- Published:

- Written by: B.F.S Industries

Shuttering Material List: A Complete Guide for Construction Projects

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

In the construction industry, shuttering—also referred to as formwork—is an essential technique for shaping concrete into precise structural elements such as walls, columns, slabs, and bridges. A well-prepared shuttering material list is crucial for ensuring accuracy, safety, and efficiency on site. These materials range from traditional timber and plywood to advanced steel, aluminum, and modular panel systems, each offering distinct performance characteristics that directly impact project quality, cost, and productivity.

At BFS Industries, we specialize in supplying high-quality concrete slab formwork systems and shuttering systems designed to meet the demanding requirements of professional contractors. By understanding the strengths and limitations of each material, construction teams can select solutions that balance durability, reusability, and budget.

This guide provides an in-depth look at the most widely used shuttering materials, their applications, key advantages, potential drawbacks, and proven best practices for selection and maintenance—helping both industry experts and serious project planners achieve optimal results from start to finish.

This podcast Shuttering Material List

What Is Shuttering in Construction?

In today’s competitive construction industry, precision, durability, and efficiency are non-negotiable. Shuttering—also known as formwork—forms the backbone of quality concrete work, shaping structures such as slabs, walls, bridges, and Concrete Column Formwork for high-rise buildings. The right system not only ensures structural accuracy but also impacts project timelines, safety, and overall cost-effectiveness.

At BFS Industries, we deliver advanced slab formwork, shuttering systems, and customized solutions designed for professional contractors who demand performance without compromise. From preparing a complete shuttering material list to choosing between timber, aluminum, or steel panels, we guide our clients toward options that maximize reusability, minimize labor time, and deliver a flawless concrete finish. Whether you’re planning a large-scale infrastructure project or a high-precision commercial build, our expertise ensures your formwork system works as hard as you do.

Definition and Purpose of Shuttering

Shuttering, a key element of the formwork process, acts as a temporary mold that supports and shapes freshly poured concrete until it hardens and develops the strength to stand on its own. This system ensures the concrete attains the precise dimensions, structural integrity, and smooth surface finish required for both safety and visual appeal. Properly installed shuttering not only prevents cracks, warping, and surface irregularities but also guarantees long-term durability. Inadequate or poorly executed shuttering, on the other hand, can result in costly repairs, safety hazards, and compromised structural performance.

Difference Between Shuttering and Formwork

While often used interchangeably, shuttering and formwork have subtle differences. Shuttering generally refers to vertical molds used for constructing elements like walls and columns, whereas formwork is a broader term that includes all types of temporary molds, including horizontal ones for slabs and beams. In practice, both terms are commonly used to describe the same process, but recognizing this distinction is useful—especially when discussing topics such as Shuttering Removal Time, which directly relates to how long these molds remain in place before being safely dismantled.

Common Applications in Building Projects

Shuttering plays a crucial role in a wide range of construction applications, from laying the foundations that provide a stable base for buildings to shaping walls that form the vertical framework of a structure. It is essential for creating strong, load-bearing columns, as well as forming horizontal elements like beams and slabs that support floors and roofs. In more intricate architectural designs, shuttering enables the construction of staircases, arches, and domes, ensuring precision and structural integrity. Each of these applications may require different materials, chosen carefully based on factors such as load capacity, project scale, and environmental conditions.

Importance of Choosing the Right Shuttering Material

Choosing the right shuttering material is a critical decision that can greatly influence the quality, efficiency, and cost-effectiveness of any construction project. The material you select not only determines the structural integrity and finish of the concrete but also affects installation speed, durability, and overall project timeline. From ensuring precise dimensions to withstanding environmental challenges, the choice of shuttering plays a direct role in achieving successful outcomes. Here’s why this decision matters so much:

Impact on Structural Quality

The choice of shuttering material plays a crucial role in determining both the surface finish and the structural strength of concrete elements. High-quality formwork materials ensure precise shaping and uniform curing, which contribute to optimal load-bearing capacity and long-term durability of the construction. Conversely, using substandard or inappropriate shuttering materials often results in common defects such as honeycombing—characterized by voids or air pockets within the concrete—misalignment of structural components, and surface irregularities including roughness or cracks. These issues not only compromise the aesthetic appeal but can also undermine the integrity of the structure, leading to premature deterioration, safety risks, and significant repair costs. Therefore, selecting durable, dimensionally stable, and properly treated shuttering materials is essential to achieving high-performance concrete structures that comply with engineering standards and extend the lifespan of the project.

