- Published:

- Written by: B.F.S Industries

Shuttering Removal Time in Concrete Construction: Slabs, Beams, Columns & Staircase Guide

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

Shuttering removal time, also known as formwork stripping time, is a critical phase in concrete construction that directly affects the structural performance, safety, and timeline of any building project. For civil engineers, site managers, and contractors, knowing the right time to remove shuttering is essential to ensure that concrete components—such as slabs, beams, and columns—have developed adequate strength to safely support structural loads.

Removing formwork too early can compromise the integrity of the structure, lead to cracking or collapse, and result in costly rework. On the other hand, unnecessary delays in stripping can slow down progress and increase labor costs. This detailed guide covers the importance of shuttering removal time, the standard industry practices, key influencing factors, associated risks, best practices, and expert recommendations to help professionals make informed decisions.

What is Shuttering (Formwork) in Construction

Shuttering, also known as formwork, is a temporary mold used in concrete construction to shape and support freshly poured concrete until it gains sufficient strength to stand on its own. This essential component is used to form structural elements such as slabs, beams, columns, and foundations, ensuring dimensional accuracy and smooth finishes. Understanding what shuttering is—and how it functions—is fundamental for civil engineers, builders, and contractors involved in concrete works. This section introduces the concept of shuttering, its role in structural integrity, and its importance in the overall construction process.

Types of Shuttering (Formwork) Systems Used in Construction

A wide range of shuttering systems is used in modern construction, each tailored to meet the unique demands of different project sizes, budgets, and environmental conditions. From traditional timber formwork to advanced modular and reusable systems, the choice of shuttering depends on factors such as construction speed, required finish quality, cost-efficiency, and reusability. Understanding the differences between these types helps engineers and contractors select the most effective solution for slabs, columns, beams, and walls in residential, commercial, and infrastructure projects. In the sections below, we explore the most commonly used shuttering systems and their specific applications—covering everything from modular panel assemblies to the specialized tunnel formwork system supplier solutions that are transforming large-scale housing and repetitive structure projects.

Timber Shuttering

Timber shuttering, commonly made from wood or plywood, remains a popular choice for small-scale or customized construction projects due to its affordability and ease of use. This traditional formwork system is especially favored in residential buildings and light commercial structures, where flexibility in cutting and shaping is required. While timber shuttering is cost-effective and readily available, it comes with notable limitations, including a tendency to warp, rot, or degrade after limited reuse—typically around 5 to 10 cycles. Despite these drawbacks, when applied properly and in line with industry standards, including those recommended by BFS Industries, timber shuttering can deliver reliable performance in controlled, short-term construction settings. However, for long-term or large-scale projects, more durable alternatives may be advisable.

Steel Shuttering

Steel shuttering is constructed using robust metal panels and is particularly suited for large-scale and repetitive construction projects. This formwork system stands out for its exceptional durability and precision, often being reused up to 2000 times when properly maintained. Its smooth finish makes it ideal for exposed concrete surfaces in high-rise buildings, bridges, and infrastructure developments. While the initial investment for steel shuttering is significantly higher compared to timber or plastic alternatives, and it requires skilled labor due to its weight and assembly complexity, its long-term cost-effectiveness is unmatched. Many leading construction professionals, including those who rely on BFS Industries systems, choose steel shuttering for its reliability, strength, and ability to deliver consistent quality on demanding projects. In comprehensive Shuttering Material List planning, steel panels are often prioritized for core structural elements where durability and precision are essential, reinforcing their role as a key component in high-performance concrete works.

Aluminum Shuttering

Aluminum shuttering consists of lightweight panels typically made from high-strength aluminum alloys, widely used in modern construction projects that demand speed and precision. These systems are corrosion-resistant, quick to assemble, and highly reusable, making them ideal for high-rise buildings and architecturally complex structures. While the cost is higher than timber formwork, and aluminum lacks the load-bearing strength of steel, its lightweight nature significantly reduces labor time and effort. Leading manufacturers like BFS holding provide advanced aluminum shuttering systems that deliver consistent performance, durability, and excellent surface finishes, particularly suited for fast-paced, large-scale projects.

Plastic Shuttering

Plastic shuttering, manufactured from either recycled or virgin plastic, is rapidly gaining popularity in the construction industry due to its sustainability and ease of use. These systems are lightweight, eco-friendly, and reusable up to 50 times, making them a practical choice for residential and commercial projects aiming for environmental responsibility. Plastic formwork also provides good thermal insulation, helping maintain optimal curing temperatures for concrete. Although it may not withstand extremely heavy loads like steel or aluminum, plastic shuttering remains an excellent solution for low to mid-load applications.

