Zigma Panel

| Material |

High-strength steel frame with premium plywood or propylene facing |

|---|---|

| Panel Heights |

150 cm, 270 cm, 330 cm |

| Panel Widths |

30 cm, 45 cm, 60 cm, 75 cm, 90 cm, 120 cm, 240 cm |

| Flexural Strength |

80 kN/m² (per DIN 18202 standard) |

| Concrete Pressure Capacity |

Up to 80 kN/m² for columns, 60 kN/m² for walls |

| Connection System |

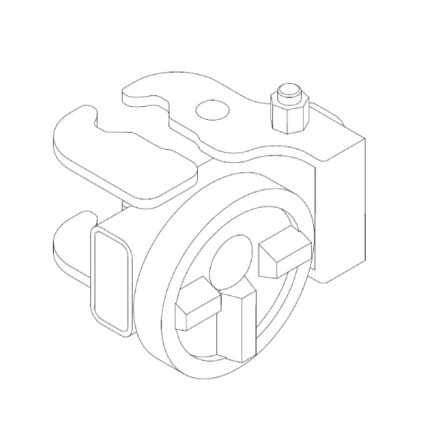

Hammer-driven special locks for horizontal and vertical connections |

| Locking Component |

DW 15 Bolt (designed to tolerate hydrostatic pressure of concrete) |

| Panel Orientation |

Usable in both horizontal and vertical directions |

| Modular Design |

Widths in multiples of 15 cm for compatibility with standard dimensions |

A Legacy of Engineering Excellence: The B.F.S. Industries Approach to Formwork

B.F.S. Industries is a globally recognized provider of engineered solutions for the concrete construction sector, specializing in formwork systems, steel structures, and scaffolding. With more than 20 years of dedicated experience in the industry, the company has strategically positioned itself as a partner for construction professionals, providing a distinct technical and economic advantage to its clientele.

Operating from its headquarters in the Jebel Ali Free Zone in the United Arab Emirates (UAE), B.F.S. Industries manages a modern manufacturing plant in Jebel Ali, Dubai, and has established offices across key markets in Europe, Asia, and the Middle East to serve a diverse client base. This extensive international footprint underscores a commitment to providing localized support and rapid delivery, essential for the fast-paced nature of modern concrete construction projects.

B.F.S. Industries has built its reputation on a foundation of reliability, engineering rigor, and a commitment to excellence. With a strong focus on delivering innovative and durable solutions, the company continues to play a vital role in shaping the future of global concrete construction.

The Zigma Panel Formwork System: Engineered by B.F.S. Industries

The Zigma panel formwork system serves as a prime example of B.F.S. Industries’ core engineering philosophy: to create robust, efficient, and versatile solutions for concrete construction. The system is specifically engineered to streamline processes and ensure structural integrity and high-quality finishes, addressing the critical needs of contractors and builders in a competitive market. Its design focuses not merely on individual components but on a holistic system that optimizes efficiency and delivers significant value throughout the project lifecycle.

