Large Panel System (Zigma)

Introduction

Large Panel System has become a game-changing solution in Dubai’s construction sector, which is globally recognized for its scale, speed, and ambition. In a market shaped by mega-projects and record-breaking skylines, choosing the right concrete formwork system is no longer just a technical requirement—it is a strategic decision that determines profitability, efficiency, and structural integrity. For contractors, developers, and project managers navigating this competitive environment, selecting a partner with deep knowledge of regional construction challenges is essential to long-term success.

As a leading concrete wall formwork system supplier, BFS Industries provides more than just products; it delivers tailored solutions designed for the realities of Concrete Construction in the UAE. With its flagship Large Panel Zigma, the company sets new standards in speed, durability, and reliability, ensuring that large-scale projects are completed faster and with greater precision. By combining global expertise with a strong local presence in Dubai, BFS Industries has positioned itself as the trusted choice for modern formwork technology and efficient project delivery.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

Large Panel System (Zigma) Products

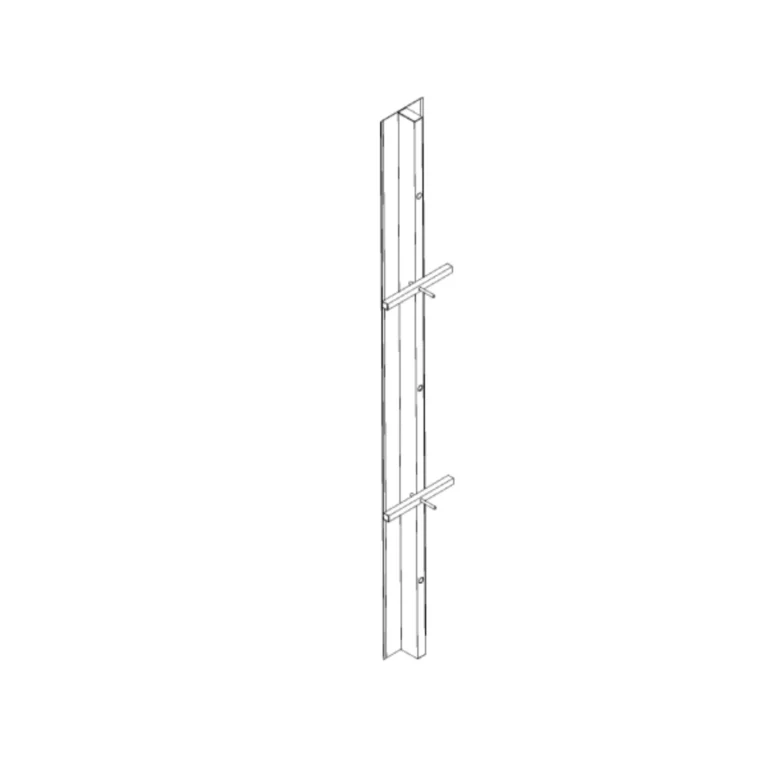

Zigma Filler Plate

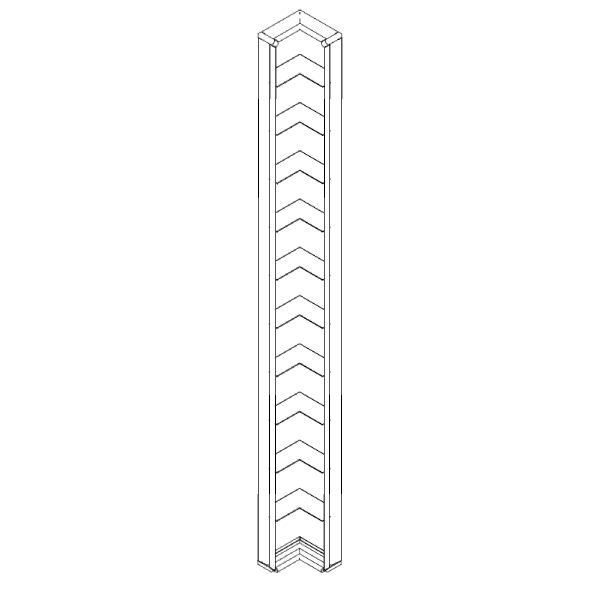

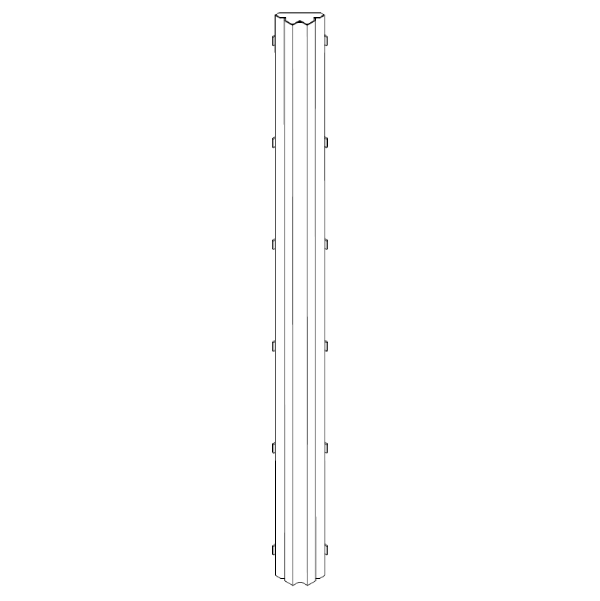

Zigma Inside Corner

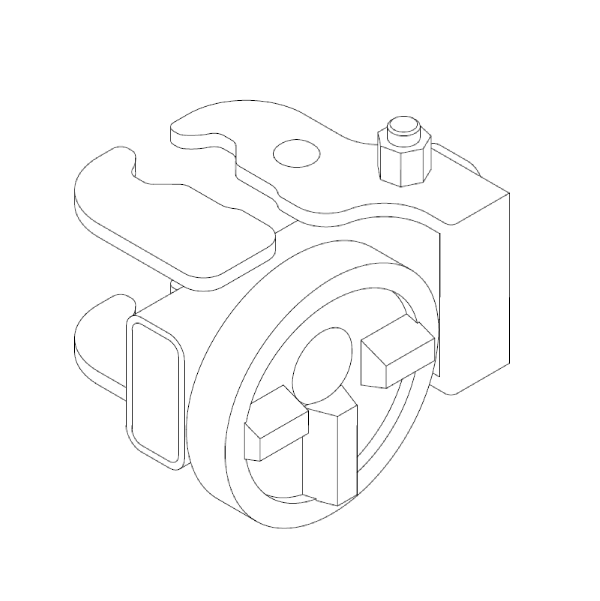

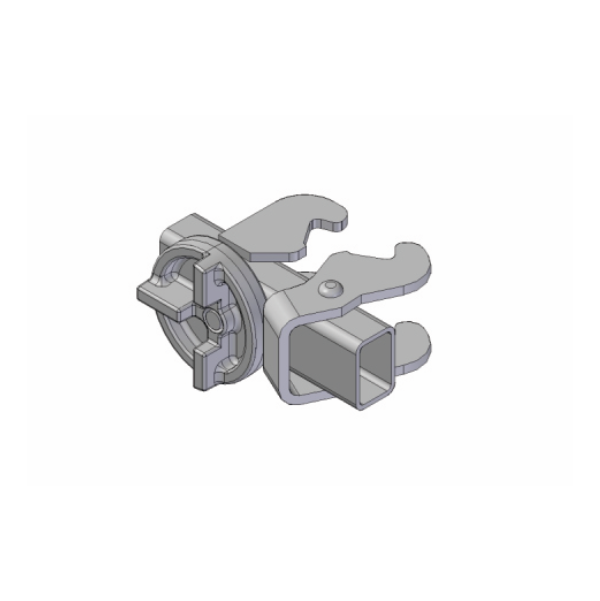

Zigma Lock

Zigma Outside Corner

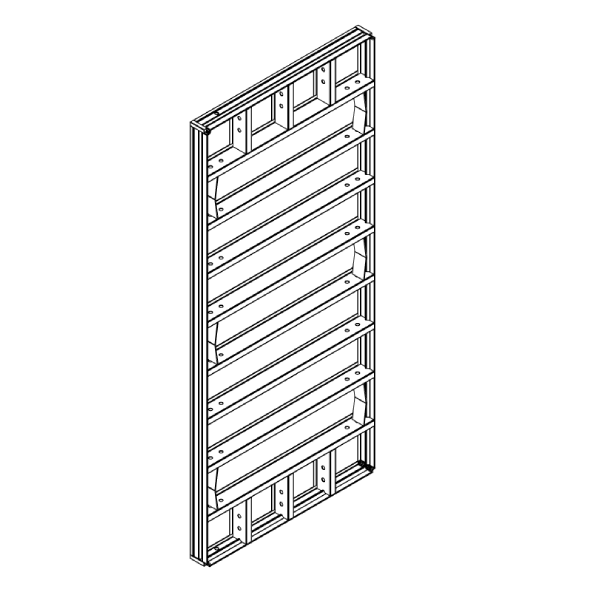

Zigma Panel

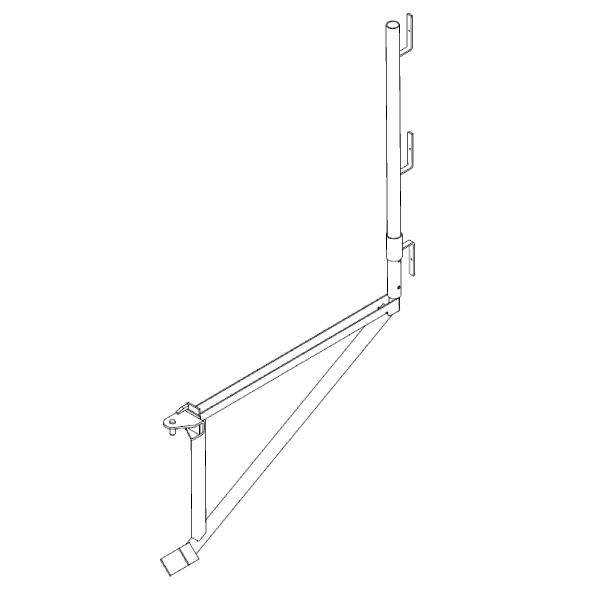

Zigma Pouring Platform

The Dubai Construction Market

Dubai’s construction market stands out for its ambition, scale, and speed, but this rapid growth is accompanied by significant operational and financial challenges. Rising material costs and ongoing supply chain volatility have become critical concerns for contractors and developers across the UAE. Prices of core construction materials such as steel and aluminum continue to rise due to global shipping disruptions and intense regional competition driven by simultaneous giga-projects. This situation directly erodes profit margins and is a leading cause of cost overruns in large-scale developments.

