms are ideal for corrosive environments due to their chemical resistance and lightweight nature, while steel forms excel in heavy-duty applications requiring maximum strength and durability. Each material offers a balanced combination of strength, weight, and cost, allowing you to select the most suitable option that aligns with both performance demands and budget constraints.

7.3. Project-Specific Requirements

When planning your manhole construction, it is essential to thoroughly evaluate the soil type at the project site, anticipated load-bearing demands, and all relevant regulatory standards and codes. Different soil conditions—whether sandy, clayey, or rocky—can significantly influence the choice of materials and formwork systems. Similarly, understanding the expected loads, including vehicular traffic and environmental pressures, ensures the selected manhole form can withstand operational stresses without compromising structural integrity.

In addition, adherence to local, regional, and national regulations is critical to avoid costly delays and ensure safety compliance. Our experienced team works closely with you to analyze these factors and recommend the most suitable solutions, whether your project calls for precast sewer manholes or cast-in-place manhole systems. By tailoring our recommendations to your unique project parameters, we help you achieve durability, efficiency, and regulatory approval with confidence.

8. How to Order Manhole Forms from Our Factory

Ordering manhole forms from our factory is a simple and efficient process designed to get you equipped quickly with high-quality products. Begin by browsing our comprehensive catalog to explore the full range of available manhole forms. Once you have selected the products that meet your project needs, you can easily submit your order online or place it via phone for rapid processing.

If you require pricing information tailored to your specific requirements, don’t hesitate to contact us for a personalized quote—there’s no obligation, just professional guidance. We offer nationwide shipping with multiple delivery options, including expedited services to ensure your order arrives safely and on time at your site.

Throughout the entire process, our dedicated customer support team is available to assist you—from helping with product selection to providing support after your purchase, ensuring a smooth and satisfactory experience.

Frequently Asked Questions (FAQs) About Manhole Forms

1. What is the installation process for manhole forms?

The installation process includes site preparation, form assembly, concrete pouring, and curing. Thanks to our user-friendly designs, this is typically completed within a few hours.

2. How is the maintenance and durability of the manhole forms?

Minimal maintenance is required; simply clean the forms after use and store them properly. Our forms are designed to last for years and come with warranties that guarantee their durability.

3. How is pricing determined and what is the lead time?

Pricing varies based on the type and size of the form. You can request a personalized quote for detailed pricing information. Lead times typically range from 2 to 4 weeks, ensuring timely delivery.

4. Are the manhole forms customizable?

Yes, we offer full customization options, including dimensions and reinforcements, to meet the unique demands of your project.

5. Can these manhole forms be reused for multiple projects?

Absolutely. Our manhole forms are designed for durability and reusability, allowing them to be used across numerous projects, which maximizes your return on investment and reduces overall costs.