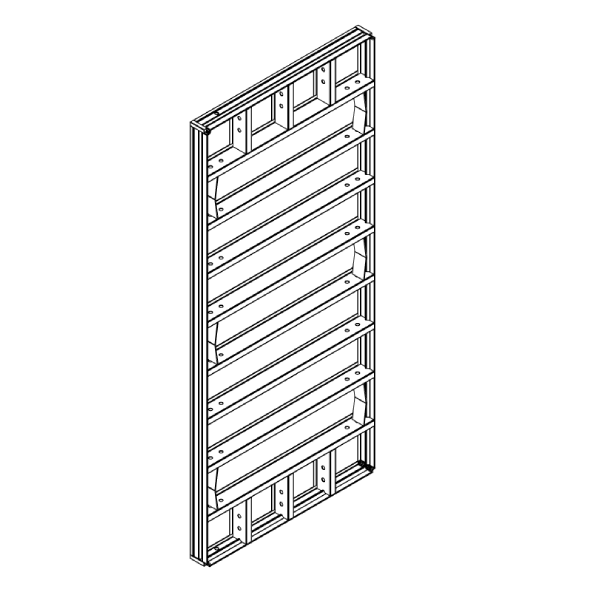

Precision-Engineered for Unmatched Versatility

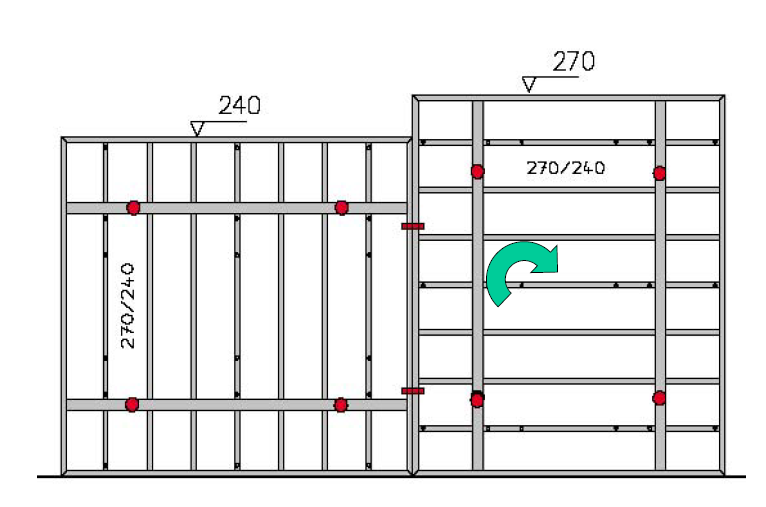

The Zigma system’s modular design is a strategic feature that directly translates into economic and logistical benefits on the job site. The panels are available in a broad range of heights—150 cm, 270 cm, 300 cm, and 330 cm—which aligns with standard building dimensions, thereby minimizing material waste and reducing the number of panels required for a project. Furthermore, the panel widths are engineered as multiples of 15 cm, including 30 cm, 45 cm, 60 cm, 75 cm, 90 cm, 120 cm, and 240 cm. This standardized, yet flexible, sizing allows for seamless integration and greatly reduces the need for on-site cutting and custom fabrication, which are major sources of time and material waste.

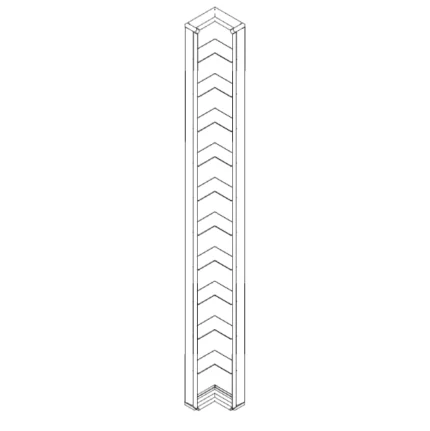

The system’s adaptability is a key competitive advantage. The panels are designed to be used in both horizontal and vertical orientations, providing contractors with extensive flexibility for diverse structural layouts. For large-scale projects, the 330×240 cm and 270×240 cm panels are particularly effective, as they cover significant surface areas rapidly, thereby accelerating assembly and reducing labor hours. For more complex or non-standard geometries, specialized filler plates are available, ensuring that the system can accommodate a wide array of structural requirements without compromising precision or efficiency. This comprehensive, modular approach positions the large panel system as a tool for achieving system-wide efficiency, directly supporting B.F.S. Industries’ mission to provide an economic competitive edge to its clients.

Robust Performance Under Pressure

The Zigma panel formwork system is engineered for exceptional structural performance, making it suitable for the most demanding construction challenges. A critical technical specification is its flexural strength of 80 kN/m², which adheres to stringent DIN 18202 standards. This high value signifies the panels’ ability to withstand the significant hydrostatic pressure exerted by fresh concrete, a necessity for casting tall walls, columns, and foundations. This resistance to pressure is a key indicator of safety and structural integrity.

