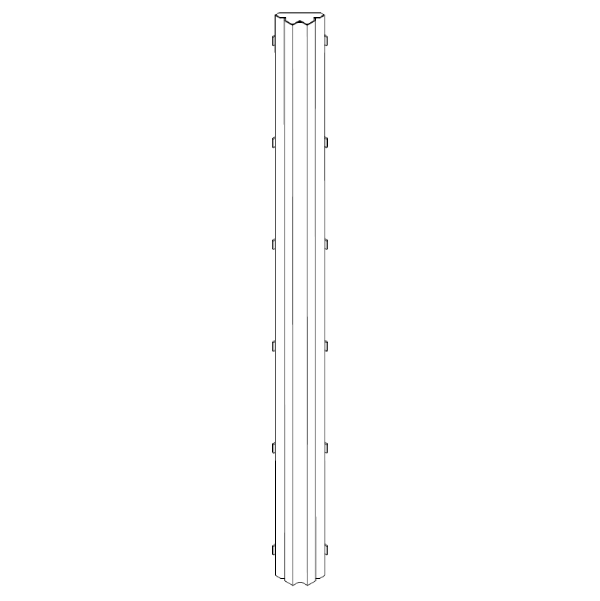

Zigma Outside Corner

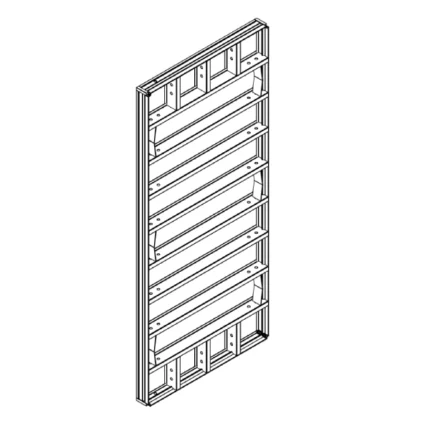

| Primary Use |

Wall formwork for construction projects (residential, commercial, industrial) |

|---|---|

| Available Sizes |

330, 300, 270, 150 |

| Corner Design |

Specially shaped for easy horizontal and vertical movement |

| Profile/Section |

rigid and stable, optimized for structural integrity |

| Material Quality |

Premium-grade materials for durability and easy cleaning |

| Cleaning |

Simplified cleaning process due to section design and material quality |

| Lifespan |

Extended due to high-quality materials and robust construction |

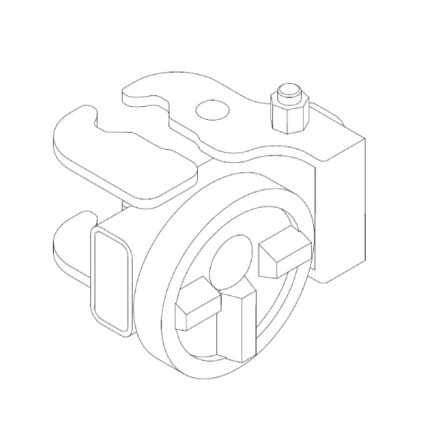

| Connection System |

Modular locks for quick and easy opening/closing |

| Lock Design |

Specially shaped for balanced, level, and compressed formwork alignment |

| Connection Method |

Hammer stroke on lock’s ball or nut for secure, unified connections |

Elevating Construction Projects: The B.F.S Industries Approach to Modern Formwork Solutions

In the demanding landscape of modern Concrete Construction, success is no longer defined solely by the timely completion of a project but by a commitment to precision, efficiency, and long-term value. Forward-thinking contractors and project managers understand that the tools and partnerships they select are not mere purchases; they are strategic investments in their company’s future. The Zigma Outside Corner, a core component of the B.F.S Industries wall formwork system, exemplifies this philosophy. It is not simply a product but a tangible representation of a comprehensive solution designed to empower construction professionals. This report examines the strategic business value offered by B.F.S Industries, exploring how its innovative approach to formwork transcends traditional methods to become a true partnership for operational excellence. The focus is on the company’s commitment to solving the industry’s most pressing challenges, from enhancing on-site productivity to ensuring a superior structural finish that meets the highest industry standards.