Time Efficiency in Project Completion

Using efficient shuttering materials significantly shortens construction timelines. Materials such as steel and aluminum, known for their ease of assembly and disassembly, enable rapid formwork cycles. This speed is especially vital in large-scale projects where meeting tight deadlines is crucial. By facilitating quicker setup and removal, these materials not only enhance productivity but also reduce labor costs and minimize project delays, ultimately contributing to more streamlined and cost-effective construction processes.

Safety Considerations

Shuttering materials must be robust enough to withstand the intense pressure exerted by wet concrete as well as any additional construction loads during the curing process. Using inadequate or substandard materials can compromise the formwork’s strength, leading to potential safety hazards like structural collapses or failures. Such incidents not only put workers at risk but also threaten the overall integrity and success of the construction project, causing costly delays and repairs.

Shuttering Material List (Names, Types & Images)

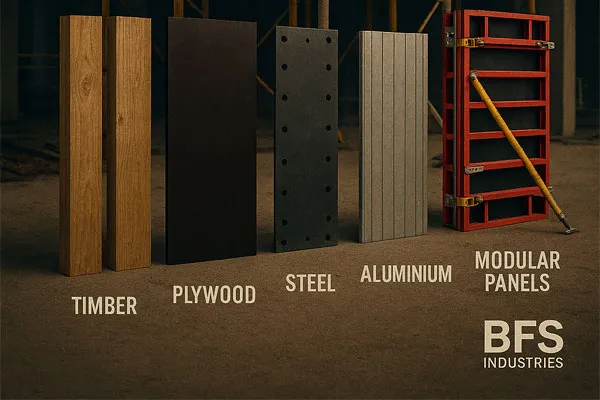

The list of shuttering materials encompasses a variety of options, each tailored to meet specific project requirements and conditions. The main materials commonly used include timber and plywood, known for their ease of use and cost-effectiveness in smaller projects; steel, valued for its durability and reusability in large-scale constructions; aluminum, appreciated for its lightweight and corrosion resistance; plastic, favored for sustainability and insulation properties; and composite materials that combine the strengths of different substances to optimize performance. Selecting the right material depends on factors such as load capacity, project scale, environmental conditions, and budget constraints.

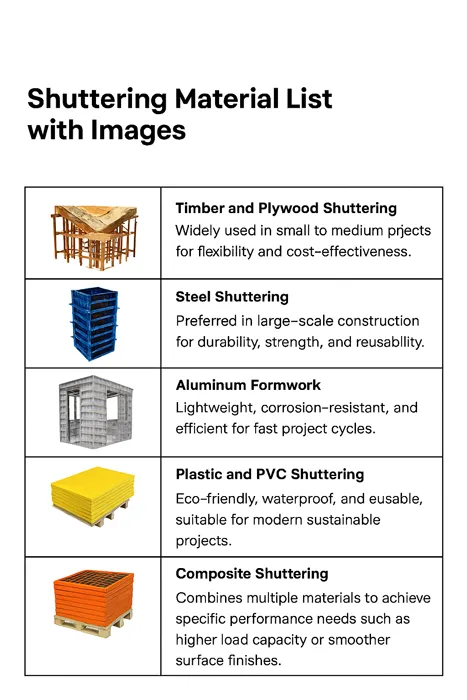

Shuttering Material List with Images

In concrete construction, each type of shuttering material plays a unique role in shaping slabs, beams, walls, and columns. A clear shuttering material list with images helps engineers, contractors, and students quickly recognize the materials used on-site and understand their applications.

Below you can see the most common shuttering materials with reference images:

-

Timber and Plywood Shuttering – widely used in small to medium projects for flexibility and cost-effectiveness.

-

Steel Shuttering – preferred in large-scale construction for durability, strength, and reusability.

-

Aluminum Formwork – lightweight, corrosion-resistant, and efficient for fast project cycles.

-

Plastic and PVC Shuttering – eco-friendly, waterproof, and reusable, suitable for modern sustainable projects.

-

Composite Shuttering – combines multiple materials to achieve specific performance needs such as higher load capacity or smoother surface finishes.

Slab Shuttering Material List

Slab shuttering plays a crucial role in shaping reinforced concrete floors and ceilings. A typical slab shuttering material list includes plywood sheets, timber battens, steel plates, props, adjustable jacks, and staging materials that support the formwork system. Each material contributes to achieving accurate slab thickness, level surfaces, and structural stability during concrete pouring.

