- Published:

- Written by: B.F.S Industries

Mastering the Mix: An Expert Guide to Concreting Practice in Hot Weather

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

Concrete, the world’s most versatile building material, has one critical vulnerability: heat. When ambient temperatures rise, the very chemical reactions that give concrete its strength can be dangerously accelerated, leading to a host of problems from plastic shrinkage cracking to permanent loss of ultimate strength and durability. This isn’t a minor inconvenience; it’s a structural integrity challenge. For projects in arid, tropical, or seasonally hot climates, a standard approach is a recipe for failure. A successful, durable structure demands a specialized and proactive concreting practice in hot weather, one that moves beyond basic guidelines and embraces a holistic strategy of control, from material selection to the final cure. This guide provides an expert-level framework for managing high-temperature concrete placement, ensuring long-term performance and structural resilience.

The Critical Challenges of Hot Weather Concreting

Any concreting operation where high ambient temperature, low relative humidity, and high wind speed combine to impair concrete quality is defined as hot weather concreting. According to ACI 305R, this is not just about a specific temperature; it’s about the environmental effects on the concrete. The primary challenge of any concreting practice in hot weather is managing the accelerated rate of cement hydration and the rapid evaporation of moisture from the fresh mix. These two factors create a domino effect of negative consequences, impacting workability, finishing operations, and the final hardened properties of the structure. Failure to anticipate and mitigate these challenges can result in costly repairs, compromised structural integrity, and a significantly reduced service life.

Understanding Accelerated Hydration and Its Consequences

The chemical reaction between cement and water, known as hydration, generates heat. In hot environments, this process speeds up dramatically. The concrete mix becomes hotter, faster, leading to a rapid stiffening that can catch crews off guard.

Impact on Workability and Slump Loss

This accelerated hydration causes a rapid loss of workability, or slump. A mix that was perfectly plastic at the batch plant can arrive on-site stiff and difficult to place, leading to a temptation to re-temper with water—a practice that catastrophically damages strength and durability.

The Risk of Cold Joints

In large-scale or sequential pours, the rapid set time increases the risk of cold joints. If a new layer of concrete is placed against a previous layer that has already begun to set, they may not bond properly, creating a plane of weakness that compromises the monolithic nature of the structure.

The Menace of High Evaporation Rates

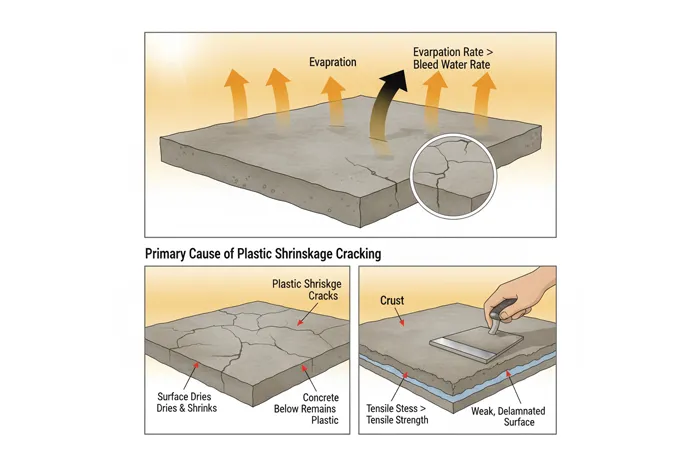

When the rate of moisture evaporation from the concrete surface exceeds the rate at which bleed water can rise, the surface begins to dry out almost immediately. This is the central threat to flatwork in hot, dry, or windy conditions.

The Primary Cause of Plastic Shrinkage Cracking

As the surface dries and shrinks while the concrete below remains plastic, tensile stresses build up. When these stresses exceed the fresh concrete’s non-existent tensile strength, they are relieved by a series of shallow, parallel cracks known as plastic shrinkage cracking.

Surface Crustation and Finishing Difficulties

Rapid surface drying can lead to “crustation,” where a stiff, unworkable crust forms on the surface while the concrete beneath is still plastic. This makes finishing operations like floating and troweling extremely difficult and can trap bleed water, creating a weak, delaminated surface.