Mivan Shuttering

Aluminum formwork systems, particularly patented modular designs, are engineered for speed, precision, and reusability—making them ideal for mass housing developments, high-rise structures, and hotel construction. These systems allow for rapid erection and dismantling, significantly reducing construction time. With proper maintenance, aluminum formwork can be reused up to 250 times, offering long-term cost efficiency despite the high initial investment. However, their use typically requires skilled labor and specialized training. One key advantage is their compatibility with standardized construction schedules, including compliance with guidelines for slab shuttering removal time as per IS code, ensuring structural integrity and timely progress across large-scale projects.

Each shuttering type plays a critical role in the formwork removal process, with materials like steel and aluminum enabling faster, safer, and more efficient dismantling due to their durability, smooth surface finish, and lightweight handling characteristics. These materials help maintain structural integrity while reducing labor time. Moreover, choosing the right shuttering type is essential for staying in compliance with safety standards and timelines, particularly regarding slab shuttering removal time as per IS code, which specifies when formwork can be safely removed based on factors like concrete strength, slab span, and environmental conditions.

Importance of Shuttering Removal Time in Concrete Structures (Slabs, Beams, Columns, Staircases)

Understanding the importance of shuttering removal time is critical in ensuring the structural performance, safety, and overall quality of any concrete construction project. Removing formwork too early can result in cracks, deflection, or even collapse, while removing it too late can delay the project and increase costs. This timing is especially vital when dealing with Concrete Column Formwork, where vertical load-bearing elements must achieve adequate strength before releasing support. A balanced and well-informed approach to formwork stripping helps optimize construction schedules, preserve structural integrity, and reduce the risk of failures.

Impact on Structural Integrity

The timing of shuttering removal plays a vital role in concrete construction, as it ensures the structure has achieved adequate compressive strength to support its own weight and any superimposed loads, including construction activities or additional structural components. If formwork—especially in elements like column formwork—is removed prematurely, it can lead to serious issues such as cracking, deformation, or even complete structural failure. Cracks may appear on the surface or within the structure due to insufficient strength, while early removal might also cause sagging or misalignment. In severe cases, premature stripping may trigger partial or full collapse, posing significant safety hazards. On the other hand, delaying shuttering removal too long typically does not compromise structural performance but can lead to unnecessary project delays and increased labor costs.

Understanding Types of Column Formwork in Modern Construction

Construction Speed and Cost Considerations

Efficient shuttering removal strikes a critical balance between structural safety and overall project efficiency. Timely removal allows construction teams to proceed with subsequent phases—such as plastering, waterproofing, or additional structural work—without unnecessary delays. This is particularly important in upper sections like slabs and roofs, where managing roof shuttering removal time effectively can directly impact the project schedule. However, removing formwork too late ties up valuable labor, equipment, and reusable materials. For instance, modular systems made of steel or aluminum may become unavailable for other areas of the job site, leading to increased costs or the need to procure additional units. In large-scale infrastructure works—such as bridges and reservoirs—close coordination with a dam formwork supplier ensures that dismantling and reuse cycles are optimized, maintaining both project momentum and material efficiency.

Standard Guidelines for Shuttering Removal Time (IS 456, ACI 347, BS 8110)

Understanding the standard guidelines for shuttering removal time is essential for ensuring structural integrity and construction efficiency. These guidelines—outlined by national and international standards such as the Indian Standard (IS 456), Eurocode, and ACI—help engineers and contractors determine the minimum time required before formwork can be safely removed. Factors such as the type of structural element (e.g., slab, beam, column), curing conditions, ambient temperature, and the grade of concrete all influence the recommended removal schedule. Adhering to these standards helps prevent premature loading, cracking, and collapse while keeping the project timeline on track.

IS Code 456 Recommendations

In India, the Indian Standard IS 456:2000 outlines specific minimum formwork removal times to ensure that concrete has gained sufficient strength before the supports are withdrawn. These recommendations are particularly applicable when using Ordinary Portland Cement (OPC) and curing under normal conditions—typically with an ambient temperature of 20–30°C and adequate moisture levels. The code emphasizes safety and structural stability by tailoring removal times to different structural elements such as slabs, beams, columns, and walls. The table below provides a summarized view of these standard timeframes as per IS 456:2000.

The typical formwork removal times for different structural elements vary based on factors such as the type of cement, ambient temperature, and the load-bearing requirements. However, under standard site conditions and proper curing, general guidelines suggest the following:

-

Columns, walls, and vertical formwork: usually removed within 1 to 2 days.

