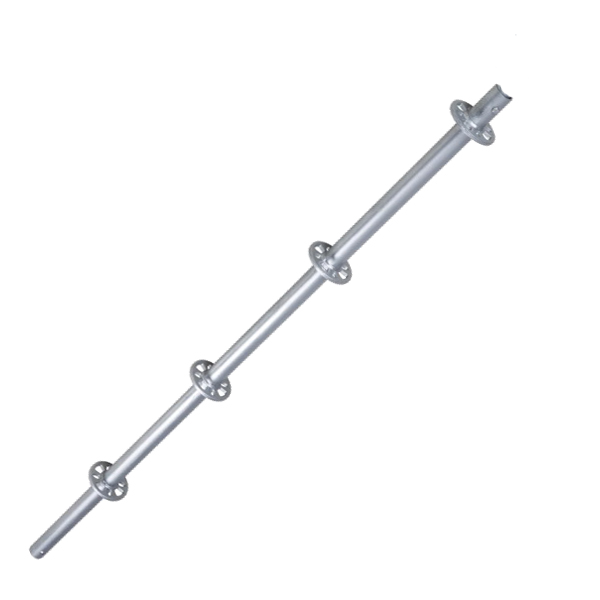

Ringlock Standard

| Material |

Steel sheet (ST37) |

|---|---|

| Diameter Of Steel Tube |

48.3 mm |

| Welding Type |

CO₂ or SMAW |

| Load Capacity |

Depends on design configuration |

| Surface Coating |

Painted |

| Availability |

Available for both sale and rental |

| Delivery Time |

Based on order quantity |

| Shipping Origin |

Jebel Ali, UAE |

Introduction

In the field of concrete construction and temporary support systems, stability and safety are everything. To achieve that, contractors and engineers rely on well-designed shoring systems that can carry the immense weight of wet concrete and formwork. At the heart of many of these systems is the Standard Ringlock, a key vertical component used to create strong, modular, and scalable support structures.

In this article, we take a closer look at what makes the Standard Ringlock so essential in construction, its core features, and where it’s most effectively used.

What is a Standard Ringlock?

The Standard Ringlock is a vertical post, or upright, used primarily in Ringlock Shoring Systems and scaffolding. It is equipped with fixed rosettes (ring-shaped discs) at uniform intervals—typically every 50 cm—which allow secure connection of other components such as ledgers and braces.

This product is manufactured from high-strength galvanized or painted steel, ensuring it can handle heavy vertical loads while remaining durable under tough site conditions. The Standard Ringlock is designed for modularity, meaning different heights and loads can be accommodated with minimal effort.

Main Components and Technical Design

1. Rosette (Ring Disc) System

Welded every 50 cm along the shaft of the Standard Ringlock, the rosette acts as the central connecting point. Each rosette offers eight connection points, supporting both right-angle and diagonal joints. This allows for maximum design flexibility and structural integrity.

2. Spigot (Vertical Connector)

Most Standard Ringlocks are designed with a built-in or detachable spigot at the top. This allows multiple standards to be vertically stacked while maintaining perfect alignment and load continuity.

3. Base jack

The bottom of the Standard Ringlock is usually placed on an adjustable base jack and universal jack, allowing height adjustments and level compensation for uneven surfaces.

4. Surface Treatment

To ensure long-term performance, the Standard Ringlock typically undergoes hot-dip galvanization or electro-galvanization or pained steel, offering protection against corrosion, rust, and mechanical wear.

Key Benefits of Using Standard Ringlock

High Load Capacity

Engineered for heavy-duty use, the Standard Ringlock can support significant vertical loads, making it ideal for shoring applications, especially in cast-in-place concrete works.

Fast & Tool-Free Assembly

The wedge-lock system used in Ringlock technology allows for quick assembly and disassembly without specialized tools. This helps reduce labor costs and improve project timelines.

Exceptional Versatility

The modular design of the Standard Ringlock enables it to adapt to various project sizes, heights, and configurations. It fits well in slab support, beam formwork, and multi-level structures.