Long-Term Durability and Strength Concerns

The negative effects are not limited to the fresh concrete. A poor concreting practice in hot weather has profound, negative impacts on the hardened properties of the material, compromising the structure’s entire design life.

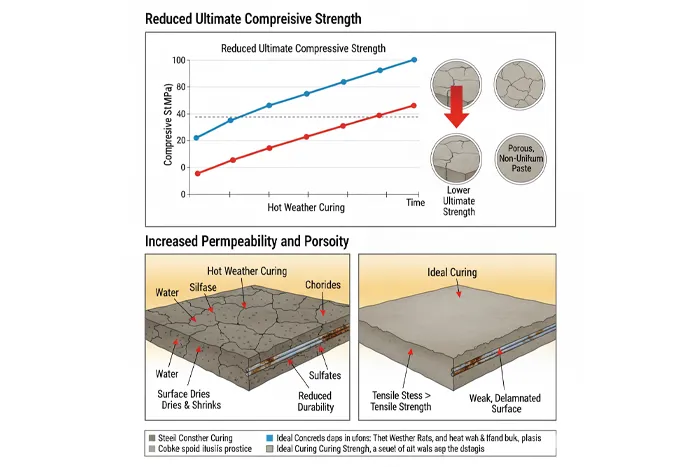

Reduced Ultimate Compressive Strength

While high temperatures can lead to higher early strength, they often result in lower ultimate strength. The accelerated hydration forms a less uniform and more porous cement paste structure, permanently limiting the concrete’s potential 28-day strength and beyond.

Increased Permeability and Porosity

The same poorly structured paste that reduces strength also increases the concrete’s permeability and porosity. This makes the concrete more susceptible to the ingress of water, chlorides, and sulfates, leading to rebar corrosion and significantly reduced durability.

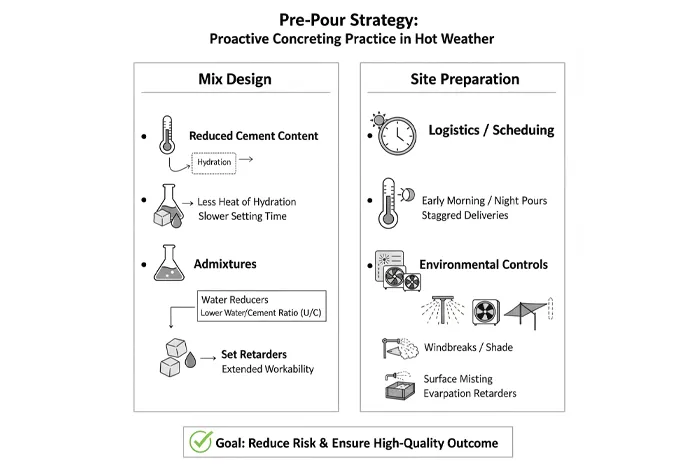

Pre-Pour Strategy: Proactive Concreting Practice in Hot Weather

The battle against hot weather is often won or lost before the first concrete truck ever arrives on site. A robust, proactive strategy is the most effective concreting practice in hot weather. This involves meticulous planning that considers every variable, from the chemical composition of the mix to the logistical coordination of the pour. This planning phase focuses on two primary goals: first, designing a mix that is inherently less sensitive to high temperatures, and second, preparing the site to be an ally, not an adversary, in the placement process. By anticipating challenges, project managers can implement controls that reduce risk and ensure a high-quality outcome.

Advanced Mix Design for Concreting Practice in Hot Weather

The concrete mix itself is the first line of defense. The goal is to design a mix with the lowest possible cement content and heat of hydration that still meets the project’s strength and durability requirements.

Selecting Cements with Lower Heat of Hydration

ASTM Type II (Moderate Heat) or Type IV (Low Heat) cements are preferable to the standard Type I. By generating less heat during hydration, they inherently slow the temperature rise within the concrete, which is especially critical for mass concrete placements.

The Role of Supplementary Cementitious Materials (SCMs)

Using SCMs like fly ash (Class F) or slag cement (GGBFS) as a partial replacement for an_portland cement is a cornerstone of concreting practice in hot weather. SCMs not only reduce the heat of hydration but also improve workability and significantly enhance long-term durability and impermeability.