Navigating the Complexities of Modern Wall Formwork

The construction industry operates on tight margins and even tighter schedules. The evolution of architectural design, coupled with the increasing demand for high-quality finishes, has placed unprecedented pressure on contractors. This has created a need for advanced systems that can deliver on the promise of speed and precision without compromising on quality or safety. In today’s competitive environment, every delay, design error, or inefficiency can quickly translate into significant financial losses and reputational damage. As projects grow more complex—with intricate geometries, taller structures, and stricter regulatory standards—the traditional methods of construction are proving inadequate to keep pace. Modern contractors are therefore turning toward innovative formwork systems, automation tools, and integrated project management solutions that not only accelerate timelines but also ensure structural integrity and consistency of results. These advancements are no longer seen as optional upgrades; they are strategic necessities for companies seeking to thrive in a market where clients demand both rapid execution and long-term durability of the built environment.

The Evolving Demands on Today’s Contractors

Today’s construction professionals must balance a multitude of critical factors, from managing escalating material costs to addressing ongoing labor shortages. Project timelines are often compressed, and the demand for a flawless end product, especially for exposed concrete elements, is a non-negotiable requirement. These pressures have rendered traditional, labor-intensive methods of construction increasingly unsustainable. The modern market requires solutions that not only perform their core function but also contribute to a project’s overall profitability by reducing rework, streamlining operations, and improving on-site safety. Meeting these demands requires a paradigm shift away from a “get-it-done” mentality and toward a more strategic, solution-oriented approach to every aspect of a project.

The Pitfalls of Conventional Formwork Methods

For decades, conventional formwork systems, often reliant on timber or other materials, were the industry standard. However, their limitations have become a significant liability in the context of modern construction demands. These traditional methods are inherently time-consuming, requiring extensive on-site cutting, measuring, and skilled labor for assembly and adjustment. This process is not only inefficient but also generates substantial material waste, directly impacting a project’s budget and environmental footprint.

Furthermore, conventional systems are prone to dimensional inaccuracies. Materials can warp or swell under the weight of wet concrete, leading to imperfections in the final structure. Correcting these flaws necessitates costly and time-consuming rework, which erodes profit margins and extends project timelines. This cycle of inefficiency and correction underscores why the industry has sought superior alternatives. The challenges posed by traditional formwork are not merely inconveniences; they are direct obstacles to profitability and project success, creating a clear and compelling need for the innovative solutions that B.F.S Industries provides.

The B.F.S Industries Advantage: A Solution-Centric Partnership

In a marketplace crowded with product offerings, B.F.S Industries distinguishes itself by providing not just components, but a comprehensive, solution-oriented partnership. This approach is built on a deep understanding of the construction industry’s operational challenges and a commitment to delivering tangible value at every stage of a project. Rather than focusing solely on the sale of individual products, B.F.S Industries emphasizes the importance of integrated systems—such as its advanced Concrete Wall Formwork System ,that streamline workflows, reduce downtime, and optimize resource utilization. The company positions itself as a trusted partner that anticipates potential bottlenecks, mitigates risks, and offers technical expertise tailored to the unique demands of each project. By combining engineering innovation with responsive customer support, B.F.S ensures that contractors are not only equipped with durable, high-performance solutions but are also empowered with guidance that enhances efficiency, safety, and long-term profitability. In this way, B.F.S goes beyond the role of a supplier, emerging as a strategic ally invested in the success and sustainability of its clients.

From Supplier to Strategic Partner: Our Commitment to Your Success

A hallmark of the B.F.S Industries business model is its focus on building a relationship that extends far beyond the point of sale. The company positions itself as a strategic partner, offering a full suite of services that support clients from the initial blueprint stage to final project completion. This includes expert consultation, in-house design services, and meticulous project planning to ensure that the formwork system is perfectly tailored to the unique requirements of the job.

This commitment to a collaborative approach distinguishes B.F.S Industries from a simple product supplier. It empowers clients with the reassurance that the equipment they receive is not only high-quality but has been rigorously serviced and tested prior to delivery. This model helps to alleviate the shared responsibilities between the contractor and the supplier, minimizing complications and surprises on site. By focusing on professional relationships and stories of impact, a company can extend its brand beyond a mere portfolio of completed work. This strategy cultivates a reputation for trustworthiness and expertise, essential for nurturing long-term relationships and securing future projects.

