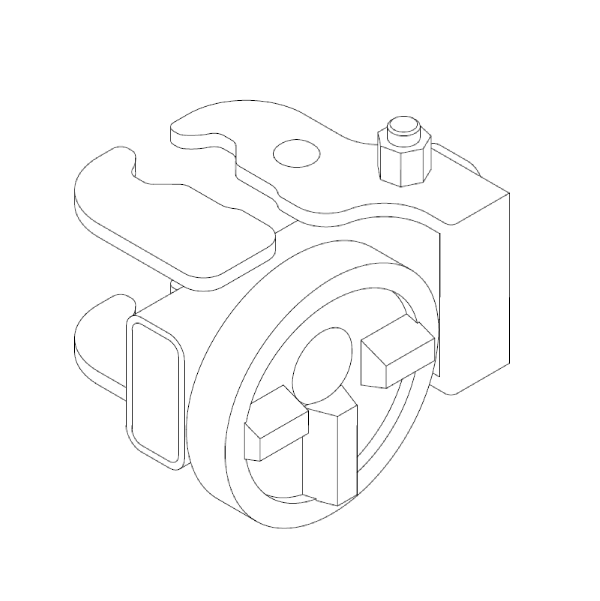

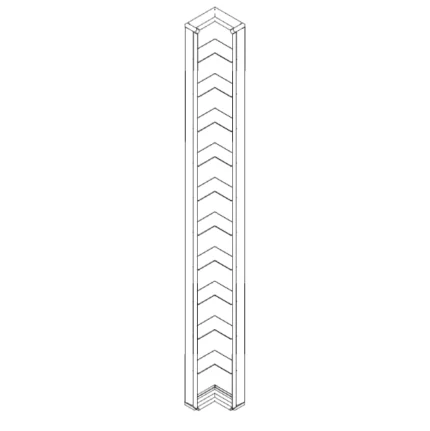

Zigma Lock

| Product Name |

Zigma Lock |

|---|---|

| Manufacturer |

BFS Industries |

| Primary Use |

Connecting Zigma Panels in wall formwork |

| Size |

Universal, no specific size required |

| Connection Method |

Modular lock with hooks |

| Durability |

Premium materials for long-lasting performance |

From Product to Partnership: The Strategic Value of B.F.S Industries in the Middle East Construction Sector

An analysis of the modern construction landscape reveals a sector undergoing a significant transformation, particularly within the Middle East. As global and regional economic forces converge, a new set of pressures demands a fundamental shift in strategy for project developers and contractors. This report evaluates how B.F.S Industries, a company with its headquarters and manufacturing facilities in the United Arab Emirates, has strategically positioned its capabilities to address these challenges. Specializing in formwork, scaffolding, steel structures, and advanced solutions for Concrete Construction, the company delivers comprehensive systems that directly enhance efficiency and reliability across diverse project types. It is important to note at the outset that this entity, B.F.S Industries, is distinct from the similarly named U.S.-based B.F.S Industries, LLC, a manufacturer of boiler room equipment. The following analysis is focused exclusively on the UAE-headquartered organization and its pivotal role as a strategic partner in complex construction projects.

Navigating the Middle East Construction Landscape: A New Era of Challenges and Opportunities

The construction industry in the UAE and the wider Middle East is defined by a series of critical headwinds that threaten traditional project delivery models. Rising material costs, fluctuating supply chains, labor shortages, increasingly complex regulatory requirements, and the growing demand for sustainable and environmentally responsible solutions all combine to create a landscape of heightened uncertainty. In this environment, delays and inefficiencies can quickly escalate into substantial financial losses, undermining profitability and eroding client trust. A comprehensive approach to project management therefore requires not only an awareness of these challenges but also the implementation of proactive strategies designed to mitigate their impact on timelines, budgets, and safety standards. B.F.S Industries’ core business model is specifically engineered to address these issues head-on, delivering integrated solutions such as its advanced Concrete Wall Formwork System that enhance efficiency, streamline operations, and ensure that Projects are executed with precision and reliability despite external pressures.

