- Published:

- Written by: B.F.S Industries

Understanding Types of Slab Formwork in Modern Construction

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

Formwork, the temporary mold or structure into which fresh concrete is poured and held until it gains sufficient strength, is arguably the most critical component in any structural Concrete Construction project, dictating not only the final shape and alignment of the element but also significantly impacting the safety, timeline, and overall cost of the build. For horizontal structural elements, specifically concrete slabs, the choice of formwork system is paramount, requiring careful consideration of the project’s scale, budget, complexity, and reusability requirements. An expert-level understanding of the different Types of Slab Formwork is essential for construction professionals, project managers, and engineers aiming for optimal efficiency and superior structural integrity. This comprehensive article, presented by BFS Industries, serves as a definitive guide to the principal categories and specialized systems available today, delving into their material compositions, operational characteristics, advantages, and limitations to facilitate informed decision-making in the field, ultimately ensuring every pour achieves the highest standards of quality and economy. The initial selection process involves evaluating whether a traditional, built-on-site approach is feasible, or if a modern, prefabricated system offers the required speed and cost-effectiveness for mass replication, especially in multi-story residential or commercial developments.

Formwork Classified by Material: Traditional vs. Engineered Systems

The fundamental classification of formwork systems often begins with the material used to construct the primary mold, as the material dictates characteristics such as weight, surface finish, lifespan, reusability, and initial capital investment. The evolution of formwork materials reflects a continuous drive for greater sustainability, reduced labor costs, and improved dimensional accuracy. Traditional materials, such as timber and plywood, have long been the industry standard due to their universal availability, low initial cost, and ease of cutting and assembling into virtually any custom shape on site, making them ideal for complex or non-standard geometry requiring bespoke solutions. However, their limitations—chiefly their finite number of reuses before degradation, susceptibility to moisture damage, and high reliance on skilled carpentry labor—have spurred the widespread adoption of engineered materials. These modern alternatives, including steel, aluminum, and advanced plastics, offer superior dimensional stability, exceptional durability, and significantly higher reusability rates, often translating into lower lifetime costs and faster cycle times, especially in projects where the same slab dimensions are repeated across multiple floor levels, setting the benchmark for modern concrete slab formwork systems.

Engineered metal systems, particularly those utilizing steel or aluminum, represent the gold standard for projects demanding high-volume repetition and the utmost surface quality, minimizing post-pour finishing work. Steel formwork, known for its exceptional strength and rigidity, is capable of withstanding high concrete pressures and providing a perfectly flat and uniform surface finish over hundreds of uses. While heavier and requiring crane assistance for assembly and striking, steel systems offer unparalleled longevity, making them a sustainable choice for long-term contractors. Aluminum formwork, while slightly less durable than steel, boasts a significantly lighter weight, facilitating quicker manual handling and assembly without heavy machinery, which drastically improves site logistics and labor productivity, particularly in areas with restricted crane access. Furthermore, advanced composite materials, including specialized plastics and fiberglass-reinforced panels, are increasingly employed, offering the lightweight benefits of plywood combined with the excellent surface finish and water resistance of metal systems, providing a versatile option for specific architectural requirements where smooth curves or intricate patterns are mandated by the design specifications. The decision between these materials hinges on a detailed cost-benefit analysis considering labor rates, material lifespan, and the required construction pace.

Timber and Plywood Formwork: Versatility and Limitations

Timber formwork, constructed from conventional lumber (like spruce, pine, or fir), remains a staple in the Concrete Construction industry, offering unmatched flexibility and adaptability, particularly valuable for smaller, custom, or architecturally complex projects where standardized panel systems are impractical. Its primary appeal lies in its low material cost and the ability for on-site carpenters to quickly cut, shape, and erect forms tailored to non-typical dimensions, curved edges, or irregular penetrations. This customizability ensures that even unique structural elements, such as stepped slabs or complex cantilevers, can be formed with relative ease, making it the choice for one-off residential builds or intricate heritage restoration work. However, this system is inherently labor-intensive and its quality is highly dependent on the skill of the carpentry crew, leading to variability in the finished surface and dimensional accuracy. Furthermore, timber is susceptible to warping, swelling, and shrinkage due to changes in moisture content and temperature, which limits its reusability, often to fewer than ten cycles, ultimately increasing waste generation and requiring careful planning and material stock management to maintain cost efficiency throughout the project lifecycle.

