- Published:

- Written by: B.F.S Industries

Steel Column Shuttering: A Complete Guide for Efficient Formwork

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

In modern construction, selecting the right concrete formwork systems for concrete columns is more than just a practical choice—it’s a key factor influencing structural reliability, surface finish, and overall project cost. Among the available options, steel column shuttering stands out for its strength, reusability, and dimensional accuracy. Widely adopted across commercial, infrastructure, and high-rise projects, steel shuttering provides both durability and precision, making it a preferred solution for demanding construction environments.

This in-depth guide delves into every aspect of steel column shuttering—its definition, various types, benefits, core components, installation techniques, field applications, and common challenges. It also presents expert-recommended best practices to maximize efficiency and safety on-site. Whether you’re a civil engineer, site supervisor, or a technical content reader, this article offers the insights you need to understand and apply this essential formwork system effectively.

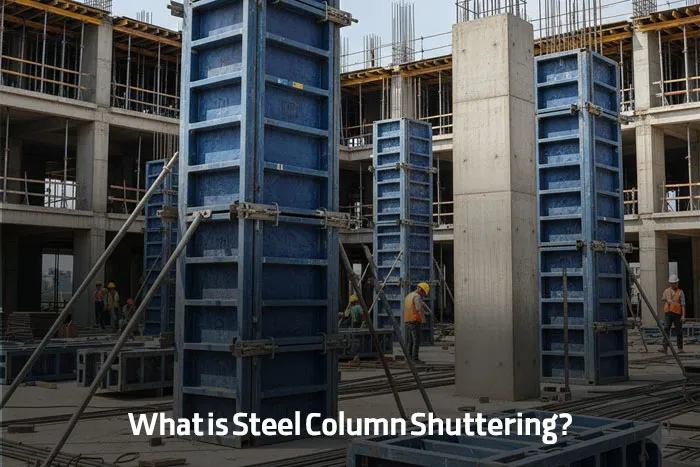

1. What is Steel Column Shuttering?

Steel column shuttering refers to a formwork system made from durable steel panels, used to shape and support concrete during the casting of vertical structural elements in reinforced concrete (RCC) and composite steel structures. This temporary mold holds freshly poured concrete in place until it gains adequate strength to stand on its own and support design loads. Its primary function is to ensure precision in shape, alignment, and dimensions—critical factors in achieving structural stability and durability. Properly installed steel shuttering minimizes the risk of deformation or misalignment, preventing weak spots and ensuring consistent column quality throughout the structure.

In RCC constructions, particularly in high-rise towers and infrastructure projects, steel column shuttering is vital for forming load-bearing columns with high dimensional accuracy. In hybrid or steel-framed structures, it works in tandem with steel elements to create seamless structural connections. BFS Industries, a recognized name in advanced construction systems, offers high-performance steel shuttering solutions that meet modern engineering standards, making them a preferred choice for demanding concrete column applications.

Steel column shuttering systems offer several advantages over traditional timber or plywood formwork. Their reusability and durability significantly reduce long-term costs in large-scale projects. Shuttering steel panels, especially in adjustable column shuttering systems, allow engineers to modify column dimensions quickly without compromising alignment or finish quality, making them ideal for projects with varying column sizes. The smooth steel surface also minimizes the need for extensive plastering or finishing after concrete removal, improving overall project efficiency.

In practice, steel shuttering is complemented by accessories such as tie rods, clamps, and braces, which ensure stability under the hydrostatic pressure of fresh concrete. Proper installation and alignment are critical to avoid honeycombing, uneven surfaces, or weak points in the column, which could compromise structural performance. Additionally, adjustable column shuttering and shuttering steel contribute to faster construction cycles, as panels can be assembled, disassembled, and reused multiple times, supporting tight project schedules without sacrificing safety or quality.

Modern construction projects, especially high-rise buildings, bridges, and commercial complexes, increasingly rely on shuttering steel and adjustable column shuttering due to their precision, reliability, and adaptability. Companies like BFS Industries provide comprehensive solutions, including modular and adjustable systems, training for onsite handling, and integration with other formwork types, ensuring that engineers and contractors achieve high-quality, structurally sound concrete columns consistently throughout the project.

