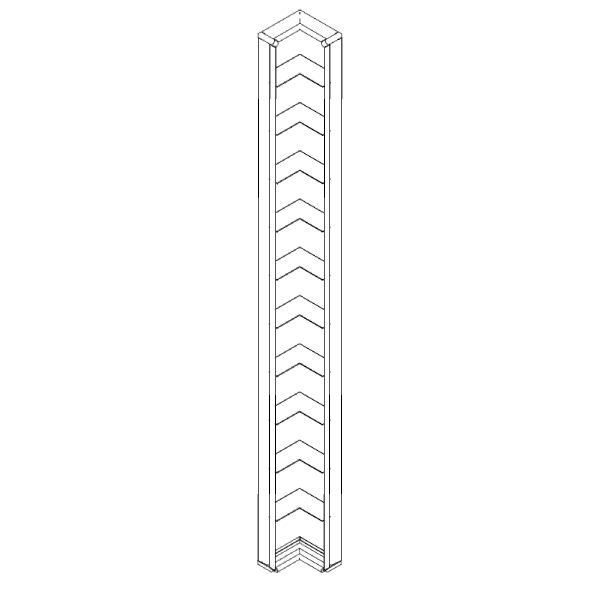

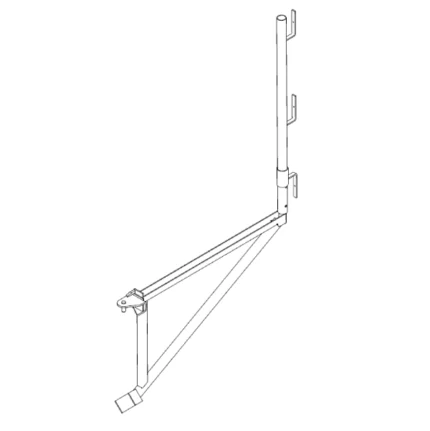

Zigma Inside Corner

| Primary Use |

Wall formwork for construction projects (residential, commercial, industrial) |

|---|---|

| Corner Design |

Specially shaped corners for easy horizontal and vertical movement |

| Hammer Requirement |

No hammering required for panel alignment |

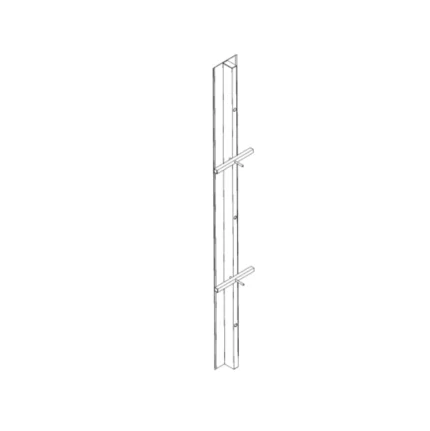

| Profile/Section |

Sturdy and stable, optimized for structural integrity |

| Material Quality |

Premium-grade materials for durability and easy cleaning |

| Lifespan |

Extended due to high-quality materials and robust construction |

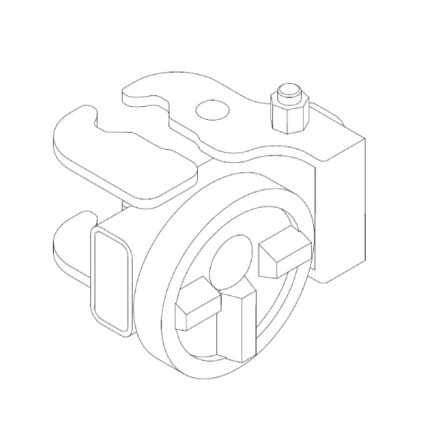

| Connection System |

Modular locks for quick and easy opening/closing |

| Lock Design |

Specially shaped for balanced, level, and compressed formwork alignment |

A Strategic Guide to Modern Concrete Formwork: The B.F.S Industries Approach to Mitigating Project Risk and Boosting Profitability

In the fast-paced world of Concrete Construction, where project timelines are tight and financial margins are often precarious, the stability and reliability of a key partner are non-negotiable. Delays, design errors, or equipment failures can quickly escalate into costly setbacks that jeopardize both profitability and reputation. Within this high-stakes environment, modern concrete formwork emerges not only as a technical necessity but as a strategic enabler of efficiency, safety, and long-term success. It is in this very context that the seven-decade history of B.F.S Industries stands out, offering more than just products—it delivers proven expertise, innovative engineering solutions, and a partnership model designed to mitigate risks and secure measurable returns. By combining tradition with cutting-edge formwork systems, B.F.S Industries provides construction professionals with the confidence that every project can be executed with greater precision, reduced downtime, and enhanced profitability.

A Legacy of Engineering Excellence: A Strategic Profile of B.F.S Industries

B.F.S Industries stands as a symbol of endurance and innovation in the global engineering landscape. With a legacy spanning more than seven decades, the company has consistently demonstrated financial stability, operational excellence, and long-term reliability. Unlike many competitors that have disappeared through mergers, acquisitions, or bankruptcies, B.F.S has preserved its independence as a family-owned business since its founding in 1946. This continuity has allowed the company to cultivate trusted relationships with clients and representatives, some lasting more than half a century. For contractors and project managers, this enduring presence represents more than just corporate longevity—it signals a secure, low-risk partnership in an industry often characterized by financial and logistical uncertainties.