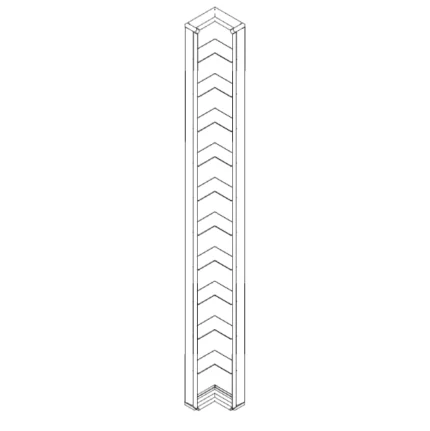

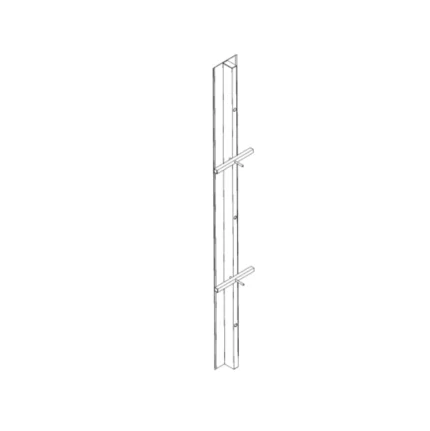

Engineering Innovation for Real-World Precision

The Zigma Outside Corner is a direct result of B.F.S Industries’ solution-centric engineering philosophy. Rather than simply listing product features, the focus is on how each design element directly addresses a specific on-site problem. The product’s “specially shaped corner design,” for example, is not merely an aesthetic choice; it is an innovative solution that allows for effortless movement and adjustment in both horizontal and vertical directions. This eliminates the need for cumbersome hammering to align components, directly translating into significant time and labor savings on the job site.

Similarly, the “rigid and stable profile” of the Zigma Outside Corner is engineered to solve the problem of structural integrity. Its section shape enhances durability, ensuring the product can withstand the demanding conditions of any construction environment. This design also makes cleaning a straightforward process, which is a significant value-add for contractors who depend on low-maintenance equipment. The use of “premium-grade materials” is a further extension of this philosophy, ensuring the longevity of the product and reducing the frequency of replacements, which directly contributes to long-term cost-effectiveness. Each of these elements works in concert to provide a holistic solution that goes beyond the basic function of a corner piece, offering a pathway to greater on-site precision, efficiency, and financial return.

The Strategic Business Benefits of Our Advanced Formwork Systems

The benefits of a partnership with B.F.S Industries are not isolated; they are interconnected and create a synergistic effect that contributes to a project’s overall success. A holistic view of the company’s value proposition reveals how improvements in one area, such as efficiency, have a direct and positive impact on other critical factors like cost and safety. For example, the implementation of advanced solutions like the Concrete Modular Formwork not only accelerates assembly and reduces labor requirements but also minimizes material waste and enhances job site safety. These advantages extend beyond immediate project execution, as they contribute to long-term durability, lower maintenance demands, and improved resource allocation across multiple projects. By aligning innovation with practical application, B.F.S Industries ensures that gains in speed and precision translate into measurable cost savings, risk reduction, and higher-quality outcomes. This interconnected value creates a reinforcing cycle where efficiency drives profitability, safety supports reliability, and innovation strengthens competitiveness—making B.F.S not just a supplier, but a catalyst for sustainable success in the construction industry.

Unlocking Unmatched Time and Labor Efficiency

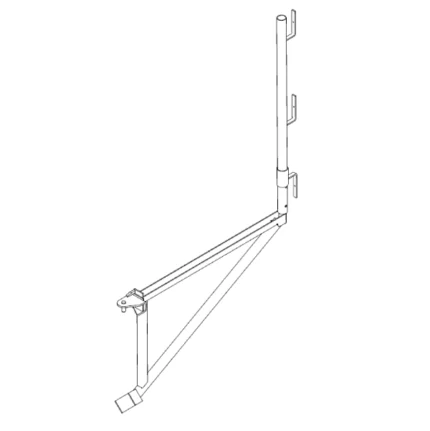

In a time-is-money industry, the speed of construction is paramount. Modern formwork systems are designed for rapid assembly and dismantling, significantly reducing project timelines compared to traditional methods. The Zigma Outside Corner’s modular lock system is a prime example of this design philosophy. It allows workers to connect components with minimal effort, making the system intuitive and worker-friendly, even for those new to formwork.

The ease of use and clearly distinguished connection points eliminate guesswork and on-site adjustments, reducing errors to near-zero and speeding up the assembly process. This streamlined approach minimizes downtime between pouring sessions and reduces the amount of skilled labor required for setup and breakdown. For contractors, this translates directly into the ability to complete projects faster, meet aggressive deadlines, and ultimately take on more work.

