- Published:

- Written by: B.F.S Industries

Concrete Formwork Pricing Per M² Guide

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

The successful execution of any concrete construction project, regardless of its scale or complexity, relies fundamentally on accurate and insightful cost estimation, with Concrete Formwork Pricing being one of the most volatile and critical line items in the overall budget. Understanding the true cost per square meter ($https://www.google.com/search?q=/m²) of formwork is not merely about calculating the initial purchase or rental price of the materials; it involves a sophisticated financial assessment that integrates labor efficiency, reuse potential, material amortization, and logistical overhead. For project managers and cost estimators, mastering the variable costs associated with formwork—the temporary mold into which concrete is poured—is essential for maintaining profitability and timeline adherence. This comprehensive guide, informed by industry experience and backed by trusted suppliers like BFS Industries will dissect the multi-layered factors that drive formwork costs, providing procurement engineers and construction companies with the detailed knowledge needed to make cost-effective decisions, particularly by comparing different types of concrete formwork systems.

Understanding Concrete Formwork Pricing and Cost Drivers

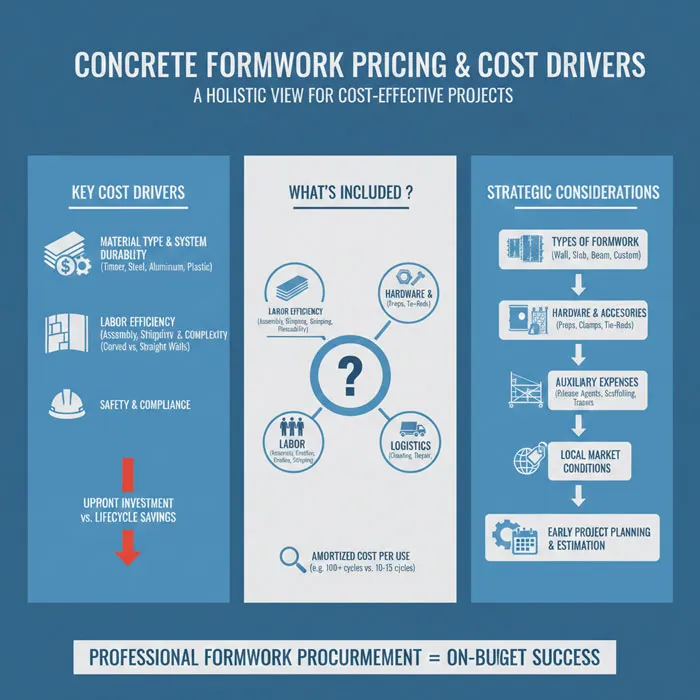

Calculating the precise formwork pricing per m2 requires moving beyond simple material costs and examining the full lifecycle of the chosen system, which is where many projects either find significant savings or incur unexpected overruns. The primary cost drivers are intrinsically linked to the material itself—be it timber, steel, aluminum, or plastic—and the system’s ability to be efficiently deployed, stripped, and redeployed over the project’s duration. The upfront investment in high-quality, durable systems is often offset by a superior reuse rate and faster cycle times, whereas cheaper, less robust options may initially seem appealing but can lead to soaring labor costs and material wastage over time. This section will elaborate on the key variables that dictate the final, effective cost of formwork on a job site, emphasizing the need for a holistic view of the construction workflow, rather than just the initial price tag, making a strong case for integrating formwork cost estimation into the earliest phases of project planning.

The true expense of formwork is a dynamic value influenced by local market conditions, project geometry, the complexity of the pour, and the necessary safety compliance measures, all of which contribute to the final square meter rate. For instance, intricate structural elements like curved walls or complex beam and slab formations inherently demand custom or specialized formwork solutions, dramatically increasing the cost per unit area compared to straightforward wall panels or slab formwork. Furthermore, the selection of types of concrete formwork is a strategic decision that affects not only the direct material cost but also auxiliary expenses, such as the type and quantity of release agents, the required scaffolding, and the need for specialized lifting equipment like tower cranes. A careful analysis of these interconnected factors is what differentiates a successful, on-budget project from one plagued by spiraling costs, necessitating a detailed and professional approach to formwork procurement for any serious contractor or construction company.

What Is Included in Concrete Formwork Pricing?

