Double Sided Wall Formwork Supplier

Introduction

Double sided wall formwork is a cornerstone of modern concrete construction, offering unmatched durability, precision, and operational efficiency. By supporting both sides of a wall simultaneously, it ensures consistent, structurally sound results for every project. Whether you are constructing high-rise commercial buildings, robust infrastructure, or secure residential basements, this system provides one of the most reliable and versatile solutions in the construction industry today

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

Double-Sided Wall Formworks Category

Double-Sided Wall Formworks Products

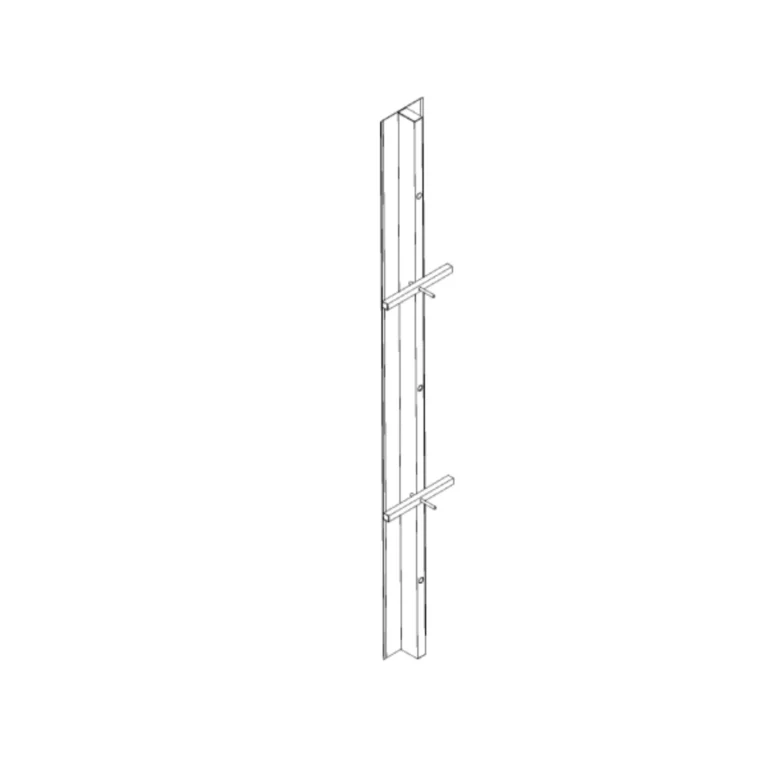

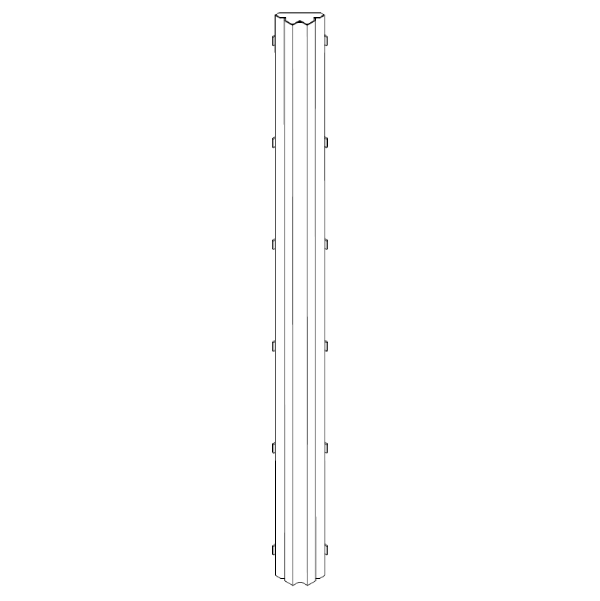

Zigma Filler Plate

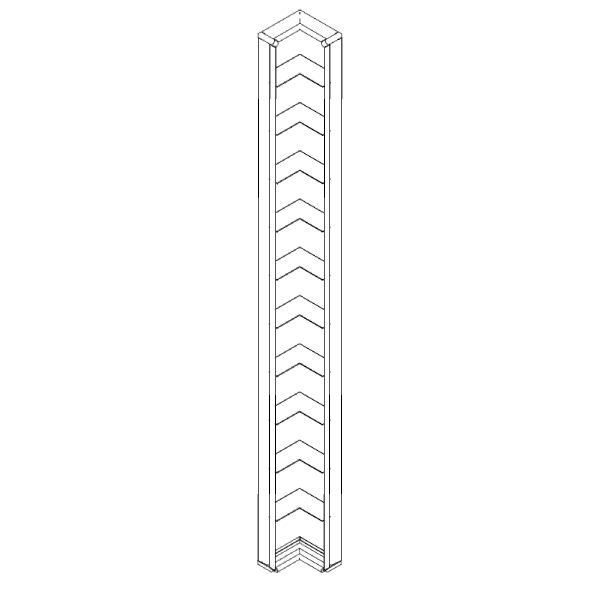

Zigma Inside Corner

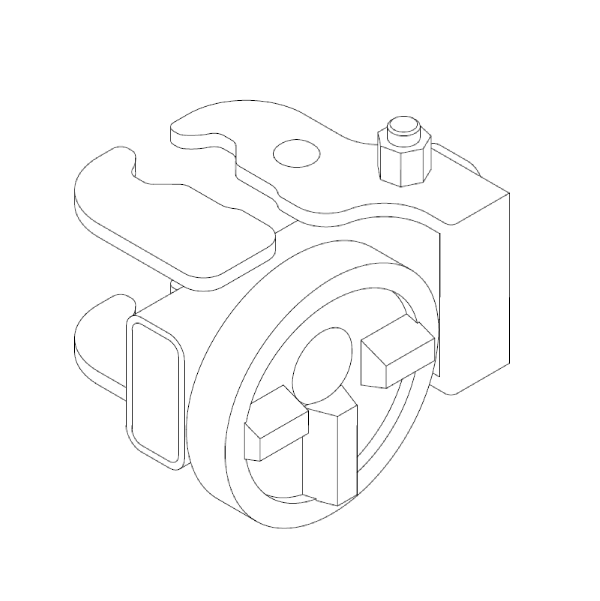