Rising Costs and Supply Chain Volatility

The most immediate pressure facing construction firms in 2025 is the sharp increase in material costs and the persistent volatility of supply chains. Reports indicate a projected rise in building costs of between 3% and 5% in the UAE, driven by intense competition for resources like steel, concrete, and aluminum as numerous “giga-projects” are executed simultaneously. Global shipping disruptions further compound the problem, leading to unpredictable material supply and cost overruns that can severely erode profit margins and cause significant project delays. The conventional reliance on a fragmented supply chain model, where a different supplier is sourced for each individual component, exacerbates this financial risk. A supplier that can lock in prices and offer a consistent, reliable source for critical structural components provides a powerful mechanism for cost control and risk mitigation.

The Skilled Labor Shortage and Talent Gaps

Beyond material costs, the region faces a profound shortage of skilled labor. A 2025 survey highlighted that 46% of firms in the UAE struggle to hire specialized talent, with demand for project managers, BIM experts, and AI-driven professionals far exceeding supply. This labor bottleneck has direct consequences on project quality, increases costs, and can slow down the execution of large-scale projects. The demand for construction expertise extends from the design and planning phase to on-site execution, and a shortage of technical know-how in any of these areas can lead to significant inefficiencies. This dynamic places a premium on partners who can deliver solutions that simplify on-site processes, reduce reliance on manual labor, and integrate seamlessly with modern digital workflows.

Digital Fragmentation and Slow Technology Adoption

Despite widespread recognition of the benefits of digital transformation, the Middle East construction sector lags in technology adoption. It is estimated to be 5–7 years behind the United States in cloud adoption, with many firms still operating with siloed systems, ad-hoc technology use, and paper-based workflows. This fragmentation of digital tools hinders real-time collaboration, weakens project tracking, and introduces significant inefficiencies. In this environment, a company that integrates advanced technology into its products and services offers a strategic advantage, enabling clients to improve their own efficiency and coordination.

B.F.S Industries’ approach is not merely to provide products but to deliver a comprehensive solution to these challenges. By leveraging advanced manufacturing techniques and a deep understanding of market dynamics, the company transforms its product offerings into strategic assets that enhance client profitability and operational resilience. The following table provides a concise overview of this value proposition.

| Challenge | B.F.S Industries’ Capability | Strategic Benefit to Client |

|---|---|---|

| Rising Costs & Supply Chain Volatility | Robotic Manufacturing, Modular Formwork Systems | Minimized material waste and on-site dependency; Long-term reusability and reduced cost per pour |

| Skilled Labor Shortage & Talent Gaps | Simplified Assembly, Custom Engineering & Design | Reduced on-site labor hours and simplified training; Predictable timelines and superior project quality |

| Digital Fragmentation | Technical Documentation, Engineering & Project Support | Seamless integration with client workflows; Proactive risk mitigation and dispute avoidance |

B.F.S Industries’ Core Capabilities: A Legacy of Engineering Excellence and Innovation

B.F.S Industries has a history of uninterrupted growth and success, with a clear maxim for continuous development based on its own strengths. This growth is not merely an expansion of size, but a deepening of its core capabilities to meet the evolving demands of the global construction market. Over the years, the company has consistently invested in innovation, advanced manufacturing processes, and a highly skilled workforce, ensuring that its solutions remain both relevant and competitive in an increasingly challenging environment. Its progress reflects not only an ability to adapt to shifting market dynamics but also a long-term vision of leadership in formwork, scaffolding, steel structures, and concrete construction systems. By aligning its expertise with the pressing needs of modern contractors—such as speed, safety, sustainability, and cost-efficiency, B.F.S Industries has transformed growth into a platform for delivering measurable value to its partners and clients across the Middle East and beyond.

The Engineering & Fabrication Advantage: Precision and Automation

At the heart of B.F.S Industries’ value proposition is its highly equipped manufacturing facility in the UAE, which is a pioneer in applying modern technology, including robotic manufacturing, to the design of formwork systems. This advanced fabrication capability provides a significant competitive edge. The reliance on robotics reduces the risk of human error, ensuring an exceptional level of precision and consistency in every component produced.