Durable & Long-Lasting

Thanks to galvanized steel construction and precise welding, this product is designed for repeated use across multiple job sites, delivering excellent return on investment.

Enhanced Safety

Tightly secured joints, high structural integrity, and compatibility with certified shoring accessories make Standard Ringlocks compliant with international safety standards.

Applications of Standard Ringlock

The Standard Ringlock is widely used in:

-

Slab Shoring Systems

To temporarily support slabs during casting and curing phases. -

Bridge and Infrastructure Projects

Providing support to heavy horizontal structures and formwork under load. -

High-Rise Construction

As part of vertical support towers and multi-level shoring setups. -

Industrial Projects

Offering access and load-bearing support in refineries, power plants.

Available Sizes and Load Ratings

Standard Ringlocks come in a range of sizes to match different structural and height requirements. Common lengths include:

-

500 mm

-

1000 mm

-

1500 mm

-

2000 mm

-

3000 mm

Load capacity varies depending on the pipe thickness, steel grade, and design configuration. For safety, always refer to engineering specifications or request load charts from your supplier.

Integration with Shoring Accessories

The Standard Ringlock seamlessly connects with various components in the shoring system:

-

Horizontal Ledgers

-

Diagonal Braces

-

U-Heads or Beam Brackets

-

Adjustable Base Jacks

-

Aluminum Beams or Timber Formwork Panels

This compatibility allows for custom configurations, whether you need a tower system, a grid, or frame-integrated layout. It also makes Standard Ringlock a universal product suitable for small and large projects alike.

Storage and Maintenance Tips

To extend the life of your Standard Ringlocks and ensure safety:

-

Inspect regularly for signs of deformation, rust, or damage at rosette welds.

-

Store vertically on steel pallets or racks in a clean, dry area.

-

Avoid mixing with incompatible scaffolding brands or systems.

-

Lubricate wedge connections and spigots periodically if used in humid or coastal regions.

BFS-48 Standard Ringlock (Painted Series)

At BFS Industries, our Standard Ringlock uprights are available in multiple sizes to suit a wide range of shoring configurations. The BFS-48 Standard series, made from high-grade steel and finished with durable industrial paint, ensures excellent performance and cost-efficiency.

Below is the list of available lengths:

| Product Name | Length | Surface Finish |

|---|---|---|

| BFS-48 Standard 50 cm Painted | 50 cm | Painted |

| BFS-48 Standard 100 cm Painted | 100 cm | Painted |

| BFS-48 Standard 150 cm Painted | 150 cm | Painted |

| BFS-48 Standard 200 cm Painted | 200 cm | Painted |

| BFS-48 Standard 250 cm Painted | 250 cm | Painted |

| BFS-48 Standard 300 cm Painted | 300 cm | Painted |

| BFS-48 Standard 400 cm Painted | 400 cm | Painted |

Each unit is compatible with Ringlock shoring accessories, including ledgers, diagonal braces, U-head jacks, radial, and base jacks. Painted finish offers added protection against wear and tear during frequent use on construction sites.

Why Contractors Trust Standard Ringlock

Contractors and engineers choose Standard Ringlock not only just for its technical specifications but also for its reliability in real-world conditions. The product’s universal design, rugged construction, and easy-to-use features make it a core asset in modern shoring systems.

Whether you are managing a large-scale infrastructure project or a fast-track residential development, the Standard Ringlock offers the strength, speed, and safety you need to build with confidence.

Final Thoughts

The Standard Ringlock is more than just a scaffolding upright—it’s a critical building block in efficient and secure concrete construction. From slab formwork to bridge decks, it provides the vertical stability that every shoring system relies on.

For maximum performance, always choose high-quality, certified Ringlock components from trusted manufacturers. Proper planning, correct sizing, and trained installation will ensure your shoring system stands strong from foundation to finish

أحمد الزهراني –

هل هذا النوع من الستاندرد معالج ضد الصدأ؟ وكم قدرة التحمل القصوى له؟