- Published:

- Written by: B.F.S Industries

Essential Components of Formwork: A Detailed Breakdown

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

Essential Components of Formwork represent the backbone of every successful concrete project. In the fast-paced world of modern construction—where towering skyscrapers and expansive infrastructure projects define cityscapes—formwork stands as the unsung hero that gives shape and strength to our built environment. Imagine a seamless concrete pour transforming into a perfectly aligned wall or a sprawling slab—that’s the precision and reliability of a well-engineered formwork system. As a cornerstone of concrete construction, formwork guarantees structural integrity, accuracy, and efficiency. This is particularly vital in high-stakes projects across the UAE’s booming real estate and infrastructure sectors. Companies like BFS Industries play a key role in supplying advanced formwork solutions that help contractors and civil engineers meet strict deadlines and quality standards.

But what exactly are the essential components of formwork that make this possible? From durable sheathing that holds freshly poured concrete in place to robust supports that bear immense loads, these elements work together to achieve flawless results. For civil engineers, contractors, and construction managers, understanding these components is not just technical know-how—it’s the foundation for safer, more cost-effective, and higher-quality builds.

In Dubai, where iconic projects like the Burj Khalifa and the Expo 2020 pavilions have set global benchmarks, choosing the right formwork system is critical. This article dives deep into the essential components of formwork, examining their roles, benefits, and best practices. From traditional timber formwork to innovative modular formwork systems, we’ll provide practical insights aligned with UAE construction standards. Whether you are overseeing a residential high-rise, a commercial complex, or a large-scale infrastructure project, mastering these fundamentals can elevate your project’s efficiency and long-term performance. Let’s break it down step by step.

Understanding Formwork in Construction

This podcast covers Essential Components of Formwork

Formwork is a temporary mold designed to shape fresh concrete until it develops sufficient strength to support itself. More than just a container, it acts as a system that stabilizes the concrete during casting, pouring, and curing before being removed. In the UAE, where projects face extreme temperatures, fast-paced schedules, and seismic considerations, choosing durable and efficient formwork is critical for both safety and productivity.

Different materials define the essential components of formwork, each suited to specific applications. Timber formwork remains popular for smaller or complex details due to its flexibility and ease of customization. Plywood offers smoother finishes and cost efficiency, making it useful for slab construction in mid-rise buildings. For heavy-duty projects, steel formwork delivers unmatched durability and precision, while aluminum provides lightweight strength and speeds up assembly, which is vital in Dubai’s high-rise developments. Plastic formwork is also gaining attention for its corrosion resistance, low maintenance, and sustainable profile.

Beyond traditional methods, modular formwork systems such as the Large Panel System have transformed concrete construction. These prefabricated systems allow rapid assembly, reduce labor requirements, and improve reusability, aligning with sustainable practices. Advanced solutions like slipform and tunnel formwork further enhance efficiency by enabling continuous pours for vertical structures such as cores or full building shells.

It is also essential to distinguish formwork from falsework: formwork shapes the concrete, while falsework provides temporary external support. Selecting the right system depends on project size, budget, and site conditions. In the UAE, where labor and material imports influence costs, reusable systems like steel and aluminum often provide the best long-term value. Ultimately, understanding the role and selection of formwork ensures stronger, faster, and more sustainable concrete construction outcomes.

Primary Components of Formwork Systems

At the foundation of every successful formwork setup are the essential components of formwork, which collectively guarantee stability, alignment, and the proper containment of fresh concrete. These elements do not function in isolation; rather, they work together as a precisely engineered system that defines the quality of the final structure. The first critical element is the sheathing, the surface that comes into direct contact with the concrete. Depending on the material—timber, plywood, steel, aluminum, or plastic—sheathing determines the finish, smoothness, and overall appearance of the hardened surface. Beyond aesthetics, it must also resist pressure from wet concrete while minimizing deformation. Equally important is the framing, which supports the sheathing and ensures that the mold maintains its shape during pouring and curing. Strong frames prevent leakage, bulging, or misalignment, making them a backbone of reliable concrete construction.

Supporting these structural layers are the braces, props, and ties, which provide vertical and lateral stability against the immense loads exerted during casting. These supports transfer forces safely to the ground, protecting workers and ensuring the concrete sets in its intended form. Finally, a range of accessories—such as clamps, wedges, spacers, and release agents—play smaller yet crucial roles in fine-tuning performance. They simplify assembly, guarantee tight joints, and allow for easier dismantling without damaging either the formwork or the finished concrete. In advanced projects, especially across Dubai and the UAE, modern systems like modular and Large Panel System solutions integrate these components into prefabricated units for faster deployment and higher efficiency. By understanding each of these parts and how they interact, contractors and engineers can make informed choices that improve safety, reduce costs, and deliver durable, high-quality results in every project.