Over Seven Decades of Enduring Innovation and Trust

Founded in 1946 and remaining a family-owned business to this day, B.F.S Industries has a track record that extends over 70 years of operation, a period in which many of its competitors have “come and gone” due to consolidations, mergers, and bankruptcies. This history is more than a simple chronology of corporate existence; it is a tangible symbol of financial resilience, operational excellence, and a deep-seated commitment to its market. The company’s sustained success is rooted in its ability to cultivate and maintain valuable, long-term relationships with its clients and representatives, with some professional affiliations spanning “four, five and six decades”. For a contractor or project manager, this longevity signals a low-risk procurement choice. In an industry where delayed payments, cost overruns, and supply chain disruptions are common stressors, partnering with a vendor that has weathered over seven decades of market fluctuations offers a degree of security that a newer, less-established firm cannot match.

Beyond Formwork: A Multi-Divisional Engineering Powerhouse

A common misconception is that B.F.S Industries is exclusively a formwork company. A deeper analysis of its business profile reveals a far more comprehensive engineering and manufacturing enterprise. The company’s core expertise lies in the design and fabrication of critical, high-performance systems for industrial applications, notably in the boiler room equipment sector, a business it has been in for over 70 years. This expertise is further evidenced by its dedicated Controls Group, which specializes in the design and fabrication of industrial control panels and UL-certified PLC-based systems with HMI touch screens.

While these business units may seem disparate at first glance, they are united by a common thread of precision engineering, advanced material science, and an unwavering commitment to quality control. The creation of robust boiler room systems and industrial control panels, which must perform reliably under extreme conditions, requires the same level of engineering rigor that goes into the design of a high-strength modular steel formwork system. Consequently, a contractor procuring the Zigma formwork system is not merely acquiring a construction product; they are benefiting from the same engineering DNA and manufacturing excellence that underpins critical, high-stakes industrial infrastructure.

Engineered Solutions for Contractor Challenges

In the demanding landscape of modern construction, contractors face an array of challenges that threaten both efficiency and profitability, from supply chain disruptions and labor shortages to unexpected changes in project scope and rising material costs. These pressures are amplified in formwork operations, where flawed designs or substandard materials can result in structural instability, poor concrete finishes, and costly rework that undermine project timelines and cash flow. Recognizing these realities, B.F.S Industries delivers engineered solutions tailored to mitigate such risks, combining innovative system design, durable materials, and practical on-site advantages that streamline operations, enhance safety, and ultimately protect contractor profitability.

Common Project Challenges

The modern construction landscape is fraught with challenges that threaten to undermine project profitability and efficiency. Project managers and contractors are under constant pressure to deliver on time and within budget, but they frequently encounter a range of systemic obstacles, including supply chain delays, a lack of skilled labor, and unexpected changes in project scope. These issues often lead to significant financial strain and can cause a domino effect of delays that disrupt the entire project schedule and cash flow.

Specific to formwork, challenges often arise from inadequate or flawed design, which can lead to structural instability, poor concrete finishes, and extensive rework. The quality of materials is another critical concern; using low-grade materials can result in premature system failure, increased maintenance costs, and compromised final results.

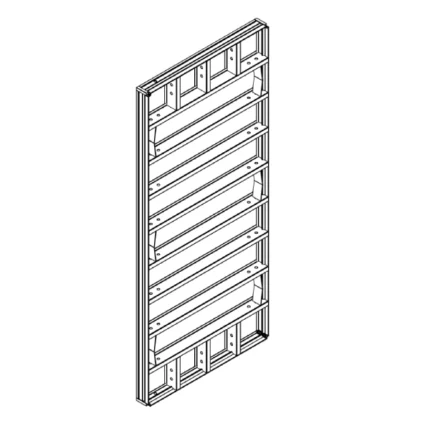

The B.F.S Industries Answer: The Zigma Formwork System

The Zigma Formwork system was engineered to directly address the most pressing pain points faced by construction professionals. Its design represents a strategic approach to mitigating risk, streamlining operations, and protecting project profitability.

At the core of the Zigma system’s efficiency is its specially shaped corner design and innovative modular lock system. Unlike traditional formwork that relies on hammering for alignment, the Zigma Panel’s unique corners allow for effortless movement in both horizontal and vertical directions, saving valuable on-site time. The modular locks are designed for quick and easy opening and closing, enabling a crew to work faster and more efficiently than with traditional, cumbersome wedge systems.

A significant value proposition of the Zigma system is its ability to eliminate the need for props (underpinnings) in the formwork setup. This is a singular advantage that simplifies the entire installation process and reduces the amount of equipment required on-site. This design innovation directly solves a major challenge for heavy-duty construction projects, which often require extensive and time-consuming bracing. Furthermore, the robust and stable profile of the Zigma Panel is built to withstand the high hydrostatic pressures exerted by fresh concrete, ensuring minimal deformation and leakage during pours.

