Concrete Wall Formwork Systems (Modular, One-Sided & Double-Sided)

Introduction

Building the future faster and smarter starts with the right foundation. In Dubai and across the UAE, where projects demand speed, strength, and precision, choosing the right Concrete Wall Formwork is essential for safe and efficient construction. Also known as wall formwork, wall shuttering systems, or concrete wall shuttering, these systems are critical for retaining wall shuttering, basement walls, and high-rise structures—delivering accurate geometry, clean finishes, and faster casting cycles.

As a Dubai-based concrete wall formwork system supplier, manufacturer, and exporter, BFS Industries provides durable, modular solutions engineered for demanding site conditions. Our systems help contractors and developers reduce labor time, control project costs, and improve on-site safety—while maintaining consistent quality across repetitive pours.

From standard modular wall formwork to engineered one-sided retaining wall shuttering systems for confined sites, BFS Industries supports modern construction with reliable supply, technical guidance, and formwork solutions designed for long-term performance across the UAE and beyond.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

concrete wall formwork Category

concrete wall formwork Products

Zigma Filler Plate

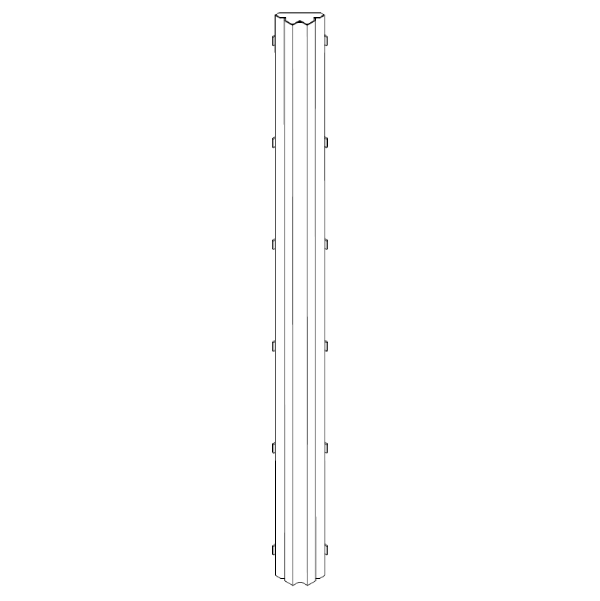

Zigma Inside Corner

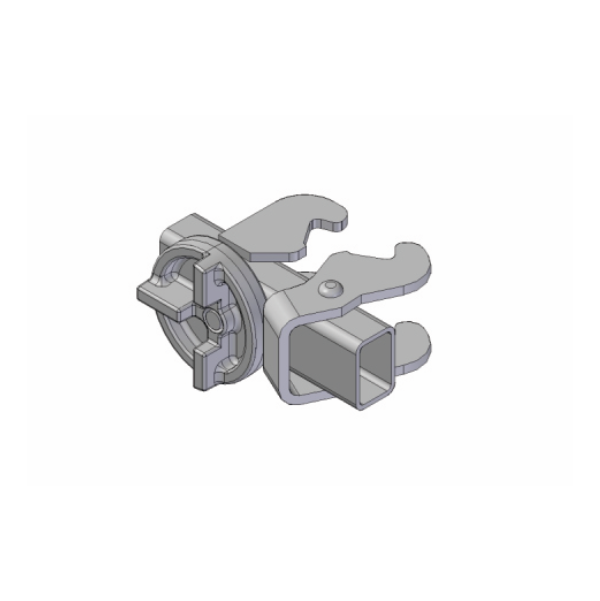

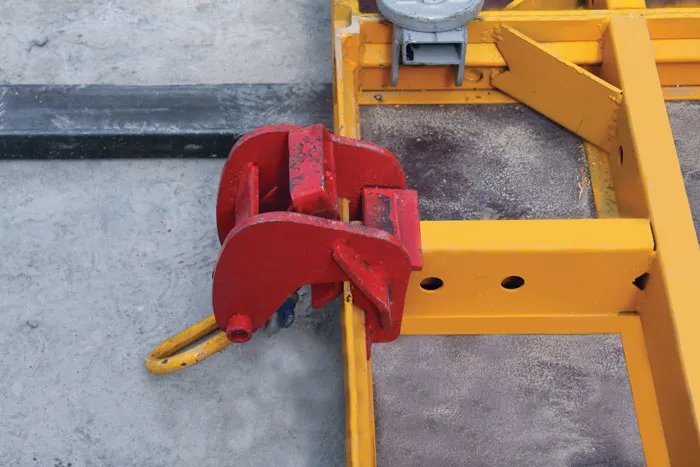