Shuttering Material List: A Complete Guide for Construction Projects

Plywood, especially structural and film-faced varieties, represents a significant refinement over raw timber planks, offering a much smoother surface finish and improved resistance to water absorption, thereby extending its potential reuses. Film-faced plywood, coated with a resin or plastic film, is particularly popular as it minimizes adhesion between the concrete and the form face, resulting in a cleaner, less porous concrete surface that often requires less post-pour treatment or repair. Plywood panels are typically used as the primary sheeting material supported by a secondary timber or metal framework of joists, bearers, and props. Despite these improvements, even the best plywood panels still degrade over time, with edge damage, screw holes, and delamination eventually necessitating replacement. Consequently, while offering a cost-effective solution for small to medium-sized projects or those with limited repetition, the total cost of ownership for plywood systems must account for high material turnover and the associated labor costs for repeated installation, striking, and maintenance, prompting many large-scale developers to seek the durability and higher upfront cost but lower life-cycle cost of engineered Types of Slab Formwork like steel or aluminum systems.

Steel and Aluminum Formwork: Durability and Reusability

Steel formwork systems are celebrated for their unparalleled durability, robustness, and ability to deliver consistently high-quality surface finishes, making them the preferred choice for massive civil engineering projects, infrastructure, and high-rise developments where the same slab configuration is repeated dozens or even hundreds of times. Fabricated from high-gauge steel plates, these panels are exceptionally rigid, capable of withstanding the immense hydrostatic pressure exerted by deep or high-density concrete pours without deflection. The galvanized or treated steel surface ensures minimal corrosion and superior resistance to abrasion, allowing for hundreds of reuse cycles with minimal maintenance, a key factor in achieving economies of scale on large projects. This high reusability significantly lowers the material cost per pour compared to single-use timber, contributing to greater overall project sustainability by minimizing construction waste. However, the weight of steel panels necessitates the use of heavy-duty scaffolding and crane lifting for almost all operations, which adds complexity to site logistics and requires greater spatial planning, and the initial capital outlay for purchasing a complete steel formwork system is substantially higher than for traditional materials.

Difference Between Shoring and Scaffolding – An In-Depth Guide for Engineers and Contractors

Aluminum formwork, on the other hand, provides a compelling balance between the strength and reusability of metal and the lightweight handling ease of plywood. Constructed from high-strength aluminum alloy, these panels offer excellent rigidity and surface quality while being significantly lighter—often light enough to be handled manually by a small crew. This reduction in weight eliminates the reliance on heavy lifting equipment in many scenarios, accelerating the cycle time for pouring successive slabs and reducing construction noise and energy consumption. Aluminum systems are typically designed as modular, integrated concrete slab formwork systems, where the form face, supporting structure, and accessories are interconnected, allowing for rapid assembly and dismantling. This monolithic design often leads to highly coordinated and rapid construction schedules, making it exceptionally popular for mass housing and repetitive multi-story projects. Though slightly more susceptible to damage from rough handling compared to steel, aluminum formwork still offers excellent reusability, typically exceeding one hundred cycles, making it a powerful solution for BFS Industries clients focused on fast-track, high-volume residential and commercial construction where speed and consistent quality are essential.

System-Based Classification: Modular and Flying Solutions

System-based formwork represents a major evolution from material-specific solutions, focusing instead on optimizing the process of assembly, reuse, and cycle time through standardization and integration. These advanced systems are defined by their use of pre-engineered, often lightweight metal components that interlock quickly, drastically reducing the dependency on highly skilled on-site carpentry labor and minimizing human error. The primary benefit of adopting system-based Types of Slab Formwork is the acceleration of the construction schedule, often enabling a floor-to-floor cycle time measured in days rather than weeks, which translates directly into cost savings and earlier project completion. The initial investment in these systems is higher than in traditional timber, but the long-term returns from increased speed and material reuse, particularly in projects with high slab repetition, overwhelmingly justify the expense, making them a cornerstone of modern, large-scale commercial and residential construction.

The two most prominent system-based solutions are modular panel systems and flying forms, which cater to different scales of repetition and project height. Modular systems, characterized by handheld, standardized components, excel in mid-rise buildings and complex layouts where flexibility is still needed, allowing for rapid early stripping and maximum component utilization. In contrast, flying forms are built for pure speed and volume in high-rise construction, utilizing massive, crane-lifted tables that are assembled once and flown from floor to floor. The selection between these two approaches hinges on site logistics, including crane access and laydown area, as well as the geometric uniformity of the slab design. Both systems, however, are integral to the portfolio of modern construction techniques, delivering superior dimensional accuracy and predictability compared to traditional stick-built methods.