This approach to manufacturing directly addresses the challenge of labor shortages. By automating key production processes, B.F.S Industries reduces its own dependency on the volatile labor market, ensuring a stable and predictable supply chain for its clients. This consistency is then passed on to the customer in the form of high-quality products that arrive on time and are built to exacting standards.

Furthermore, the company’s team of engineers excels at planning and designing bespoke formwork and scaffolding solutions. This is not a simple matter of selecting from a catalog; it is a collaborative process that takes into account technical requirements, on-site boundary conditions, and specific client needs. The outcome is a solution that is optimized for each individual project, complete with detailed implementation drawings and verifiable static calculations. This ensures not only the safety and structural integrity of the final build but also a streamlined process that reduces both execution times and costs for the client. The company’s commitment to quality is evident in its use of premium-grade materials, specifically high-strength steel frames with premium plywood or propylene facing, which ensures durability and allows for repeated use across multiple projects, thereby reducing long-term material and labor costs.

A Global Presence, Built on Local Expertise

B.F.S Industries operates with a global perspective while maintaining a strong local presence. With its head office and manufacturing plant located in the UAE, the company is strategically positioned to serve the dynamic Middle Eastern market. Simultaneously, its network of offices and subsidiaries across Europe, Asia, and the Middle East allows it to provide localized support and to bundle valuable international experience into its product and service development. This model ensures that local knowledge is transformed into a global advantage, with the benefits of acquired international expertise being passed on to every customer, regardless of the project’s size. The company’s maxim is to be closer to its customers, enabling it to serve them more effectively and efficiently.

Delivering Excellence: Project Spotlights

The capabilities of B.F.S Industries are best illustrated through its portfolio of high-profile projects. These case studies demonstrate a consistent ability to overcome complex challenges through innovative engineering and a client-centric approach.

| Project Name | Location | B.F.S Industries’ Contribution | Key Innovation/Feature |

|---|---|---|---|

| Laleh Tower | Dubai, UAE | Patented BFS-Table Form Systems (Patent registration 63948) | Hydraulic trolley system; Two-level lifting C-hook; Telescopic wheels |

| Diftah-Shis Road & Tunnel | UAE | Tunnel Lining Formwork expertise | Engineering for large-scale infrastructure projects |

| Uzbekistan Wastewater Plant | Uzbekistan | Modular Formwork Systems for circular structures | Precision and speed in complex geometries |

| Iraq Wastewater Treatment Plant | Iraq | Complex Digester Construction | Handling of large-scale, high-pressure structures |

The Laleh Tower: A Case Study in Bespoke Engineering

The Laleh Tower project in Dubai serves as a powerful testament to B.F.S Industries’ capacity for bespoke engineering and problem-solving. The construction required the creation of approximately 1,000 square meters of post-tensioned slab per story, a task that presented unique logistical and technical challenges. Rather than relying on a standard product, the B.F.S team in Dubai designed and implemented a custom solution: the patented BFS-Table Form Systems.

This project reveals a crucial aspect of the company’s value proposition. The team identified three core challenges and developed specific, unprecedented innovations to address them:

- The first challenge was the presence of a 90 cm concrete beam around the roof perimeter, which complicated the dismantling of the formwork tables. B.F.S designed a hydraulic trolley system that allowed the tables to be lowered by 1.2 meters, enabling them to be easily lifted to the next floor.

- Second, due to the simultaneous formworking of two slab roofs, the team designed a two-level lifting C-hook system. This innovation facilitated lifting the tables two floors at once, a capability that dramatically increased the speed and efficiency of the project.

- Finally, to overcome the limitations of a large formwork area and the difficulty of removing tables through the slab roof, B.F.S designed and implemented four telescopic wheels for each table. This simple yet revolutionary feature allowed a single worker to independently lift and transfer each table, which greatly accelerated the speed of movement on site.