The calculation for Concrete Formwork Pricing per square meter typically includes several key components, extending far beyond the raw material cost to provide a true picture of the expenditure, which is vital for accurate financial planning for contractors. This all-inclusive cost model covers the initial material purchase or rental fees, the specialized connection hardware and accessories (like props, clamps, and tie-rods), the amortized labor hours required for assembly, erection, and stripping, and the subsequent costs of cleaning, repair, and transportation between project phases or sites. When evaluating formwork suppliers, it is crucial for procurement engineers to request a clear breakdown that accounts for the system’s longevity, as a higher-priced system with a guaranteed 100+ reuse cycles offers a dramatically lower effective cost per use compared to a cheaper system providing only 10 to 15 uses. This comprehensive approach to formwork cost estimation ensures that the full financial impact of the chosen formwork system market solution is understood, enabling a more informed and cost-effective formwork decision.

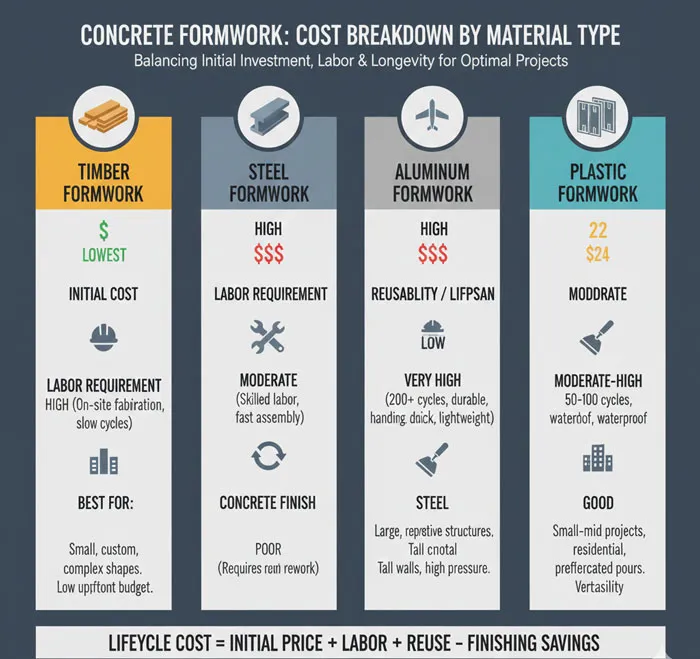

The choice of formwork material is arguably the single most influential factor determining the overall Concrete Formwork Pricing for a project, with each option—timber, steel, aluminum, and plastic—presenting a unique balance of initial cost, labor requirements, durability, and finish quality. This segment will provide a detailed formwork cost estimation breakdown by material type, moving from the most traditional, labor-intensive options to the more modern, highly engineered systems, helping construction companies identify the optimal material for their specific project needs. The key distinction lies in the concept of reusability, where high-durability materials like steel and aluminum command a higher upfront price but offer hundreds of reuse cycles, drastically reducing the cost per use, while lower-durability materials like wood are cheaper initially but often become single-use or require frequent, costly repairs, influencing the long-term formwork pricing per m2 calculation. Furthermore, the inherent surface finish quality delivered by the formwork dictates the subsequent finishing work required, a cost factor that is often overlooked in the initial assessment but is critical for minimizing overall formwork building cost.

Timber Formwork Cost per m²: Pricing, Advantages, and Limitations

Timber formwork, encompassing lumber, plywood, and various plywood derivatives, remains the most accessible and cheapest material for initial outlay, making it a staple in the wooden formwork systems market, particularly for smaller, residential, or custom-shaped projects where complex geometry necessitates site fabrication. The cost for material alone is highly variable, but the effective cost per square meter ranges widely, largely depending on the amount of labor and the anticipated reuse rate, which is typically low due to the material’s susceptibility to moisture damage and warping. The primary advantage of timber is its extreme flexibility and ease of customization; it can be cut and assembled by semi-skilled labor with basic tools directly on-site, which significantly lowers the initial capital expenditure compared to purchasing or renting specialized modular systems. However, its limitations include a high labor component for construction, slow cycle times, poor concrete finish requiring extensive rework, and very low reusability, meaning the overall formwork pricing per m2 often becomes disproportionately high for large-scale, repetitive structures where materials cannot be reused effectively.

