- Published:

- Written by: B.F.S Industries

Shuttering in Construction: Complete Guide to Formwork Systems

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

Shuttering in construction, also known as formwork, is essential for shaping and supporting freshly poured concrete until it hardens. Proper shuttering ensures concrete structures achieve the right shape, strength, and surface quality. High-quality formwork not only enhances structural stability and aesthetics but also reduces material waste and labor costs.

Shuttering is used across a wide range of projects—from residential foundations, slabs, and walls to complex commercial and industrial structures like curved facades or large-span beams. Infrastructure developments, including tunnels, highways, and bridges, rely on specialized formwork for precise concrete casting.

For reliable shuttering solutions, construction professionals often turn to trusted providers like B.F.S Industries, offering durable and reusable formwork systems suitable for projects of any scale.

This podcast Shuttering in Construction

Types of Shuttering in Construction

Shuttering in construction comes in a variety of forms, each specifically designed to address the unique requirements of a project, including its scale, budget, and site conditions. Selecting the right type of formwork not only improves construction productivity but also ensures structural accuracy, reduces material waste, and lowers labor costs. Different projects demand different solutions, and understanding the characteristics of each type is essential for achieving high-quality concrete structures.

Among the most common types are slab formwork, used to support horizontal concrete elements; wall formwork, designed for vertical surfaces; and Concrete Column Formwork, which is specifically shaped to create strong, precise vertical columns that form the backbone of many structures. Each of these formwork systems comes with its own set of advantages and limitations. For example, slab formwork allows for efficient large-area coverage but may require additional support for long spans. Wall formwork ensures smooth vertical finishes but can be labor-intensive to assemble. Column formwork, on the other hand, provides precise shaping for vertical load-bearing elements, is often modular for reuse across multiple columns, and plays a critical role in maintaining the stability and alignment of the entire structure.

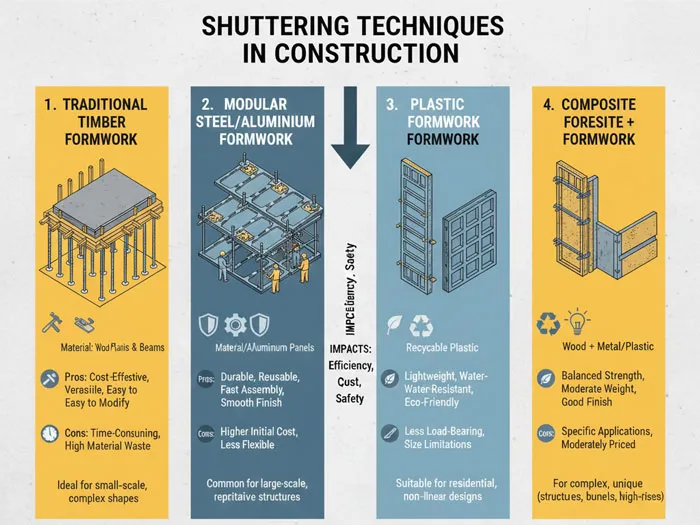

Timber Shuttering

Timber shuttering, one of the oldest and most traditional forms of formwork, uses wood materials such as plywood, planks, or battens to create molds for concrete casting. Its high adaptability allows on-site fabrication for irregular or custom shapes, making it particularly suitable for small-scale projects such as residential foundations, low-rise buildings, and minor infrastructure works. Timber formwork is widely appreciated for its affordability, ease of handling, and accessibility in areas where advanced materials or specialized equipment may not be available.

The advantages of timber shuttering include its flexibility for complex geometries and its natural insulation properties during the concrete curing process, which can improve the final quality of the surface. However, it has some limitations: timber formwork typically offers limited reusability—around 5 to 10 cycles—and is sensitive to moisture, which can lead to warping, swelling, or reduced durability. To maximize its lifespan and achieve smooth, defect-free finishes, best practices recommend using treated plywood along with proper release agents and careful maintenance.

For instance, in rural or resource-limited construction sites, timber shuttering remains a reliable and cost-effective choice due to its widespread availability and simplicity in on-site assembly, proving that even traditional methods continue to play a vital role in modern construction.

Steel Formwork

Steel formwork offers a robust and highly durable alternative to traditional timber shuttering. Constructed from steel plates, angles, and channels, it is particularly suited for large-scale projects requiring high precision, such as bridges, industrial facilities, and multi-story commercial buildings. Steel formwork provides excellent strength, dimensional stability, and consistency in concrete finishes, making it a preferred choice for demanding construction tasks.