Zigma Lock

Zigma Outside Corner

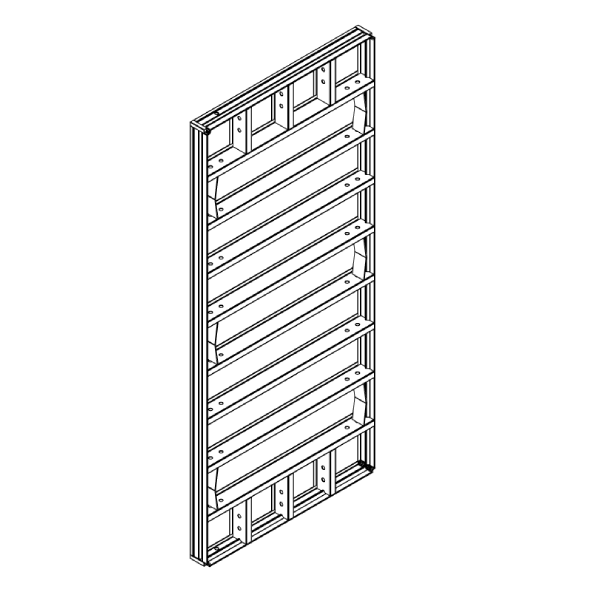

Zigma Panel

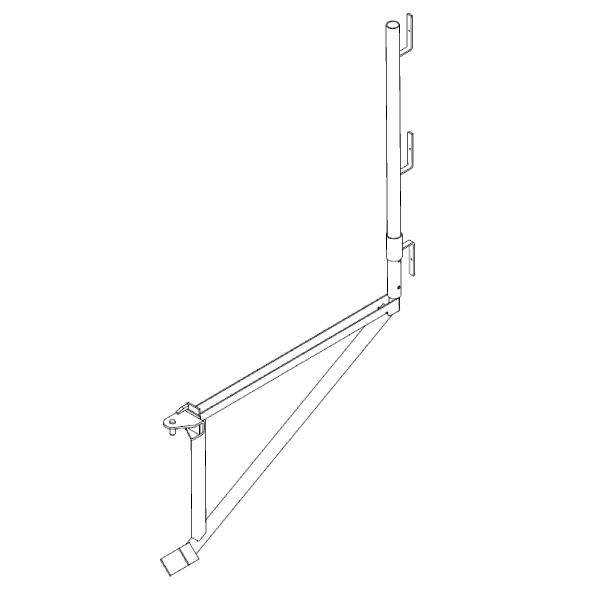

Zigma Pouring Platform

Modular Wall Formwork for Rapid Construction

For today’s construction teams, a modular wall formwork system is more than a tool—it’s a practical solution for controlling labor, cost, and schedule risk on concrete wall projects. Project managers and contractors routinely face major challenges such as skilled labor shortages, supply chain volatility, tight budgets, and delays between pours that reduce productivity.

BFS Industries addresses these pain points with Concrete Wall Formwork solutions engineered for fast cycles and reliable performance. Our modular panels and accessories simplify assembly and stripping, reduce dependency on specialized carpentry, improve site safety, and help teams maintain consistent wall geometry and finish quality. The result is faster execution, better cost predictability, and improved overall profitability—especially on repetitive pours, retaining walls, basements, and high-rise wall construction.

Comprehensive Wall Formwork for Wall Construction Solutions

From Blueprint to Completion, BFS Industries provides end-to-end formwork for wall construction solutions designed to solve your toughest concrete challenges. Our expertise as a trusted supplier, manufacturer, and exporter ensures that every project moves seamlessly from planning to execution—delivering speed, precision, and lasting strength.