-

Slab soffits: typically require about 3 days before removal.

-

Beam soffits: often need around 7 days of support.

-

Props to slabs: for spans up to 4.5 meters, around 1 week; longer spans may need 2 weeks.

-

Props to beams and arches: generally kept in place for up to 2 weeks.

These timeframes assume that the concrete has gained sufficient strength—typically twice the expected stress upon removal—to ensure structural safety and minimize the risk of cracking or deformation.

British Standards vs. American Concrete Institute Guidelines

While national codes like IS 456 offer comprehensive guidance on shuttering removal, international standards also play a crucial role in shaping best practices globally. Organizations such as the American Concrete Institute (ACI) and British Standards Institution (BSI) have established their own sets of recommendations—ACI 347 and BS 8110 respectively—which, while broadly aligned, incorporate nuanced differences based on regional construction techniques, environmental conditions, and material properties. Understanding these variations is essential for engineers and contractors working across international or multi-standard projects.

ACI 347 (American Concrete Institute)

ACI 347, issued by the American Concrete Institute, provides clear guidelines for the removal of formwork based on typical curing conditions and structural demands. According to this standard, formwork for walls and columns can generally be removed within 12 to 24 hours, assuming the concrete has achieved initial strength. Slab formwork typically requires 3 to 4 days, while beams need 7 to 10 days before the soffit formwork can be safely removed. As for props and supports, the removal period depends on the span and imposed loads, but they usually range between 7 to 14 days. These timelines are intended to balance structural safety with construction efficiency, making ACI 347 a widely used reference in the U.S. and internationally.

BS 8110 (British Standards)

British Standards (BS 8110) generally align with IS 456 in terms of formwork removal timing, but incorporate minor modifications to reflect local cement types, environmental conditions, and construction practices in the UK. These slight variations highlight the need for professionals to follow region-specific codes while also considering project-specific factors such as the type of concrete mix used, curing methods, and ambient temperature. For example, compared to IS 456, ACI 347 may allow for slightly earlier formwork removal—particularly for walls—due to differences in cement composition and strength gain characteristics commonly found in the U.S. construction industry.

| Structural Element | IS 456:2000 (India) | ACI 347 (USA) | BS 8110 (UK) |

|---|---|---|---|

| Vertical Formwork (Walls, Columns) | 24 to 48 hours (1–2 days) | 12 to 24 hours | 1 to 2 days |

| Slab Soffit (Formwork Only) | Minimum 3 days | 3 to 4 days | 3 to 4 days |

| Beam Soffit (Formwork Only) | Minimum 7 days | 7 to 10 days | 7 to 10 days |

| Props to Slabs | Up to 4.5m: 7 days Over 4.5m: 14 days |

7 to 14 days (depends on span/load) | Similar durations |

| Props to Beams & Arches | 14 days | 10 to 14 days | Around 14 days |

| Assumed Cement & Conditions | OPC, 20–30°C, moist curing | Normal curing conditions | UK-specific cement & climate |

| Main Consideration | Safety & strength gain | Initial strength & speed | Local practices & adjustments |

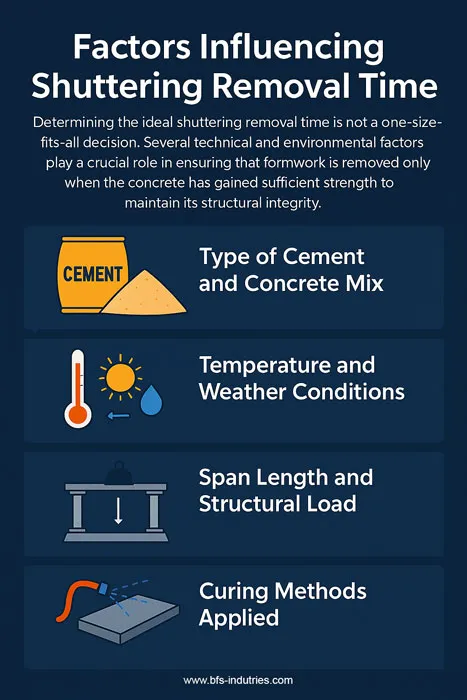

Factors Influencing Shuttering Removal Time

Determining the ideal shuttering removal time is not a one-size-fits-all decision. Several technical and environmental factors play a crucial role in ensuring that formwork is removed only when the concrete has gained sufficient strength to maintain its structural integrity. Engineers and construction professionals must evaluate these variables carefully to avoid premature stripping—which can compromise safety—or unnecessary delays that impact project timelines and costs. Understanding these influencing factors is essential for maintaining quality, safety, and efficiency on any construction site.