Key advantages of steel shuttering include long-term durability, often allowing for 100 or more reuses, resistance to deformation under heavy loads, and the ability to achieve smooth surface finishes, reducing the need for additional plastering or surface treatment. However, steel formwork also comes with drawbacks, including higher initial costs and significant weight, which often requires cranes or mechanical assistance for installation.

In practical applications, steel shuttering is especially effective in repetitive tasks such as column formwork, where quick assembly using clamps or modular systems can significantly accelerate construction cycles. Additionally, the use of reusable formwork not only enhances efficiency but also provides economic benefits over the lifespan of the project, offsetting the initial investment with repeated usage.

Aluminium Formwork

Aluminium formwork combines lightweight properties with high strength, making it particularly suitable for high-rise and fast-paced construction projects. The panels, extruded from durable aluminium alloys, are often pre-assembled into modular systems, allowing for quick installation and consistent concrete finishes.

The key advantages of aluminium shuttering include corrosion resistance, rapid erection—up to 4-5 times faster than traditional timber formwork—and excellent reusability, often exceeding 200 cycles. It is especially effective for monolithic casting of walls and slabs, minimizing joints and improving structural performance in seismic zones. Aluminium systems are also widely used for Rectangular Column Formwork Systems providing precise shaping and alignment for vertical load-bearing elements in multi-story buildings.

Despite its benefits, aluminium formwork does have challenges. The initial investment is higher than timber, and the panels are sensitive to impacts, which can cause dents or surface damage if not handled properly. Nonetheless, contractors in urban developments often prefer aluminium due to its labor-saving attributes, faster cycle times, and reliability—particularly in projects such as multi-story apartment complexes, where floor construction can be completed in as little as 4-5 days per level.

Plastic and Composite Formwork

Plastic and composite formwork has emerged as an innovative solution in modern construction, utilizing materials such as fiberglass-reinforced plastics or recycled composites to create lightweight, durable molds. These systems are particularly suited for curved or intricate designs, making them ideal for architectural features, decorative walls, and specialized infrastructure projects such as marine structures.

Key advantages of plastic and composite formwork include excellent weather resistance, ease of cleaning, and environmental sustainability through recyclability. These systems also reduce handling effort on-site due to their lightweight nature, while maintaining a smooth finish for concrete surfaces. However, their limitations include lower load-bearing capacity compared to metal formwork, which restricts their use in heavy-duty applications.

To overcome these challenges, best practices often involve hybrid setups, combining plastic or composite panels with steel supports to create a stable and reliable wall formwork system. This approach ensures the precision and strength required for vertical concrete elements while leveraging the benefits of lightweight, reusable materials. As a result, contractors can achieve complex wall designs efficiently, without compromising on structural performance or surface quality.

Modular and Prefabricated Systems

Modular and prefabricated shuttering systems utilize pre-engineered panels that snap together, typically made from steel, aluminium, or composite materials. These systems are transforming shuttering in construction, particularly for large-scale projects such as stadiums, airports, and multi-story commercial complexes.

Key benefits include faster assembly, high precision, and reduced on-site labor—construction cycles can be up to 70% quicker than traditional methods. The modular design also promotes reusability and minimizes material waste, supporting sustainable construction practices. Additionally, precise planning of the shuttering removal time ensures that concrete achieves sufficient strength before formwork is removed, maintaining both safety and structural quality.

Despite these advantages, challenges include higher initial design complexity and transportation costs for large panels. Practical examples include table formwork for slabs, where entire units are lifted and repositioned between floors, optimizing efficiency in high-rise projects. In summary, selecting the appropriate shuttering type depends on factors such as project scale, budget, environmental conditions, and the required speed of construction. Hybrid approaches, blending traditional and modern formwork systems, often deliver the best balance of performance, cost-efficiency, and structural integrity.

Components of a Shuttering System

A shuttering system in construction consists of a series of interconnected components that work together to support freshly poured concrete until it gains sufficient strength. Understanding these elements is crucial for ensuring reliable formwork assembly, preventing structural failures, and enhancing overall construction efficiency.