1.1 Why Use Steel Instead of Timber or Plywood?

The preference for steel over traditional materials such as timber or plywood in column shuttering stems from its superior performance across multiple dimensions. Durability and longevity are key advantages—unlike timber or plywood, which are prone to warping, rotting, or deterioration over time, steel formwork remains structurally sound through repeated use. This makes it not only a reliable but also a cost-effective solution, especially in large-scale or repetitive projects. When evaluating options within a comprehensive Shuttering Material List, steel consistently ranks among the top choices for its performance and reusability. In terms of precision and surface finish, steel offers a smooth, uniform concrete face, often eliminating the need for post-casting surface treatment. This level of accuracy is essential in high-rise buildings and civil infrastructure where both aesthetics and engineering precision are critical. Furthermore, steel’s resistance to environmental factors such as humidity, temperature fluctuations, or exposure to water gives it a distinct edge over wood-based systems. While timber may expand, contract, or lose its integrity under harsh conditions, steel retains its shape and strength, ensuring consistent quality and performance on-site.

2. Types of Steel Column Shuttering Systems

In modern concrete construction, selecting the right type of steel column shuttering system is essential for ensuring structural accuracy, efficiency, and cost control. Steel shuttering solutions are engineered in diverse forms, each tailored to suit specific project needs—ranging from high-rise buildings to industrial structures. These variations not only accommodate different column shapes and sizes but also optimize installation speed, surface finish, and reusability. Understanding the types of steel column shuttering available is crucial for engineers and contractors aiming to achieve quality results while adhering to tight project timelines and performance standards.

2.1 Modular Steel Formwork

Modular steel formwork features pre-fabricated steel panels designed for quick assembly and dismantling, making it an excellent solution for fast-paced construction environments. Its modular nature supports repeated use and allows easy adaptation to various column dimensions and shapes. This versatility not only enhances productivity but also makes it especially suitable for large-scale concrete construction projects where time efficiency and consistency are critical.

2.3 Adjustable Column Boxes

Adjustable column boxes are versatile formwork systems that can be modified to accommodate different column dimensions. This adaptability makes them suitable for projects with varying design specifications, such as irregular or custom-shaped columns. Adjustable systems are particularly useful in projects where column sizes change frequently, as they reduce the need for custom-built formwork and save time during construction cycles.

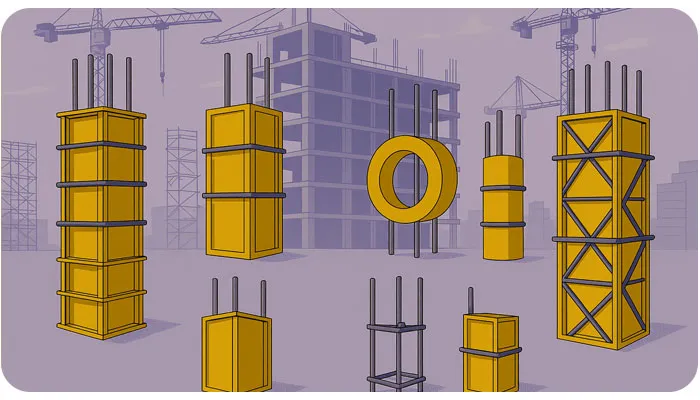

2.4 Circular vs. Rectangular Steel Shuttering

Circular Steel Shuttering:

Used for columns that require a round cross-section, often for aesthetic or structural reasons in architectural designs. Circular formwork is particularly useful for projects like bridges or high-rise buildings where circular columns are preferred for their load-bearing capacity and visual appeal. Typically, circular formwork consists of two identical half-circles bolted together.

Rectangular Steel Shuttering:

The most common type, used for standard column constructions where a square or rectangular shape is needed. Rectangular formwork is versatile and widely applicable across various construction projects, from residential buildings to industrial facilities.