Type of Cement and Concrete Mix

The type and grade of cement used directly impact the shuttering removal timeline.

Ordinary Portland Cement (OPC) follows standard curing durations, as recommended by IS 456. However, Rapid Hardening Portland Cement (RHPC) and High Early Strength Cement allow concrete to achieve strength more quickly—making it possible to reduce formwork stripping times, such as removing slab shuttering in 2–3 days instead of the typical 3 days. Similarly, higher concrete grades like M30 or M40 develop compressive strength faster than lower grades like M20, which can expedite the removal process across various elements, including staircase shuttering removal time. This makes cement selection a critical factor in balancing safety and construction efficiency.

Steel Column Shuttering: A Complete Guide for Efficient Formwork

Temperature and Weather Conditions

Environmental conditions like temperature and humidity significantly affect shuttering removal schedules.

High temperatures—typically above 30°C—accelerate cement hydration, which can speed up curing and potentially allow earlier formwork removal. However, rapid curing may also increase the risk of shrinkage cracks if proper moisture is not maintained. On the other hand, cold temperatures (below 10°C) slow down the curing process, requiring longer durations before shuttering can be safely removed. Similarly, humidity plays a crucial role: low humidity causes excessive evaporation, which may hinder strength development, while high humidity provides a more favorable environment for consistent curing. Understanding these environmental impacts is essential when planning safe and effective shuttering removal.

Span Length and Structural Load

Span length and structural loading are critical determinants in the timing of shuttering removal.

Longer spans—such as slabs exceeding 4.5 meters or beams over 6 meters—are subjected to greater flexural stresses and therefore require extended curing periods to develop the necessary strength. Removing shuttering prematurely from these elements can lead to deflection, cracking, or even structural failure. Additionally, structures designed to bear heavy loads—like industrial floors, warehouses, or bridges—must undergo longer curing before formwork removal to ensure that the concrete can safely support the imposed stresses. Proper assessment of both span dimensions and loading conditions is essential for safe and efficient removal scheduling.

Curing Methods Applied

Curing method significantly impacts shuttering removal time by affecting the rate of concrete strength development.

Water curing—through continuous ponding or periodic spraying—ensures uniform hydration and steady strength gain, making it ideal for large on-site pours. In dry or windy environments, membrane curing is often preferred; it involves applying a sealing compound that locks in moisture, preventing surface dehydration and shrinkage. For projects that require accelerated timelines, especially in precast construction, steam curing is employed. This method uses controlled heat and humidity to rapidly increase early strength, allowing for earlier formwork removal without compromising structural integrity.

Recommended Shuttering Removal Time for Slabs, Beams, Columns, Staircases, and Roofs

Determining the right time to remove shuttering is crucial for maintaining structural integrity, safety, and workflow efficiency on any construction site. Different structural elements—such as slabs, beams, and columns—carry varying loads and have different curing requirements, which means their formwork removal times must be carefully calibrated. This section outlines the commonly recommended timeframes for each element based on standard guidelines and best practices, helping engineers and contractors make informed decisions that balance speed with safety.

Slab Shuttering Removal Time

Soffit formwork—which supports the underside of slabs—is generally removed after approximately 3 days, provided that Ordinary Portland Cement (OPC) is used and proper curing conditions are maintained. However, this does not mean the structural element is ready to bear full loads. For this reason, props must remain in place for an extended period to prevent deflection and ensure structural stability. For slabs with spans up to 4.5 meters, props are typically retained for at least 7 days. For longer spans exceeding 4.5 meters, the props should be left in place for around 14 days, depending on the concrete grade, environmental conditions, and applied loads.

Beam Shuttering Removal Time

Soffit formwork for beams is typically removed after 7 days, since beams are subjected to higher bending stresses compared to slabs. The extended period allows the concrete to gain sufficient strength before formwork is stripped. However, even after the soffit is removed, the props should remain in place for about 14 days to support the load and prevent any deflection or cracking. This ensures the structural integrity of the beam is maintained during the early stages of curing.

Column Shuttering Removal Time

Vertical formwork, such as that used for columns and walls, is generally removed after 16 to 24 hours. Since columns primarily carry compressive loads and have smaller cross-sections, they tend to gain strength more rapidly than horizontal elements. As long as the ambient curing conditions are adequate, early removal is both safe and efficient, enabling faster progress on upper-level construction tasks.