Key components typically include panels (such as timber, steel, aluminium, or composite), supporting frames, props, clamps, ties, and accessories that hold the panels in precise alignment. Each element plays a vital role: panels shape the concrete, props and frames provide stability, and ties or clamps maintain the correct spacing and structural integrity. Proper integration of these components not only guarantees safety but also accelerates construction cycles, reduces material waste, and contributes to high-quality concrete finishes.

Panels and Boards

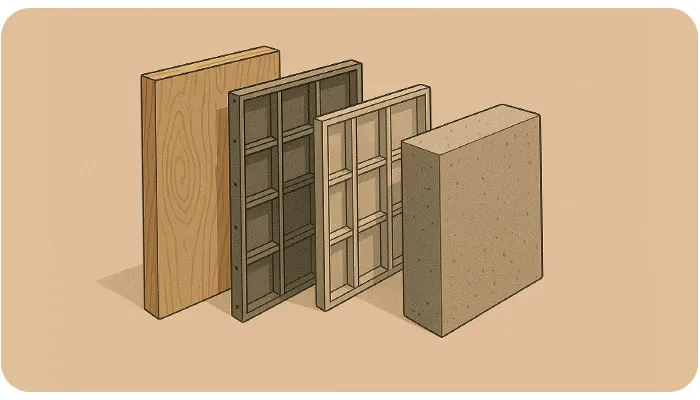

Panels and boards are the primary components in any shuttering system, forming the direct contact surface with concrete and determining the final shape, texture, and finish. They can be made from plywood, steel, aluminium, or plastic, depending on the project requirements and formwork type. To perform effectively, panels must be rigid and strong enough to withstand concrete pressure without deflection, ensuring dimensional accuracy and structural consistency.

In modular formwork system, panels often interlock via pins or connectors, reducing seams and improving alignment. Best practices include applying form release oils or agents to prevent concrete adhesion and achieve smooth demolding. As essential formwork components, panels play a critical role in shaping structural elements such as beams, walls, slabs, and rectangular column formwork, maintaining precise geometry and high-quality finishes across the structure.

Supports, Props, and Clamps

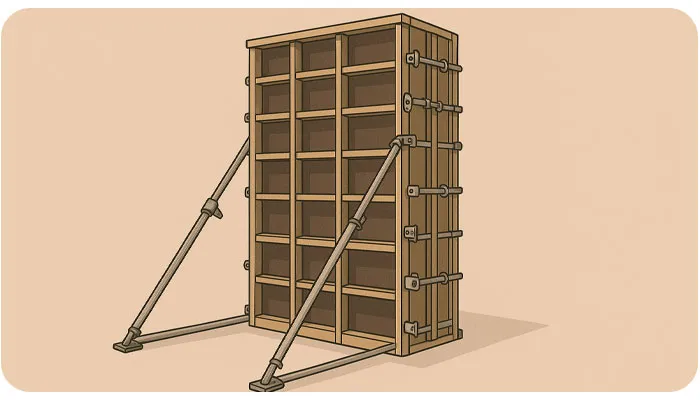

Supports, including vertical props and diagonal braces, are critical components of a shuttering system, providing stability against both lateral and vertical loads during concrete casting. Adjustable steel props allow precise height customization, accommodating different slab thicknesses and project requirements, while clamps and fasteners secure joints between panels and frames to maintain alignment.

In high-load scenarios, such as slab or beam casting, props are typically spaced at 1–2 meters to evenly distribute the concrete weight and prevent deflection or structural failure. Proper planning and adherence to engineering load calculations are essential, as overloading can compromise safety and damage formwork components.

Ties and Fasteners

Ties and fasteners anchor the system, preventing outward bulging. Types include tie rods with nuts or snap ties that break off post-curing. They ensure watertight seals, minimizing leakage. Incorporating concrete reinforcement ties into the design integrates shuttering with rebar, boosting structural integrity.

Overall, a well-coordinated shuttering system minimizes defects, with regular inspections ensuring component integrity.

Materials Used in Shuttering

Material selection in shuttering in construction plays a crucial role in determining the durability, cost-efficiency, and environmental impact of a project. Choosing the right materials ensures that the formwork can withstand concrete pressures, support repeated use, and maintain dimensional accuracy while optimizing labor and resource utilization. Key options for shuttering materials balance factors such as strength, weight, reusability, and sustainability, making informed selection essential for achieving both structural integrity and economic efficiency in modern construction projects.