Using the right slab shuttering materials ensures safety, strength, and a smooth surface finish for the concrete. Steel and aluminum shuttering systems are increasingly popular in high-rise construction because of their durability and reusability. On the other hand, timber and plywood remain common in smaller projects for their affordability and adaptability. A well-organized list helps contractors minimize errors, reduce wastage, and improve project efficiency.

Column Shuttering Material Names

Columns carry the vertical load of a structure, making column shuttering materials critical in construction. Commonly used items include steel column formwork, timber planks, plywood sheets, clamps, ties, nuts, and bolts. These materials work together to hold fresh concrete in position until it hardens and gains sufficient strength. The choice of material often depends on the column’s height, size, and required surface finish.

Understanding Types of Column Formwork in Modern Construction

Steel column shuttering is widely preferred for its strength and reusability, especially in high-rise projects. However, timber and plywood are also used for smaller residential or commercial structures. A column shuttering material name list helps site engineers and workers identify required items quickly and ensure proper assembly. Having this checklist ready improves accuracy, reduces delays, and guarantees a safe and efficient construction process.

Roof Shuttering Material List

Roof shuttering materials are essential for casting reinforced concrete slabs and ensuring that the structure can bear live and dead loads effectively. A roof shuttering material list typically includes plywood sheets, timber beams, steel plates, staging materials, adjustable props, and safety supports. The selection of these materials directly impacts the quality, cost, and safety of roof construction.

For modern projects, reusable systems like steel, aluminum, and plastic shuttering are preferred due to their durability and fast assembly. In contrast, timber and plywood remain common in traditional and small-scale construction because of their low initial cost. Providing a detailed roof shuttering material list helps construction teams plan efficiently, reduce material wastage, and achieve high-quality results with minimal risks.

Timber Shuttering Materials

Timber has long been a traditional and popular choice for shuttering due to its wide availability, ease of handling, and cost-effectiveness. Various types of timber are used in construction, each selected based on their specific properties suited for formwork applications. Common softwoods include pine, which is favored for its affordability and ease of workability; spruce, valued for its dimensional stability and often used in three-ply plywood panels; and fir, which offers good strength and durability for smaller-scale projects. Typically, these woods are used untreated since concrete does not demand treated timber; however, treated timber options may be chosen when enhanced resistance to moisture and durability is required.

Pros and Cons of Timber Shuttering

Timber shuttering offers several advantages and disadvantages that influence its suitability for different construction projects. On the positive side, timber is highly cost-effective, especially for small-scale projects where budget constraints are significant. Its ease of cutting and shaping allows for customized designs tailored to specific architectural needs, making it versatile for various applications. Additionally, timber is widely available in most regions, ensuring accessibility and quick procurement.

However, timber also has notable limitations. Its reusability is limited, typically lasting only 5 to 10 uses before deterioration affects performance. Timber is susceptible to warping and swelling when exposed to moisture, which can compromise the accuracy and stability of the shuttering. Furthermore, assembling timber shuttering requires skilled labor to ensure precise fitting and alignment, adding to labor costs and complexity.

Plywood for Shuttering

Plywood is commonly utilized either as a facing material over timber shuttering or as independent panels in formwork systems. Among its varieties, film-faced plywood—also referred to as shuttering plywood—is especially favored in concrete construction due to its enhanced durability and water resistance. This type of plywood features a phenolic or melamine film overlay, which protects the surface from moisture and wear during the concrete pouring process. Manufactured from layers of hardwood or softwood veneers bonded together with phenol-formaldehyde resin, film-faced plywood delivers a smooth, high-quality finish on the concrete surface, reducing the need for additional surface treatment.

Advantages in Reusability

Film-faced plywood offers significant advantages in construction due to its durability and reusability. With proper maintenance, it can be reused between 20 to 50 times, making it a more cost-effective choice compared to regular plywood or timber, especially for projects that involve multiple concrete pours. The smooth, treated surface not only ensures a clean and precise concrete finish but also reduces the need for additional surface finishing, saving both time and labor costs.