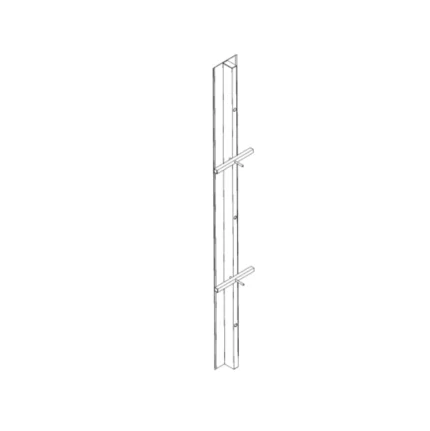

The system’s integrity is further enhanced by the use of high-strength components, specifically the DW 15 Bolt. This bolt is engineered to tolerate the immense forces of concrete pouring, ensuring the formwork remains stable and secure throughout the process. By using high-strength steel frames, the Zigma panels are not only capable of handling heavy loads but also offer exceptional durability and longevity, allowing for repeated use across multiple projects. Adherence to European Standards and the GSV guide further guarantees compliance with strict safety and structural requirements, positioning B.F.S. Industries as a partner that prioritizes engineering rigor and on-site safety. This commitment to robust construction provides contractors with the confidence to undertake large-scale and complex projects without concern for formwork failure or structural instability.

Streamlining Construction with Simplified Assembly

The Zigma system’s user-friendly assembly mechanism has profound implications for labor management and project logistics. The panels are connected using a simple locking mechanism that can be easily engaged or disengaged with a hammer. This practical, no-frills approach minimizes the need for specialized tools or extensive training, which in turn reduces labor costs and accelerates project timelines. The simplicity of this system allows for quick and efficient setup and dismantling, ensuring that projects remain on schedule without sacrificing quality.

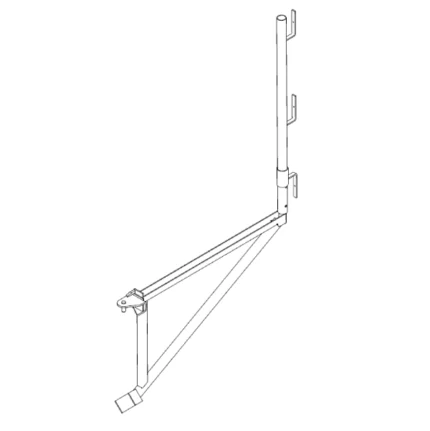

The true strategic value of this simplicity lies in the elimination of props or underpinnings in the formwork setup. This is a major logistical and economic advantage, as it reduces the amount of equipment required on-site, simplifies the worksite layout, and saves considerable time. By removing this traditional requirement, B.F.S. Industries has created a system that is not just a collection of components, but a tool for optimizing the entire construction process. This innovation translates directly into tangible business benefits: reduced labor costs, accelerated schedules, and a safer, more organized work environment. This reinforces the B.F.S. Industries value proposition as a company that genuinely understands and addresses the on-the-ground challenges faced by construction teams.

Delivering Architectural-Grade Finishes

Beyond its structural and logistical benefits, the Zigma system is specifically engineered to produce superior concrete finishes. The panels feature a high-quality facing material that minimizes concrete adhesion, resulting in smooth, fair-faced concrete surfaces that meet the highest aesthetic and structural standards. The use of large panels naturally results in fewer joints, which contributes to a clean, professional finish that is particularly valuable for architectural projects, such as landmark buildings or structures with exposed concrete.

This focus on finish quality is not merely about aesthetics; it is a direct cost-saving feature. By minimizing the need for extensive post-pour finishing or surface treatments, the Zigma system saves significant time, labor, and material costs. The panels are also easier to clean, which is a crucial detail for their reusability and long-term cost-effectiveness. Therefore, the Zigma system is positioned not just as a formwork solution but as an integral tool for achieving high-quality results efficiently, thereby enhancing a project’s overall value and appeal.

A System Beyond the Panel: Supporting Components & Engineering

The Zigma panel is a flagship product within a much broader and more comprehensive ecosystem of solutions offered by B.F.S. Industries. The company is a recognized leader in steel frames, formworks, and scaffolding, offering a full range of products for all stages of a construction project. Their product portfolio extends to slab formworks, column formworks (both circular and rectangular), a variety of scaffolding systems (Cuplock, Ringlock), and even highly specialized solutions like tunnel lining formwork, dam formworks, and self-climbing systems.