Sheathing: The Concrete’s First Line of Defense

Sheathing serves as the surface that comes into direct contact with fresh concrete, playing a critical role in defining both the finish and shape of the hardened structure. Think of it as the “skin” of the formwork—smooth, impermeable, and resilient enough to withstand the hydrostatic pressure of wet concrete. Materials used for sheathing vary widely, from traditional plywood sheets to coated steel panels for heavy-duty applications. In plywood systems, marine-grade boards are often treated with release agents, preventing adhesion during stripping. This ensures clean releases while minimizing surface imperfections, which is especially important for aesthetic-focused projects like exposed concrete walls in Dubai’s luxury developments. In steel formwork, panels are typically welded or bolted, offering superior watertightness and durability over multiple uses.

The benefits of high-quality sheathing extend beyond appearance. It directly impacts curing efficiency, helping to reduce voids and honeycombing while maintaining the precise shape of the concrete. In UAE projects, where temperature and humidity fluctuations can influence pour times, durable materials such as aluminum sheathing resist warping and maintain alignment throughout the curing process. Regular inspection for cracks, wear, or warping is essential to ensure consistent quality and extend the lifespan of reusable formwork components. By carefully selecting and maintaining sheathing as a key essential component of formwork, contractors and engineers can achieve superior results in both structural integrity and finish quality for every concrete construction project.

Framing Elements: Building the Skeleton

No formwork system can function without a robust frame, and this is where the essential components of formwork—studs, joists, walers, and strongbacks—play pivotal roles. Studs, vertical members attached to sheathing, provide initial rigidity, while joists, positioned horizontally and perpendicular to studs, distribute loads evenly, similar to floor beams in traditional construction. Walers, thicker horizontal beams, tie the frame together and counteract the outward pressure exerted by poured concrete, ensuring structural alignment and safety. Strongbacks, acting as additional reinforcement, span across joists to prevent sagging under weight. In timber formwork, these components are typically made from sawn lumber, making them cost-effective for one-off projects. For modular or repetitive projects, steel or aluminum frames dominate due to their precision, speed of assembly, and compatibility with concrete wall formwork supplier solutions.

Consider a standard wall formwork setup: studs spaced 12–16 inches apart support plywood sheathing, with joists installed at 24-inch intervals. Walers, braced every four feet, are designed to handle hydrostatic pressures up to 1,500 psf during pouring. Such load-bearing design is critical for safety, particularly in seismic zones like parts of the UAE. Framing systems also enhance efficiency by allowing careful disassembly without damaging components, with aluminum frames reusable over 50 cycles. Regular maintenance, including anti-corrosion coatings for steel elements, is vital to withstand Dubai’s salty coastal air and ensure long-term durability. Understanding these framing elements is essential for engineers and contractors working with high-quality concrete wall formwork supplier systems in modern concrete construction projects.

Supports: Shores, Braces, and Stability

Supports form a critical part of the essential components of formwork, ensuring that the entire assembly remains upright and stable while transferring loads safely to the ground. Shores, vertical props such as adjustable steel posts, carry both the dead load of wet concrete and live loads from workers and equipment. Braces, diagonal ties connected to the frame, prevent lateral movement and maintain plumb alignment, which is essential for the accuracy of walls, slabs, and columns. In slab formwork, shores are often arranged in a grid pattern and spaced 4–6 feet apart depending on span calculations and load requirements. For elevated or uneven surfaces, base plates help distribute the load evenly, preventing settlement and ensuring stability throughout the construction process.

In column formwork, adjustable shores allow precise vertical alignment, enhancing the quality of concrete construction and minimizing surface defects. Many falsework systems incorporate these supports to extend stability for cantilevered or overhanging elements. In UAE high-rise projects, where wind loads and seismic considerations introduce additional challenges, braces must comply with standards such as BS EN 12812 for temporary works. Properly designed supports reduce deflection—typically under L/360—resulting in smoother finishes, fewer corrections, and greater efficiency. For engineers and contractors working with BFS Industries or a trusted concrete wall formwork supplier, understanding and implementing these supports is key to achieving safe, durable, and high-quality concrete structures.