Staircase Shuttering Removal Time

Staircase shuttering removal time usually depends on the strength gain of concrete and the design load of the stairs. According to IS 456 guidelines, formwork for staircases (similar to slabs) can generally be removed after 7 to 10 days, provided the concrete has reached sufficient strength. ACI 347 and BS 8110 also recommend keeping the shuttering for a minimum of 7 days in normal weather conditions, while in colder climates or for longer spans, it may extend up to 14 days. Premature removal can cause cracks on risers and treads, leading to serviceability issues. Therefore, engineers often perform on-site inspections and consider curing quality before stripping staircase shuttering to ensure safety and durability.

Special Structures (Cantilevers, Domes, etc.)

Cantilever structures are subject to significant tensile stresses, especially at the fixed ends, and therefore require a longer curing period, typically 14 to 21 days, before shuttering can be safely removed. Similarly, domes and arches, due to their complex geometry and variable load distribution, may need 21 days or more, depending on the span, design intricacy, and material strength. In such cases, engineering judgment and, where necessary, on-site testing are essential to determine the appropriate removal time to avoid deflection or cracking.

Risks of Early or Late Shuttering Removal in Slabs, Beams, Columns, and Staircases

The timing of shuttering removal is a critical aspect of concrete construction, directly impacting both structural integrity and project efficiency. Removing formwork too early—before the concrete gains adequate strength—can lead to serious structural issues, while delayed removal can hamper progress and escalate costs. Understanding the risks associated with premature or delayed shuttering removal is essential for engineers and contractors to ensure safety, optimize schedules, and maintain construction quality across various structural elements like slabs, beams, columns, and cantilevers.

Structural Failures and Cracking

Premature Removal: Removing shuttering before the concrete has developed adequate compressive strength can compromise the structural integrity of the element. For instance, dismantling slab formwork before the recommended 3-day curing period—especially when using Ordinary Portland Cement—can result in surface cracks, deflection, or even partial collapse. These failures not only jeopardize safety on-site but also necessitate costly structural repairs, potentially delaying the overall project timeline.

Shuttering in Construction: Complete Guide to Formwork Systems

Delay in Subsequent Construction Activities

Delayed Removal: Leaving formwork in place beyond the required curing period can hinder progress on subsequent construction activities, such as plastering, reinforcement installation, or pouring additional concrete elements. This unnecessary delay often results in increased labor costs, idle equipment, and longer project durations, ultimately impacting budget efficiency and construction schedules.

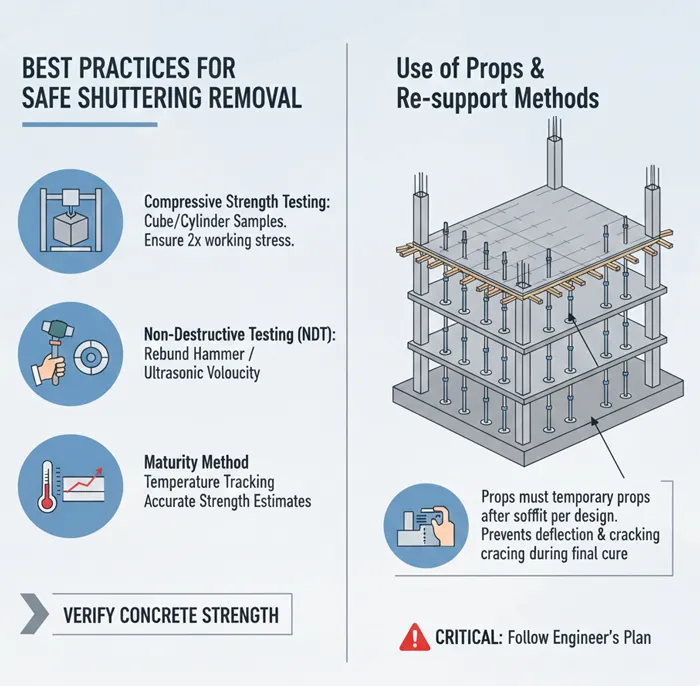

Best Practices for Safe Shuttering Removal

To ensure safe and efficient shuttering removal, construction professionals should follow these best practices:

Proper formwork removal is not just about timing—it’s also about understanding the structural behavior of different elements. For instance, circular columns, due to their geometry and loading characteristics, often require careful assessment before formwork is stripped to prevent surface defects or alignment issues. Adopting best practices helps avoid premature removal, reduces the risk of damage, and ensures a smoother workflow for subsequent construction stages.

