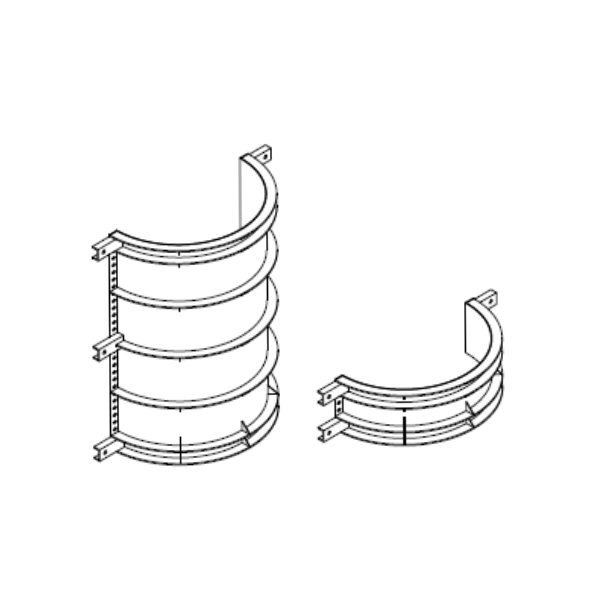

Normal Circular Column Panel

| Product Name |

Circular Column Panel |

|---|---|

| Manufacturer |

BFS Industries |

| Primary Use |

Forming circular concrete columns |

| Available Sizes |

D<100 cm (H=100 cm, 150 cm); D>100 cm (H=50 cm, 100 cm, 150 cm) |

| Material |

High-strength steel |

| Manufacturing |

Full automatic cutting machinery |

| Compatibility |

Works with climbing systems and props |

Circular Column Panel: Precision and Strength in Circular Column Formwork

In the evolving landscape of construction, where versatility and durability are essential, the Circular Column Panel from BFS Industries sets a new standard for circular column formwork systems. Designed and manufactured with meticulous attention to detail by the BFS Industrial Group, this product caters to the unique demands of creating round columns with varying heights and diameters. Available in configurations such as diameters less than 100 cm with heights of 100 cm and 150 cm, and diameters greater than 100 cm with heights of 50 cm, 100 cm, and 150 cm, the Circular Column Panel offers a flexible and robust solution for a wide range of projects. Whether you’re constructing residential towers, commercial buildings, or industrial structures, this panel brings precision, efficiency, and strength to your concrete pouring process. Built with the expertise of BFS Industries, a leader in formwork innovation based in the United Arab Emirates, this product is engineered to meet the highest industry standards. Let’s explore what makes the Circular Column Panel a cornerstone of modern construction.

Why Choose the Circular Column Panel?

The Circular Column Panel is a testament to BFS Industries’ commitment to advanced manufacturing and practical design. Utilizing full automatic cutting machinery to address the sensitivities of diameter variations, this steel formwork system ensures consistency and accuracy in every panel. Its compatibility with climbing systems, including brackets and adjusting props, further enhances its utility, making it ideal for multi-story constructions. Available in tailored sizes—D<100 cm (H=100 cm, 150 cm) and D>100 cm (H=50 cm, 100 cm, 150 cm)—it adapts to diverse project needs with ease. Here’s what sets it apart:

1. Precision Manufacturing with Automatic Cutting

The Circular Column Panel is crafted using full automatic cutting machinery, ensuring precise diameter control and a perfect fit for circular columns. This advanced manufacturing process minimizes errors and guarantees uniformity, even with varying diameters. Whether you’re working with columns under 100 cm in diameter or exceeding it, the panels are produced to exact specifications, delivering a seamless formwork solution every time.

2. Versatile Height and Diameter Options

Designed to accommodate a range of column sizes, the Circular Column Panel offers flexible height and diameter configurations. For diameters less than 100 cm, heights of 100 cm and 150 cm are available, while diameters greater than 100 cm come with heights of 50 cm, 100 cm, and 150 cm. This versatility allows contractors to tailor the formwork to specific project requirements, from small decorative columns to large structural supports, without the need for additional adjustments.