This breadth of offering demonstrates a deep well of knowledge and engineering capability that goes far beyond a single product line. A compelling example of this expertise is the Diftah-Shis Road & Tunnel project in the UAE, for which B.F.S. Industries designed and manufactured a novel, patented “full-hydraulic, full-steel self-propelled tunnel lining formwork system”. The fact that this was the first time such a system was used in the UAE is a powerful testament to the company’s innovation and its capacity to provide tailored solutions for complex infrastructure challenges. This positions B.F.S. Industries not as a product vendor but as a full-service partner capable of providing integrated solutions for an entire project, from a foundational perspective to high-rise vertical construction and complex civil engineering.

B.F.S. Industries in Action: Global Projects Powered by Zigma

Moving from technical specifications to real-world application, B.F.S. Industries has a proven track record of successfully executing complex projects globally. The company’s project portfolio serves as a powerful testament to its engineering capabilities and the effectiveness of its formwork systems.

Case Studies in Excellence

- Wastewater Treatment Plants (Uzbekistan & Iraq): B.F.S. Industries has demonstrated its expertise in handling large-scale, intricate circular structures in both Uzbekistan and Iraq. The Uzbekistan project involved a circular structure with a diameter of 18 meters and a height of 4.5 meters, for which a modular formwork system was employed to ensure precision and speed. Similarly, the project in Karbala, Iraq, required the construction of a digester with a diameter of 17.40 meters and a height of 25.96 meters. For this challenging structure, the company utilized ascending modular arcuate forms, showcasing its ability to tackle demanding geometries with specialized, engineered solutions. These projects underscore the company’s competence in providing high-precision, heavy-duty formwork for critical infrastructure.

- High-Rise & Residential Projects (UAE): The company’s work on high-rise and residential buildings in the UAE, including the Laleh Tower, Tecom Tower, and Dubailand Residence, highlights its capacity for innovation and efficiency in urban construction. For the Laleh Tower, B.F.S. Industries’ Dubai office developed a patented “BFS-Table Form Systems” and a “2-level lifting C-hook system” to accelerate the construction of post-tensioned slabs. This innovative approach enabled the lifting of tables two floors at a time, significantly speeding up the project timeline. At the Tecom Tower, the company’s “BFS-SK (Deck And Infill Beam)” system was used to ensure the project met its stringent timing schedule while reducing expenditures and labor costs. The Dubailand Residence project required a specialized one-sided formwork system for a 3.5-meter retaining wall, demonstrating the company’s ability to create bespoke, cost-effective solutions for unique structural challenges.

- Road & Tunnel Projects (UAE): The Diftah-Shis Road & Tunnel project stands as a landmark achievement, showcasing B.F.S. Industries’ advanced engineering and innovation. For this critical infrastructure project, the company designed and manufactured a novel, patented “full-hydraulic, full-steel formwork with a self-propelled tunnel lining formwork system”. This system, used for the first time in the UAE, was crucial for the high-speed and efficient execution of the project and was praised by government officials for its technical and engineering expertise. This case study is a powerful validation of B.F.S. Industries’ authority and ability to solve even the most difficult and complex engineering challenges.

The B.F.S. Industries Advantage: A Strategic Comparison

The choice of formwork is a critical strategic decision for any construction project, with material selection representing a core consideration. B.F.S. Industries’ focus on steel-framed formwork is a deliberate strategy that offers specific, quantifiable advantages over other material systems like traditional timber or aluminum.

Comparative Analysis: The Steel Frame Advantage

The strategic value of steel formwork lies in its superior strength, durability, and long-term cost-effectiveness. The Zigma system’s capacity to handle high hydrostatic pressures (up to 80 kN/m²) positions it as the optimal choice for demanding applications such as high-rise buildings and infrastructure. This is in contrast to traditional timber systems, which have limited strength and are often only suitable for single-use, low-pressure applications. While aluminum systems offer the advantage of being lightweight, their load capacity and overall durability may not be sufficient for the heavy-duty projects that are the hallmark of B.F.S. Industries’ portfolio.