Strategic Use of Chemical Admixtures

Modern chemical admixtures are essential tools for controlling concrete behavior in high temperatures. They provide the flexibility to modify the mix’s properties to counteract the effects of heat.

High-Range Water Reducers (Superplasticizers)

These admixtures allow for significant reductions in the water-cement ratio while maintaining or even increasing slump. This produces a high-strength, low-permeability concrete without the “stickiness” or risk of segregation associated with high-slump, high-water mixes.

Set-Retarding Admixtures

ASTM C494 Type B (retarding) or Type D (water-reducing and retarding) admixtures are critical. They chemically slow down the hydration process, providing the necessary time to transport, place, consolidate, and finish the concrete before it sets, thus mitigating the risk of cold joints.

Logistics and Site Preparation

On-site conditions must be controlled just as rigorously as the mix design. This means planning the pour around the environment and actively modifying the environment when possible.

Scheduling Pours for Cooler Periods (Night Concreting)

The most effective, and often simplest, strategy is to schedule pours during the cooler parts of the day, such as early morning or at night. This reduces the thermal gradient between the concrete and the ambient air, slows evaporation, and provides a much larger window for finishing.

Erecting Windbreaks and Sunshades

Active site modification is a key concreting practice in hot weather. Erecting temporary windbreaks (using barriers or netting) and sunshades (using tenting or tarps) can dramatically reduce the two biggest drivers of rapid evaporation: high wind speed and direct solar radiation.

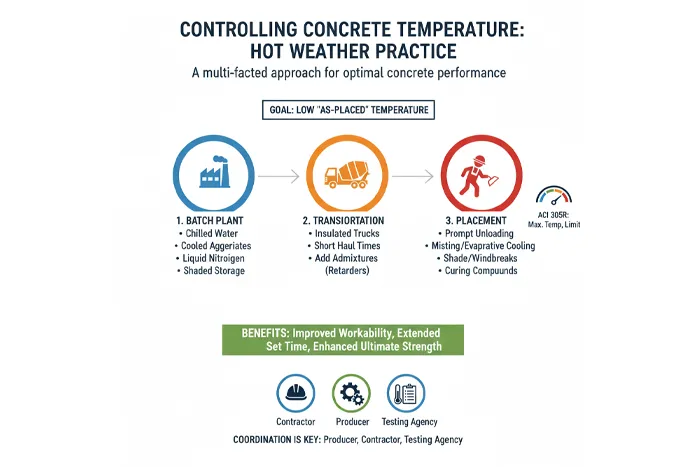

Controlling Concrete Temperature: The Core of Hot Weather Practice

The ultimate goal of a hot weather concreting plan is to control the concrete’s temperature at the point of placement. ACI 305R emphasizes the importance of a low “as-placed” temperature, as every degree reduction provides significant benefits in workability, set time, and ultimate strength. This requires a multi-faceted approach that starts at the batch plant and continues through transportation and placement. An effective concreting practice in hot weather is, at its core, a practice of thermal management, demanding coordination between the concrete producer, the contractor, and the testing agency to ensure the concrete is delivered and placed within the specified temperature limits.

Cooling Concrete Materials at the Batch Plant

The most efficient way to produce cool concrete is to cool its individual ingredients before mixing. The batch plant is the primary control point for concrete temperature, as it is far easier to cool aggregates or water than it is to cool the entire concrete mass.

Using Chilled Water or Ice Flakes

Water is the easiest and most effective component to cool. Using chilled water (below 5°C or 40°F) or, more effectively, substituting a portion of the mix water with flaked or crushed ice can dramatically lower the final concrete temperature. The heat of fusion absorbed by the melting ice provides a powerful cooling effect.

Shading and Sprinkling Aggregate Stockpiles

Aggregates, which make up the bulk of the concrete, store a massive amount of heat. Shading stockpiles from direct sun is a simple first step. A more active method is to use misting or sprinkler systems to wet the stockpiles, allowing evaporative cooling to lower the aggregate’s core temperature.