On-Site Inspection and Load Testing

Before removing formwork—especially in critical elements like slabs, beams, and circular columns—verifying the concrete’s strength is essential to ensure structural safety. Several techniques are used on-site or in the lab to assess whether the concrete has achieved sufficient compressive strength.

Compressive strength testing involves taking cube or cylinder samples from the poured concrete and testing them under controlled laboratory conditions. These tests confirm whether the concrete has reached at least twice the anticipated working stress at the time of shuttering removal. For in-place assessment, non-destructive testing (NDT) methods such as the rebound hammer test or ultrasonic pulse velocity can provide strength estimates without damaging the structure. Additionally, the maturity method—which tracks the concrete’s temperature over time—uses maturity curves to estimate strength development accurately, allowing for more precise timing in fast-paced projects.

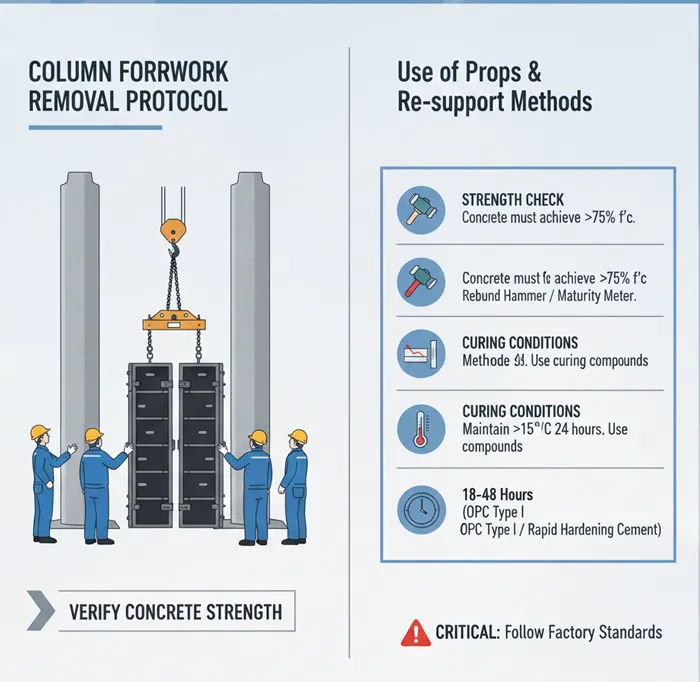

Use of Props and Re-support Methods

After removing the soffit formwork, it’s essential to install props beneath slabs and beams to ensure continued structural support while the concrete gains its full design strength. These temporary supports play a critical role in preventing deflection or cracking that may occur if the member is left unsupported during the final curing stage.

Props must be carefully spaced and sized according to the specific structural loads, slab spans, and beam sizes, as outlined in the design drawings or determined by the structural engineer. Proper placement ensures that the structure behaves safely during this transitional phase, especially in large spans or in regions subject to high live loads. Ignoring this step can compromise structural integrity, delay finishing work, or increase the risk of costly repairs.

Safety Measures for Workers

Ensuring safety during shuttering removal is essential to protect workers and maintain structural integrity. Proper training is the first step—workers must be educated in safe dismantling procedures, including gradual loosening of formwork to avoid sudden load transfers that could damage the structure or cause injury. Equally important is the use of personal protective equipment (PPE) such as helmets, gloves, safety harnesses, and non-slip boots to safeguard workers on-site. For heavy or large formwork components, using cranes, hoists, or other mechanical lifting devices significantly reduces the risk of manual handling injuries and ensures smoother, safer operations.