Steel Formwork Pricing per m²: Strength, Durability, and Reuse Rate

Steel formwork represents a robust, high-durability alternative to timber, characterized by its high initial investment but superior longevity, which ultimately drives down the long-term Concrete Formwork Pricing across large, repetitive construction projects. These panels are prefabricated and designed for heavy-duty applications, offering exceptional structural integrity that is necessary for demanding pours, such as tall walls or high-pressure applications like those encountered with Concrete Column Formwork. The high reuse rate of steel, often exceeding 150 cycles, is the key factor in its superior cost-effectiveness; while the outright purchase or rental cost is significantly higher than timber, the amortized cost per use drops dramatically. The precision and smooth surface of steel panels also ensure a high-quality concrete finish, minimizing the need for subsequent plastering or repair work. Although the installation of steel systems may require specialized handling equipment and a more skilled workforce compared to wooden systems, the speed and predictability of the assembly and stripping process drastically improve the construction schedule and reduce the overall formwork cost estimation related to labor.

Aluminum Formwork Cost: High Efficiency and Fast Cycle Projects

Aluminum formwork systems are positioned as the high-efficiency solution, particularly favored in markets where repetitive designs and fast cycle times are paramount, making it a critical player in the aluminum formwork sector and a strong competitor in the broader modular formwork systems landscape. The Aluminum Formwork Cost is comparable to or slightly higher than steel initially, but its unparalleled lightness allows for manual handling without the need for heavy machinery, streamlining the erection and dismantling process and significantly cutting down on labor time and equipment costs. This system is ideal for monolithic concrete structures, such as those found in high-rise residential construction, offering a consistent and precise finish while achieving a high reuse count, typically exceeding 200 cycles. Projects utilizing these systems, especially those requiring complex lifting operations, can benefit from the integration of advanced solutions like a self climbing formwork system to further optimize cycle times and improve worker safety as the structure ascends. The speed advantage provided by aluminum formwork is often the deciding factor, turning a higher formwork pricing per m2 into a lower overall project cost due to the considerable reduction in the construction timeline and associated overhead.

Plastic Formwork Pricing: Lightweight, Reusable, and Market Trend

Plastic formwork, often manufactured from highly durable engineered polymers, is gaining significant traction due to its appealing combination of low weight, impressive reusability, and versatility, positioning it as an emerging force in the plastic formwork market for contractors seeking cost-effective formwork solutions. The Plastic Formwork Pricing sits at a moderate point between timber and the metallic systems, offering a favorable return on investment with reuse rates that can easily surpass 80 cycles, depending on the quality of the polymer and care during use. These systems excel in small-to-mid-sized residential and commercial projects, particularly those that leverage a prefabricated formwork approach, where speed of assembly by unskilled labor is a priority. Their major benefits include being fully waterproof, easy to clean, and capable of being quickly assembled using simple, often integrated, locking mechanisms. This reduced complexity in the erection process translates directly into lower skilled labor dependency and faster cycle times, which can significantly reduce the effective formwork pricing per m2, making it an increasingly attractive option within the evolving formwork system market.

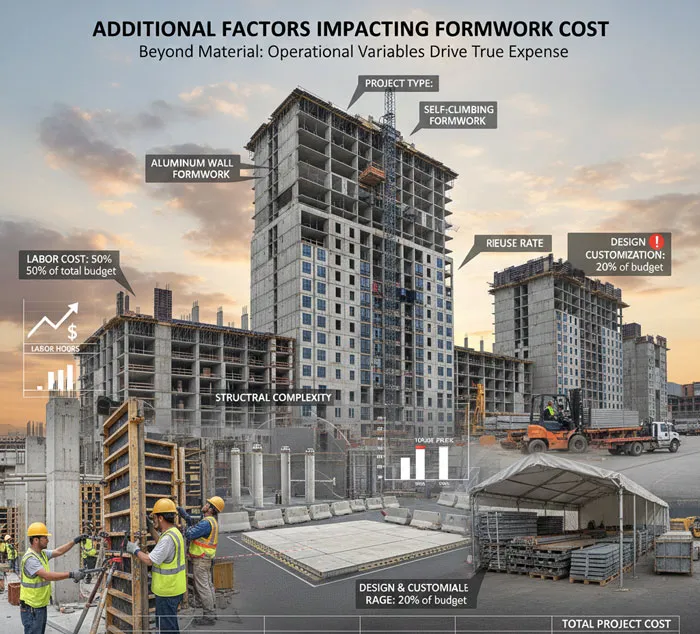

Additional Factors That Impact Formwork Cost

Beyond the inherent material and system type, a multitude of site-specific and operational variables contribute significantly to the final, realized Concrete Formwork Pricing on any construction project. These factors transform the theoretical cost per square meter, derived from material pricing and reuse potential, into the actual expenditure incurred by the construction company. Key among these variables are the intricacies of labor and productivity, the complexities of logistics and storage, and the specific structural elements required by the project design, such as Concrete Column Formwork versus slab forms. Project managers and estimators must carefully model these operational costs, as they often constitute the majority of the formwork budget, overriding any initial savings achieved through material selection alone. A failure to accurately predict and manage these auxiliary costs can derail a project budget, emphasizing the need to analyze the entire workflow and not just the cost of the physical formwork itself.