Liquid Nitrogen (LN2) Injection

For extreme conditions or stringent specifications, liquid nitrogen (LN2) can be injected into the concrete mix, typically in the mixer truck drum. This method provides powerful, instantaneous cooling, but it requires specialized equipment, safety protocols, and precise calibration to be effective.

Managing Temperature During Transport and Placement

Once the concrete is batched, the clock is ticking. The transportation and placement phase must be optimized to minimize heat gain and time delays.

Painting Mixer Drums White

A simple but effective measure is to ensure all transit mixer trucks have their drums painted white. A white, reflective surface can reduce the solar heat gain of the concrete during transit by a noticeable margin compared to a darker, heat-absorbing color.

Minimizing Transit and Waiting Times

Logistics are paramount. The plant and job site must be in constant communication to schedule truck dispatch, minimizing on-site waiting time. Every minute a truck waits in the sun, the concrete gets hotter, loses slump, and moves closer to setting.

The Role of Formwork in Temperature Management

Formwork and the surrounding reinforcement grid act as heat sinks, pulling moisture and heat from the fresh concrete. In hot weather, these elements must be managed to prevent them from “shocking” the mix or accelerating surface drying.

Pre-cooling Formwork and Rebar

Just before placement, the forms, rebar, and any subgrade should be cooled. This is typically done by fogging or misting them with cool water. This not-placing concrete against hot steel or dry ground is a recipe for flash setting and surface defects.

Utilizing Insulated or Cooled Formwork Systems

The type of formwork itself plays a role. Steel forms gain and transfer heat rapidly, while insulated formwork (ICF) or timber forms can help manage thermal differentials. Understanding the thermal properties of the shuttering in construction is a key part of an advanced hot weather plan.

Placement and Finishing: Techniques for High-Temperature Environments

The placement and finishing phase is where a well-planned concreting practice in hot weather is put to the test. This is a high-pressure operation that demands speed, efficiency, and a deep understanding of how the concrete will behave. With reduced workability and accelerated setting times, the window for error is virtually non-existent. The placement crew and finishing team must work in seamless coordination, backed by the right equipment and preparatory measures. The primary goals are to get the concrete in place quickly, consolidate it properly, and manage the surface evaporation rate to prevent plastic shrinkage cracking before the finishing operation can even begin.

Efficient Placement and Consolidation

Delays during placement are a primary cause of cold joints and finishing defects. The entire operation must be geared towards rapid, continuous, and efficient placement.

Ensuring Adequate Manpower and Equipment

This is not a time to be short-staffed. The project must have sufficient manpower, vibrators, and screeding equipment on hand to place, spread, and consolidate the concrete as fast as it is being discharged from the trucks. Any bottleneck will compromise the pour.

Rapid and Thorough Vibration

Consolidation is critical for achieving density and strength. In hot weather, it must be done immediately and thoroughly. Delayed vibration may be impossible as the concrete stiffens, leading to honeycombing and poor bond with reinforcement.

Managing the Evaporation Rate on-Site

This is arguably the most critical on-site activity during hot weather finishing. If the surface moisture evaporates faster than it is replenished by bleed water, plastic shrinkage cracking is inevitable.

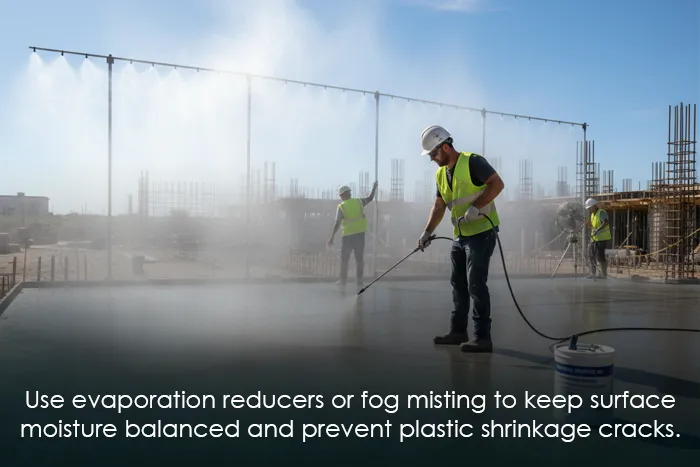

Applying Evaporation Reducers (Aliphatic Alcohols)

Also known as finishing aids, these materials are sprayed onto the surface immediately after screeding. They form a thin, monomolecular film that reduces the rate of evaporation, buying critical time for the finishers without affecting the concrete’s chemical set or final properties.