Labor Efficiency and Safety

Modern formwork systems are designed to reduce the reliance on highly specialized labor. BFS Industries provides lightweight, modular, and pre-engineered systems that simplify on-site assembly and dismantling. This design minimizes the need for extensive training and reduces the physical strain on workers, which in turn leads to a safer job site with fewer injuries and accidents. By adopting these advanced systems, project teams can improve productivity and streamline their operations, effectively addressing the widespread industry challenge of finding skilled labor. The transition from physically demanding carpentry to modular assembly and installation also makes construction a more appealing career for a new generation of professionals.

Cost Control and Return on Investment (ROI)

The long-term financial viability of a project is heavily dependent on the reusability and durability of its materials. While the initial investment in modern systems may be higher than traditional alternatives, BFS Industries’ formwork solutions are engineered for longevity, offering a significantly lower life-cycle cost. For example, a case study on a large-scale infrastructure project demonstrated that an investment in reusable plastic formwork, despite a higher upfront cost, resulted in a 30% savings on overall formwork expenses compared to using single-use plywood. The ability to reuse panels dozens or even hundreds of times dramatically reduces material waste and procurement costs, providing predictable budgeting and a strong return on investment.

Schedule Acceleration and Timely Delivery

Meeting aggressive project deadlines is a constant pressure point for contractors. BFS Industries’ systems are designed for speed of construction. Their prefabricated and modular designs allow for rapid assembly and dismantling, minimizing downtime between concrete pours and accelerating the overall project timeline. Furthermore, the consistent quality and precision of these systems reduce the need for costly and time-consuming rework, ensuring that each phase of the project progresses smoothly and on schedule. The efficiency of these systems is a direct answer to the industry challenge of delays caused by fragmented data and inadequate tracking.

Advanced Modular Wall Formwork Systems & Shuttering

The selection of the right formwork material is a critical decision that balances a project’s budget, technical requirements, and environmental objectives. BFS Industries’ portfolio includes a range of materials, each optimized for specific applications, ensuring clients have access to the most appropriate solution for their needs.

Double-Sided Wall Formwork (Tie-Rod Based Systems)

A double sided wall system is the most common solution for high-accuracy wall casting, where both sides of the formwork are accessible and fast cycling is required. This double sided wall formwork approach uses tie-rods to lock panels together, control spacing, and safely resist fresh concrete pressure—making it a reliable choice for concrete wall formwork on basements, cores, shear walls, and high-rise construction. As a proven wall shuttering system, it delivers stable alignment, consistent wall thickness, and a clean concrete finish while improving productivity through modular, repeatable assembly.

One-Sided Retaining Wall Shuttering Solutions

BFS Industries specializes in engineered single-sided wall formwork systems designed for projects where space constraints or site conditions prevent access to the rear side of the wall. These solutions are widely used in retaining walls, basement walls, tunnels, and deep foundation structures, where conventional double-sided shuttering is not feasible.

Our one-sided retaining wall shuttering systems utilize heavy-duty pressure brackets and support frames that securely anchor the formwork to the foundation. This engineered approach safely resists the lateral pressure of fresh concrete without the need for through-ties, ensuring structural stability, dimensional accuracy, and a leak-proof concrete finish even in the most demanding civil engineering environments.

As a leading formwork supplier and manufacturer in Dubai, we provide modular components fully compatible with our standard steel and plastic formwork panels, creating a flexible and scalable system for complex infrastructure projects. Our single-sided concrete wall forming systems are engineered to meet international safety standards, reducing on-site labor requirements, simplifying installation, and accelerating construction schedules.

Compared to traditional timber shuttering, BFS Industries’ single-sided wall formwork solutions deliver higher precision, faster cycle times, lower labor costs, and superior durability, making them an ideal choice for contractors working on confined urban sites, deep excavations, and high-performance retaining wall structures.

Retaining Wall Formwork & Retaining Wall Shuttering System

Retaining wall formwork must deliver high stability and precise alignment because retaining structures are exposed to heavy lateral loads and strict dimensional tolerances. A well-engineered retaining wall shuttering setup controls wall thickness, prevents leakage at joints, and maintains clean concrete lines—especially on basement walls, ramps, and deep excavation works where accuracy and safety are non-negotiable.