Labor Cost, Skilled Workforce, and Assembly Time

The cost of labor is usually the largest single contributor to the final formwork cost estimation, making the efficiency of the assembly and stripping process paramount for achieving cost-effective formwork solutions. For systems like traditional timber, the sheer volume of time required for cutting, measuring, nailing, and dismantling drives up the labor hours significantly, demanding a high ratio of skilled carpenters, thus influencing the overall formwork pricing per m2. Conversely, highly engineered modular formwork systems, particularly aluminum or steel, are designed for rapid, repetitive assembly using standardized components and simple connection methods, dramatically reducing the labor time per cycle, even if the initial labor rate for the specialist installers is higher. The project must carefully consider local labor rates and the required crew size in conjunction with the system’s design complexity and the specific requirements of the entire formwork construction steps, as optimized workflow and reduced assembly time are the most effective strategies for lowering the total expenditure on labor.

Logistics, Storage, Reuse Rate, and On-Site Productivity

Effective logistics and careful management of the formwork inventory are non-negotiable elements that directly influence the calculated formwork pricing per m2 by maximizing the reuse potential and minimizing downtime. Transportation costs—moving large, heavy steel or aluminum panels to and from the site—must be factored in, as must the cost of dedicated, secure on-site storage to protect valuable assets from damage or theft. The system’s reuse rate is perhaps the most critical financial metric: a panel rated for 100 uses that is only used 50 times due to poor site management, damage, or inadequate planning effectively doubles the unit cost per application. Maintaining high on-site productivity involves ensuring minimal material damage during stripping and cleaning, establishing a streamlined process for concrete pouring and curing to allow for faster formwork cycling, and ensuring that formwork is readily available at the point of use to avoid delays in the workflow.

Project Type: Residential, Industrial, or High-Rise Construction

The nature of the construction project dictates the most suitable and cost-efficient formwork system, directly affecting the ultimate formwork pricing per m2 and the choice of types of concrete formwork. Residential construction, often characterized by repetitive wall structures and lower overall complexity, typically benefits greatly from Best Formwork Systems for Residential Construction like aluminum or lightweight plastic systems due to their quick cycle times and ease of use. Industrial projects, such as power plants or large infrastructure developments, often require specialized, heavy-duty formwork to manage extremely large volumes of concrete and high pressures, sometimes necessitating custom steel prefabricated formwork or specialized components like jersey barrier forms for road applications, which carry a higher initial cost but are built for specific, demanding loads. High-rise construction, meanwhile, relies heavily on complex, integrated systems like self-climbing or table formwork to minimize time and complexity in the vertical movement of materials, making the large capital investment worthwhile due to the speed and safety gains.

Comparison of Pricing Across Formwork Systems

A nuanced comparison of formwork pricing per m2 across various systems reveals that the initial price is rarely indicative of the final, amortized cost; the decision must pivot on calculating the life-cycle cost based on the expected number of uses and the necessary labor input. This analytical approach, essential for professional cost estimators, moves the focus from the material purchase price to the total cost of ownership (TCO) over the project’s entire duration, or over the useful life of the formwork inventory. The comparison is fundamentally between systems that require high labor input but low material outlay (conventional timber) and systems that demand high material outlay but significantly reduced, often less-skilled, labor input (modular, engineered systems). Understanding this trade-off is central to selecting the most economically viable formwork solution, especially when comparing different types of concrete formwork for various structural applications.

Modular vs. Conventional Formwork Pricing Trends

The comparison between modular formwork systems and conventional, site-built formwork highlights a major trend towards industrialized construction methods driven by rising labor costs and demands for faster project completion. Conventional formwork, which is primarily made of timber, has a lower upfront material cost but often results in the highest overall formwork building cost due to the time-intensive site fabrication, dismantling, and limited reusability, sometimes being single-use. In contrast, modular formwork pricing for engineered systems (steel, aluminum, plastic) is characterized by a significantly higher initial investment, either through purchase or rental. However, these systems drastically reduce the labor component, simplify the formwork construction steps, and offer high reusability (sometimes hundreds of times). The current trend in the formwork system market favors modularity, as the reduction in labor and faster cycle times typically create such profound project efficiencies that they easily absorb the higher material costs, making modularity the more financially prudent choice for all but the smallest or most uniquely shaped structures.