Ties and Accessories: The Unsung Connectors

Connecting all elements of a formwork system are the often-overlooked but critical ties and accessories, including form ties, spreaders, clamps, anchors, and base plates. Form ties are rods or bars that span opposing form faces, holding them securely against the immense pressure of wet concrete. Snap ties, equipped with plastic cones for clean breakbacks, are especially common in wall formwork, ensuring a smooth finish and easy stripping. Spreaders maintain uniform spacing between panels, while clamps hold sheathing and framing tightly during assembly. Anchors embed into the ground or existing structures to enhance stability, and base plates provide firm footing for adjustable shores. In modern projects, modular systems employ quick-release clamps that can reduce setup time by up to 30%, significantly improving workflow efficiency.

For a trusted Concrete Modular Formwork Supplier like BFS Industries, these accessories are engineered for interoperability, allowing seamless integration across diverse projects. Proper placement of form ties—typically spaced 2–3 feet horizontally—prevents panel bulging, a common challenge in high pours. These essential components of formwork are not static; their configuration adapts to specific systems such as slipform for continuous vertical pours or tunnel formwork for monolithic slabs. In large-scale UAE projects, including Dubai Metro expansions, integrated ties and braces in tunnel formwork have reduced cycle times from weeks to days, demonstrating how thoughtful accessory selection directly improves concrete construction quality, safety, and efficiency.

Specialized Formwork Systems in Action

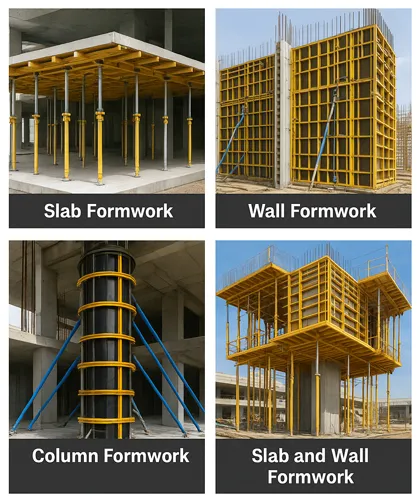

While the primary essential components of formwork provide the foundation, specialized formwork systems amplify their effectiveness for unique applications in modern concrete construction. Slab formwork, typically using panelized aluminum tables supported on adjustable props, excels in flatwork applications such as parking decks or elevated floors, offering speed and repeatability. Wall formwork, often assembled in gang forms with large reusable panels, is ideal for vertical pours in shear walls and structural cores. Column formwork demands precision, with round or square steel molds reinforced with internal spreaders to ensure perfect alignment and leak-free casting. For climbing structures, slipform systems employ hydraulic jacks to gradually ascend, making them particularly suitable for elevator shafts and high-rise cores in UAE towers.

Tunnel formwork, a hybrid system combining wall and slab capabilities, enables the pouring of entire room modules overnight, dramatically accelerating residential or commercial projects. Falsework provides essential external support during erection, as seen in bridge girders where adjustable shores manage dynamic loads. In the UAE, environmental factors such as sandstorms, intense heat, and high humidity accelerate wear on formwork components. As a result, systems prioritize durability with corrosion-resistant materials: anodized aluminum finishes and UV-protected plastics meet local standards, extending lifecycle performance.

The Formwork Process: From Assembly to Stripping

Mastering the essential components of formwork requires a comprehensive understanding of the entire lifecycle of a concrete structure. The process begins with careful assembly, starting with precise layout and alignment, often guided by laser systems to ensure millimeter accuracy. Sheathing panels are snapped into frames, secured with clamps and braces, and erected on base plates. During the pouring phase, concrete is placed in layers and vibrated to eliminate air pockets, ensuring a dense, uniform structure. Release agents, typically oil-based emulsions, coat the sheathing beforehand, facilitating smooth stripping and protecting the finish. Controlled curing, usually spanning 7 to 28 days, is monitored with sensors in modern smart systems to maintain optimal moisture levels and prevent early cracking.

Stripping, or form removal, follows a sequential approach: side forms are removed first, followed by vertical supports and braces. Disassembly mirrors the assembly process, with all components cleaned and inspected for defects to ensure durability and reusability. Maintenance, such as sanding plywood or applying anti-corrosion coatings to steel, extends the lifecycle of formwork components. In UAE projects, adherence to DM 401 guidelines is critical, emphasizing phased stripping to avoid thermal cracks and structural stress.

