- Published:

- Written by: B.F.S Industries

Wall Formwork: A Comprehensive Guide to Systems, Design, and Applications

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

Wall formwork is a cornerstone of modern construction, acting as the temporary mold into which fresh concrete is poured to create durable vertical structures. These systems consist of multiple elements—such as formwork panels, support frames, braces, and specialized ties—that work together to contain and shape liquid concrete until it hardens and gains sufficient strength. The main objective of reliable wall formwork systems is to achieve accuracy in wall dimensions, stability in structural performance, and a smooth finish that often eliminates the need for extensive plastering or secondary treatments. Whether applied in residential housing, large commercial projects, or infrastructure such as retaining walls, bridge abutments, and shear walls, concrete wall formwork ensures precision and uniformity, enabling contractors to meet strict engineering and architectural specifications with confidence.

The importance of wall formwork goes beyond being a simple temporary container; it is a structural safety system that directly influences the quality and economy of an entire project. Poorly designed or incorrectly installed formwork can result in bulging, honeycombing, or surface defects, leading to costly rework or compromised durability. In addition to carrying the weight and hydrostatic pressure of wet concrete, wall formwork must withstand live loads from workers and equipment during the construction process. Considering that formwork-related activities may account for up to 25% of total structural costs, the industry continues to innovate with modular, reusable, and flexible wall formwork solutions. These advanced systems improve safety, reduce waste, and optimize efficiency, transforming wall formwork from a basic on-site necessity into a sophisticated engineering solution for modern construction.

This podcast covers Wall Formwork: A Comprehensive Guide to Systems, Design, and Applications

The Foundational Role of Wall Formwork

Wall formwork plays a critical role in modern construction by serving as the essential temporary mold for shaping concrete into precise vertical structures. Its foundational purpose goes beyond simply containing wet concrete; it ensures the structural integrity, dimensional accuracy, and surface quality of walls. High-quality wall formwork systems—including panels, braces, support frames, and formwork ties—allow engineers and contractors to construct walls that meet stringent design specifications for residential, commercial, and infrastructure projects. Properly designed formwork also reduces the likelihood of surface defects such as bulges, honeycombing, or uneven finishes, ensuring both structural performance and aesthetic appeal. Without reliable formwork, the construction of straight, uniform walls would be almost impossible, risking costly rework, delays, and compromised safety.

In addition to shaping concrete, wall formwork provides temporary structural support, holding the considerable weight and hydrostatic pressure of freshly poured concrete until it achieves sufficient strength. It must also accommodate live loads from construction crews, machinery, and equipment, which makes stability and rigidity essential. The strategic significance of wall formwork is further highlighted by its impact on project costs, as it can account for a substantial portion of labor and material expenditures. Advances in modular, reusable, and adjustable wall formwork systems have revolutionized the construction process, improving efficiency, reducing waste, and enhancing safety on-site. By fulfilling both engineering and practical needs, wall formwork remains a foundational component of successful concrete construction projects.

Introduction to Wall Formwork Systems

Wall formwork systems are specialized construction solutions designed for forming vertical concrete structures, ranging from residential building walls to foundations in large-scale civil engineering projects. Serving as temporary molds, these systems ensure that freshly poured concrete adopts the precise shape and dimensions intended by the project design. Core components of wall formwork include panels—commonly made from steel, aluminum, or plywood—supported by braces, frames, and formwork ties to maintain stability under the immense pressure of wet concrete. The design of these systems is highly customizable to accommodate factors such as wall height, thickness, architectural complexity, and the desired surface finish. A properly engineered wall formwork system not only guarantees dimensional accuracy but also enhances construction efficiency, reduces errors, and contributes to the overall quality and durability of the completed structure.

The performance of a wall formwork system directly affects the quality and integrity of the resulting concrete structure. Poorly constructed or insufficiently rigid forms can lead to surface defects like bulges, honeycombing, and uneven finishes, which may require costly corrective measures. Furthermore, wall formwork is a temporary structural system that must withstand live loads from workers and equipment in addition to the weight and hydrostatic pressure of fresh concrete. With formwork accounting for up to 25% of the total structural cost, construction firms are motivated to adopt reusable, modular, and efficient formwork solutions. Innovations in prefabricated components, advanced materials, and digital planning tools are transforming traditional wall formwork into a precise, cost-effective, and safe construction technology, enabling projects to be completed on time, within budget, and to the highest standards.