Maximizing Long-Term Cost-Effectiveness and ROI

While the initial investment in modern systems may seem higher than conventional alternatives, the long-term cost benefits are substantial. The reusability of a high-quality modular system like the Zigma Outside Corner drastically reduces the cost per use over a project’s lifespan. This eliminates the need to continuously purchase and replace materials, which is a common expense with conventional timber or single-use formwork.

The design of the Zigma system also minimizes material waste by reducing the need for on-site cutting and customization. This not only contributes to a cleaner, safer work environment but also helps contractors stay within budget by preventing the costly disposal and replacement of excess materials. When compared to conventional methods, the long-term savings in labor, materials, and rework costs make modular formwork a financially sound and strategic choice. To illustrate this clear advantage, a comparative analysis is presented in the table below.

| Key Criterion | Conventional Formwork Methods | B.F.S Industries’ Modular System |

|---|---|---|

| Time-to-Project Completion | Time-consuming; requires extensive setup and dismantling | Rapid; designed for quick assembly and disassembly |

| Labor Requirements | High labor needs for skilled workers and on-site adjustments | Low labor needs; intuitive and worker-friendly |

| Cost Over Time | High cost per use; requires continuous material purchase | Significant long-term savings; highly reusable over many projects |

| Reusability | Low or single-use; materials often warp or break | Highly reusable; maintains structural integrity over time |

| On-Site Waste | Significant waste from cutting and damaged materials | Minimal waste; standardized components reduce the need for cutting |

| Final Surface Finish | Rough or inconsistent; often requires additional finishing work | Superior and smooth; a professional finish is achieved every time |

| On-Site Safety | Higher risk of failure due to warping and instability | Enhanced safety and stability; pre-engineered to withstand heavy loads |

Achieving Superior Quality and Finish, Every Time

Modern construction demands a high degree of dimensional accuracy, which is a defining feature of the B.F.S Industries system. The special shape of the modular locks ensures that the Zigma Outside Corner remains perfectly balanced and level during concrete pouring. This creates a compressed and stable formwork system that delivers a smooth, consistent, and uniform finish that meets or exceeds architectural standards.

A high-quality surface finish is particularly important for exposed concrete elements, as it enhances the aesthetic appeal of the final structure and reduces the need for additional finishing work such as plastering or polishing. This not only saves time and labor but also contributes to the structure’s long-term durability and resilience. The precise molding process minimizes imperfections and cracks, which are common causes of deterioration over time.

Elevating On-Site Safety and Stability

Safety is a top priority on any construction site, and modern formwork solutions play a crucial role in maintaining a secure work environment. Unlike traditional systems that are prone to warping and failure, the pre-engineered kits of the B.F.S Industries modular system are more reliable and durable, reducing the risk of collapse during concrete pouring.

The “worker-friendly” design of the Zigma Outside Corner also contributes to on-site safety. The ease of assembly and disassembly minimizes workers’ exposure to potential hazards and reduces the physical strain associated with conventional methods. By providing a stable, secure, and intuitive system, B.F.S Industries is not only protecting a project’s financial investment but, most importantly, ensuring the well-being of the on-site crew. This focus on safety demonstrates a company’s commitment to responsible business practices and builds trust with clients who prioritize the welfare of their teams.

Partner with B.F.S Industries to Build Your Success

In the rapidly evolving world of construction, the difference between a good project and a great one often lies in the quality of the partnerships and the tools selected. The B.F.S Industries wall formwork system, featuring the Zigma Outside Corner, represents a comprehensive solution that addresses the industry’s most critical challenges—efficiency, cost, quality, and safety. By reframing the conversation from a product-centric one to a solution-centric one, B.F.S Industries has demonstrated its understanding of what truly matters to today’s B2B clients: a pathway to greater operational success.

Ready to Transform Your Formwork Process

The Zigma Outside Corner is more than just a component; it is an entry point to a more productive, cost-effective, and streamlined way of working. It embodies the principles of innovation, durability, and user-friendliness that define the B.F.S Industries brand. The strategic business benefits—from unparalleled time savings and long-term cost-effectiveness to superior quality and enhanced safety—are a direct result of a design philosophy that puts the contractor’s needs first. To explore how the B.F.S Industries formwork system can be tailored to meet your specific project demands, a personalized consultation is available. By partnering with B.F.S Industries, clients are not just acquiring advanced tools; they are investing in a future of building success.

رائد الشمري –

هل يتوافق هذا الكورنر الخارجي مع جميع ألواح Zigma؟ وكم سماكة الصاج المستخدم فيه؟