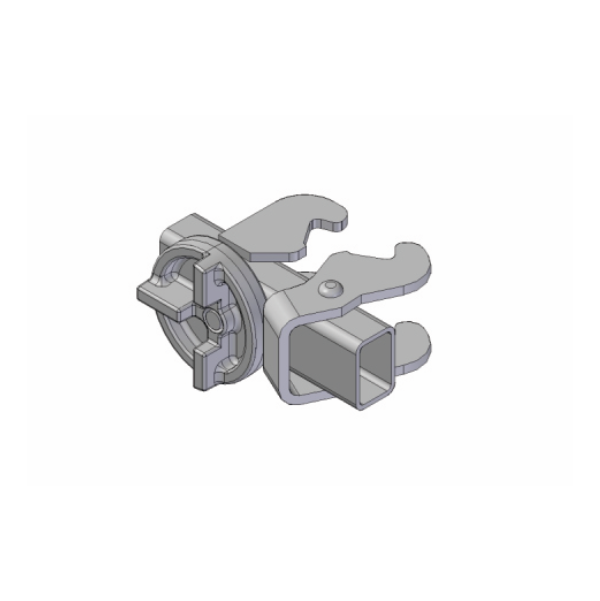

Zigma Lock

Zigma Outside Corner

Zigma Panel

Zigma Pouring Platform

1. What Is Double Sided Wall Formwork?

Fundamentally, double-sided wall formwork is a technique used in concrete construction to support both sides of the form with an adjustable, structured system in order to mold vertical concrete walls. Double-sided wall systems are freestanding in contrast to single-sided systems, in which only one face of the formwork is supported and the other is dependent on an existing structure, such as soil or a slab. Because of this, they are highly adaptable for a variety of uses, particularly in situations where the wall is being poured in an open area. This flexibility is further enhanced when integrated with Modular Formwork Systems, which allow for quick assembly, easy customization, and repeated use across multiple projects.