Classifications and Types of Wall Formwork

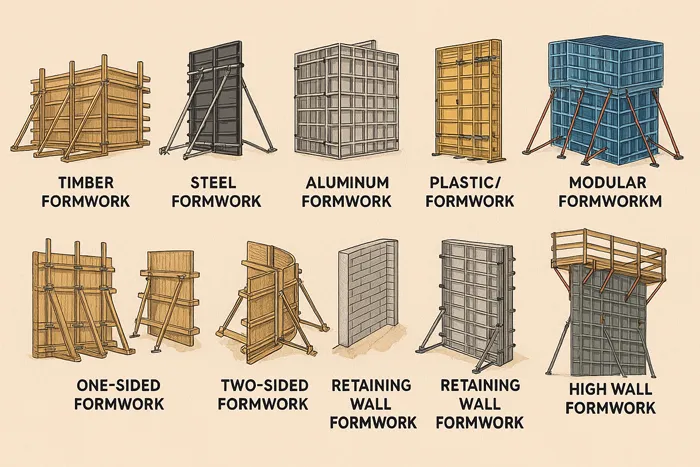

Wall formwork can be classified into several types based on material, design, and specific construction applications, each offering distinct advantages depending on the project requirements. The primary classifications include timber formwork, steel formwork, aluminum formwork, plastic or PVC formwork, and modular or prefabricated systems. Timber formwork is widely used for smaller projects due to its flexibility and ease of handling, whereas steel and aluminum systems offer superior strength and durability, making them suitable for high-rise buildings and large infrastructure projects. Modular wall formwork systems provide significant efficiency improvements through reusable panels and components, reducing labor costs and construction time. For contractors seeking reliable solutions, choosing a reputable concrete wall formwork supplier ensures access to high-quality materials and expert guidance for every project. Additionally, the choice of formwork type is often influenced by the required surface finish, wall height, load-bearing requirements, and the complexity of the architectural design. Proper selection ensures structural accuracy, safety, and economic efficiency.

Functionally, wall formwork can also be categorized according to the specific type of vertical structure being formed. This includes single-sided or one-sided formwork, used when only one face of a wall is exposed, and double-sided formwork for walls requiring precision on both faces. Curved and circular wall formwork are designed for architectural features or round columns, while retaining wall formwork provides stability for soil-retaining structures. Specialized systems such as shear wall, core wall, basement, abutment, and parapet wall formwork address unique load and structural conditions. High wall formwork and adjustable systems cater to large-scale or complex projects, while reusable and modular solutions promote cost savings and sustainability. Understanding these classifications allows engineers and contractors to select the most appropriate wall formwork system for each specific project scenario.

Single-Sided vs. Double-Sided Wall Formwork

Double Sided Wall Formwork is typically the standard choice, meaning that concrete forms are erected on both faces of a wall to contain and shape the fresh concrete. This conventional system relies on form ties to resist the substantial lateral pressure exerted by wet concrete while maintaining accurate spacing between the opposing panels. These ties are often encased in plastic sleeves, allowing them to be reused in future pours after the formwork is stripped. For tall walls or structures exposed to external forces such as wind, heavy-duty braces or push-pull props are installed to maintain precise alignment and prevent movement during pouring and curing. The underlying design principle of Double Sided Wall Formwork is force equilibrium: the lateral pressure on one side is counterbalanced by the opposing form, with the ties functioning as critical tension members. Proper implementation ensures straight, uniform walls, structural integrity, and minimal surface defects.

In contrast, single sided wall formwork is engineered for situations where installing a second form is impractical, such as casting walls against existing structures, rock faces, or temporary construction pits. Without an opposing form, all lateral concrete pressure must be transferred to the ground, existing structures, or robust foundations using specialized support frames and braces. Systems like the modular Triplex provide stability and precise alignment through anchored frames and adjustable props, ensuring safe and efficient construction. Single sided wall formwork solutions exemplify modern engineering approaches that address specific site challenges, transforming complex construction constraints into reliable, purpose-built systems. By accommodating unique conditions, single sided wall formwork ensures both safety and high-quality concrete finishes even in challenging scenarios.

Specialized Wall Formwork Systems for Unique Applications

Specialized wall formwork systems are engineered to meet unique structural requirements and resist specific forces, ensuring high precision and safety in complex construction projects. Shear wall formwork, for example, is critical in high-rise buildings, providing the strength necessary to resist in-plane lateral loads from wind and seismic activity. These systems must be robust, flexible, and accurately aligned to maintain structural integrity and durability, particularly in seismic zones. Retaining wall formwork is another specialized application, designed to withstand the immense lateral pressure of freshly poured concrete. Steel and Concrete Modular Formwork components are commonly used for their strength, reliability, and reusability. By tailoring formwork solutions to the demands of each project, engineers can achieve precise wall dimensions, uniform surface finishes, and enhanced safety, while optimizing labor and material efficiency across diverse construction environments.

For high-rise building cores that accommodate elevators, stairwells, and other vertical shafts, formwork technology has advanced into self-climbing, automated systems commonly known as jump forms. These systems use high-capacity hydraulic rams to lift entire formwork assemblies, including working platforms and braces, to successive levels in a single synchronized operation, often in as little as 20 minutes. Large Panel System configurations are frequently integrated into these setups to increase efficiency and reduce on-site assembly time. This method minimizes reliance on cranes, reduces bottlenecks, and allows work to continue safely in challenging conditions such as high winds. Self-climbing formwork systems exemplify the move toward purpose-built, high-performance engineering solutions that address the unique challenges of tall building construction. By combining speed, precision, and safety, specialized wall formwork systems represent the forefront of modern concrete construction, replacing traditional, one-size-fits-all approaches with intelligent, adaptable technology.

Materials Used in Wall Formwork

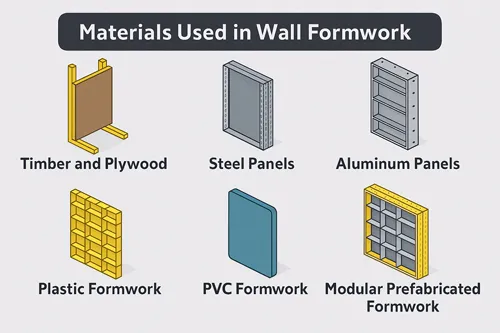

Wall formwork is constructed using a variety of materials, each chosen based on project requirements, cost considerations, and the desired durability of the system. Timber and plywood remain popular for smaller projects due to their flexibility, availability, and ease of handling, making them ideal for custom or irregular wall shapes. Steel and aluminum panels, on the other hand, provide superior strength, dimensional stability, and long-term durability, making them suitable for high-rise buildings and large-scale infrastructure projects. Plastic and PVC formwork are increasingly used in applications where lightweight, reusable, and corrosion-resistant materials are preferred. Modular prefabricated systems combine multiple materials to provide the benefits of reusability, speed of installation, and precision. Each material type must be carefully evaluated for load-bearing capacity, resistance to concrete pressure, and compatibility with the desired surface finish to ensure high-quality, defect-free walls.