3. Advantages of Using Steel Shuttering for Columns

The adoption of steel shuttering for columns offers several distinct advantages. Its high durability allows for multiple reuses without significant wear, making it a cost-effective choice in the long run. Steel provides a smooth, uniform finish that often eliminates the need for additional plastering or surface treatment. Furthermore, steel shuttering resists moisture, warping, and deformation, ensuring consistent performance under varying environmental conditions. These qualities make it particularly valuable in large-scale or high-rise construction projects, where precision, efficiency, and durability are critical to success.

Steel formwork offers exceptional durability and reusability, making it a practical choice for modern construction, especially in projects involving reinforced concrete or steel structures. Unlike timber or plywood, steel can endure the demanding conditions of construction sites and be reused across 200–300 cycles, significantly reducing material waste and long-term operational costs. In advanced projects utilizing technologies such as the self climbing formwork system, steel shuttering plays an essential role due to its ability to maintain stability and alignment during vertical progression.

Another key advantage is the smooth finish and precision it provides. The surface of steel formwork results in a clean, high-quality concrete finish, which minimizes the need for post-casting treatments—particularly valuable in steel structure projects where visual appeal and structural accuracy are essential. Moreover, steel’s resistance to warping and moisture ensures reliable performance in diverse environmental conditions. Unlike wooden formwork that may swell or distort due to humidity, steel remains stable, making it a dependable solution for high-rise buildings, bridges, and other complex steel structure developments.

4. Design and Components of Steel Column Shuttering

Understanding the design and components of steel column shuttering is crucial for effective implementation in any concrete construction project. A well-designed shuttering system not only ensures the desired shape and alignment of concrete columns but also enhances safety, efficiency, and surface finish. From locking mechanisms and stiffeners to alignment aids and base plates, each component plays a specific role in maintaining structural accuracy during casting. By mastering these elements, engineers and construction teams can streamline the formwork process, minimize errors, and achieve consistent, high-quality results—especially in projects involving repetitive or high-volume column production.

4.1 Panels, Clamps, Tie Rods, and Spacers

Steel column shuttering systems rely on several key components to ensure structural integrity and precise execution during concrete construction. Panels form the primary mold for concrete and are manufactured from high-strength steel, such as S275 mild steel or S355 grade, capable of withstanding the pressure of wet concrete. These panels typically have a thickness of 3mm for standard use, while heavy-duty versions range from 5mm to 8mm, often finished with powder coating or hot-dip galvanizing for enhanced durability. Clamps are essential for securing the panels together, maintaining rigidity throughout the pouring process. Common types include wedge clamps, universal locks, and spring clamps, some of which are adjustable for varying panel dimensions. Tie rods, made from high-tensile steel, connect opposite faces of the formwork to resist bulging and ensure alignment. They come in various diameters (D12 to D20mm) with load capacities between 123KN and 190KN. Spacers play a vital role by preserving the correct gap between the shuttering and reinforcement bars, ensuring the designed concrete cover is maintained for durability and strength.

Shuttering Removal Time in Concrete Construction: Slabs, Beams, Columns & Staircase Guide

4.2 How to Assemble and Disassemble

The assembly of steel column shuttering begins with positioning the base supports to establish a stable foundation. Once the base is in place, steel panels are attached using clamps and tie rods, ensuring all joints are tightly secured to resist the pressure of fresh concrete. For larger or irregularly shaped columns, additional bracing systems may be incorporated to maintain proper alignment and stability during pouring.

After the concrete has adequately cured—typically within 2 to 3 days, depending on the mix and environmental conditions—the disassembly process can begin. This involves removing the clamps and tie rods first, followed by carefully detaching the steel panels. It is essential to clean the formwork thoroughly after each use to remove concrete residue and ensure the system remains reusable and efficient for future applications.

5. Installation Process of Steel Column Shuttering

The installation of steel column shuttering is a systematic process that demands precision, planning, and adherence to safety and engineering standards. From setting up the base supports to securing the panels with clamps and tie rods, each step plays a vital role in ensuring that the formwork remains stable and aligned during concrete placement. Proper installation not only guarantees structural accuracy but also extends the lifespan and reusability of the formwork system. In the following sections, we break down the key stages of installation to help professionals execute this process effectively and efficiently.