Fog Misting the Air Above the Slab

A fine fog mist sprayed into the air above (not onto) the slab can significantly increase the local humidity and reduce wind speed at the surface. This is a highly effective method for reducing evaporation, but it must be done carefully to avoid-spraying water directly onto the fresh concrete.

Finishing Operations Under Pressure

The finishers must be prepared for a mix that will stiffen much faster than normal. The window for floating and troweling will be short, and they must be ready to act the moment the concrete is ready.

Avoiding Premature Troweling

A common mistake is to begin trowel finishing too early, while bleed water is still present or trapped below a crusted surface. This can lead to delamination, “checking,” or scaling. Finishers must test the surface to ensure it is ready before sealing it with a trowel.

Preparing for Rapid Surface Stiffening

Given the accelerated set, finishers may need to get on the concrete sooner. This may require the use of knee boards or special finishing equipment. The key is to complete all floating and troweling operations before the concrete becomes unworkable.

Post-Placement: The Critical Curing Phase in Hot Weather

Once the last finisher has left the slab, the work is far from over. The curing phase is the final and most critical step in a successful concreting practice in hot weather. Curing is the process of maintaining adequate moisture and temperature in the concrete for a sufficient period to allow for proper hydration and strength gain. In hot weather, this process is under constant attack. High temperatures and dry air will pull moisture from the concrete at an astonishing rate, stopping hydration and causing shrinkage. An inadequate or delayed curing process will negate all the careful planning that came before it, resulting in a weak, cracked, and permeable final product.

The Curing Imperative in Concreting Practice in Hot Weather

Curing must begin immediately after finishing operations are complete. In some cases, such as with low-humidity and high-wind conditions, curing measures must be applied during the finishing process itself (e.g., fogging).

Why Curing Must Begin Instantly

The moment the concrete surface can withstand the application without being marred, curing must start. Even a delay of a few minutes can allow the surface to dry out, leading to crazing, reduced strength, and a “dusty” surface.

Water Curing Methods

Water curing is the “gold standard” as it provides 100% relative humidity and can also help cool the concrete surface. However, it must be done carefully to avoid causing “thermal shock.”

Ponding or Immersion

For flat surfaces like slabs and pavements, creating small temporary dams (ponds) or immersing the concrete in water is the most effective method. This ensures a continuous supply of moisture and helps dissipate heat.

Fogging and Sprinkling (Without Thermal Shock)

Misting or sprinkling the concrete can be effective, but the water must be applied continuously. Intermittent wetting and drying is more harmful than no curing at all. Critically, the curing water should not be more than 11°C (20°F) cooler than the concrete surface to prevent thermal shock and cracking.

Burlap, Cotton Mats, and Other Wet Coverings

Applying saturated burlap or cotton mats directly to the concrete surface and covering them with plastic sheeting is an excellent method. The coverings hold a large amount of water against the surface, and the plastic prevents it from evaporating.

Membrane-Forming Curing Compounds

When water curing is impractical, membrane-forming curing compounds (ASTM C309) are the next best option. These are liquid compounds sprayed onto the surface to form an impermeable film that locks in mix water.

White-Pigmented vs. Clear Compounds

In hot, sunny climates, white-pigmented compounds are essential. They reflect solar radiation, keeping the concrete surface cooler and reducing the thermal gradient. Clear compounds should be avoided as they can act like a greenhouse, trapping heat.

Application Rates and Timing

The compound must be applied at the manufacturer’s recommended rate (e.g., 3.5-5.0 m²/liter or 150-200 ft²/gallon). Applying too little will result in a weak, ineffective membrane. It must be applied immediately after the surface sheen has disappeared.