In addition to structural performance, material choice in wall formwork also impacts cost-efficiency and environmental sustainability. Steel and aluminum panels, though initially more expensive, are highly reusable, reducing long-term costs across multiple projects. Timber and plywood panels, while cheaper and easier to work with, may require more frequent replacement and maintenance. Plastic formwork offers lightweight handling and fast assembly, which minimizes labor expenses and accelerates project timelines. The combination of modularity, reusability, and material performance allows contractors to select systems tailored to both the technical demands and economic constraints of a project. By choosing the appropriate materials, engineers can optimize wall formwork for strength, safety, speed, and sustainability, ensuring high-quality concrete structures that meet modern construction standards.

Traditional Timber and Modern Steel/Aluminum Materials

Choosing the right wall formwork material is a critical decision that balances initial cost, reusability, and project-specific requirements. Traditionally, timber and plywood have been the most common materials for small to medium-sized projects due to their low upfront cost and versatility. Timber formwork is easy to handle, can be cut on-site, and allows for the creation of unique or complex wall shapes, making it a cost-effective solution for one-off constructions. However, timber and plywood have a limited lifespan, typically lasting only four to six uses before replacement is needed. They are prone to warping, cracking, and moisture absorption from wet concrete, which can compromise the uniformity and finish quality of the final wall. While plywood offers larger panels and smoother surfaces than raw timber, it remains vulnerable to damage and has a relatively short service life compared to modern alternatives.

The limitations of traditional materials have encouraged the adoption of modern formwork systems using steel and aluminum. Steel formwork is highly durable, capable of withstanding heavy loads and repeated use, often exceeding fifty cycles, making it suitable for high-rise buildings and large-scale infrastructure projects. Despite its higher initial cost and significant weight requiring lifting equipment, steel provides strong, dimensionally accurate forms that can produce a smooth concrete finish when proper release agents are applied. Aluminum formwork, in contrast, offers a lightweight and crane-independent solution, with reusability rates often surpassing 200 cycles. Its reduced weight lowers labor and transportation costs, enhancing project efficiency. By carefully selecting the appropriate material, contractors can optimize wall formwork for cost-effectiveness, durability, and high-quality concrete finishes, aligning with modern construction standards and demanding architectural requirements.

Innovative Plastic and Modular Wall Formwork Systems

The evolution of wall formwork has progressed with the adoption of innovative plastic and modular systems that offer efficiency, sustainability, and high-quality results. Plastic formwork, often manufactured from recycled materials, provides a lightweight, crane-independent solution that is resistant to water, chemicals, and wear. Its durability allows for more than 100 reuses, while the smooth, non-absorbent surface ensures a consistent concrete finish with minimal post-processing. This eco-friendly system reduces material waste and contributes to long-term cost savings, making it an ideal choice for projects that prioritize sustainability, economic efficiency, and high-quality results. By minimizing labor requirements and providing consistent performance across multiple pours, plastic formwork has become a modern alternative to traditional timber or metal systems.

Modular formwork systems take construction efficiency to the next level through prefabricated, standardized panels that can be quickly assembled and disassembled on-site. These systems reduce field modifications, cutting labor time, and accelerating project timelines. Modular panels offer high reusability, consistent quality control, and adaptability to various wall heights, thicknesses, and project types. Their factory-produced precision ensures uniformity, while adjustable components accommodate complex architectural designs and structural demands. By combining speed, sustainability, and precision, modular formwork systems represent a holistic approach to modern construction, addressing cost-effectiveness, labor efficiency, and quality simultaneously. These solutions exemplify the industry’s shift from traditional, single-material systems toward innovative, engineered methods that optimize wall formwork for a wide range of applications.

Design Considerations for Wall Formwork

Designing an effective wall formwork system requires careful evaluation of structural, geometric, and safety considerations. Engineers must account for the height, thickness, and shape of the wall, as well as the hydrostatic pressure exerted by fresh concrete during the pour. The selection of materials—timber, plywood, steel, aluminum, or plastic—directly affects the formwork’s load-bearing capacity, durability, and surface finish quality. In addition, the type of wall, such as shear walls, retaining walls, or core walls, dictates the specific formwork configuration and support requirements. Adjustable braces, props, and modular panels are often incorporated to maintain alignment and prevent deflection or bulging, ensuring that the concrete sets to precise dimensions. Proper planning also includes consideration for the sequence of pours, accessibility for workers, and integration with other structural components, which collectively influence both safety and efficiency on site.

Safety is a fundamental aspect of wall formwork design, as improperly designed systems can lead to structural failure, accidents, and costly delays. Engineers must ensure that formwork can withstand live loads from workers and equipment, lateral forces from concrete, and dynamic conditions such as wind or seismic activity. Accurate calculations for spacing, tie placement, and bracing strength are critical to prevent movement during concrete placement. Additionally, the ease of installation and removal, compatibility with reusable panels, and adherence to local building codes play a significant role in the overall design. By integrating structural requirements, safety protocols, and material characteristics, wall formwork systems can deliver consistent quality, reduce labor costs, and enhance the predictability and success of construction projects.