These solutions were not just convenient; they were a direct response to on-site limitations and an example of how B.F.S Industries’ engineering prowess translates into tangible operational benefits, such as reduced labor and accelerated timelines. The company’s ability to move beyond a standard product line and deliver customized, patented systems positions it as a genuine partner in project success, capable of handling the most demanding engineering challenges.

The Diftah-Shis Road & Tunnel: Accelerating Infrastructure

B.F.S Industries’ expertise extends to large-scale infrastructure projects, as evidenced by its involvement in the Diftah-Shis Road & Tunnel Project in the UAE. The company offers a range of formwork systems specifically designed for such applications, including tunnel lining formwork, slip formwork, and self-climbing systems. This demonstrates a versatility that is essential in a region focused on monumental civil works. The company’s ability to provide tailored solutions for complex tunnels and other large-scale structures reinforces its position as a leading provider of comprehensive formwork solutions.

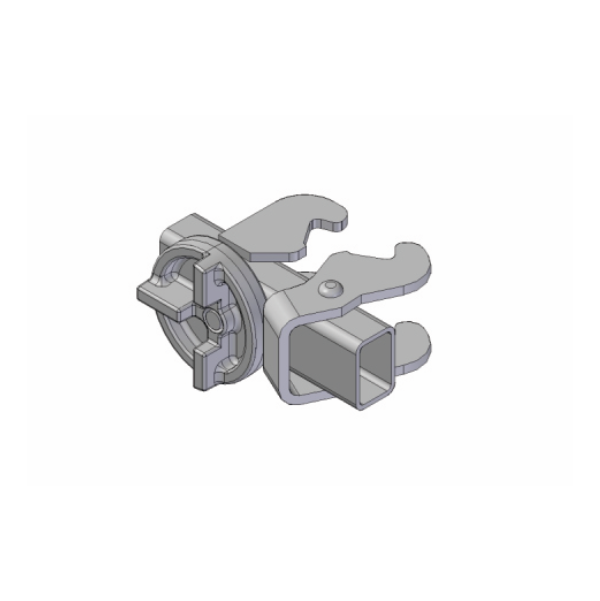

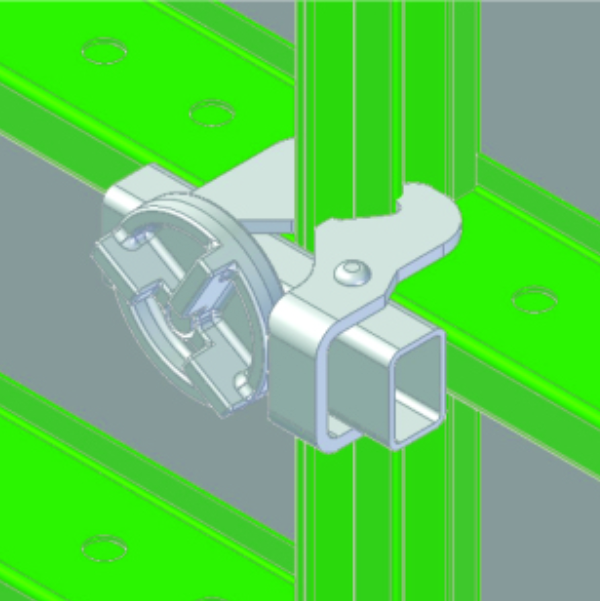

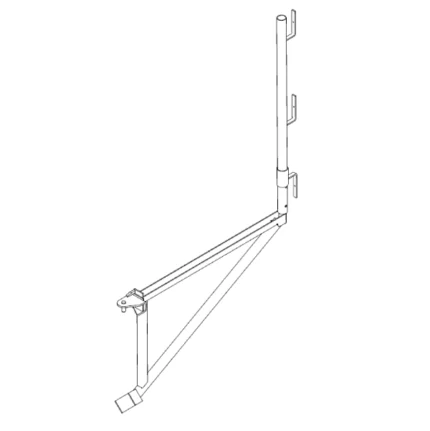

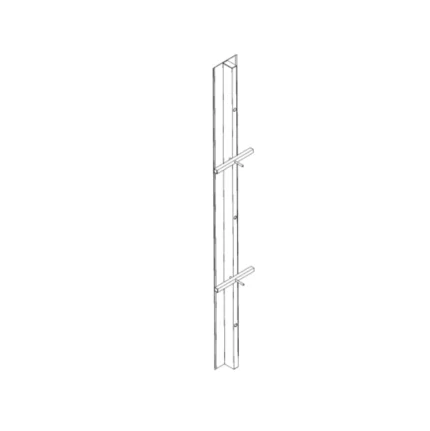

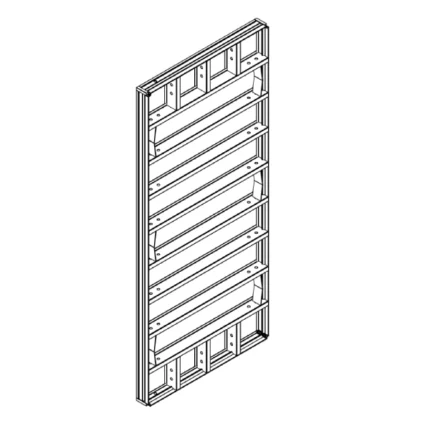

The B.F.S Formwork System as a Strategic Asset

The Zigma Panel Formwork system is a prime example of how B.F.S Industries’ products are engineered to be more than just components; they are strategic assets designed to enhance project efficiency, safety, and profitability. Unlike conventional equipment that serves a single functional purpose, the Zigma system integrates robust engineering, modular adaptability, and long-term durability to provide contractors with a tool that directly contributes to their competitive advantage. Its design and technical specifications are carefully developed to address the most pressing business concerns of construction firms today, from reducing labor dependency and minimizing material wastage to accelerating project timelines without compromising quality.