Steel Shuttering Materials

Steel shuttering, particularly steel column shuttering, is widely preferred in construction, especially for large-scale projects, due to its exceptional strength and durability. Its high strength allows it to withstand heavy loads and the intense pressure exerted by wet concrete, ensuring safety and structural integrity during the curing process. With a long lifespan, steel formwork can be reused hundreds of times, making it a cost-effective investment over multiple projects. Additionally, steel shuttering produces a smooth, level concrete surface that reduces the need for further finishing work. Its resistance to warping and deformation under stress ensures consistent performance, maintaining precise shapes and dimensions throughout the construction cycle.

Applications in High-Rise Construction

Steel formwork is highly regarded in the construction industry for its exceptional strength, durability, and versatility, making it an ideal choice for demanding projects such as high-rise buildings, bridges, and dams. Its robust design allows it to withstand repeated use over multiple construction cycles without compromising performance, which is essential for large-scale projects where efficiency and cost-effectiveness are critical. Additionally, steel formwork is capable of supporting substantial loads and pressures from wet concrete and construction activities, ensuring structural safety throughout the building process. One of its most significant advantages is its ability to deliver consistently smooth and precise concrete finishes, reducing the need for additional surface treatment and enhancing the overall quality and appearance of the final structure. This combination of durability, load-bearing capacity, and superior finish quality makes steel formwork a preferred solution for projects that demand both reliability and aesthetic excellence — especially in collaboration with experienced tunnel lining formwork suppliers who provide customized systems for complex infrastructure and underground construction projects.

Aluminum Shuttering

Aluminum formwork provides an excellent balance between strength and lightweight characteristics, making it a popular choice in modern construction projects. Its lighter weight compared to steel allows for easier handling and installation on-site, which in turn reduces labor costs and accelerates the construction process. Because aluminum formwork requires fewer supports and tie rods, the overall setup and dismantling times are shorter, leading to faster project completion. In addition to its practical advantages, aluminum is highly resistant to corrosion, making it especially suitable for use in humid or corrosive environments where durability is critical. Furthermore, aluminum formwork can be reused multiple times without significant degradation, offering long-term cost savings similar to steel systems. This combination of lightweight ease, durability, and reusability makes aluminum formwork a valuable solution for a wide range of construction applications.

Plastic and PVC Shuttering

Plastic shuttering is increasingly favored in construction due to its lightweight nature and environmentally friendly characteristics. One of its major benefits is excellent weather resistance; plastic formwork is waterproof and highly resistant to moisture, which prevents common issues like warping that affect timber shuttering. This makes plastic shuttering well-suited for harsh weather conditions, where traditional materials like wood may fail. Although the initial cost of plastic shuttering is moderate to high, its ability to be reused up to 50 times or more offers significant economic advantages. Additionally, low maintenance requirements contribute to reduced long-term expenses, making plastic shuttering a cost-effective solution for many projects.

Composite shuttering materials represent another advanced option, combining different substances to capitalize on their individual strengths. Hybrid designs often merge plastics or fiberglass with materials resembling plywood to achieve optimal stiffness and durability tailored to project demands. These composite systems are especially useful in specialized applications that call for unique properties such as enhanced reusability, lightweight structures, or specific surface finishes. As a result, composite shuttering is well-suited for complex architectural designs and high-performance construction requirements.

Choosing the Right Shuttering Material for Construction Projects

Choosing the right shuttering material involves careful evaluation of several key factors to ensure both efficiency and cost-effectiveness in construction projects. Project size and budget play a major role; smaller projects with limited funds often prefer timber or plywood because of their lower initial costs, while large-scale projects with repetitive structures benefit significantly from steel or aluminum shuttering due to their high durability and reusability, which ultimately reduce expenses over time. Climate and environmental conditions also influence material selection—steel, aluminum, and plastic are favored in humid or wet environments for their resistance to moisture, whereas timber and plywood can perform well in dry climates when properly treated. Additionally, the availability of materials locally can impact the decision, as transportation costs may increase the overall budget. Finally, adhering to local building codes and standards is critical for ensuring safety and compliance. In particular, for vertical structures such as walls, selecting the appropriate wall formwork system is essential to maintain structural integrity and achieve the desired finish.