Formwork Pressure, Structural Stability, and Load Management

Designing wall formwork requires precise engineering to account for various forces and loads acting on the system. The most critical of these is the lateral pressure exerted by fresh concrete, a hydrostatic force that increases with both pour depth and pour rate. Factors such as concrete density, temperature, and vibration method significantly influence this pressure. A faster pour rate results in a greater volume of liquid concrete, increasing pressure at the bottom of the form. In addition to lateral forces, the formwork must support the dead weight of the concrete and panels, along with live loads from workers, equipment, and construction activities. Accurate calculations of these forces are essential to ensure the stability of the formwork and the dimensional integrity of the finished wall, preventing costly defects like bulging or uneven surfaces that could compromise structural quality.

To manage these forces, formwork bracing systems are crucial for maintaining rigidity and alignment throughout the concrete pour. Heavy-duty props, adjustable support frames, and braces help transfer lateral and vertical loads safely into the foundation or existing structures. Bracing also resists external influences such as wind or seismic forces, which can be significant for tall walls. In single-sided formwork applications, these supports are particularly vital, as there is no opposing form to counteract concrete pressure. By integrating precise load calculations, robust bracing, and carefully selected materials, wall formwork becomes a temporary structural system that ensures both safety and the successful creation of high-quality concrete walls. This demonstrates that modern wall formwork is a sophisticated engineering solution rather than a simple construction tool.

Safety Requirements, Compliance, and Best Practices

Safety is a fundamental consideration in wall formwork design and installation, governed by strict regulations to protect construction workers from potential hazards. Agencies such as the Occupational Safety and Health Administration (OSHA) require fall protection for all personnel working at heights of six feet or more, including those operating on formwork faces or reinforcing steel. Compliance measures include the installation of guardrail systems, safety nets, and personal fall arrest systems, as well as providing secure access to elevated work platforms. Additionally, workers must use appropriate Personal Protective Equipment (PPE), including hard hats, gloves, and protective footwear. Proper training and adherence to these standards help reduce accidents, prevent injuries, and ensure the structural integrity of both temporary and permanent components of the project. Prioritizing safety is essential not only for regulatory compliance but also for maintaining construction efficiency and workforce confidence.

Modern wall formwork systems increasingly incorporate proactive safety features directly into their design. Self-climbing formwork platforms, for example, include integrated guardrails, spacious working areas, and secure anchor points, allowing workers to operate safely even at significant heights. The preassembly and modularity of these systems eliminate unsecured edges during climbing and assembly, reducing the risk of falls. These innovations demonstrate the industry’s shift from reactive to proactive safety management, where engineered solutions address hazards before they arise. By integrating safety into the design of the formwork itself, manufacturers enhance both worker protection and operational efficiency, highlighting that safety, productivity, and cost-effectiveness can coexist in modern construction practices.

Accessories & Components of Wall Formwork

Wall formwork relies on a variety of accessories and components to ensure structural stability, ease of assembly, and accurate concrete shaping. Key elements include formwork panels, tie rods, braces, and support frames, all of which work together to maintain alignment and resist the lateral pressure of fresh concrete. Form ties are particularly important, as they connect opposing panels and transfer hydrostatic forces safely into the supporting structure. Sleeves or spacers are often used to allow for easy reuse of ties, while clamps and brackets secure panels in place. Adjustable props and push-pull systems provide fine-tuning of panel positions, ensuring verticality and uniformity in the finished wall. Ancillary components, such as walers and ledgers, further enhance rigidity, while lifting hooks and modular connectors improve assembly speed and safety. The careful selection and proper installation of these components are critical to achieving both efficiency and quality in wall construction.

In addition to structural performance, formwork accessories play a significant role in project safety and labor efficiency. Heavy-duty props and support frames ensure that panels remain stable under the immense pressure of fresh concrete, preventing deflection, bulging, or collapse. Tie rods and clamps not only maintain the correct spacing but also allow for quick disassembly and reuse, reducing labor costs and material waste. Accessories such as formwork brackets, kicker panels, and adjustable wedges facilitate complex wall shapes, single-sided applications, and multi-level pours. By integrating these components into a cohesive system, contractors can achieve precise wall dimensions, smooth surface finishes, and enhanced structural integrity while maintaining high standards of safety and productivity. This combination of functionality, durability, and efficiency underscores the importance of accessories in modern wall formwork systems.

Essential Hardware, Ties, and Support Frames

A complete wall formwork system combines foundational components and essential accessories to create a rigid, reliable mold for concrete construction. The core elements are formwork panels, which shape the concrete, and support frames, which provide stability throughout the pouring process. Formwork ties are among the most critical accessories, designed to hold panels securely and resist the lateral pressure of wet concrete. Different tie types serve specific purposes: snap ties offer quick installation and ease of use, threaded ties provide superior strength and precise alignment adjustments, and loop ties are highly versatile, adaptable to various formwork systems. The careful selection and correct installation of these ties are essential for maintaining structural integrity, achieving accurate wall dimensions, and preventing costly defects such as bulging, cracking, or misalignment in the finished concrete.