To meet these demands, BFS Industries provides an integrated retaining wall shuttering system built for fast installation, reliable load transfer, and consistent finish quality across repetitive pours. For heavy-duty applications, steel shuttering for retaining wall projects offers maximum rigidity, long service life, and high reusability—making it an ideal option for infrastructure and high-pressure concrete pours where durability and performance directly impact schedule and cost.

One-Sided vs Double-Sided Wall Formwork (Quick Comparison)

| Feature | One-Sided / Single-Sided Wall Formwork | Double-Sided Wall Formwork |

|---|---|---|

| Best for | Retaining walls, basement walls against shoring, tunnels, deep excavations, boundary walls (no rear access) | Shear walls, cores, basements with access, high-rise walls, general wall construction |

| Access constraints | Rear side blocked or limited space; only one face is reachable | Access available on both sides of the wall line |

| Concrete pressure resistance method | Resists lateral pressure using heavy-duty brackets, support frames, anchors, and foundation reaction (no through-ties) | Resists pressure using tie-rods (ties), walers/soldiers, and through-connections between both faces |

| Speed / cycle time | Fast once set, but setup is heavier due to bracing and anchoring; ideal for staged pours | Typically faster cycling for repetitive walls; simpler alignment and stripping |

| Cost drivers | Brackets/frames, anchoring, strongback/soldiers, higher hardware demand; engineering & layout important | Tie-rods, cones, walers, corners; lower bracing demand; strong ROI in repetitive pours |

| Finish quality | Excellent finish possible; no tie holes through the wall (cleaner face), depends on bracing accuracy | Consistent finish; may have tie holes (patched or cone-finished), high dimensional accuracy |

The Power of Materials: Engineered for Durability and Maximum ROI

At BFS Industries, every concrete wall formwork system is designed to deliver unmatched strength, reliability, and long-term value. Our engineered solutions not only ensure structural durability but also optimize costs and project efficiency, giving contractors and developers a measurable return on investment from the very first pour.

Steel Formwork Systems

Steel formwork is engineered for projects requiring maximum strength, rigidity, and long-term durability. As a premier choice for large-scale and high-load infrastructure, it is the ideal solution for retaining wall shuttering and heavy-duty concrete structures. One of the most significant advantages of steel formwork panels is their incredible reusability, often exceeding 100 cycles, with the added benefit of being repairable and refurbishable for an extended functional life. Because steel does not absorb water, it effectively eliminates the “honeycombing effect,” ensuring a smooth, high-quality concrete finish. While its weight typically requires crane assistance, its unparalleled load capacity and longevity make it a highly cost-effective investment for professional contractors.

Aluminium Formwork Solutions

Aluminium formwork systems provide a superior weight-to-strength ratio, offering a significantly lighter alternative to steel. This lightweight design makes them perfect for hand-set (crane-independent) applications, allowing for easier transport and faster on-site handling. These systems are exceptionally cost-efficient for repetitive construction projects, such as residential developments and mass housing schemes. With a high reusability rate of 150 to 200 cycles, aluminium systems deliver substantial long-term ROI. To match the load-bearing capacity of steel, these systems are used in optimized larger sections, balancing ease of use with structural performance.

Modular Plastic Formwork

Plastic formwork is a modern, lightweight, and eco-friendly alternative to traditional plywood. Its 100% water resistance makes it immune to the warping and delamination common in humid environments, ensuring dimensional stability throughout the project. These reusable formwork panels can be used 50 to 100 times or more, drastically reducing procurement costs and material waste. The non-stick surface provides a clean, consistent finish that minimizes the need for expensive post-pour plastering or grinding. Additionally, BFS Industries’ plastic solutions contribute to a circular economy, helping contractors meet green building certifications through the use of sustainable, recyclable materials.

Quick Comparison: Steel vs. Aluminium vs. Plastic Formwork

| Feature | Steel Formwork | Aluminium Formwork | Plastic Formwork |

| Best For | High-load & Retaining Walls | Repetitive Residential Projects | Lightweight & Eco-friendly projects |

| Reusability | 100+ Cycles | 150 – 200 Cycles | 50 – 100 Cycles |

| Handling | Crane-dependent (Heavy) | Hand-set (Lightweight) | Hand-set (Ultralight) |

| Water Resistance | High (Non-absorbent) | High | 100% Waterproof (No warping) |

| Finish Quality | Smooth (No honeycombing) | High-quality repetitive finish | Consistent (Minimal post-pour work) |

| Maintenance | Repairable & Refurbishable | Low maintenance | Easy to clean & Recyclable |

Precision and Performance: Meeting Global Standards

BFS Industries’ solutions are not only highly durable but also engineered with meticulous precision to meet the most stringent project specifications. As a leading concrete wall formwork dimensions supplier and exporter, the company ensures that all products adhere to global engineering standards. Standard panel sizes are readily available, designed to provide dimensional stability and structural integrity throughout the concrete curing process. The systems are versatile and robust, capable of accommodating a wide range of wall depths and heights for diverse construction needs.