Cost of Shuttering Materials (Wood, Steel, Aluminum, Plastic)

Understanding the cost implications of different shuttering materials is essential for effective budget management in construction projects. The initial purchase cost varies widely: timber is generally the most affordable option, followed by plywood with moderate pricing, while steel and aluminum come with higher upfront costs. Plastic materials range from moderate to high cost, depending on quality, and composite materials can vary significantly based on their composition and manufacturing process. Maintenance and repair expenses also differ among materials. Timber requires frequent replacement and is prone to damage, leading to higher ongoing costs. Plywood, especially film-faced types, demands moderate maintenance, whereas steel and aluminum incur low maintenance costs, thanks to their durability and corrosion resistance, although steel may need occasional rust prevention. Plastic materials are easy to clean and maintain, resulting in low upkeep costs, while composite materials fall between low to moderate maintenance depending on their design. When considering cost per usage cycle, timber tends to be the most expensive due to its limited reuse capacity, while plywood offers a better cost-efficiency, particularly film-faced plywood. Steel and aluminum formworks provide the lowest cost per cycle because of their extensive reusability, often lasting hundreds of uses. Plastic and composite shuttering materials also offer low cost per use, making them competitive alternatives for projects prioritizing both economy and sustainability.

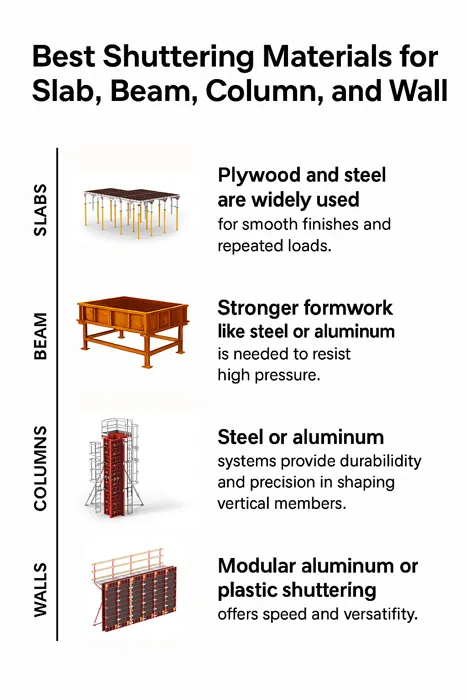

Best Shuttering Materials for Slab, Beam, Column, and Wall

Different types of construction projects demand specific shuttering materials tailored to their unique structural requirements, environmental conditions, and project scales. Selecting the appropriate shuttering material not only ensures the structural integrity and quality of the concrete but also optimizes construction efficiency and cost-effectiveness. Understanding these distinctions helps engineers and contractors make informed decisions to meet both technical specifications and practical constraints on diverse building sites.

For slabs, plywood and steel shuttering are widely used due to their ability to provide smooth finishes and withstand repeated loads. Beams typically require stronger and more stable formwork such as steel or aluminum, which can resist high pressure during concrete pouring. Columns benefit from steel or aluminum shuttering systems that deliver durability and precision in shaping vertical members, while walls can be efficiently formed using modular aluminum or plastic shuttering for speed and versatility. By choosing the best material for each structural element, projects can achieve higher quality results, reduce material wastage, and improve overall safety on site.

Comparison of Different Shuttering Materials

| Material | Strength | Weight | Lifespan |

|---|---|---|---|

| Timber | Moderate | Light | Multiple uses |

| Plywood | High | Light | Multiple uses |

| Steel | Very High | Heavy | Long-lasting |

| Aluminum | High | Light | Long-lasting |

| Plastic | Moderate | Very Light | Extended use |

| Composite | Customizable | Varies | High reusability |

Surface Finish Quality of Shuttering Materials

The choice of shuttering material directly influences the final surface finish of the concrete, which in turn affects both aesthetics and subsequent finishing work. Timber formwork tends to produce a rougher surface, often necessitating additional plastering or smoothing. Plywood, especially film-faced plywood, offers a much smoother finish that helps reduce the costs and time required for surface finishing. Steel formwork provides a very smooth and precise finish, making it ideal for architectural projects where surface quality is paramount. Aluminum formwork delivers a similarly smooth finish comparable to steel, while plastic shuttering also offers a smooth surface that can minimize plastering needs. Composite materials can be engineered to achieve specific surface finishes tailored to project requirements, combining durability with aesthetic flexibility.

Load-Bearing Capacity and Durability

Different shuttering materials vary in their load-bearing capacities, making them suitable for specific types of construction loads. Timber shuttering is generally appropriate for small to medium loads, commonly used in residential or light commercial projects. Plywood, particularly film-faced plywood, performs well across a range of loads and is versatile for many applications. Steel shuttering stands out for its excellent strength, making it ideal for heavy loads in large-scale structures such as high-rise buildings, bridges, and industrial facilities, as well as in advanced systems like the self climbing formwork system where vertical construction efficiency and structural precision are critical. Aluminum offers good strength for various uses but typically supports lighter loads compared to steel. Plastic shuttering is best suited for light to medium loads, offering benefits in lightweight and eco-friendly projects. Composite materials can be engineered to handle high loads, tailored to meet specific structural demands.