Other hardware and support components play equally vital roles in ensuring safety and efficiency. Braces and kicker panels stabilize panels and maintain verticality, while lifting brackets, anchor systems, and form release agents enhance assembly, disassembly, and durability. Form tie plugs seal the tie holes after removal, contributing to waterproofing and long-term wall performance. Together, these accessories optimize the speed, quality, and safety of construction operations, enabling contractors to execute complex wall designs with confidence. The integration of high-quality hardware and support systems ensures that wall formwork functions not merely as a temporary mold but as a precise, engineered structure that directly impacts the success of the final concrete wall.

Advanced and Specialized Accessories for High-Rise and Complex Structures

Beyond standard hardware, the wall formwork industry has developed advanced accessories to tackle complex construction challenges. Climbing formwork systems, for example, are specialized assemblies used for tall vertical structures such as high-rise cores, elevator shafts, and bridge piers. These systems can be crane-dependent or self-climbing, using hydraulic rams to lift the formwork from one level to the next. Self-climbing systems are particularly strategic for reducing crane reliance, shortening cycle times, and enabling construction to continue efficiently even under challenging conditions like high winds. Although the initial investment is significant, these systems dramatically reduce labor costs and accelerate project timelines, making them cost-effective for high-value and large-scale projects. Their precision engineering ensures that walls are constructed safely, quickly, and accurately, maintaining alignment and stability throughout successive pours.

Other specialized accessories further optimize efficiency and quality. Form tie plugs seal holes left in the concrete after tie removal, contributing to waterproofing and structural durability. Form release agents prevent concrete from sticking to panels, facilitating smooth stripping and high-quality finishes. Additional components, including anchor bolts, coil ties, and she bolts, provide robust support for light, medium, and heavy-duty formwork applications. These innovations reflect the industry’s shift toward high-performance, purpose-built solutions that address logistical, safety, and quality challenges simultaneously. Investing in such specialized accessories enables contractors to execute complex projects with precision, reliability, and efficiency, reinforcing the integral role of advanced formwork systems in modern construction.

The Wall Formwork Installation Process

The installation of wall formwork is a critical step in ensuring the structural integrity and dimensional accuracy of concrete walls. The process begins with careful site preparation, including leveling the base and verifying measurements for wall alignment. Prefabricated panels, whether timber, steel, aluminum, or modular, are then positioned according to the design layout. Support frames, braces, and props are installed simultaneously to maintain verticality and prevent movement during the concrete pour. Form ties are inserted and secured to hold opposing panels in place, ensuring that the lateral pressure of fresh concrete is properly resisted. Proper sequencing, alignment checks, and bracing adjustments are crucial at this stage, as any deviation can lead to bulging, uneven surfaces, or misaligned walls, potentially compromising the structural quality of the final construction.

Attention to detail during installation extends to safety and efficiency. Workers must use appropriate lifting equipment for heavy panels, secure anchor points, and follow all PPE requirements. Modular and adjustable formwork systems allow faster assembly while minimizing on-site modifications, reducing labor costs and accelerating project timelines. Additionally, pre-assembled platforms, integrated working spaces, and access ladders facilitate safe movement and efficient operations during the pour. Successful installation ensures not only the correct shape and alignment of the wall but also the durability and aesthetic quality of the finished concrete surface. By combining meticulous planning, precision alignment, and robust support systems, the installation process transforms temporary formwork into a reliable structural tool that directly impacts project success.

Step-by-Step Erection and Assembly

The erection of wall formwork is a precise, multi-step procedure that requires careful planning and execution to ensure both structural integrity and high-quality finishes. The process begins with a detailed design and planning phase, during which structural drawings are analyzed, and load calculations are performed to confirm that the formwork can safely withstand concrete pressure and live loads. Site preparation follows, including marking wall locations, leveling the base, and positioning any necessary steel reinforcement. Panels may be pre-assembled off-site into larger gang-forms to accelerate assembly and reduce on-site labor. A form release agent is applied to the concrete-facing surfaces to prevent adhesion and allow smooth stripping. The first side of the formwork is then erected, aligned vertically, and securely braced using struts and props to ensure stability throughout the pour.

After the initial side is stabilized, the opposing panels are installed and connected using form ties to maintain correct spacing and resist lateral hydrostatic pressure. Pouring platforms, sideguards, and access ladders are set up to provide safe working conditions. Concrete is placed in controlled layers, with vibrators used to eliminate air pockets and achieve dense, uniform consolidation. This methodical, step-by-step approach ensures that walls are structurally sound, accurately aligned, and finished to a high standard. Adherence to this systematic procedure reduces the risk of defects such as bulging, honeycombing, or misalignment, reinforcing the importance of meticulous planning, precise execution, and proper formwork handling in modern construction projects.

Installation Safety Measures for Wall Formwork

Safety is a fundamental and continuous consideration throughout the wall formwork installation process. A stable and properly prepared foundation is the first safeguard against structural failure, requiring the ground to be leveled and compacted according to engineering specifications. All formwork components must be installed in strict compliance with manufacturer guidelines to ensure alignment and stability. Workers involved in the installation must be adequately trained in the specific system being used, competent in assembly procedures, and equipped with appropriate Personal Protective Equipment (PPE), including helmets, gloves, safety boots, and high-visibility clothing. Integrating safety into every stage of the process ensures that potential hazards are anticipated and mitigated, reducing the risk of accidents and protecting both personnel and the integrity of the formwork system.