Modular Panel Systems: Efficiency and Speed

Modular panel formwork systems are defined by standardized, interchangeable components that connect quickly and securely, drastically reducing on-site labor and eliminating the need for cutting or custom fabrication. These systems typically comprise primary panels (often made of aluminum or steel), quick-release dropheads, and lightweight aluminum or timber beams, all designed to interact seamlessly. The primary advantage lies in their efficiency and the speed of the striking process. Once the concrete has achieved sufficient early strength, the dropheads allow the beams and form panels to be lowered and removed from the slab for immediate reuse on the next floor, while the props (shores) remain in place to continue supporting the slab until it reaches full design strength. This method, often referred to as “early striking,” maximizes the utilization rate of the expensive formwork components, leading to faster floor cycles and lower inventory requirements for the entire project.

Within the modular category, several specialized Types of Slab Formwork exist, tailored for specific slab designs, such as waffle and beam-and-slab systems. Waffle slab forms, often made of plastic or fiberglass, create a grid of ribs underneath the slab, reducing the concrete volume and weight while maintaining structural strength over long spans. These reusable plastic molds are set on a supporting grid and struck once the concrete cures, leaving a distinct waffle pattern. Similarly, specialized beam-and-slab modular systems are designed to form the complex geometry of supporting beams and infill slabs concurrently, using pre-engineered, often adjustable, metal panels. The adoption of these modular concrete slab formwork systems is a defining feature of modern, fast-paced commercial and industrial construction, where minimizing construction time is a critical financial objective. The simplified training required for site crews, combined with the safety features integrated into the modular design, further enhances their appeal for large contractors working on demanding, multi-phase projects.

Table and Flying Forms: High-Rise and Large-Scale Projects

Table formwork, often referred to as ‘flying forms,’ is a highly specialized and extremely efficient system engineered explicitly for the rapid, repetitive construction of flat slabs in high-rise buildings and other multi-story structures with open floor plans. A table form is essentially a massive, pre-assembled section of slab formwork, complete with its surface deck, primary and secondary beams, and support scaffolding, which is assembled only once at ground level. Once the concrete cures, the entire table unit—which can cover several hundred square meters—is hydraulically lowered, rolled to the building’s edge, and then ‘flown’ by a crane to the next floor level for immediate reuse. This mechanism dramatically minimizes the labor-intensive assembly and dismantling of individual formwork components at height for every floor, significantly compressing the construction schedule. The rapid transfer and setup allow for an extremely fast floor-to-floor cycle time, which is crucial for meeting tight deadlines on towering commercial or residential blocks, ensuring the maximum return on investment for the building developer.

The successful implementation of flying forms requires specialized equipment, including high-capacity cranes, and clear access points on the perimeter of the structure for lifting and maneuvering the large units. Despite the high initial investment in the fabricated metal forms and the necessary lifting logistics, the massive savings in on-site labor and construction time make flying forms the most economically viable solution for projects with ten or more identical slab repetitions. Furthermore, because these forms are robust, often constructed of steel or heavy-duty aluminum, they maintain superior dimensional accuracy and offer exceptional reusability over a prolonged project timeline. While primarily suited for regular, flat slabs, specialized configurations can accommodate perimeter spandrel beams or slab edge requirements, further expanding their application. For major developments, the unparalleled speed and efficiency of these specialized Types of Slab Formwork underscore their role as a fundamental technology in modern, high-volume vertical construction.

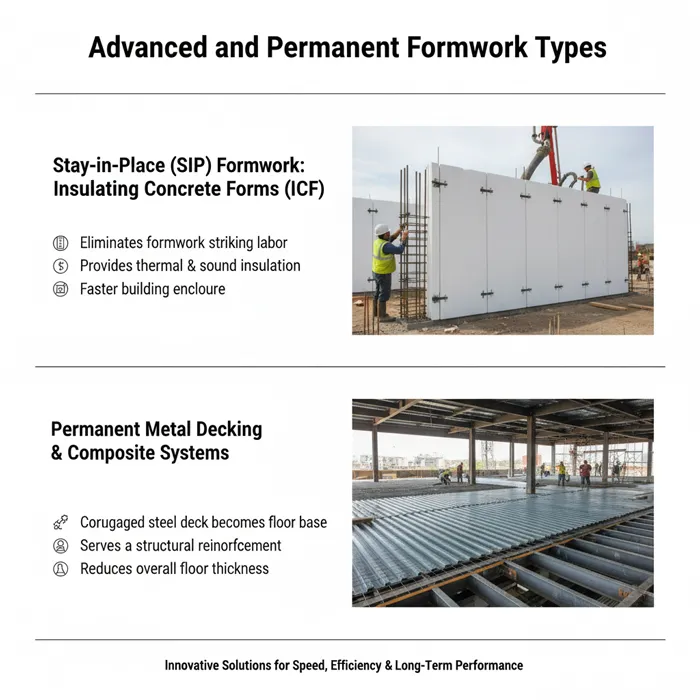

Advanced and Permanent Formwork Types

Beyond reusable metal and timber systems, a distinct category of advanced formwork is designed not for striking and reuse, but for becoming a permanent part of the structure itself. These systems, often referred to as ‘Stay-in-Place’ (SIP) formwork, address not only the structural forming requirement but also provide additional long-term benefits such as thermal insulation, sound dampening, or integrated reinforcement. This innovative approach eliminates the entirety of the formwork striking labor and disposal costs, significantly impacting both project timelines and the environmental footprint of the construction. The material used is typically lightweight, durable, and engineered to maximize energy efficiency once the concrete is cured.