Furthermore, when combined with the company’s Concrete Modular Formwork, the Zigma Panel Formwork expands its value proposition by offering contractors unprecedented flexibility across different project scales and structural requirements. The modular approach enables seamless adaptation to complex architectural geometries, while the panel system ensures strength and stability in demanding concrete construction environments. Together, these systems represent a holistic solution that goes beyond traditional formwork, reinforcing B.F.S Industries’ role as a strategic partner in delivering projects that meet the highest standards of efficiency, safety, and cost-effectiveness.

Zigma Panel Formwork: Engineering for Performance, Efficiency, and Finish Quality

The Zigma panel is engineered for exceptional structural performance. Its core technical specification, a flexural strength of 80 kN/m², is not merely a number but a critical safety feature. This high load-bearing capacity, which adheres to the DIN 18202 standard, signifies the panel’s ability to withstand the immense hydrostatic pressure exerted by fresh concrete during a pour. By preventing bulging, leakage, or panel failure, this strength ensures the structural integrity of the final concrete element and, more importantly, a safer working environment on site.

The system’s design is a direct solution to the skilled labor shortage. The panels are connected using a simplified, hammer-driven special lock system. This user-friendly mechanism significantly reduces the time and specialized skill required for on-site assembly and dismantling. This allows contractors to accelerate their construction schedules and to complete more pour cycles in less time, which translates directly into reduced labor hours and more predictable project timelines. The modular design, with panel widths in multiples of 15 cm and a range of heights (150 cm, 270 cm, 330 cm), further optimizes material usage and minimizes waste, providing an additional layer of cost control.

Beyond structural integrity and efficiency, the Zigma system’s focus on finish quality provides a powerful, often overlooked, business benefit. The panels feature a high-quality facing material that minimizes concrete adhesion, resulting in smooth, fair-faced surfaces. This is not simply an aesthetic consideration. It is a direct cost-saving feature that reduces the need for expensive and labor-intensive post-pour finishing work. By delivering an architectural-grade finish from the outset, B.F.S Industries enables its clients to enhance their project reputation while simultaneously reducing their total project costs.