Timber, Plywood, Laminates

Timber and plywood remain the most commonly used materials in traditional formwork, primarily due to their cost-effectiveness, ease of handling, and wide availability. Marine-grade plywood offers excellent resistance to moisture, making it suitable for outdoor and high-humidity applications, while laminated plywood adds protective layers to achieve smoother concrete finishes and reduce surface imperfections.

Shuttering Material List: A Complete Guide for Construction Projects

Key advantages of timber and plywood include ease of cutting, nailing, and on-site customization, which makes them ideal for irregular shapes or smaller-scale projects. However, untreated wood is prone to biodegradation over time, reducing its reusability. For enhanced durability and multiple uses, phenolic-coated plywood is often employed, extending the lifespan of formwork panels to 20 or more cycles while maintaining consistent surface quality.

Steel and Aluminium

Steel formwork provides exceptional strength and stability, making it ideal for heavy-duty construction applications such as multi-story buildings, bridges, and industrial structures. Galvanized or coated steel panels resist rust and corrosion, ensuring long-term durability and consistent concrete finishes. Steel formwork also allows for multiple reuses, making it a cost-effective and sustainable option over large projects.

Aluminium formwork, on the other hand, combines high strength with lightweight properties, significantly reducing handling and labor efforts, which is particularly advantageous for overhead or multi-level construction. Aluminium panels are also highly reusable, often exceeding 200 cycles, and deliver precise, smooth concrete finishes. Both steel and aluminium support modern wall formwork systems, rectangular column formwork, and other structural elements, offering an optimal balance of strength, reusability, and environmental sustainability in contemporary construction projects.

Plastic / Composite Materials

Plastic and composite materials have become increasingly popular in modern shuttering due to their lightweight, durable, and eco-friendly properties. Plastics such as PVC (Polyvinyl Chloride) or GRP (Glass Reinforced Plastic) offer excellent chemical resistance and facilitate easy demolding, reducing labor effort and speeding up construction cycles.

Composite formwork panels combine fibers and resins to enhance toughness, impact resistance, and long-term durability. Their lightweight nature makes handling and installation more efficient, while their reusability supports sustainable construction practices and minimizes material waste.

Shuttering Techniques in Construction

Shuttering techniques play a pivotal role in determining both the efficiency and quality of concrete casting. The method chosen influences construction speed, labor requirements, structural accuracy, and surface finish. Each shuttering technique is designed to meet specific project demands, taking into account factors such as structural complexity, load-bearing requirements, site conditions, and available resources.

From traditional timber frameworks to advanced modular, aluminium, composite systems, and even special formwork in construction used for highly complex or customized structural elements, proper implementation of shuttering techniques ensures uniform concrete distribution, prevents deformation or bulging, and optimizes shuttering removal time for safe and timely stripping. Selecting the right technique not only improves construction efficiency but also enhances durability, minimizes material waste, and contributes to sustainable practices, making it a cornerstone of modern concrete construction.

Traditional Casting Method

Traditional casting methods involve assembling static formwork, pouring concrete, and allowing it to cure fully before stripping the molds. This method is particularly suitable for simple or small-scale structures, where precision and detailed inspections are required. One of its key advantages is the ability to monitor each stage of casting closely, ensuring proper alignment, reinforcement placement, and surface quality.

In larger structural elements, such as columns, Steel Column Shuttering can be integrated into traditional casting methods to provide enhanced strength, stability, and reusability. Using steel formwork for columns allows for better dimensional accuracy and smoother finishes, while still benefiting from the controlled, step-by-step approach of traditional casting. Although effective, this method is time-intensive compared to modern modular or prefabricated techniques, requiring careful planning of shuttering removal time to maintain structural integrity and safety.

Slip Forming

Slip forming is a technique that enables continuous vertical casting, where the formwork gradually “slips” upward as the concrete sets and gains sufficient strength. This method is widely used for constructing tall, uniform structures such as silos, chimneys, or high-rise cores, and it can accelerate vertical construction by 1–2 meters per day, significantly improving project timelines.

Effective slip forming relies on precise control of concrete hydration and setting times to prevent cold joints or structural weaknesses. Additionally, Shoring Scaffolding Systems are often integrated to provide temporary support and stability for both the formwork and workers during the continuous casting process. By combining slip forming with well-planned shoring scaffolds, construction teams can achieve safe, efficient, and high-quality vertical structures without interruptions.