The B.F.S Industries Value Proposition: A Strategic Comparative Analysis

In a market defined by intense competition and rapidly evolving project demands, the true value of a formwork provider lies not only in the quality of its products but in its ability to strategically balance speed, strength, and cost-efficiency. B.F.S Industries differentiates itself by addressing the critical gaps left by traditional systems, offering the Zigma Concrete Wall Formwork System as a solution that merges the lightweight efficiency of fast-assembly systems with the robust performance of heavy-duty designs. This dual capability enables contractors to minimize downtime, reduce dependency on extensive shoring, and achieve higher returns on investment. By combining engineered innovation with expert consultation and reliable after-sale support, B.F.S Industries establishes itself as more than just a supplier—it positions as a long-term partner, providing construction professionals with both the tools and the technical guidance necessary to mitigate risk and secure sustainable profitability.

Zigma Formwork in a Competitive Landscape

The market for concrete formwork is highly competitive, with a number of well-established players offering a wide range of specialized solutions. Companies like Doka, MEVA, and PERI provide systems that cater to different project types, from lightweight, crane-independent solutions to large-format, heavy-duty formwork. For instance, MEVA offers the MevaLite, a lightweight modular system suitable for a wide range of hand-set applications , while Doka’s Top 50 is a modular gang form system that can be configured for any shape and tie-hole pattern. PERI’s offerings range from the universal, lightweight DUO system to the heavy-duty TRIO, both with a focus on ease of use and reduced shuttering times.

A key competitive tension exists between speed and strength in the formwork market. Lightweight, crane-independent systems are fast to assemble but may not be suitable for projects with high hydrostatic pressures, which are common in heavy-duty construction. Conversely, large-scale, heavy-duty systems, while strong, can be slow to assemble and often require extensive shoring or bracing. It is this strategic gap that the Zigma system is designed to fill. By combining the speed and simplicity of assembly (a feature often associated with lightweight systems) with the high-strength, prop-free design needed for large, complex structures, the Zigma system occupies a distinct and valuable position in the market.

The following table provides a strategic overview of how the Zigma system’s unique features compare to those of its competitors:

| Feature/Benefit | Zigma Formwork (B.F.S) | MEVA (MevaLite/Imperial) | Doka (Top 50) | PERI (TRIO/DUO) |

|---|---|---|---|---|

| Core Material | Premium-grade Steel | Aluminum (MevaLite), Steel (Imperial) | Timber Beams, Steel Walings | Steel (TRIO), Technopolymer (DUO) |

| Primary Application | Heavy-Duty, Large-Scale Vertical Construction | Versatile, Crane-independent (MevaLite); Tall, Thick Walls (Imperial) | Universal, for Architectural & Industrial | Universal, Lightweight (DUO); Universal Panel (TRIO) |

| Key Differentiator | Prop-free modular lock system | Crane-independent, single-person setup (MevaLite) | Adaptable “construction kit” | Lightweight, no hammer required (DUO) |

| On-Site Efficiency | Very High; streamlined, error-free assembly | High; quick, hand-set assembly | High; large gang units | High; minimum number of components |

| Crane Dependency | Required for large-format panels | Crane-independent (MevaLite); Crane-dependent (Imperial) | Crane-dependent | Crane-independent (DUO); Crane-dependent (TRIO) |

Partnership Beyond Products: A Foundation of Support and Consultation

For a B2B client, the decision to purchase a formwork system is often a complex, high-stakes choice that is tied to specific project requirements. It is a decision that requires not only a high-quality product but also a clear pathway to expert-level support and guidance. In this regard, B.F.S Industries is well-positioned to serve as a long-term strategic partner.

The company has a proven track record of being responsive to customer inquiries, providing timely deliveries, and offering excellent after-sale support. Crucially, B.F.S employs experienced personnel and degreed engineers who possess the knowledge to design systems that meet or exceed the most stringent project specifications. This capability is a vital component of the company’s value proposition, as it allows clients to offload a significant portion of project-related design and planning risk. By providing access to this technical expertise, B.F.S Industries goes beyond a simple transaction and becomes a trusted collaborator.

Investing in Long-Term Success

The Zigma Formwork System is designed as a strategic capital asset for contracting businesses, offering more than standard Concrete Modular Formwork solutions. While typical modular systems focus mainly on basic reusability and standardized panels, Zigma combines effortless assembly, superior durability, and high load-bearing capacity to deliver a measurable return on investment. By minimizing material waste, eliminating the need for props, and reducing maintenance costs, it ensures long-term cost efficiency. Built from premium-grade materials to withstand demanding site conditions, Zigma reduces the need for frequent replacements, making it a truly reliable and profitable investment. Partnering with B.F.S Industries, with its seven decades of engineering expertise and a product portfolio designed to solve real contractor challenges, allows businesses to achieve project goals with greater efficiency, safety, and confidence.

طارق القيسي –

هل القطعة تدعم زوايا مختلفة أم أنها مخصصة فقط لزاوية قائمة؟ وهل متوفرة حالياً في الشحن السريع؟