Working at height represents one of the most significant risks during installation, requiring the use of secure access platforms, ladders, guardrails, and safety nets. Fall protection systems, such as harnesses and lanyards, must be employed whenever personnel operate six feet or more above the ground. Proper material handling through mechanical lifting equipment reduces manual handling risks, while clear communication among team members ensures coordinated and safe operations. A well-defined emergency response plan, detailing procedures for incidents like formwork collapse or worker falls, further strengthens site safety. Modern construction best practices emphasize that safety is a collective responsibility embedded within the workflow, demonstrating that effective planning, training, and safety integration are just as critical as the technical installation process itself.

Formwork Removal and Stripping Process

The removal, or stripping, of wall formwork is a critical stage in concrete construction that must be executed carefully to avoid damaging the freshly cast wall. The timing of formwork removal depends on multiple factors, including the type of concrete used, ambient temperature, curing conditions, and the specific wall design. Premature stripping can result in deformation, cracking, or surface blemishes, while delayed removal can unnecessarily extend project timelines. Standard practice involves gradually releasing the lateral support, beginning with props, braces, and ties, to allow the concrete to bear its own weight safely. During this process, workers must follow strict guidelines for sequencing and load redistribution to prevent sudden stress on the structure, ensuring that the concrete has achieved sufficient strength to maintain its shape without support.

Specialized considerations are required for different types of formwork systems. For single-sided formwork, heavy-duty props and support frames must be removed in a controlled sequence to maintain stability, while double-sided systems require careful detachment of form ties to avoid surface damage. Reusable modular panels, steel, and aluminum formwork are often cleaned, inspected, and prepped for subsequent use, enhancing both sustainability and cost efficiency. Proper formwork stripping not only preserves the integrity and aesthetic quality of the concrete wall but also contributes to labor optimization and project schedule adherence. By combining precise timing, methodical sequencing, and attention to structural behavior, contractors can ensure safe, efficient, and high-quality formwork removal.

Factors Affecting Stripping Time

The timing of wall formwork removal, or “stripping,” is a critical decision that requires balancing construction efficiency with structural integrity. Removing formwork too early can cause the concrete to deform, crack, or even collapse, while leaving it in place longer than necessary can lead to uneven drying, reduced surface quality, and a brittle structure. The most important determinant is the concrete’s compressive strength, which must be sufficient for the wall to support its own weight as well as any subsequent loads. Industry standards often recommend a minimum curing period of 24 hours for structural walls and columns, but this duration can vary depending on the type of concrete, wall thickness, and project-specific design. Accurate assessment of concrete strength before formwork removal ensures that the structure maintains its intended shape and durability without compromising safety or long-term performance.

Environmental conditions also play a significant role in determining stripping time. Ambient temperature, humidity, and wind conditions can accelerate or delay the concrete’s hardening process, requiring adjustments in removal schedules. Cold, humid conditions may necessitate a longer wait to achieve adequate strength, while chemical admixtures in the concrete mix can accelerate curing and allow earlier stripping. Site-specific monitoring, including on-site strength tests, provides reliable data to make informed decisions about formwork removal. By carefully evaluating concrete performance and environmental factors, contractors can optimize the balance between construction speed and quality, ensuring safe, efficient, and high-quality wall construction.

Traditional vs. Modular Systems

Wall formwork systems can be broadly classified into traditional and modular types, each offering distinct advantages and limitations. Traditional formwork, often made of timber or plywood, is highly versatile and easy to customize on-site, making it suitable for one-off or complex wall shapes. However, these systems have a limited lifespan, are labor-intensive, and are prone to warping, cracking, or absorbing moisture from the concrete. While cost-effective for small projects, traditional formwork requires frequent replacement and careful handling to maintain alignment and surface quality. Contractors must also invest significant time in cutting, measuring, and assembling panels on-site, which can slow project timelines and increase labor costs. Despite these challenges, traditional systems remain a popular choice for projects where flexibility and bespoke configurations are prioritized over efficiency and reusability.

Modular formwork systems, by contrast, consist of prefabricated, standardized panels that can be quickly assembled and disassembled on-site. These systems are designed for repeated use, with durable materials such as steel, aluminum, or plastic, offering high precision and consistent surface finishes. Modular systems significantly reduce on-site labor requirements, minimize errors, and accelerate construction schedules, making them ideal for large-scale or repetitive projects such as high-rise buildings and infrastructure. Additionally, their standardized components provide better quality control and improved safety, as fewer manual adjustments are required during assembly. The combination of efficiency, reusability, and precision makes modular formwork a modern solution that addresses the limitations of traditional methods while enhancing project predictability and long-term cost-effectiveness.

A Comparative Analysis of Efficiency and Reusability

The debate between traditional and modular wall formwork systems highlights a key trade-off in modern construction: on-site customization versus off-site prefabrication. Traditional formwork, typically constructed with timber or plywood directly on-site, allows for high flexibility in creating unique wall shapes and intricate designs. Its lower initial material cost makes it attractive for small or one-off projects. However, this method is labor-intensive, requiring skilled carpenters, and generates significant waste due to cutting and modifications on-site. Additionally, its limited lifespan—often only a few uses—renders it inefficient for repetitive projects, while variability in craftsmanship can lead to surface imperfections and alignment issues, impacting the quality and durability of the finished concrete wall.