Flying Formwork

Flying formwork, also known as table formwork, involves large pre-assembled panels or units that are lifted by cranes and moved between floors during construction. This method is particularly advantageous for high-rise buildings and projects with repetitive slab layouts, as it allows entire sections of slab formwork to be repositioned quickly without disassembly.

By minimizing manual assembly and disassembly, flying formwork significantly reduces cycle times, enhances construction efficiency, and maintains uniform quality across multiple floors. It also ensures precise alignment of structural elements, reduces labor costs, and improves safety by limiting on-site handling. Widely used in skyscrapers, commercial towers, and multi-story residential complexes, flying formwork integrates seamlessly with shoring scaffolding systems to provide temporary support during lifting and positioning, delivering both speed and reliability in modern vertical construction.

Climbing Formwork

Climbing systems, also known as Climbing Formwork System, are advanced shuttering solutions that autonomously ascend using hydraulic jacks or mechanical mechanisms. They are particularly suited for constructing tall vertical elements such as core walls, elevator shafts, and shear walls in high-rise buildings.

By self-ascending, these systems minimize the need for manual repositioning, enhancing on-site safety and reducing labor-intensive operations. Climbing formwork ensures precise alignment, uniform concrete surfaces, and consistent structural quality throughout the height of the building. Additionally, they significantly improve construction efficiency by maintaining continuous casting cycles and shortening project timelines, making them an indispensable choice for modern high-rise construction projects.

Advantages of Modern Shuttering Systems

Shuttering in construction has advanced with modern formwork systems like modular, aluminium, steel, and composite panels, offering higher efficiency and quality than traditional methods. Key advantages include speed and productivity, as pre-assembled systems allow quick installation and dismantling, ideal for high-rise buildings and repetitive elements. Precision and quality improve with uniform surfaces and accurate dimensions, exemplified by rectangular column formwork and wall formwork systems.

Reusability and sustainability are also notable, as steel, aluminium, and composite panels can be reused multiple times, reducing waste and labor. Lightweight materials further enhance safety and ease handling. Additionally, Slip Formwork Construction has become essential for continuous vertical structures such as silos, cores, and towers, enabling uninterrupted casting and significantly accelerating project timelines. Overall, modern shuttering boosts efficiency, safety, and cost-effectiveness while ensuring consistent high-quality concrete finishes.

Common Challenges and Solutions in Shuttering

Challenges in shuttering in construction arise from factors such as complex project designs, high structural loads, site constraints, material limitations, and tight schedules. These challenges can lead to issues like misalignment, concrete leakage, surface defects, and delays if not addressed properly. Proactive planning, careful selection of materials and techniques, and adherence to engineering standards are essential to overcome these obstacles and ensure safe, efficient, and high-quality concrete construction.

-

Complex project designs – Difficult geometries requiring custom formwork solutions.

-

High structural loads – Risk of deformation or failure if formwork is insufficient.

-

Site constraints – Limited space, accessibility, or environmental restrictions.

-

Material limitations – Durability, reusability, or weight of formwork affecting efficiency.

-

Labor and skill availability – Shortage of trained workers may slow installation.

-

Time constraints – Tight schedules impacting curing and shuttering removal.

-

Concrete quality issues – Leakage, honeycombing, or uneven surfaces.

-

Safety concerns – Risks during installation, handling, or dismantling of formwork.

-

Environmental factors – Weather conditions affecting material performance and concrete curing.

-

Coordination with other trades – Misalignment with reinforcement, MEP, or finishing work.

Conclusion

Shuttering in construction is a cornerstone of modern concrete construction, directly impacting structural quality, efficiency, and safety. From traditional timber formworks to advanced steel, aluminium, plastic, and modular systems, the right shuttering solution enhances precision, reduces labor, and supports sustainable practices.

While challenges such as complex designs, high loads, site constraints, and safety concerns exist, proactive planning, careful material selection, and adherence to engineering standards can overcome these obstacles. Modern shuttering techniques, including flying, slip, climbing, and modular systems, offer faster, safer, and more cost-effective construction, making them essential for both small-scale projects and high-rise developments.

Ultimately, leveraging appropriate shuttering systems ensures durable, high-quality concrete structures, optimized project timelines, and safer work environments, solidifying its role as a critical component of successful construction management.