Managing Thermal Cracking in Mass Concrete

For large-scale placements (mass concrete), the challenge shifts from ambient heat to the concrete’s own internal heat of hydration. The core of the concrete can get extremely hot, while the surface cools, creating a large thermal differential.

Controlling the Thermal Differential

The primary rule in mass concrete is to control the temperature difference between the hot core and the cooling surface. This differential should generally be kept below 20°C (35°F) to prevent the surface from cracking under thermal stress.

Using Insulating Blankets Post-Curing

This may seem counter-intuitive, but a key concreting practice in hot weather for mass concrete is to insulate the concrete after it has set. By applying insulating blankets, the surface is allowed to cool slowly, in step with the core, thus managing the thermal differential and preventing cracking.

Checklist and Planning: A Framework for Successful Hot Weather Concreting

A pre-pour meeting is mandatory for any complex concreting practice in hot weather. This checklist, based on ACI 305R, should be reviewed by the project manager, concrete supplier, finishing contractor, and testing agency to ensure all parties are aligned.

Pre-Pour Planning and Preparation Checklist

- Environmental:

- [ ] Have 5-day weather forecasts (temp, humidity, wind) been obtained?

- [ ] Is there a “go/no-go” criteria based on the evaporation rate (nomograph)?

- [ ] Has the pour been scheduled for the coolest time of day (night/early AM)?

- [ ] Are sunshades and windbreaks procured and planned for erection?

- Mix Design & Materials:

- [ ] Is the mix design approved and optimized for hot weather (SCMs, low cement factor)?

- [ ] Are set-retarding and water-reducing admixtures specified?

- [ ] Are aggregates shaded and equipped with a misting/sprinkler system?

- [ ] Is a chilled water or ice-batching system in place and verified?

- [ ] Is a maximum concrete temperature at placement specified (e.g., 32°C / 90°F)?

- Site & Equipment:

- [ ] Are all forms, rebar, and subgrade to be pre-cooled (misted) before the pour?

- [ ] Is all equipment (pumps, vibrators, finishing tools) on-site and operational?

- [ ] Is there adequate manpower scheduled for rapid placement and finishing?

- [ ] Is backup equipment (e.g., spare vibrator) available?

During-Pour Execution and QC Checklist

- Logistics:

- [ ] Is dispatch in communication with the site to manage truck spacing and avoid delays?

- [ ] Are all trucks painting their drums white to reflect sun?

- [ ] Is a “maximum drum revolution” limit being enforced?

- Testing:

- [ ] Is the testing agency sampling and testing the first truck immediately upon arrival?

- [ ] Is concrete temperature, slump, and air content being tested for every truck?

- [ ] Is on-site addition of water strictly prohibited (unless part of a verified slump-management plan)?

- Placement & Finishing:

- [ ] Is concrete being placed and consolidated rapidly?

- [ ] Is an evaporation reducer (finishing aid) being applied as needed?

- [ ] Are fog misters in place and operational?

Post-Pour Curing and Protection Checklist

- Curing:

- [ ] Is the specified curing method (water, blankets, compound) ready to be applied immediately?

- [ ] If using water, is the water temperature controlled to prevent thermal shock?

- [ ] If using compound, is it white-pigmented and is the spray equipment ready?

- Protection & Monitoring:

- [ ] Are thermal blankets (for mass concrete) or plastic sheeting available?

- [ ] Are temperature sensors (for mass concrete) in place to monitor core vs. surface differential?

- [ ] Are facilities for proper curing of test cylinders (e.g., “hot box” or water bath) prepared?