In contrast, modular formwork systems utilize prefabricated, standardized panels produced in controlled factory environments. This approach significantly streamlines on-site assembly and dismantling, reducing labor costs, project timelines, and the likelihood of errors. Factory production ensures precise dimensions and consistent quality, enhancing surface finishes and structural accuracy. Though the upfront cost is higher, modular systems offer long-term benefits through high reusability, reduced material waste, and predictable project outcomes. This shift represents a broader industrialization in construction, moving away from bespoke, craft-based methods toward efficient, repeatable, and scalable solutions that balance quality, safety, and cost-effectiveness.

Cost Factors, Reusability, and Long-Term Economic Analysis

The cost of wall formwork systems is influenced by several factors, including material type, system complexity, labor requirements, and project scale. Traditional timber and plywood formwork often have a lower initial material cost, making them appealing for small or one-off projects. However, their limited lifespan and high labor intensity can lead to increased overall project expenses, as repeated replacements and on-site modifications are frequently necessary. Other cost considerations include transportation, storage, and maintenance of panels, as well as the potential for waste generated during cutting and assembly. Contractors must weigh these upfront and recurring costs against project timelines, quality requirements, and the desired level of precision, as selecting an inappropriate formwork system can compromise efficiency and result in costly rework.

In contrast, modular and modern reusable formwork systems, often made from steel, aluminum, or plastic, involve a higher initial investment but offer substantial long-term savings. These systems are designed for repeated use, sometimes exceeding 50–200 cycles depending on the material and maintenance practices. Their standardized components and prefabricated panels reduce on-site labor, accelerate construction schedules, and minimize material waste. Proper maintenance, including cleaning, inspection, and storage, further extends their lifespan and ensures consistent performance across multiple projects. The ability to reuse modular systems not only lowers the effective per-use cost but also improves sustainability by reducing timber consumption and construction waste. By analyzing the cost-benefit trade-offs, contractors can select the most suitable wall formwork system that balances budget, efficiency, and project quality.

Economic Considerations for Formwork Materials and Systems

The total cost of a wall formwork system extends well beyond the initial material purchase, encompassing labor, transportation, storage, and the number of reusable cycles. Labor alone can account for up to 44% of total formwork costs, making it a critical factor in overall project budgeting. Traditional timber and plywood formwork, while low-cost upfront, has limited reusability—typically only 4 to 6 uses—which increases the effective cost per use. Additionally, on-site customization, cutting, and assembly require skilled carpenters, further driving labor expenses. These factors, combined with potential waste from cutting and trimming, make traditional systems less economical for large-scale or repetitive projects. Contractors must carefully consider not just material costs, but also lifecycle costs, installation time, and the potential for errors that could necessitate rework or repairs.

Modern formwork materials such as steel, aluminum, and plastic, though more expensive initially, offer significant long-term economic advantages due to their high reusability. Plastic formwork panels can be used over 100 times, while aluminum panels can exceed 200 cycles, substantially reducing the cost per use over multiple projects. Steel systems, known for durability and strength, also provide repeated usability, making them ideal for large-scale or high-rise construction. High reuse rates enhance project predictability, reduce supply chain dependencies, and ensure consistent concrete quality across multiple applications. By considering these economic and operational benefits, construction firms can transform wall formwork from a short-term expenditure into a strategic, long-term investment that delivers efficiency, cost savings, and reliable performance.

| Material | Initial Cost | Reusability (Lifespan) | Weight | Key Advantages | Key Disadvantages |

|---|---|---|---|---|---|

| Timber/Plywood | Low ($35-$80/m²) | Low (4-6 uses) | Lightweight | Easy to customize on-site, low initial cost, widely available | Short lifespan, susceptible to warping and moisture damage, labor-intensive |

| Steel | High ($40-$84/m²) | High (50+ uses) | Heavy | High strength, extremely durable, ideal for heavy loads and large projects | Heavy and requires lifting equipment, high initial cost, less flexible for custom shapes |

| Aluminum | High ($60-$120/m²) | Very High (200+ uses) | Lightweight | Lightweight and crane-independent, high reusability, quick assembly/disassembly | Higher initial cost than steel, less sturdy under very heavy loads |

| Plastic | High ($50-$90/m²) | Very High (100+ uses) | Lightweight | Lightweight, eco-friendly (often recycled), high reusability, water and chemical resistant | Higher initial cost, less flexible for custom shapes |

Special Applications and Advanced Systems

Wall formwork systems have evolved beyond standard applications to address specialized construction requirements that demand precision, efficiency, and enhanced structural performance. One key example is shear wall formwork, which is critical in buildings located in seismic zones, as these walls resist lateral forces from wind and earthquakes. The formwork for shear walls must be robust, adjustable, and capable of maintaining perfect alignment under significant hydrostatic pressure from fresh concrete. Similarly, retaining wall formwork requires systems designed to withstand high lateral loads and ensure stability, with steel and modular prefabricated components commonly employed due to their durability and reusability. These specialized applications highlight how tailored engineering solutions are applied to meet the unique demands of complex projects, ensuring safety, structural integrity, and construction efficiency.

High-rise building cores, bridge piers, and other tall vertical structures utilize advanced formwork technologies such as self-climbing or jump form systems. These systems employ hydraulic rams or crane-assisted lifting to raise the formwork and integrated working platforms to the next level with each successive concrete pour. Self-climbing systems reduce dependence on cranes, accelerate construction timelines, and allow work to continue in adverse weather conditions. Modular and pre-engineered systems also improve safety and precision by standardizing components and reducing on-site adjustments. The implementation of these advanced systems demonstrates the industry’s commitment to innovation, combining automation, reusability, and engineering sophistication to overcome challenges associated with height, load, and speed, transforming complex construction tasks into efficient and predictable processes.