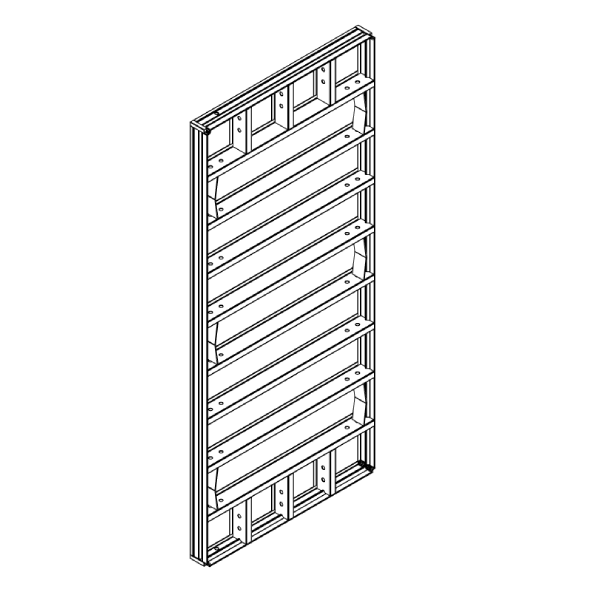

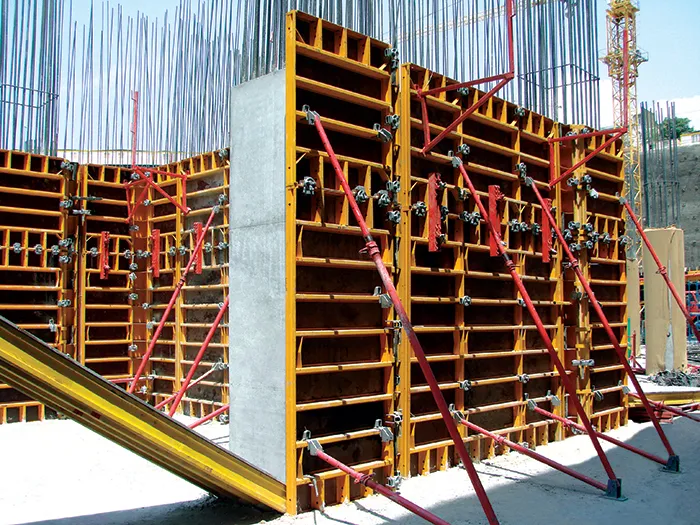

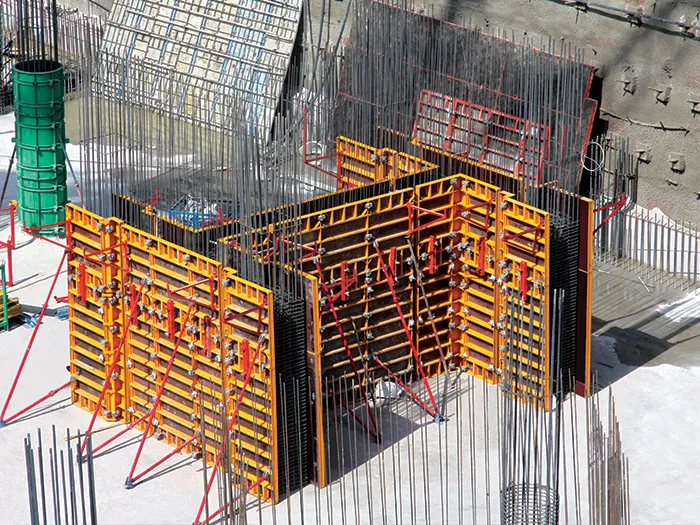

Usually, the system consists of two formwork panels placed opposite each other, leaving a space for concrete between them. Steel walers, tie rods, alignment bars, and vertical supports hold these panels securely in place, ensuring precise structural alignment and uniform wall thickness. Once the concrete is poured and has cured, removing the forms reveals a neat, well-formed wall ready for the next construction phase.

At B.F.S Industries, a leading wall formwork manufacturer, we produce high-quality double-sided Wall Formworks Systems that combine durability, precision, and efficiency. Designed for residential, commercial, and infrastructure projects, our systems provide contractors with reliable solutions that save time, reduce costs, and deliver superior concrete finishes.

2. Key Components of a Double Sided Wall System

A properly configured double sided wall system relies on several critical components, each serving a unique purpose in maintaining form alignment, supporting loads, and ensuring safety. Here’s a breakdown of the essential elements:

| Component | Function |

| Formwork Panels | These are the actual molds where concrete is poured. Usually made of steel or aluminum for durability and reusability. |

| Tie Rods | Positioned through both panels to hold them together and maintain consistent wall thickness. |

| Walers | Horizontal steel or aluminum beams that help distribute the concrete pressure evenly across the panels. |

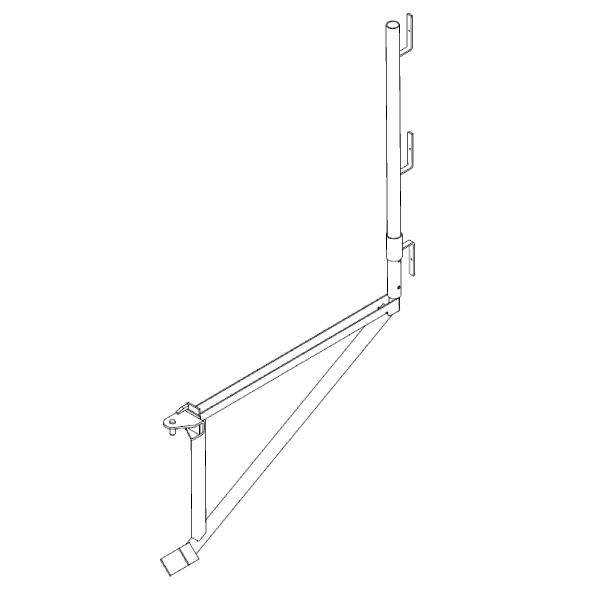

| Alignment Bars / Braces | Keep the panels vertically aligned during concrete pouring and curing. |

| Anchoring System | Ensures stability by securing the formwork to the ground or structural base. |

These elements come together to form a safe, reusable, and highly efficient mold for wall construction. Most systems are modular, making them adaptable for different wall heights and thicknesses.