Adding to these financial strains is a shortage of skilled labor, particularly in specialized fields like project management and modern construction technologies. Recent surveys reveal that a large portion of UAE-based firms face difficulties in sourcing qualified professionals, creating project bottlenecks and driving up labor costs. These combined challenges not only extend timelines but also risk compromising the quality and structural integrity of completed projects.

Large Panel System: Efficient Formwork Solutions

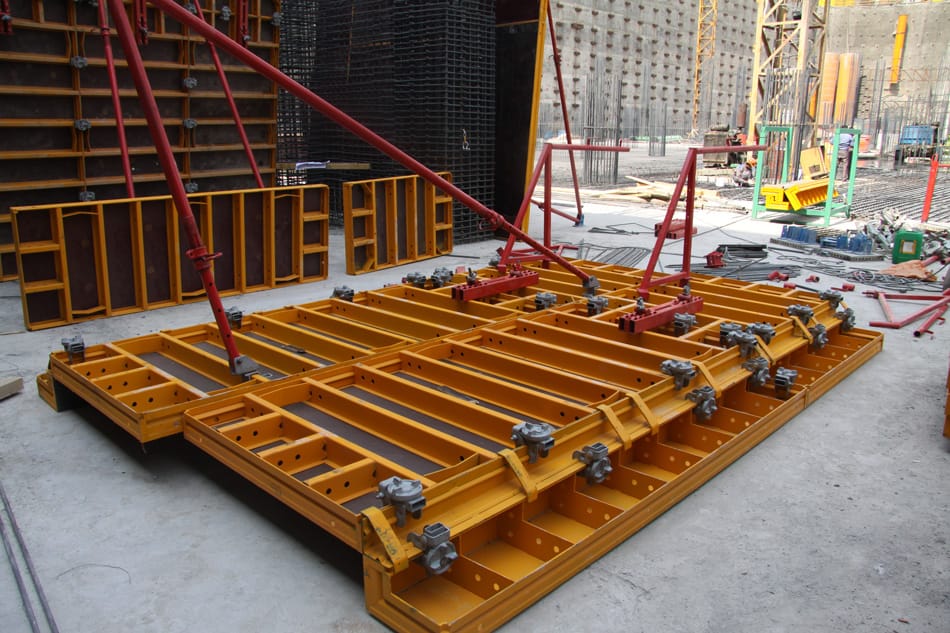

The Large Panel System has become a cornerstone of efficient panel formwork solutions, transforming the way large-scale projects are executed in Dubai and across the UAE. By reducing on-site complexities, cutting down construction time, and ensuring consistent quality, this system directly addresses the core challenges faced by contractors and developers. Its ability to streamline workflows makes it not just a technical choice, but a strategic investment for modern Concrete Construction.