Table: ACI 305R Recommendations vs. Standard Practice

This table illustrates the critical differences between a standard, temperate-climate approach and the rigorous concreting practice in hot weather recommended by ACI 305R. Adhering to these recommendations is essential for project success.

| Parameter | Standard (Temperate) Practice | Expert Hot Weather Practice (ACI 305R) |

|---|---|---|

| Concrete Temperature | Typically < 27°C (80°F). Often not specified. | Strictly controlled. Max placement temp specified (e.g., 32°C / 90°F). Active cooling (ice, LN2) required. |

| Evaporation Rate | Monitored only in extreme cases. | Actively monitored. If rate exceeds 1.0 kg/m²/hr (0.2 lb/ft²/hr), proactive measures (fogging, windbreaks) are mandatory. |

| Mix Design | Standard Type I cement. Admixtures used for strength. | Type II/IV cement + SCMs (fly ash, slag). Retarding and water-reducing admixtures are essential. |

| Curing Initiation | Can be delayed 1-2 hours after finishing. | Immediate. Must begin the instant the surface is ready. Evaporation reducers used before final set. |

| Curing Method | Often a single-application clear curing compound. | Continuous water curing (ponding, fogging) for 7 days is preferred. If not possible, a white-pigmented compound is mandatory. |

| Site Prep | Subgrade and forms are placed dry. | Subgrade, rebar, and forms are pre-cooled with water to prevent wicking moisture and heat shock from the mix. |

| Pour Scheduling | During standard work hours. | Pours are scheduled for night or early morning to avoid peak heat, sun, and wind. |

Case Study: Concreting Practice in Hot Weather on a Landmark Project

A proactive concreting practice in hot weather is not theoretical; it is the standard operating procedure for any significant project in a challenging climate. This case study, based on common practices for landmark structures, demonstrates an integrated strategy.

The Project: Mass Concrete Foundation for a Super-tall Tower

Consider a 4-meter (13-foot) thick mat foundation for a skyscraper in a desert climate like Dubai or Riyadh, where daytime ambient temperatures regularly exceed 45°C (113°F). The total concrete volume is 15,000 cubic meters, requiring a continuous 24-hour pour.

The Challenge: Extreme Ambient Heat and Mass Concrete Thermals

The project faced a dual challenge: 1) Extreme ambient heat accelerating the set time of fresh concrete during placement, and 2) The massive internal heat of hydration from the thick foundation, which could lead to delayed etrringite formation (DEF) and catastrophic thermal cracking.

The Solution: An Integrated Hot Weather Strategy

A multi-stage concreting practice in hot weather was designed, treating the concrete like a temperature-sensitive patient.

Mix Design and Material Cooling

The mix design replaced 60% of the Portland cement with fly ash and slag to drastically reduce the heat of hydration. All mix water was batched as flaked ice, and aggregates were stored in shaded, misted bins. The target placement temperature was a strict 28°C (82°F).

Advanced Formwork and Placement

The pour was conducted continuously over 24 hours. To manage the thermal differentials, the Steel Column Shuttering and perimeter forms for the foundation were heavily insulated to keep the surface temperature high, matching the core. For the tower’s vertical elements, a self climbing formwork system was chosen to ensure rapid, systematic, and safe construction cycles, minimizing the time fresh concrete was exposed.

Real-time Temperature Monitoring

A grid of over 100 thermal sensors was embedded within the foundation. These sensors provided real-time data on the core temperature and the core-to-surface differential, allowing engineers to manage the curing process dynamically.

The Result: Long-Term Durability Achieved

By chilling the concrete at the plant and then insulating the forms to allow for a slow, uniform cooling process, the team successfully kept the thermal differential below the 20°C (35°F) limit. This proactive strategy prevented thermal cracking and ensured the foundation achieved its design strength and 100-year service life.

The Role of Advanced Formwork in Hot Weather Concreting

In any large-scale project, the formwork system is intrinsically linked to the concreting practice in hot weather. Modern formwork is far more than just a mold; it is a critical piece of engineering that influences placement speed, safety, and thermal management. For a specialized partner with expertise in complex, large-scale projects, consulting with industry leaders like tunnel lining formwork suppliers becomes essential. These systems are designed to perform under the extreme pressures—both physical and thermal—of demanding projects.

Formwork as a Thermal Control Tool

The material and design of the formwork system directly impact the concrete’s temperature profile. This is a critical consideration in both hot and cold weather.

Insulating Properties of Modern Formwork

Formwork systems that incorporate insulating materials (like timber or specialized composites) can be used to protect the concrete from extreme ambient heat. Conversely, as seen in the case study, they can also be used to retain the concrete’s internal heat, ensuring a slow and steady cooling process for mass placements.