5.1 Step-by-Step Formwork Setup

- Prepare the Base: Ensure the foundation is level and clean to provide a stable base for the formwork. A concrete pad, known as a starter, may be poured to secure the formwork and ensure alignment.

- Assemble the Formwork: Connect the steel panels, clamps, and tie rods to create the column mold. For circular columns, use two identical half-circles bolted together. For rectangular columns, ensure panels are aligned to form the desired shape.

- Place Reinforcement: Position the reinforcement bars (rebar), typically TMT (Thermo Mechanically Treated) bars, inside the formwork as per the structural design. Use spacers to maintain proper concrete cover.

- Pour Concrete: Fill the formwork with concrete, using vibrators to eliminate air pockets and ensure complete filling. This step is critical to avoid voids that could weaken the column.

- Cure Concrete: Allow the concrete to cure for the specified period, typically 2–3 days, depending on the mix and environmental conditions. Rapid-hardening cement or warm weather may allow for earlier removal.

- Remove Formwork: Once the concrete has gained sufficient strength (at least twice the stresses it will face upon removal), disassemble the formwork carefully, starting with vertical supports and then horizontal elements.

5.2 Alignment and Verticality Checks

During the installation of steel column shuttering, precision in alignment is essential to ensure structural integrity and design compliance. Utilize tools such as spirit levels, plumb bobs, and laser levels to verify verticality and alignment throughout the assembly. For columns exceeding 4.2 meters in height, it is strongly recommended to incorporate additional bracing and leveling beams to counteract potential displacement or buckling. Accurate alignment not only ensures the aesthetic and dimensional quality of the column but also minimizes corrective work post-concreting.

6. Common Sizes and Dimensions of Steel Column Formwork

Understanding the standard sizes and dimensions of steel column formwork is crucial for efficient planning, cost estimation, and on-site execution. These formwork systems are manufactured in a variety of height, width, and thickness configurations to suit different structural and architectural requirements. From compact residential columns to massive high-rise or infrastructure elements, selecting the right dimensions ensures proper load transfer, concrete flow, and minimal formwork adjustments. In the following section, we explore the most commonly used sizes in modern construction.

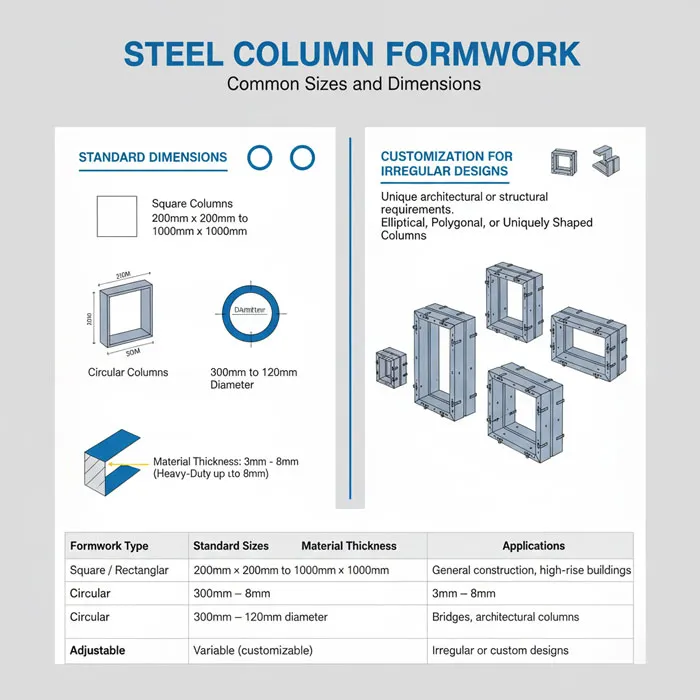

6.1 Standard Dimensions

- Square Columns: Typically range from 200mm x 200mm to 1000mm x 1000mm.

- Circular Columns: Diameters commonly range from 300mm to 1200mm.

- Material Thickness: Normal steel formwork panels are 3mm thick, while heavy-duty options range from 5mm to 8mm.

- Film-Faced Plywood (if used with steel): Thickness ranges from 12mm to 25mm.