Which Formwork System Delivers the Best Cost-Performance Ratio?

The formwork system that provides the best cost-performance ratio is universally the one that maximizes its reuse rate while minimizing the required labor hours per cycle, leading to the selection of cost-effective formwork solutions that prioritize efficiency over initial material savings. For large-scale infrastructure and high-rise projects with high repetition, the durability and speed of steel or aluminum modular systems consistently deliver the lowest effective formwork pricing per m2, despite their high upfront cost, due to their extended lifespan and rapid deployment. Conversely, for small, custom residential additions or repair work where the unique geometry is non-repetitive, the flexibility and low material outlay of traditional timber may offer a better, albeit labor-intensive, balance. Therefore, determining the best ratio requires a dynamic calculation that factors in local labor rates, the complexity of the geometry, the number of anticipated concrete pours, and the system’s ability to minimize subsequent surface finishing work, which often tips the scales in favor of precision-engineered, prefabricated formwork solutions.

How to Estimate Formwork Cost Per m² for Your Project

Accurate formwork cost estimation is a critical skill for construction professionals, requiring a structured, systematic approach that moves beyond simple spreadsheet calculations to encompass a full understanding of the system’s operational lifecycle and interaction with the site environment. This estimation process must account for every variable, from the direct cost of material to the hidden costs of maintenance, damage, and storage, ensuring that the calculated formwork pricing per m2 is as close as possible to the final incurred cost. A professional approach involves not just the selection of types of concrete formwork but also the detailed planning of their deployment, including the number of personnel required, the lifting methodology, and the anticipated time between pouring and stripping for each element. This meticulous level of detail prevents costly surprises and provides a reliable foundation for all subsequent project budgeting.

Step-by-Step Process for Pricing Calculation

The professional method for calculating Concrete Formwork Pricing per square meter involves a seven-step process that provides comprehensive formwork cost estimation. First, determine the total formwork area required for the specific structural element (wall, column, slab). Second, select the formwork system (e.g., steel, aluminum) and determine its initial purchase or rental cost. Third, establish the anticipated reuse rate of the system for the project duration or its full lifespan. Fourth, calculate the amortized material cost per use by dividing the total material cost by the reuse rate. Fifth, calculate the labor cost per use by multiplying the labor hours required for one full cycle (erection, pouring, stripping) by the average hourly labor rate, being mindful of complexity factors for elements like Concrete Column Formwork. Sixth, incorporate overheads, which include storage, transport, cleaning, and repair costs, usually calculated as a percentage of the material cost. The final formwork pricing per m2 is the sum of the amortized material cost, labor cost per square meter, and overheads, providing a robust and realistic figure for the formwork building cost.

Realistic Cost Ranges for Different Project Scales

Providing a single, static figure for formwork pricing per m2 is impossible due to the immense variability of material, complexity, and labor markets; however, realistic cost ranges can be established based on the project scale and the chosen types of concrete formwork. For highly repetitive, large-scale commercial or high-rise projects utilizing advanced modular aluminum or steel systems, the effective, amortized cost can range from $40 to $80 per square meter, reflecting the high reuse rate and low labor component. Mid-sized projects using durable plastic or modular timber panels may see costs ranging from $60 to $120 per square meter, as the reuse factor is lower and labor input is slightly higher. Custom residential or highly complex architectural elements requiring conventional timber formwork will typically incur the highest cost, ranging from $100 to over $200 per square meter, due to the low reusability and significantly increased labor intensity of the wooden formwork systems market. These ranges underscore why accurate formwork cost estimation is essential for determining the viability of a construction method.

Choosing a Reliable Formwork Supplier

The selection of a formwork supplier is a strategic partnership that carries as much weight as the choice of the formwork system itself, profoundly impacting a project’s efficiency, safety, and ultimately, the total Concrete Formwork Pricing. A reliable supplier offers more than just the physical materials; they provide essential services such as engineering design, project-specific layout drawings, on-site technical support, and comprehensive training on the proper formwork construction steps for their specific modular formwork systems. This technical partnership is particularly crucial when implementing high-tech solutions like a self climbing formwork system or customized prefabricated formwork, where precision and safety protocols are non-negotiable. Contractors must look for suppliers with a proven track record, extensive inventory, and a transparent approach to pricing, ensuring that all components and accessories are readily available to avoid costly delays and maintain high on-site productivity.