3. Why Use Double Sided Wall Formwork?

Now that we’ve covered what it is and how it’s built, let’s explore why the double sided wall formwork system—also known as a double wall system—is a preferred solution for professionals in Concrete Construction Formwork. This system combines strength, precision, and efficiency, making it ideal for high-quality, structurally sound walls in residential, commercial, and infrastructure projects.

3.1. Strength and Stability

Unlike single-sided systems, which often require an existing surface or backfill to resist concrete pressure, double sided wall systems are completely self-supporting. This makes them ideal for applications like lift shafts, stairwells, tanks, and free-standing walls, where stability and strength are non-negotiable.

3.2. Speed and Efficiency

Formwork is one of the most time-consuming aspects of wall construction. Double sided wall formwork systems accelerate the process by allowing both sides of the wall to be formed and poured simultaneously, significantly reducing labor time and equipment requirements. The modular design further enhances efficiency by making assembly and disassembly faster and simpler. Working with a reputable double sided formwork company ensures access to high-quality, durable systems that streamline construction schedules, improve productivity, and deliver reliable results across a wide range of projects—from residential basements to large-scale commercial developments.

3.3. Accuracy and Finish Quality

Thanks to rigid components such as steel panels and tie rods, double sided wall formwork systems maintain perfect alignment and produce consistent wall thickness throughout the project. This precision ensures high-quality concrete finishes that often require minimal or no additional treatment or surface correction. Sourcing from a reliable double sided formwork factory guarantees that every component meets strict quality standards, delivering durability, accuracy, and superior performance for both small-scale and large-scale construction projects. With this level of precision, contractors can achieve flawless results while saving time and reducing the need for costly rework.

3.4. Reusability and Cost Savings

Most double sided wall formworks are designed for repeated use across multiple projects, making them a highly cost-effective choice for contractors. This reusability not only significantly reduces material expenses but also minimizes construction waste—a key advantage for companies focused on sustainable building practices. By sourcing from reputable double sided wall formwork suppliers and trusted double sided formwork exporters, contractors can ensure consistent quality, durability, and performance across every project. This combination of efficiency, sustainability, and reliability makes modern double sided wall formwork an essential solution for commercial high-rises, residential developments, and large-scale infrastructure projects alike.

4. Common Applications of Double Sided Wall Formwork

Double sided wall systems are used across various construction projects—from small-scale buildings to massive infrastructure works. Here are some of the most common applications:

- Basement walls: These walls often need to withstand soil pressure and moisture, making a strong, consistent concrete wall essential. Double sided wall formwork provides that strength with a clean, reinforced build.

- Water tanks and retaining walls: These structures must hold back large volumes of water or soil, which puts stress on both faces of the wall. Using double sided systems ensures structural integrity on both sides.

- Lift shafts and stair cores: In commercial and residential high-rises, elevator shafts and stairwells are usually among the first vertical elements constructed. Double sided formwork helps build them quickly and accurately.

- Tunnels and bridges: In civil engineering, formwork systems that provide high load resistance and fast cycle times are crucial. Double sided wall formworks meet those demands effectively.

Whether you’re building a multi-storey apartment or an industrial-grade facility, the versatility of this system makes it a reliable tool in nearly all vertical concrete construction.

5. How to Set Up Double Sided Wall Formwork: Key Tips

Proper setup of double sided wall formwork is essential to ensuring safety, accuracy, and speed on-site. Here are some professional tips and best practices:

- Plan according to the pour height and wall thickness: Different wall dimensions require different types and strengths of formwork panels, tie rods, and supports.

- Check the alignment continuously: Misalignment can cause uneven walls and stress concentrations. Use laser levels or plumb bobs to make sure your setup is vertically accurate.

- Install tie rods at the correct spacing: Too few tie rods can result in panel bulging or even blowouts during pouring. Refer to manufacturer’s guidelines for spacing and tension requirements.

- Lubricate the formwork panels before pouring: A release agent ensures that panels don’t stick to cured concrete, making removal easier and extending the lifespan of your equipment.