BFS Industries also specializes in custom-cut panels for specialized applications, helping to optimize material use and minimize waste on site. The engineering team collaborates closely with clients to determine the ideal size and spacing of studs and wales, ensuring the formwork can withstand the pressures of fresh concrete while delivering smooth, accurate surfaces. This commitment to detail and customization positions BFS Industries as a trusted consultative partner, offering more than just products—delivering solutions that enhance efficiency, quality, and project outcomes.

Wall Formwork Design, Sketch & Calculation

Accurate wall formwork design is critical to ensure structural safety, dimensional accuracy, and cost efficiency during concrete wall construction. A well-engineered wall formwork system must be designed to withstand fresh concrete pressure, optimize tie spacing, and ensure proper load transfer through studs, walers, and anchors.

Wall formwork calculation typically considers concrete pour rate, wall height, concrete density, and vibration method. BFS Industries supports contractors and engineers with optimized wall formwork layouts, including single-sided wall formwork calculation for retaining walls and basement applications, where lateral pressure must be resisted without through-ties.

To simplify execution, our engineering team provides wall formwork sketches and layout drawings that ensure correct panel alignment, safe load distribution, and fast installation on site. Whether for standard double-sided wall systems or complex one-sided retaining wall shuttering, our solutions are designed to meet international engineering standards and project-specific requirements.

Versatility and Application: Building for Every Purpose

The versatility of BFS Industries’ formwork systems allows for their application across a wide spectrum of construction projects. The company’s solutions are central to the creation of everything from residential and commercial properties to large-scale infrastructure. This broad applicability, combined with a reputation as a trusted concrete wall formwork factory, concrete wall formwork company, and a reliable provider of shuttering system concrete walls, makes BFS Industries a comprehensive partner.

High-Rise Construction

High-rise buildings present unique challenges related to consistency and speed. Even a minor deviation at a lower level can compound into significant alignment problems on higher floors. BFS Industries’ formwork systems are engineered to ensure uniformity across every level, with rapid cycling times that help meet the demands of vertical growth. Modern formwork, including self-climbing and digitally-designed solutions, minimizes the need for a crane and ensures a consistent, high-quality finish floor after floor.

Infrastructure and Civil Works

Beyond buildings, BFS Industries’ formwork is essential for a variety of infrastructure projects, including the construction of foundations, tunnels, and bridges. The durability and strength of the systems are critical for these demanding applications, ensuring the integrity and safety of the final structure. The ability to deliver tailored systems for complex structures showcases the company’s expertise and reliability in civil engineering projects.

BFS Industries: Your Trusted Partner in a Dynamic Market

The United Arab Emirates is a highly competitive construction market, and BFS Industries has established a strong presence as a trusted concrete wall formwork manufacturer and supplier in Dubai. With a proven track record on iconic projects, the company sets itself apart not just by its experience, but by leveraging its strategic location in one of the world’s leading trade hubs. This allows BFS Industries to deliver timely, high-quality formwork solutions that meet the demanding needs of contractors, developers, and engineering firms across the region and beyond.

A Dubai-Based Manufacturer with Global Reach

BFS Industries’ local presence in Dubai provides distinct advantages. As a direct concrete wall formwork manufacturer, the company offers clients faster delivery times, direct access to technical support, and competitive pricing by eliminating the need for intermediaries. The ability to engage directly with a local concrete wall formwork factory ensures that solutions are not only tailored to project needs but also delivered with the agility and responsiveness required in the fast-paced UAE construction industry. This positions BFS Industries as an agile and investor-friendly partner, a key differentiator in a market known for its strong multinational competition.