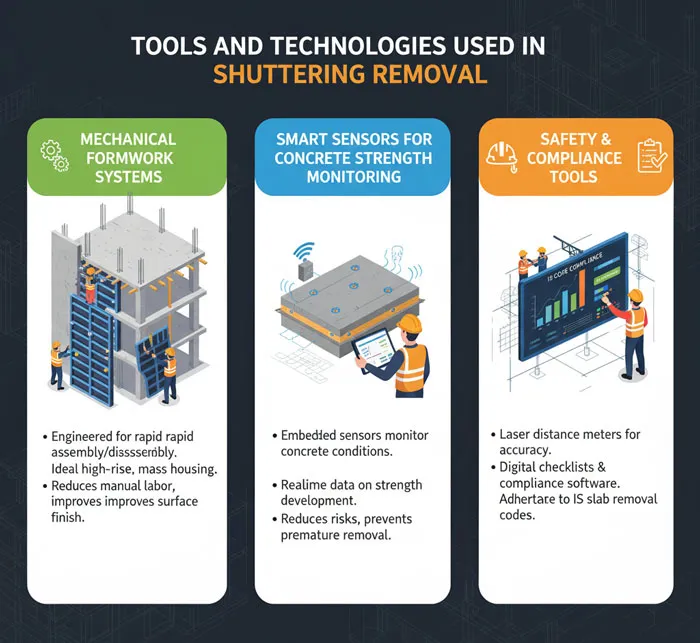

As construction projects grow in complexity and scale, the tools and technologies used for shuttering removal have become increasingly specialized. Efficient and safe dismantling not only protects the integrity of the structure but also speeds up project timelines. From basic hand tools to advanced mechanical systems, and even digital monitoring solutions, modern construction sites rely on a variety of equipment to ensure precise, controlled, and labor-efficient formwork removal. The choice of tools depends on factors such as the type of shuttering system, structural design, and safety requirements.

Mechanical Formwork Systems

Modern formwork systems—such as Mivan and tunnel formwork—are engineered to streamline the construction process by enabling rapid assembly and disassembly. These systems are especially valuable in large-scale developments, including high-rise buildings, mass housing, and infrastructure projects. By significantly reducing manual labor requirements and minimizing setup time, they enhance operational efficiency, ensure better surface finishes, and support consistent construction cycles. Their precision-manufactured components also contribute to improved safety and structural quality.

Smart Sensors for Concrete Strength Monitoring

Embedded sensors are integrated into concrete to continuously monitor temperature, humidity, and strength development in real time. These smart devices offer data-driven insights, enabling engineers to make informed decisions regarding the optimal timing for shuttering removal. By reducing reliance on estimations and traditional schedules, embedded sensors help minimize structural risks, prevent premature removal, and enhance overall construction safety and efficiency.

Expert Tips from Civil Engineers

Effective shuttering removal is not just a matter of following codes—it’s an art informed by experience, site conditions, and sound engineering judgment. To bridge the gap between theory and real-world challenges, experienced civil engineers offer valuable insights that go beyond standard guidelines. Their expertise helps prevent costly mistakes, ensures structural safety, and improves project timelines. The following expert tips reflect practical knowledge gained from years of hands-on experience in various construction environments.

Real-world Case Studies

While codes and guidelines provide a reliable foundation, real-world outcomes ultimately depend on how faithfully these standards are followed on-site. Examining actual construction projects reveals the critical consequences of shuttering removal decisions—both positive and negative. The following case studies from major Indian cities illustrate how timing, judgment, and compliance can determine the success or failure of a structure.

Common Mistakes to Avoid

Despite clear guidelines and technological advancements, several recurring mistakes continue to compromise structural safety and project efficiency. One of the most frequent errors is inadequate curing, where failure to maintain proper moisture levels weakens the concrete and leads to surface cracks upon formwork removal. Additionally, ignoring weather conditions—such as extreme heat or cold—without adjusting removal schedules can severely affect strength development. Another critical oversight is removing soffit formwork without installing props, which may result in dangerous deflections in slabs and beams. Lastly, relying solely on fixed timelines without performing strength tests increases the risk of premature removal and structural failure.

Environmental Impact of Shuttering Materials

The selection of shuttering materials plays a crucial role not only in construction speed and quality but also in the overall environmental sustainability of a project. Different materials carry varying ecological footprints depending on their source, reusability, and manufacturing process. For instance, timber can be environmentally friendly when sourced from certified sustainable forests, but it contributes to deforestation if harvested irresponsibly. Steel and aluminum have high embodied energy due to energy-intensive production processes, yet their long lifespan and full recyclability offset this impact over time. Plastic formwork, often derived from recycled content, helps reduce landfill waste and supports circular construction practices. Among modern systems, Mivan formwork, made from aluminum, offers exceptional reusability—up to 250 cycles—making it a sustainable choice for large-scale developments. By consciously selecting eco-friendly shuttering options, construction teams can significantly reduce the carbon footprint and material waste associated with their projects.

Training and Certification for Shuttering Workers

Proper training is essential for workers involved in shuttering operations, especially during the critical stage of formwork removal. A well-trained workforce is more likely to follow safety protocols, adhere to structural guidelines, and avoid mistakes that could compromise the integrity of the structure. Certifications from accredited organizations—such as the Construction Skill Development Council of India (CSDCI)—help ensure that workers possess standardized knowledge and practical skills. These credentials not only enhance on-site efficiency but also significantly reduce the risk of accidents, material damage, and project delays.