3. Robust Steel Construction

Made from high-strength steel, the Circular Column Panel is built to withstand the pressures of wet concrete and the rigors of construction sites. The steel’s durability ensures the formwork maintains its shape during pouring, providing a reliable mold for circular columns. This robust construction also supports multiple uses, making it a cost-effective choice for repetitive projects.

4. Compatibility with Climbing Systems

The Circular Column Panel is designed to integrate with climbing systems, including brackets and adjusting props, making it ideal for vertical construction. This feature allows the formwork to be raised incrementally as the building progresses, enhancing efficiency on high-rise projects. The inclusion of adjustable props ensures stability and alignment, reducing the risk of movement during the pour.

5. Smooth and High-Quality Finishes

The Circular Column Panel delivers smooth and high-quality concrete finishes thanks to its precisely engineered steel surface. The seamless design minimizes imperfections, such as joint lines or air pockets, resulting in columns that require minimal post-pouring work. This quality is especially valuable for architectural projects where aesthetics are as important as structural integrity.

How the Circular Column Panel Enhances Your Workflow

The Circular Column Panel isn’t just a formwork tool—it’s a productivity booster that streamlines circular column construction. Here’s how it improves your process:

1. Faster Setup and Pouring

The precision manufacturing and modular design of the Circular Column Panel allow for quick setup and efficient pouring. With pre-cut panels and compatible climbing systems, your crew can assemble the formwork rapidly, pour concrete, and move to the next level, accelerating project timelines.

2. Cost-Effective Reusability

The durable steel construction ensures the Circular Column Panel can be reused across multiple projects, reducing the need for frequent replacements. Its compatibility with climbing systems further lowers equipment costs by eliminating the need for extensive scaffolding, making it an economical choice.

3. Enhanced Worker Safety

The panel’s integration with climbing systems and adjusting props provides a stable and secure working environment. The robust steel framework prevents shifts or collapses during pouring, minimizing risks for workers operating at height, and ensuring a safer construction site.

4. Adaptability to Project Scales

With a range of height and diameter options—D<100 cm (H=100 cm, 150 cm) and D>100 cm (H=50 cm, 100 cm, 150 cm)—the Circular Column Panel adapts to various project scales. This flexibility makes it suitable for everything from small residential columns to large industrial supports, offering a versatile solution for diverse construction challenges.

5. Reduced Finishing Work

The smooth steel surface of the Circular Column Panel minimizes the need for extensive finishing, saving labor hours and costs. The high-quality finish achieved during the pour meets industry standards, allowing you to deliver polished columns with minimal additional effort.

Benefits for Your Construction Projects

The Circular Column Panel brings a host of advantages that make it a top choice for circular column formwork:

- Time Savings: Quick setup and pouring accelerate project timelines.

- Cost Efficiency: Reusable steel and reduced equipment needs lower expenses.

- Durability: High-strength steel ensures long-term performance.

- Safety: Climbing system integration enhances worker protection.

- Quality Finishes: Smooth surfaces deliver professional-grade columns.

Why BFS Industries?

At BFS Industries, we’re dedicated to equipping contractors with innovative tools that simplify construction and elevate results. The Circular Column Panel reflects our commitment to precision, durability, and efficiency, backed by years of expertise in the United Arab Emirates’ construction sector. When you choose our products, you’re partnering with a company that understands your challenges and delivers solutions that drive success.

Get Started with Circular Column Panel Today

Ready to transform your circular column formwork? The Circular Column Panel from BFS Industries, available in D<100 cm (H=100 cm, 150 cm) and D>100 cm (H=50 cm, 100 cm, 150 cm) configurations, offers precision, strength, and versatility for your next project. Contact us at 03:15 PM +04 on Saturday, July 26, 2025, to learn more or request a consultation. Visit our website to see how this panel can enhance your construction process. With the Circular Column Panel, you’re not just forming columns—you’re building a foundation for excellence.

جهاد المصري –

ما هو الحد الأقصى للقطر الذي تدعمه هذه الألواح؟ وهل يمكن تعديل المقاس بسهولة في الموقع؟