Our Integrated Product Ecosystem: The Total Construction Solution

Project management is simplified when a single, trusted partner can provide a comprehensive suite of solutions. BFS Industries offers an integrated product ecosystem that extends beyond concrete formwork to include complementary construction solutions. This integrated approach helps contractors and project managers avoid the stress and logistical complexities of coordinating with multiple, uncoordinated suppliers.

- Modular Formwork Systems: Beyond wall formwork, BFS Industries provides a full range of modular formwork systems for columns, slabs, and foundations. These systems are designed to be highly interoperable, allowing for seamless integration and expedited construction processes across an entire project.

- Steel Structures: The company’s expertise in steel fabrication allows it to provide essential steel structures and components that are critical for reinforcing concrete projects and providing a backbone for modern high-rise buildings.

- Scaffolding: Safe and efficient access is paramount on any construction site. BFS Industries supplies a variety of scaffolding systems, including modular and system scaffolds, which provide secure platforms for workers during formwork installation, concrete pouring, and stripping.

By offering a complete and integrated suite of products, BFS Industries establishes itself as a one-stop-shop for contractors, simplifying procurement and ensuring a unified, high-quality solution from start to finish. This ecosystem approach provides a level of synergy that enhances efficiency and overall project outcomes.

Wall Formwork Supplier & Manufacturer in Dubai

When you buy wall formwork directly from BFS Industries, you gain access to durable, precision-engineered systems designed to deliver strength, speed, and efficiency on every project. As a trusted manufacturer and global supplier, we provide cost-effective solutions without intermediaries, ensuring competitive pricing, consistent quality, and reliable delivery. Whether for residential, commercial, or large-scale infrastructure, our wall formwork systems are built to meet international standards—making BFS Industries the partner of choice for contractors worldwide.

Ready to Transform Your Next Project? Partner with BFS Industries.

In an industry where precision, speed, and reliability are non-negotiable, the choice of a formwork partner is one of the most critical decisions a project manager can make. BFS Industries offers more than just products; it provides a strategic advantage through engineered solutions, material expertise, and a commitment to customer success. As a leading concrete wall formwork systems supplier, manufacturer, exporter, and factory based in Dubai, UAE, BFS Industries is equipped to deliver the high-performance solutions your project deserves.

Whether your next challenge is a towering skyscraper, a complex infrastructure project, or a cost-effective residential development, our team of experts is ready to collaborate with you. We invite you to leverage our deep understanding of concrete, our mastery of formwork technology, and our dedication to delivering value at every stage.

Frequently Asked Questions (FAQ) About Wall Formwork

What is wall formwork?

Wall formwork is a temporary structure used to mold concrete walls during the construction process. It holds the concrete in place while it cures and provides the necessary shape, alignment, and support to ensure strong, durable walls.

What are the different types of wall formwork?

The most common types of wall formwork include:

- Timber Formwork: Traditional and affordable but less durable.

- Steel Formwork: Strong, durable, and reusable, ideal for large-scale projects.

- Aluminum Formwork: Lightweight, corrosion-resistant, and reusable, commonly used for high-rise buildings.

- Plastic or Composite Formwork: Specialized materials used for certain applications, offering ease of handling and chemical resistance.

How do I choose the right wall formwork for my project?

The choice of wall formwork depends on factors such as:

- Project Size: Larger projects often benefit from steel or aluminum formwork due to their durability and reusability.

- Budget: Plywood and timber formwork are more affordable but less durable.

- Project Complexity: For intricate designs, custom formwork or plastic options may be more suitable.

- Reusability: For long-term projects, consider systems like steel or aluminum that can be reused multiple times.

What materials are typically used in wall formwork?

Wall formwork can be made from various materials, including plywood, timber, steel, aluminum, and plastic composites. The choice of material depends on the project’s requirements, including cost, durability, and ease of handling.

How much does wall formwork cost?

The cost of wall formwork varies based on the material used and the size of the project. On average:

- Plywood formwork costs around $20–$60 per panel.

- Steel formwork ranges from $50–$150 per panel.

- Aluminum formwork typically costs $80–$200 per panel.

- Plastic/composite formwork can be priced anywhere from $100–$250 per panel.

- Additionally, labor costs, transportation, and rental fees may also contribute to the overall cost.