Accelerating Project Timelines with a Fast-Track Construction System

The Large Panel System represents a true paradigm shift in construction efficiency, directly addressing the industry’s most pressing challenges: project delays and budget overruns. Through the use of large, integrated panels, entire walls or significant structural sections can be cast in a single pour. This modular panel formwork design reduces on-site assembly and dismantling time, enabling project execution up to 30% faster compared to conventional methods. By leveraging pre-engineered concrete panels and quick assembly formwork panels, the system minimizes reliance on highly specialized labor while also reducing physical strain on workers. As a result, developers benefit from a fast-track construction system that aligns perfectly with the demanding schedules of Dubai’s large-scale construction panels.

For developers, speed translates directly into financial advantage. In Dubai’s competitive real estate market, billions of dirhams in off-plan project payments remain locked in escrow until handover and final inspections are completed. Any delay postpones critical access to this cash flow, limiting expansion opportunities and delaying returns for stakeholders. By adopting a Large Panel System, companies can accelerate delivery, unlock cash flow sooner, and reinvest capital into new developments. As a trusted partner, BFS Industries positions this solution not just as a formwork product, but as a strategic tool that improves financial fluidity, mitigates risks, and strengthens long-term competitiveness in the UAE construction market.

Building for Durability: The Long-Term Value of BFS Solutions

Beyond speed and efficiency, the true value of a Large Panel System lies in its durability and long-term cost-effectiveness. The Large Panel Zigma, designed as a heavy-duty formwork system, incorporates a robust steel frame panel system engineered to withstand the intense hydrostatic pressures of fresh concrete. This superior structural integrity minimizes deformation and leakage during pours, delivering smooth concrete surfaces with minimal joints. Such precision reduces the need for costly rework and can cut plastering expenses by 20–30%, ensuring not only streamlined project execution but also a superior final product that meets the highest quality standards.

The economic advantage of this prefabricated panel formwork becomes even more compelling when evaluated through its lifecycle. While the upfront investment in a Large Panel System may exceed traditional options, the long-term savings are undeniable. Systems engineered by BFS Industries, a leading concrete wall formwork supplier, are designed for extensive reuse—over a hundred times for steel panels and up to 150–200 times for aluminum panels. This exceptional reusability directly translates into lower total cost of ownership, predictable budgets, and stronger profitability for contractors. In a market challenged by rising costs and supply chain volatility, these large shuttering panels provide not just a technical solution, but a financial strategy that secures long-term value and project stability.

BFS Industries: Local Expertise, Global Standards

In Dubai’s highly competitive construction market, success depends on choosing partners who combine local expertise with internationally recognized quality standards. BFS Industries stands out by delivering exactly that balance—acting as a trusted regional partner while offering solutions built to global benchmarks. This unique positioning allows developers and contractors to access advanced technologies like the Large Panel System, backed by reliable service, proven durability, and a deep understanding of the UAE’s construction challenges.

The Large Panel Zigma: Engineered for High-rise concrete formwork

The Large Panel Zigma exemplifies BFS Industries’ dedication to providing engineered solutions for Dubai’s most demanding construction projects. This modular steel panel system is designed for casting large vertical concrete surfaces, making it ideal for double sided wall formwork applications such as core walls, columns, and foundations. Its heavy-duty design ensures it withstands the intense pressures of high-rise concrete formwork and infrastructure projects, while maintaining structural integrity and dimensional accuracy. The system supports a wide range of structures, including lift shafts, retaining walls, and industrial buildings, delivering precision and reliability where it matters most.

As a leading concrete wall formwork system supplier, BFS Industries goes beyond standard panels, offering customized solutions that meet unique project specifications. The Large Panel Zigma allows pre-designed openings for windows, doors, and utilities, and panels can be custom-cut to optimize material use and reduce on-site waste. Options such as galvanized or powder-coated steel frames enhance durability and performance in Dubai’s challenging climate. With a strategically located plant in Jebel Ali Free Zone, BFS Industries provides faster delivery, responsive on-site support, and deep knowledge of local regulations, giving clients a significant advantage over international competitors while ensuring seamless project execution.