The reusability of Zigma’s steel-framed panels ensures long-term cost savings that far outweigh the initial investment, a stark contrast to the high long-term costs associated with single-use timber formwork. The system’s engineering for a high-quality, fair-faced finish also minimizes post-pour rework, saving time, labor, and materials. The following table provides a detailed comparative analysis of the three primary formwork material types.

| Value Proposition | Zigma (Steel-Frame) Formwork | Traditional Timber Formwork | Aluminum Formwork Systems |

|---|---|---|---|

| Strength & Load Capacity | High; handles 80 kN/m² hydrostatic pressure | Low | Medium |

| Durability & Reusability | High; reusable across many projects | Low; single-use or limited reuse | Medium |

| Efficiency | High; large panels, fast assembly | Low; labor-intensive | High; lightweight |

| Finish Quality | High; smooth, fair-faced, fewer joints | Varies; can leave wood grain marks | High |

| Cost-Effectiveness | High long-term value due to reusability | Low initial cost, high long-term cost | High initial cost |

| Best Application | High-pressure pours, high-rise, infrastructure | Small-scale, low-pressure projects | Lightweight, general use applications |

A Partnership Approach to Success

In the B2B construction sector, a supplier’s value extends far beyond its products. The quality of the relationship and the breadth of support services are key differentiators. B.F.S. Industries’ business model is built on establishing long-term, valuable partnerships with its clients. The company maintains a “highly regarded reputation” by being responsive to inquiries, ensuring timely deliveries, and providing excellent after-sales support.

The company’s commitment to a partnership approach is evident in its technical capabilities and service offerings. B.F.S. Industries employs experienced personnel and degreed engineers who have the knowledge required to design systems that meet or exceed customer specifications, no matter how complex. This emphasis on tailored solutions and customized designs is a core component of their value proposition. The company also offers a suite of support services, including full technical support, configuration options, custom sizing, and even 24/7 support and express shipping for urgent needs. This comprehensive approach offers a level of support and reliability that is critical for a busy contractor, providing a sense of security and peace of mind on the job.

Concrete Wall Formwork System Supplier

As a leading Concrete Wall Formwork System Supplier, B.F.S. Industries delivers innovative and reliable solutions tailored to the needs of construction professionals worldwide. With over two decades of expertise, the company’s flagship Zigma panel formwork system exemplifies its commitment to quality, efficiency, and versatility. Engineered for high-pressure pours and architectural-grade finishes, B.F.S. Industries provides modular, steel-framed formwork that streamlines construction processes while ensuring structural integrity. Supported by a global presence, comprehensive technical support, and a partnership-driven approach, B.F.S. Industries empowers contractors to achieve project success with confidence and precision.

Partner with B.F.S. Industries for Your Next Project

The Zigma panel formwork system is a testament to B.F.S. Industries’ dedication to engineering excellence and client-centric solutions. By combining a robust, steel-framed design with a highly modular and user-friendly system, the company has created a superior Concrete Wall Formwork System that delivers exceptional performance, efficiency, and quality for concrete construction. The system’s ability to handle high-pressure pours, accelerate project timelines, and produce architectural-grade finishes makes it a leading choice for a wide range of applications, from foundations and retaining walls to high-rise cores and complex infrastructure projects.

B.F.S. Industries is not merely a supplier of concrete formwork; it is a strategic partner committed to providing integrated, engineered solutions. The company’s extensive experience, global project portfolio, and deep technical expertise ensure that it can deliver not just a product, but a complete solution tailored to a project’s unique challenges. For construction professionals seeking to optimize their workflow, reduce costs, and build with confidence, the modular formwork and broader solutions from B.F.S. Industries offer the strategic advantage needed to succeed in today’s competitive landscape.

To explore how B.F.S. Industries can engineer a solution tailored to your project’s unique challenges and goals, please contact a trusted formwork supplier or contact BFS Industries, LLC at their corporate headquarters.

B.F.S. Industries, LLC

Whatsapp : +971543799202

Email: info@bfs-industries.com

علاء التميمي –

هل الألواح مقاومة للانحناء تحت الأحمال العالية؟ وما هو نوع الطلاء المستخدم للحماية من الصدأ؟