6.2 Customization for Irregular Designs

In addition to standard sizes, steel column formwork offers the advantage of customization to meet unique architectural or structural requirements. For projects involving complex geometries—such as elliptical, polygonal, or uniquely shaped columns—formwork systems can be custom-fabricated with precise dimensions and configurations. This design flexibility is especially valuable in high-rise buildings, bridges, and iconic architectural structures where standard formwork may not suffice. Custom steel formwork ensures accuracy, supports structural integrity, and maintains visual consistency with the architectural intent.

| Formwork Type | Standard Sizes | Material Thickness | Applications |

|---|---|---|---|

| Square / Rectangular | 200mm × 200mm to 1000mm × 1000mm | 3mm – 8mm | General construction, high-rise buildings |

| Circular | 300mm – 1200mm diameter | 3mm – 8mm | Bridges, architectural columns |

| Adjustable | Variable (customizable) | 3mm – 8mm | Irregular or custom designs |

7. Steel Column Shuttering vs. Traditional Formwork

Comparing steel column shuttering with traditional formwork materials highlights its superiority in terms of performance, durability, and efficiency. While timber and plywood have long been used due to their availability and low upfront cost, steel offers a more reliable and long-lasting solution—especially for modern construction demands. This comparison reveals the practical benefits of steel in high-volume, precision-driven, and structurally demanding projects.

7.1 Timber vs. Steel Formwork: Pros and Cons

When comparing timber and steel formwork, each material presents distinct advantages and limitations depending on the project’s scale and requirements. Timber formwork is often favored for its lower initial cost and flexibility in shaping on-site, making it suitable for small-scale or one-off construction tasks. However, it has a short lifespan—typically lasting only 25 to 30 uses—and is vulnerable to warping, moisture damage, and frequent maintenance needs.

On the other hand, steel formwork stands out for its durability and long-term cost efficiency. Capable of being reused for 200 to 300 cycles, it offers a smooth concrete finish, resists environmental conditions, and maintains dimensional stability. While the upfront investment is higher and handling requires more effort and skilled labor, its performance in large-scale or repetitive projects makes it a preferred choice in modern construction.

7.2 Cost Comparison Over Multiple Uses

While steel formwork involves a higher initial investment, its ability to be reused extensively makes it more economical in the long run compared to timber. Timber formwork typically deteriorates after 25–30 uses, requiring frequent replacements that drive up project costs. In contrast, steel formwork can be reused 200–300 times, significantly lowering the cost per cycle. This long-term efficiency makes steel formwork a cost-effective and sustainable choice, especially for large-scale or repetitive construction projects.

8. Challenges and Solutions in Steel Column Shuttering

Despite its many advantages, steel column shuttering also presents certain challenges that must be considered during planning and execution. Its heavier weight compared to timber or aluminum makes transportation and on-site handling more labor-intensive, often requiring lifting equipment. Additionally, skilled labor is essential for proper assembly, alignment, and disassembly, which may not be readily available on all sites. Finally, the higher upfront cost can be a barrier for small contractors or projects with limited budgets, even though it pays off over time through reusability.

8.1 Handling Heavy Sections

One of the primary challenges in using steel column shuttering is handling its heavy components, particularly for large or high-rise columns. The weight of steel panels can make manual transportation and positioning difficult, increasing the risk of injury or misalignment. To address this, it’s recommended to use cranes or mechanical lifting equipment to safely maneuver heavy sections. Additionally, providing proper training for workers on safe handling practices helps ensure both efficiency and on-site safety.

8.2 Joint Tightness and Concrete Leakage Prevention

Another key challenge in steel column shuttering is maintaining tight, leak-proof joints to prevent concrete leakage during pouring. If joints are not sealed properly, the escaping concrete can lead to surface defects, honeycombing, or even weaken the structural integrity of the column. To prevent this, it is essential to use high-quality sealing materials such as rubber gaskets, silicone seals, or water stoppers at all connection points. Additionally, regular inspection of joints during the assembly process ensures that no gaps or weaknesses are present before pouring begins.