Economic Comparison: Large Panel vs. Conventional Systems

The financial advantages of adopting a Large Panel System become evident when considering the total cost of ownership. While the initial investment in a Large Panel Zigma may be higher than conventional formwork, the long-term savings are significant due to reduced labor costs, faster project timelines, and minimized material waste. By streamlining construction processes and enabling fast-track construction, this system improves project profitability and budget predictability for developers and contractors in Dubai.

The table below illustrates how upfront costs for a Large Panel System are offset over time, resulting in substantial cost efficiencies throughout the lifecycle of a project. From labor savings to decreased rework and lower maintenance expenses, the economic value of this modern formwork technology clearly surpasses that of traditional systems, making it a strategic choice for large-scale Concrete Construction projects.

| Cost & Performance Metric | BFS Large Panel Zigma (IBS) | Traditional Timber Formwork | Alternative Modular Systems |

|---|---|---|---|

| Initial Investment Cost | Higher | Lower | Medium |

| On-Site Labor Hours | Significantly Reduced | High | Reduced |

| Construction Speed Advantage | Up to 30% faster | Slow, labor-intensive | Faster, but less seamless |

| Rework/Finishing Costs | Minimized (20-30% reduction) | Significant rework often required | Some finishing still required |

| Life-Cycle Cost per Use | Lowest, due to high reusability | Highest, short lifespan | Low, high reusability |

| Financial Risk Mitigation | High (accelerates cash flow) | Low (prone to delays, penalties) | Medium (less prone to delays) |

Building Authority and Trust: Common Queries About Large Panel System

In the rapidly evolving construction landscape of Dubai, developers and contractors often have critical questions before adopting new technologies. The Large Panel System raises inquiries about efficiency, durability, cost-effectiveness, and suitability for various project types. Addressing these questions not only builds confidence in the system but also highlights the expertise of BFS Industries as a trusted partner. By providing clear, authoritative answers, stakeholders can make informed decisions and ensure that their projects benefit from the full potential of modern Concrete Construction solutions.

Conclusion: Partner with BFS Industries to Equip for Success

The challenges of Dubai’s construction market—from rising material costs and labor shortages to project delays and financial disputes—require a strategic approach to Concrete Construction. The Large Panel System, as a cornerstone of an Industrialized Building System (IBS), offers a reliable solution that directly addresses these complexities. Its flagship product, the Large Panel Zigma, combines fast-track construction capabilities with exceptional durability and reusability, delivering high-quality results across residential, commercial, and high-rise concrete formwork projects.

As a trusted concrete wall formwork system supplier with a strong local manufacturing and distribution presence, BFS Industries provides more than products—it offers a responsive partnership that ensures project predictability and long-term profitability. By choosing BFS Industries, clients gain a competitive advantage, accelerate timelines, minimize financial risk, and achieve superior quality outcomes. This commitment is at the heart of the BFS promise: “We don’t just build projects, we equip them for success.” To explore how BFS Industries formwork solutions can optimize your next project, contact the expert team for a personalized consultation.

Frequently Asked Questions (FAQs)

What is the purpose of the Zigma large formwork system?

Zigma large formwork is mostly used to make concrete walls and columns for medium- to large-scale construction projects. It has big panels and a strong steel frame that make it easy to quickly make smooth, high-quality concrete finishes.

What makes Zigma formwork different from other types?

Zigma, on the other hand, has modular steel-framed panels with fewer joints, faster setup, and more reusability than wood or small-panel formwork. It works especially well for creating walls on both sides and for tall buildings.

Is zigma large formwork useful for all kinds of work?

Zigma works well, but it’s best for big or repetitive projects where its speed and ability to be used again are most useful. For buildings that are small or don’t have a regular shape, formwork that is more flexible may be better.

How many times can you use Zigma panels?

Zigma panels are a very cost-effective choice in the long run because they can last for more than 100 uses if you take care of them.

Where can I get a big zigma panel?

If you want to buy Zigma panels, you can do so from licensed wholesalers, construction equipment suppliers, or the company that makes them. You can also buy used panels for less money, but you should check them for quality before using them.