Formwork Removal Time for Column Supplier

The formwork removal time for column factory products plays a vital role in maintaining structural integrity and project safety. In practice, column formwork is removed only after the concrete reaches the required initial strength to support loads without risk. Factors such as cement type, curing conditions, temperature, and concrete quality directly influence this timing. A professional column factory typically provides clear standards and technical instructions, ensuring that the removal process is carried out efficiently, safely, and without compromising the surface quality of the concrete.

Quick Reference: Shuttering Removal Time Table (IS 456, ACI 347, BS 8110) for Slabs, Beams, Columns, Staircase, Roof

Civil engineers often need a quick guide for deciding when to safely remove shuttering (formwork).

The exact time depends on standards like IS 456 (India), ACI 347 (American Concrete Institute), and BS 8110 (British Standards).

Below is a quick reference table for common structural elements:

| Structural Element | IS 456 (Days) | ACI 347 (Days) | BS 8110 (Days) |

|---|---|---|---|

| Slab (up to 4.5m span) | 7 days | 7 days | 7 days |

| Slab (over 4.5m span) | 14 days | 14 days | 14 days |

| Beams (soffit formwork, props left under) | 7 days | 7 days | 7 days |

| Beams (props removed, up to 6m span) | 14 days | 14 days | 14 days |

| Beams (props removed, over 6m span) | 21 days | 21 days | 21 days |

| Columns & Vertical Faces | 1–2 days | 1–2 days | 1–2 days |

| Staircases | 7–10 days | 7–10 days | 7–10 days |

| Roof Slabs | 14 days | 14 days | 14 days |

| Cantilevers | 14 days | 14–21 days | 14–21 days |

⚠️ Note: These are general guidelines. Actual stripping time depends on factors such as concrete grade, curing method, and environmental conditions. Always confirm with the project’s structural engineer before removing shuttering.

Conclusion: Optimal Timing for Maximum Safety and Efficiency

Proper training is essential for workers involved in shuttering operations, especially during the critical stage of formwork removal. A well-trained workforce is more likely to follow safety protocols, adhere to structural guidelines, and avoid mistakes that could compromise the integrity of the structure. Certifications from accredited organizations—such as the Construction Skill Development Council of India (CSDCI)—help ensure that workers possess standardized knowledge and practical skills. These credentials not only enhance on-site efficiency but also significantly reduce the risk of accidents, material damage, and project delays.

Frequently Asked Questions (FAQs) About Shuttering Removal Time

Understanding the right time to remove shuttering is crucial in concrete construction, but it often raises many practical questions among engineers, contractors, and site supervisors. From interpreting code guidelines to dealing with site-specific challenges, this FAQ section addresses common concerns related to shuttering removal time. Whether you’re working with slabs, beams, or circular columns, these answers aim to clarify key points and help ensure safe, efficient construction practices.

How Does Temperature Affect the Time for Removing Shuttering?

Temperature plays a significant role in the curing process of concrete and directly affects shuttering removal time. In hot climates—where temperatures exceed 30°C—cement hydration accelerates, potentially enabling earlier formwork removal. However, this also increases the risk of thermal cracking due to rapid moisture loss. Conversely, in cold conditions (below 10°C), curing slows down, requiring extended formwork retention to ensure adequate strength development. Humidity is another critical factor: low humidity can lead to premature drying of concrete, delaying strength gain and compromising quality. To ensure structural integrity, site-specific adjustments to shuttering removal schedules are often necessary.

What Are the Consequences of Removing Shuttering Prematurely?

Premature shuttering removal can result in serious structural issues, including cracking, deformation, or even partial collapse, primarily due to the insufficient strength of immature concrete. Such failures not only compromise safety but also incur costly repairs and extend project timelines. For instance, removing slab formwork before the recommended 3-day period—especially when using Ordinary Portland Cement (OPC)—can lead to noticeable sagging or surface cracks, affecting both durability and appearance. This highlights the importance of adhering to standard curing durations and verifying concrete strength before dismantling the formwork.

Can the Time for Removing Shuttering Be Reduced by Using Rapid-Hardening Cement?

Yes, rapid-hardening cement—such as Rapid Hardening Portland Cement (RHPC)—can significantly reduce shuttering removal times. For instance, slabs may be safely stripped in as little as 2–3 days, and vertical elements like columns in 12–18 hours, compared to conventional timelines. However, while these accelerated schedules improve efficiency, they also come with increased risks, particularly in hot climates where rapid hydration may lead to thermal cracking. Therefore, strength testing remains essential to confirm that the concrete has achieved the required compressive strength before formwork is removed.