9. Best Practices for Steel Column Formwork

To maximize the structural, economic, and practical advantages of steel column formwork, following industry-recognized best practices is essential. These practices not only enhance safety and durability but also improve installation efficiency and concrete quality. Leading construction solution providers such as BFS Holding emphasize the importance of standardized procedures to ensure consistent performance across different project scales. Whether working on a high-rise tower or an infrastructure project, implementing these proven techniques helps avoid costly errors, prolong the formwork’s lifespan, and ensure structural integrity.

9.1 Lubrication and Formwork Oil Application

Before pouring concrete, apply a uniform layer of formwork oil to the inner surfaces of the steel formwork. This prevents the concrete from adhering to the surface, allowing for easier and cleaner removal. Using form-release agents not only improves the surface finish of the concrete but also protects the formwork from abrasion and corrosion, thereby extending its service life and maintaining reusability over multiple cycles.

9.2 Cleaning and Storage After Use

After each use, clean the formwork thoroughly to remove any concrete residue. Use non-abrasive tools and cleaning agents to avoid damaging the protective coatings on the steel surface. Proper cleaning maintains the formwork’s performance and prevents buildup that could affect future concrete finishes.

Once cleaned, store the formwork in a dry, sheltered location to prevent exposure to moisture, which can cause rust or deformation. Implement a regular maintenance routine, including inspections for dents, corrosion, and structural integrity, to extend the lifespan of the formwork and ensure safe, consistent performance across multiple projects.

9.3 Safety Considerations During Installation

Ensure all personnel involved in the formwork installation are properly trained in handling heavy equipment and understand site-specific safety protocols. Inadequate handling can lead to serious injuries or structural failures during concrete placement.

Workers should use appropriate personal protective equipment (PPE), including helmets, gloves, steel-toed boots, and safety harnesses when working at heights or near heavy lifting machinery. This is especially crucial in high-rise or large-scale projects where fall hazards and material handling risks are significant.

Additionally, conduct regular inspections of the steel formwork to verify its structural integrity before each use. Checking for loose components, corrosion, or damage helps prevent accidents and ensures the safety of both workers and the structure being built.

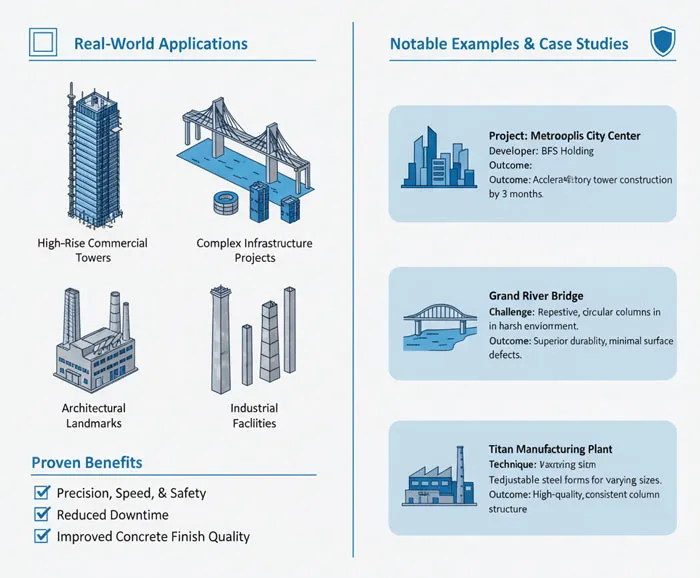

10. Case Studies and Industry Use Cases

In practical construction environments, steel column shuttering systems have proven to be not just theoretically advantageous, but highly effective across a wide range of real-world applications. From high-rise commercial towers and complex infrastructure projects to industrial facilities and architectural landmarks, the use of steel formwork has delivered outstanding results in terms of precision, speed, and safety.

The adaptability and durability of steel shuttering make it particularly suitable for challenging construction scenarios—such as areas with tight deadlines, repetitive column configurations, or exposure to harsh environmental conditions. Projects involving BFS Holding and other large-scale developers have consistently demonstrated how steel column formwork reduces downtime, minimizes surface defects, and improves the overall quality of concrete finishes.