The use of permanent formwork is a strategic choice made when the ancillary benefits outweigh the higher upfront material cost. For instance, in applications demanding high energy performance, fire resistance, or noise reduction, the integrated insulating properties of these systems offer substantial long-term value in building operation and maintenance. By functioning as both the mold and a finished, protective element, these advanced concrete slab formwork systems contribute to faster enclosure of the building, allowing interior trades to begin their work earlier. This focus on long-term performance and efficiency highlights an increasing trend in the industry toward materials that serve multiple functions throughout the construction and operational life of the structure.

Insulated Concrete Formwork (ICF) and Stay-in-Place Systems

Among these specialized options, the Insulated Concrete Form (ICF) system stands out as a unique approach to forming and insulating external walls and, increasingly, floor slabs simultaneously. ICF blocks are essentially lightweight, interlocking units made from high-density expanded polystyrene (EPS) foam, which are stacked, braced, and then filled with concrete. For slabs, specialized ICF decking systems are available that function as both the permanent formwork and the thermal insulation layer, dramatically improving the structure’s energy efficiency and reducing long-term heating and cooling costs. Once the concrete is poured and cured, the EPS forms remain in place permanently, eliminating the need for striking and providing an immediate, finished surface for subsequent layers, greatly accelerating the overall construction process and offering superior sound attenuation and fire resistance compared to traditional construction methods.

Stay-in-Place formwork, encompassing both ICF systems and composite decking, eliminates the time and cost associated with formwork removal and disposal. Composite metal decking, for example, consists of corrugated steel sheets that are laid across steel beams or joists, serving as a permanent form for the concrete pour and, after curing, acting as the primary tensile reinforcement for the slab itself. This system is quick to install, provides immediate working platforms, and is exceptionally efficient for steel-framed high-rise buildings and mezzanines. The choice between reusable and stay-in-place Types of Slab Formwork is a strategic one, balancing the labor cost savings of not striking the form against the material cost of leaving the formwork permanently in the structure. For BFS Industries clients seeking high performance and reduced environmental impact, stay-in-place options, particularly those offering improved thermal performance like ICF, present a compelling pathway to creating more sustainable and resilient buildings that meet stringent modern energy codes and occupant comfort standards while accelerating the overall construction timeline.

Strategic Selection Criteria for Optimal Formwork

The final decision on the most appropriate formwork system is a complex, multi-variable optimization problem that requires a holistic evaluation of project-specific constraints and long-term goals. Key criteria include the rate of slab repetition, where high repetition strongly favors high-reusability systems like steel, aluminum, or flying forms, driving down the unit cost per square meter. Conversely, non-repetitive or geometrically complex projects often necessitate the custom adaptability and low initial cost of timber or engineered plywood. Project scale and construction speed are also paramount; large-scale projects with aggressive deadlines, such as commercial towers, benefit immensely from the rapid cycling capabilities of modular and flying forms, despite their higher initial investment. Furthermore, the required concrete surface finish plays a crucial role; architectural concrete demanding a pristine, blemish-free appearance often requires the use of high-quality film-faced plywood or precision-machined steel/aluminum panels, minimizing the need for expensive post-pour repair work and achieving the aesthetic vision of the designer, which is a major factor in high-end projects.

The economic analysis must extend beyond just the material cost to include the full spectrum of labor, logistics, and reusability over the project lifespan. While timber has a lower initial cost, the repetitive labor for erection, stripping, and replacement, combined with material waste, can quickly surpass the initial savings, particularly on multi-story buildings. Modern concrete slab formwork systems, despite their higher upfront capital expenditure, yield significant long-term savings through reduced labor hours, faster floor cycles, and exceptional durability. Factors like site constraints, including crane availability and laydown area, must also be considered, as they heavily influence the feasibility of using bulky flying forms or heavy steel panels. Ultimately, for BFS Industries clients, the optimal solution is the one that best integrates material efficiency, labor productivity, and safety standards to deliver a high-quality structure within the allocated timeframe and budget, positioning the project for long-term success in the demanding Concrete Construction industry. The expertise to navigate this complex decision-making process is a hallmark of a professional construction partnership.