- Use safety platforms and scaffolding where necessary: For high walls, proper access and fall protection are critical.

- Disassemble carefully: After curing, remove panels in reverse order and inspect components for wear before reuse.

By following these steps, your crew can reduce errors, minimize rework, and keep the job site safer and more efficient.

6. Pros and Cons of Double Sided Wall Systems

Every system has its strengths and limitations. Here’s a quick comparison to help you evaluate if double sided wall formwork is right for your project:

| Pros | Cons |

| Supports high wall heights and thicknesses | Requires more space around the wall for installation |

| Ensures high dimensional accuracy | Initial setup can be time-consuming |

| Offers excellent concrete finish quality | Heavier than single-sided systems; may need lifting gear |

| Reusable across multiple projects | Requires training for proper use and safety |

| Suitable for free-standing and exposed wall applications | May involve higher upfront costs |

For projects that demand quality, reusability, and long-term cost-efficiency, the advantages clearly outweigh the drawbacks.

7. Choosing the Right Double Sided Wall Formwork for Your Project

Selecting the right double sided wall system depends on several critical project-specific factors. Not all formwork is created equal, and making the right choice can save both time and money.

Start by considering wall dimensions. For taller or thicker walls, you’ll need a robust formwork system with stronger tie rods and braces to withstand concrete pressure. In contrast, smaller projects may benefit from lightweight aluminum systems that are easier to handle and quicker to set up.

Next, think about reusability and project duration. If you’re managing a long-term or multi-phase build, investing in higher-quality, reusable wall formworks will pay off over time. On shorter or one-off jobs, rental options may be more cost-effective.

Also, evaluate site access and space. Some formwork systems need room on both sides of the wall for setup and bracing, which may not be feasible on tight job sites or urban construction zones.

Lastly, factor in crew experience. Complex systems may require more training or skilled labor. The right formwork should match your team’s capabilities while meeting engineering and safety standards.

Choosing wisely ensures your concrete construction process is smooth, efficient, and structurally sound from start to finish.

8. Why Double Sided Wall Formwork Matters

At a glance, formwork may just seem like a temporary step in concrete construction. But in reality, it plays a huge role in the speed, safety, and outcome of a project. Double sided wall formwork not only helps deliver structurally sound walls but also streamlines the entire building process.

From the modular double sided wall system to the clever design of tie rods and braces, this setup embodies the balance between function, flexibility, and finish quality. For any team looking to scale concrete walls with efficiency and precision, this system is a no-brainer.

9. B.F.S Industries – Manufacturer and Supplier of Double-Sided Wall Formwork Systems

B.F.S Industries provides high-quality double-sided wall formwork systems for residential, commercial, and infrastructure projects. Our durable steel and aluminum panels, precise bracing, and reusable components help contractors save time and costs while delivering smooth, accurate concrete walls.

Conclusion

Double sided wall formwork stands out as one of the most effective and reliable methods for constructing vertical concrete structures. With robust and precise components such as steel or aluminum panels, tie rods, and alignment braces, this system ensures not only superior strength and accuracy but also faster execution and higher quality results.

Its advantages—reusability, cost savings, waste reduction, enhanced safety, and excellent concrete surface finishes—make it a preferred choice across a wide range of projects, from residential and commercial buildings to large-scale industrial and infrastructure developments.

By selecting the right system and ensuring proper setup, contractors can achieve durability, efficiency, and long-term economic benefits. Ultimately, double sided wall formwork is far more than just a temporary construction tool; it is a critical factor in ensuring the success and quality of modern concrete projects.

Frequently Asked Questions (FAQs)

1. What is the difference between single-sided and double sided wall formwork?

Single-sided formwork supports only one face of the wall and is usually used when the other side has backfill or an existing structure. Double sided formwork supports both faces, making it suitable for free-standing walls or where access to both sides is available.

2. Is double sided wall formwork reusable?

Yes. Most systems are designed for multiple reuses, especially those made from steel or aluminum. With proper maintenance and storage, they can last for years.

3. Can I use double sided wall systems for curved walls?

Specialized versions of double sided formwork systems can be adjusted or fabricated to create curved wall sections, but standard systems are primarily used for straight walls.

4. What factors determine the choice of wall formworks?

Wall height, thickness, concrete pressure, site conditions, budget, and speed requirements all influence the type of formwork you should use.

5. How long should I wait to remove the formwork after pouring concrete?

This depends on temperature, humidity, and concrete type. Typically, formwork can be removed after 24–48 hours for standard concrete, but always follow your structural engineer’s recommendations.