This section explores notable examples and practical case studies where steel column shuttering has been successfully implemented, shedding light on the techniques used, challenges overcome, and the performance benefits achieved. These examples serve as valuable references for engineers, site managers, and construction planners who are seeking proven, efficient solutions in concrete column construction.

10.1 High-Rise Buildings

-

Francis Crick Institute – London: Utilized steel column formwork for its precision and durability in constructing complex structures. The formwork’s ability to handle large-scale projects with tight deadlines was a key factor in its selection.

-

BBC Television Centre: Steel formwork was used for its ability to provide a smooth finish and precise alignment, critical for the architectural design of this iconic building.

10.2 Infrastructure Projects

-

Second Forth Crossing Approach Structures – Scotland: Steel formwork was chosen for its strength and reusability in this major infrastructure project. The formwork’s durability allowed for efficient construction despite challenging weather conditions.

-

M25 Widening: Steel column formwork was used to ensure structural integrity and speed up construction on this critical transportation project.

Other notable projects include Heathrow Airport, Paddington Station, and the LUAS Light Rail Project in Dublin, where steel column formwork played a crucial role in ensuring structural integrity and meeting tight deadlines.

| Project | Location | Application | Key Benefit |

|---|---|---|---|

| Francis Crick Institute | London, UK | High-rise building | Precision and durability |

| Second Forth Crossing | Scotland | Infrastructure | Strength and reusability |

| M25 Widening | UK | Transportation | Speed and structural integrity |

11. Conclusion: Why Steel Shuttering is the Future of Column Formwork

Steel column shuttering represents a significant advancement in construction technology, offering a blend of durability, precision, and cost-effectiveness that traditional materials cannot match. Its ability to be reused multiple times, provide a smooth finish, and withstand harsh environmental conditions makes it an indispensable tool for modern construction projects. As the industry continues to evolve, steel shuttering is poised to remain at the forefront of formwork solutions, driving efficiency and sustainability in building practices.

By choosing steel column shuttering, construction professionals can ensure not only the structural integrity of their projects but also long-term economic benefits and reduced environmental impact. With its proven track record in high-rise buildings, infrastructure projects, and beyond, steel shuttering is undeniably the future of Concrete Column Formwork.

12. Frequently Asked Questions (FAQs) About Steel Column Shuttering

In the following section, we address some of the most common questions related to steel column shuttering to provide clarity and practical insights for construction professionals and enthusiasts. Whether you’re planning a high-rise structure, infrastructure project, or a complex architectural form, these answers will help you better understand the capabilities, applications, and maintenance of steel formwork systems.

12.1 What is the main difference between steel column shuttering and timber formwork?

The primary difference lies in durability and reusability. Steel column shuttering is made from high-strength steel, enabling it to be reused approximately 200 to 300 times, making it a cost-effective solution for large-scale or repetitive projects. In contrast, timber formwork typically lasts only 25 to 30 uses before degrading. Steel also offers a smoother concrete finish, greater resistance to warping and moisture, and performs reliably in harsh environmental conditions. However, the initial cost of steel formwork is higher than timber, which is more affordable but less durable and requires more frequent replacement and maintenance.

12.2 How long does it take to set up and remove steel column shuttering?

The setup time for steel column shuttering varies depending on the size and complexity of the column. For a standard column and with a skilled crew, the process typically takes 2 to 4 hours. After the concrete has adequately cured—usually within 2 to 3 days—disassembly can be completed in 1 to 2 hours. Utilizing modular or adjustable systems can significantly reduce setup time, while ensuring proper alignment and bracing helps maintain speed and structural accuracy during the process.

12.3 Can steel column shuttering be customized for unique column shapes?

Yes, steel column shuttering is highly adaptable and can be custom-fabricated to accommodate irregular or architecturally unique column designs—such as elliptical, curved, or polygonal shapes. Manufacturers can produce bespoke steel panels according to precise project specifications, ensuring that even the most complex geometries are accurately formed. This makes steel formwork an excellent solution for high-end architectural, infrastructure, or custom structural projects.