Advantages of Quality Formwork Components

Investing in high-quality essential components of formwork provides significant advantages for both small and large-scale projects in modern concrete construction. Durable materials, such as steel, extend the service life of formwork, allowing multiple reuse cycles and reducing procurement and material costs. Modular formwork designs enhance efficiency by enabling faster assembly and disassembly, which shortens project timelines and improves return on investment. High-precision tolerances in premium components also ensure consistent quality, minimizing defects, honeycombing, or misalignment, and significantly reducing rework. In regions like the UAE, where construction schedules are tight, and labor costs are high, these advantages directly translate into improved productivity and safer operations.

Formwork Process Step by Step: Complete Guide for Concrete Construction

Additional benefits include corrosion resistance in aluminum or plastic formwork, particularly relevant for coastal sites in Dubai and Abu Dhabi, where humidity and salty air can degrade less robust materials. Proper load-bearing design provides essential safety margins, ensuring stability under both wet concrete pressure and live loads. For instance, a villa project in Dubai that switched to aluminum modular formwork saw assembly time reduced by 50%, boosting crew productivity without compromising structural integrity.

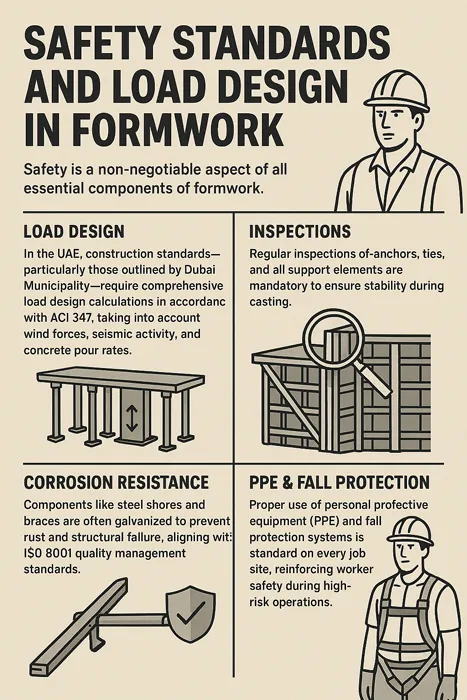

Safety Standards and Load Design in Formwork

Safety is a non-negotiable aspect of all essential components of formwork. In the UAE, construction standards—particularly those outlined by Dubai Municipality—require comprehensive load design calculations in accordance with ACI 347, taking into account wind forces, seismic activity, and concrete pour rates. Vertical shores must be capable of supporting up to 150% of the expected loads, while braces are engineered to resist buckling and lateral displacement. Regular inspections of anchors, ties, and all support elements are mandatory to ensure stability during casting. Proper use of personal protective equipment (PPE) and fall protection systems is standard on every job site, reinforcing worker safety during high-risk operations.

Corrosion resistance is another critical consideration. Components like steel shores and braces are often galvanized to prevent rust and structural failure, aligning with ISO 9001 quality management standards. Continuous training on safety protocols, load calculations, and emergency procedures fosters a culture of vigilance among engineers, supervisors, and laborers. Adhering to these rigorous standards reduces accidents and ensures that even complex concrete construction projects, such as high-rise towers or large infrastructure works in Dubai, are completed safely and efficiently. Proper planning, inspection, and maintenance of load-bearing formwork elements are therefore central to both structural integrity and workforce protection.

Conclusion: Elevate Your Projects with Expert Formwork Solutions

The essential components of formwork—ranging from sheathing and framing to ties, braces, and supports—form the foundation of successful concrete construction. Understanding how these elements interact allows engineers, contractors, and project managers to achieve precision, structural integrity, and long-term durability. From timber’s flexibility in intricate architectural details to the speed and efficiency of modular and large panel systems, each component plays a pivotal role in delivering high-quality results. In the UAE’s dynamic construction landscape, where innovation intersects with local standards and environmental challenges, mastering formwork design and execution ensures projects that are safe, sustainable, and visually impeccable.

For professionals seeking to optimize their next build, tailored formwork solutions make all the difference. BFS Industries, as a leading concrete wall formwork supplier, provides comprehensive systems ranging from Large Panel Systems to custom accessories, engineered to comply with UAE regulations. By integrating high-quality components and precise engineering, these solutions streamline workflows, reduce labor and material costs, and enhance project safety. With careful planning, proper implementation, and adherence to best practices, contractors can maximize efficiency and quality, ensuring that every concrete construction project meets or exceeds expectations.