Why BFS Industries Is a Trusted Partner in the Formwork Industry

BFS Industries stands as a trusted and recognized leader in the formwork system market, specializing in providing high-performance, cost-effective formwork solutions engineered for maximum efficiency and superior concrete finish quality. Our expertise spans the full spectrum of types of concrete formwork, from heavy-duty steel systems ideal for infrastructure and Concrete Column Formwork, to lightweight aluminum and plastic solutions perfectly suited for high-speed residential construction, including the optimal systems highlighted in the Best Formwork Systems for Residential Construction guide. We understand that accurate formwork pricing per m2 depends on more than just the initial price; it relies on our ability to maximize your system’s reuse rate, minimize your labor expenditure, and provide the technical support necessary to streamline your project’s workflow. By offering detailed engineering support and training, BFS Industries ensures that your investment in formwork translates directly into a lower total formwork building cost and a faster project completion timeline.

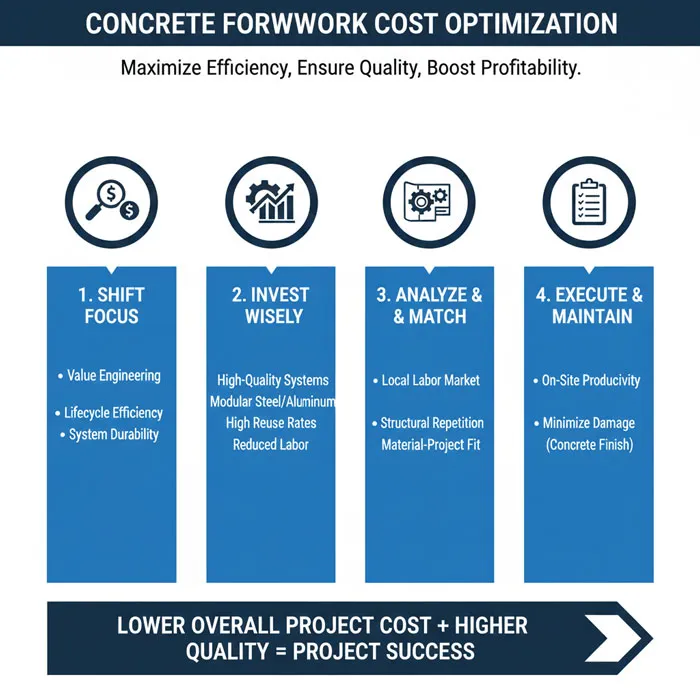

Conclusion: How to Optimize Costs While Ensuring Quality

Optimizing Concrete Formwork Pricing is a continuous exercise in value engineering, demanding that project stakeholders shift their focus from minimizing material costs to maximizing system efficiency and durability throughout the construction cycle. The most significant gains in cost-effective formwork are realized by investing in high-quality, engineered systems—like steel or aluminum modular units—that offer high reuse rates and drastically reduce the labor component, offsetting their higher initial cost. Contractors and project managers must meticulously analyze the local labor market and the structural repetition within the design to choose the material that best matches the project’s specific constraints. By prioritizing efficiency, minimizing material damage during the stripping process, and maintaining high on-site productivity, construction teams can ensure that the final formwork cost estimation aligns with or falls below the budget, all while maintaining the superior concrete surface quality that reduces the need for costly post-pour finishing work.

Final Recommendations for Contractors and Project Managers

To gain a competitive edge and ensure budget adherence, contractors and project managers should adopt several key strategies for managing the formwork cost estimation process. Firstly, always conduct a detailed lifecycle cost analysis that factors in the full cost of labor, cleaning, repair, and transport against the guaranteed reuse cycles of the chosen system; never make a decision based on initial material price alone. Secondly, standardize on highly modular formwork systems where possible, as this consistency reduces training time and maximizes deployment speed. Thirdly, partner with a reputable supplier like BFS Industries who can provide robust, well-maintained inventory and critical engineering support, particularly when dealing with specialized components or large infrastructure projects like those requiring jersey barrier forms. Implementing these professional practices ensures that your formwork pricing per m2 is accurate, manageable, and contributes positively to the overall profitability of your construction project.