Using Steel Column Shuttering in High-Heat

Steel forms, like advanced Steel Column Shuttering, are highly conductive. In hot weather, this means they must be cooled (misted) immediately before placement. However, their robustness and reusability make them ideal for fast-paced vertical construction, where speed is essential to managing a hot weather pour.

Efficiency in Large-Scale Pours

The speed and efficiency of the formwork system are critical. A system that is slow to cycle adds delays, increasing the risk of cold joints and placing undue stress on the entire operation.

The Speed of Self Climbing Formwork Systems

For high-rise buildings, a self climbing formwork system is a non-negotiable component of an efficient hot weather strategy. These systems can be cycled quickly, allowing for systematic, rapid-sequence pours that are planned for the coolest parts of the day, ensuring consistency and quality floor after floor.

Ensuring Quality in Tunnel Lining Formwork

In subterranean projects, heat and humidity can be trapped, creating an extreme microclimate. Specialized formwork from expert tunnel lining formwork suppliers is designed for these unique conditions, facilitating rapid, monolithic placements that are essential for watertight, durable structures.

Conclusion: Elevating Standards for Concreting in Arid and Tropical Climates

A successful concreting practice in hot weather is a complex but achievable endeavor. It requires a fundamental shift away from “business as usual” and towards a proactive, scientific, and integrated approach. There is no single solution; success lies in a combination of strategies: an advanced mix design, aggressive thermal controls, meticulous site preparation, and rapid-response placement and curing. For contractors and engineers, mastering these techniques is not just about meeting specifications—it’s about ensuring the safety, durability, and resilience of the structures that define our modern landscape.

A Call for Proactive Quality Control

Ultimately, success depends on a vigilant and empowered quality control team. Real-time monitoring of weather, material temperatures, and on-site evaporation rates must be non-negotiable, with the authority to halt a pour if conditions move outside the carefully defined parameters.

The Future of Hot Weather Concreting

As global temperatures rise and development pushes into more arid regions, this specialized knowledge will only become more critical. The future of construction will rely on smart materials, advanced sensor technology, and the deep expertise of engineering partners like bfs industries who understand how to build durable structures in the most challenging environments.

Frequently Asked Questions (FAQs) About Concreting Practice in Hot Weather

H3: What is the maximum safe concrete temperature at placement?

While many specifications set a “not-to-exceed” limit, such as 32°C or 35°C (90°F or 95°F), there is no single magic number. The ACI 305R guide emphasizes performance over a single temperature, as a 35°C placement may be acceptable with a highly retarded mix, while a 30°C placement could fail in high winds. The best concreting practice in hot weather is to have a limit, but back it up with a full mitigation plan.

H3: How does wind speed affect concreting in hot weather?

Wind is often more dangerous than high temperature. It dramatically accelerates the rate of surface evaporation. A 20 mph (32 km/h) wind can quadruple the evaporation rate compared to a calm day, even if the temperature is only moderately high. This is why windbreaks are a critical part of a hot weather concreting plan.

H3: Can I just add more water to the mix on-site if it’s too stiff?

No. This is the most common and most damaging mistake. Adding unauthorized water on-site (known as re-tempering) destroys the mix’s water-cement ratio. It will increase workability for a few minutes but permanently reduces strength, increases shrinkage and cracking, and drastically lowers durability. A proper concreting practice in hot weather uses admixtures (retarders and superplasticizers) to manage workability, not just water.

H3: What is the most critical step in hot weather concreting?

While all steps are linked, most experts would point to curing. A perfect mix, perfectly placed, can be completely ruined by delayed or improper curing. In hot weather, curing is not an afterthought; it must begin immediately after finishing to lock in the moisture needed for hydration and to prevent shrinkage cracking.

H3: How long do I need to cure concrete in hot weather?

Because high temperatures can accelerate strength gain, some believe curing can be shorter. This is false. To achieve long-term durability and density, concrete should be cured for a minimum of 7 days. Because the environment is so aggressive, a 7-day continuous water cure (fogging, ponding, or wet burlap) is the gold standard for any critical hot weather concrete.