Beyond Standard Walls: Insulated, Rammed Earth, and Complex Structures

Wall formwork extends far beyond conventional vertical walls, offering versatile solutions for innovative and specialized construction applications. One prominent example is Insulating Concrete Forms (ICFs), which combine formwork and permanent building elements. In ICF systems, interlocking foam blocks serve as molds for reinforced concrete walls and remain in place after curing, providing exceptional thermal and acoustic insulation. This integration of formwork into the final structure represents a paradigm shift, where formwork is no longer viewed merely as a temporary tool but as a contributor to the long-term performance, energy efficiency, and sustainability of the building. ICFs are increasingly popular in residential and commercial projects where reducing energy consumption and enhancing structural efficiency are high priorities, demonstrating how advanced materials and design strategies expand the functional role of wall formwork.

Another specialized application is in rammed earth construction, an ancient technique that has been modernized using precise formwork systems. Here, the formwork shapes layers of moist, malleable earth, which are compacted to create solid walls. Timber and plywood are often preferred due to their flexibility, durability, and ability to imprint a natural texture onto the wall surface. The choice between movable and static forms allows for design control: movable forms produce horizontal joints that can serve as visual features, while static forms yield seamless monolithic walls. These applications illustrate the adaptability of wall formwork technology, accommodating both modern, high-performance construction systems and traditional, craft-oriented techniques, while maintaining safety, efficiency, and aesthetic precision.

Innovations & Future Trends

The wall formwork industry continues to evolve through innovations that enhance efficiency, safety, and sustainability. One major trend is the increased adoption of modular and prefabricated systems, which allow for faster assembly, reduced labor costs, and improved quality control. Digital design and Building Information Modeling (BIM) are also transforming the planning phase, enabling precise calculations of formwork pressures, component alignment, and installation sequencing before work begins on-site. These tools minimize human error, optimize material use, and allow for advanced simulation of construction scenarios. Furthermore, the integration of automated and self-climbing formwork systems for high-rise buildings accelerates project timelines, reduces crane dependency, and ensures consistent structural performance, reflecting a broader industrialization of the construction process.

Sustainability and material innovation are also shaping the future of wall formwork. Reusable plastic, aluminum, and hybrid composite materials are replacing traditional timber in many projects, offering longer lifespans, lower environmental impact, and reduced maintenance costs. Smart sensors embedded in formwork panels can monitor concrete curing, temperature, and pressure in real time, providing actionable data for safer and more efficient construction management. Additionally, the use of 3D-printed formwork components and adaptive systems allows architects and engineers to explore complex geometries and custom shapes with unprecedented precision. These trends underscore a shift toward highly engineered, data-driven, and environmentally conscious solutions that maximize performance, safety, and cost-effectiveness in modern construction.

Digital Tools, 3D Printing, and Smart Formwork Solutions

The future of wall formwork is increasingly driven by digitalization and automation, transforming traditional construction workflows into highly precise and data-driven processes. Building Information Modeling (BIM) has emerged as a key technology, enabling engineers and project managers to create detailed 3D models of formwork systems before any on-site installation. Through BIM, potential conflicts, misalignments, or size inaccuracies can be detected and resolved early, reducing costly rework and material waste. Advanced 4D (time) and 5D (cost) simulations further allow teams to optimize pour sequences, labor allocation, and project timelines, providing actionable insights that improve efficiency, safety, and overall predictability. By shifting planning and problem-solving into the digital realm, BIM ensures that wall formwork projects can be executed with greater accuracy, consistency, and operational control.

Another transformative technology is 3D printing, which enables the production of highly complex and customized formwork components. Unlike conventional methods, 3D printing allows architects and engineers to realize intricate wall geometries and unique facade designs that would be difficult to achieve with timber, steel, or aluminum systems. Materials used in 3D-printed formwork can be optimized for structural performance and sustainability, reducing material usage by up to 70% while maintaining adequate strength. This approach not only accelerates production but also minimizes on-site labor and reduces environmental impact. Emerging technologies such as BIM and 3D printing illustrate a fundamental shift in wall formwork: from reactive, on-site problem-solving to proactive, digitally-driven engineering solutions that improve safety, efficiency, and design flexibility in modern construction.

Conclusion: The Backbone of Concrete Construction

Wall formwork is far more than a temporary mold; it serves as the essential structural framework that transforms concrete into stable, durable, and visually precise walls. Over time, the industry has evolved from traditional, labor-intensive timber and plywood methods to highly engineered, modular, and reusable systems. Modern solutions—ranging from lightweight plastic panels to self-climbing hydraulic formwork—address critical challenges such as cost efficiency, construction speed, and on-site safety. These innovations demonstrate that investment in advanced wall formwork directly contributes to the structural integrity and long-term success of construction projects. The versatility of these systems allows them to meet diverse requirements, from high-rise cores to complex curved walls, while minimizing errors, material waste, and labor dependency.

Choosing an effective wall formwork system goes beyond initial material cost; it is a strategic decision that balances reusability, efficiency, and safety. High-performance systems accelerate project timelines, ensure consistent concrete quality, and reduce on-site hazards, providing tangible value across multiple projects. By integrating modern engineering, digital planning, and sustainable materials, wall formwork has become a holistic solution essential for modern construction. Its role as a reliable, reusable, and precise framework cements its position as the backbone of all concrete construction, underpinning both financial and structural success.