The Partnership Advantage: How B.F.S Industries Delivers Value Beyond the System

In a competitive market, a company’s ability to provide a comprehensive, customer-centric service model is as critical as the quality of its products. B.F.S Industries has built a reputation on its unwavering commitment to fostering valuable, long-term relationships with its clients, viewing each project not as a mere transaction but as a collaborative partnership. This approach encompasses every stage of the project lifecycle, from initial planning and technical consultation to on-site support and post-project evaluation. By actively engaging with clients to understand their unique requirements and challenges, B.F.S Industries tailors its solutions—ranging from wall formwork and modular formwork systems to scaffolding and steel structures—ensuring that they deliver tangible improvements in efficiency, safety, and cost-effectiveness. Moreover, the company invests in continuous communication, training, and knowledge sharing with project teams, creating an environment of mutual trust and reliability. This holistic commitment to client success not only strengthens B.F.S Industries’ competitive position in the Middle East construction market but also reinforces its reputation as a partner that prioritizes sustainable, long-term value over short-term gains.

A Customer-Centric Approach: From Consultation to Completion

The company’s customer engagement begins long before a product is delivered. B.F.S engineers work directly with clients to understand their unique requirements and develop tailored systems. This single-source approach is supported by a robust digital framework that leverages technologies like Building Information Modeling (BIM) and Virtual Design and Construction (VDC) to optimize solutions and eliminate unforeseen issues. This integrated service model ensures that all members of the project team, from estimation and design to construction, work together toward a unified goal, which increases transparency for the client and helps to avoid unforeseen costs.

The company’s commitment to its customers continues long after the sale is finalized. B.F.S Industries maintains a reputation for being responsive to inquiries, providing timely deliveries, and offering excellent after-sales support. This dedication to a seamless customer experience is a critical form of risk mitigation for clients, as it reduces the potential for project delays and disputes, which are a common and costly issue in the Middle East. By prioritizing communication and cooperation, B.F.S Industries cultivates the trust that is essential for long-term business partnerships.

Building a Reputation on Quality and Trust

A company’s reputation is a powerful asset, and B.F.S Industries has earned its highly regarded standing within the industry through a steadfast commitment to quality and integrity. The company’s philosophy, rooted in the adage “you get what you pay for,” is that a quality product is the foundation of success. This standard begins in the design process, where engineers specify and use high-quality components to ensure exceptional system reliability. The manufacturing process incorporates multiple levels of inspection to guarantee that the equipment meets both the customer’s and the company’s high expectations.

B.F.S Industries’ enduring success over its history, marked by continuous and steady growth, stands in stark contrast to the companies that have come and gone in the industry. This longevity is a testament to the company’s adaptability, its ability to grow its capabilities, and its relentless focus on earning the repeat business of its clients.

The Path Forward: Partnering for a More Resilient Future

In a dynamic and competitive construction market, the ability to adapt and innovate is not a luxury but a necessity. The analysis demonstrates that B.F.S Industries is not merely a supplier of construction equipment; it is a strategic partner equipped with the engineering expertise, automated manufacturing capabilities, and customer-centric service model required to help clients overcome the most pressing challenges in the Middle East construction sector.

By providing bespoke, durable, and highly efficient formwork and steel solutions, B.F.S Industries enables contractors to mitigate the risks associated with rising costs and skilled labor shortages, while also enhancing the quality and speed of their project delivery. The company’s focus on engineering excellence and a partnership-driven approach positions it as a reliable ally in the pursuit of more profitable, resilient, and high-quality construction projects.

To navigate the complexities of the modern construction landscape, companies require a partner that understands their operational challenges and can provide solutions that deliver a measurable return on investment. The evidence suggests that B.F.S Industries is that partner, offering a compelling blend of technical innovation, material quality, and client-focused service.

باسم الخالدي –

هل هذا القفل مقاوم للتآكل في البيئات الرطبة؟ وما طريقة فكه وتركيبه أثناء العمل؟