Reusability of Shuttering Materials

One of the most important factors in modern concrete construction is the reusability of shuttering materials. Reusable materials such as steel, aluminum, and high-quality plastic reduce overall project costs by allowing multiple casting cycles without significant loss of strength or shape. They also ensure consistent surface finishes, making them a preferred choice for large-scale and high-rise construction projects where durability and efficiency are critical.

In contrast, traditional options like timber and plywood have limited reusability due to wear, moisture absorption, and surface damage after a few uses. While they remain economical for small projects, sustainable construction increasingly favors reusable shuttering systems that minimize waste and environmental impact. Choosing materials with higher reusability not only lowers long-term costs but also supports eco-friendly building practices.

Best Practices for Using and Maintaining Shuttering Materials

Proper handling and maintenance play a vital role in extending the lifespan of shuttering materials, ensuring their durability and cost-effectiveness across multiple construction cycles. Effective storage techniques are essential; materials should be kept in dry, covered areas to protect them from adverse weather conditions that can cause deterioration. When stacking panels, it is important to do so correctly—using spacers to allow air circulation helps prevent warping, bending, or other deformations that can compromise formwork performance. After each use, thorough cleaning is necessary to remove any concrete residue promptly. Water or mild detergents are recommended to avoid damage, especially for sensitive materials like plywood and plastic, while harsh chemicals should be strictly avoided. Regular inspection and timely repair are also crucial components of maintenance. Before each use, shuttering materials should be carefully examined for any signs of damage such as cracks, warping, or corrosion. Minor damages should be addressed immediately—for example, sealing cut edges on plywood panels or welding small cracks in steel panels—to prevent further deterioration and maintain the structural integrity required for safe and efficient formwork operations.

Shuttering Equipment and Support Materials

Shuttering systems cannot function effectively without proper equipment and support materials. These items provide the necessary stability, alignment, and load-bearing capacity to hold the formwork securely in place during concrete pouring and curing. A well-organized shuttering equipment and support plan ensures safety, prevents deformation, and guarantees high-quality concrete finishes.

Shuttering Support Material List

A shuttering support material list typically includes essential items such as props, adjustable jacks, H-beams, clamps, ties, bracing members, and base plates. These supports distribute the weight of fresh concrete evenly, ensuring that the shuttering system remains steady and aligned throughout the casting process. Proper selection and installation of support materials help avoid structural defects such as honeycombing, cracks, or misalignment.

In large-scale projects, steel and aluminum props are often preferred due to their strength and reusability, while timber supports may be used in smaller or temporary works. Having a clear list of shuttering support materials allows engineers and contractors to plan ahead, reduce delays, and maintain safe working conditions on-site.

Staging and Scaffolding in Shuttering Work

Staging and scaffolding are crucial components in shuttering, especially for slab, beam, and roof works at higher levels. Staging involves a temporary framework—commonly built with steel pipes, cup-lock systems, or timber—that supports the shuttering until the concrete gains sufficient strength. Scaffolding, on the other hand, provides safe access for workers to assemble, adjust, and pour concrete efficiently.

Modern staging systems use modular and reusable steel frameworks, which save time and improve safety compared to traditional timber supports. By integrating reliable staging and scaffolding into shuttering work, construction teams can ensure stability, reduce risks of collapse, and achieve precise structural dimensions. This makes staging and scaffolding an inseparable part of high-quality shuttering practices.

Environmental Impact and Sustainability of Shuttering Materials

Sustainability is becoming an increasingly important consideration in modern construction practices. Materials like steel and aluminum stand out for their high recyclability, which significantly reduces construction waste and supports environmental conservation. Plastic shuttering also contributes to sustainability efforts, as it is often manufactured from recycled content and can be recycled again, promoting a circular economy within the industry. Timber and plywood, while renewable resources, must be sourced responsibly to prevent deforestation and ensure long-term ecological balance. Choosing eco-friendly alternatives involves selecting materials certified for sustainability, such as those bearing the Forest Stewardship Council (FSC) label for timber products. Additionally, evaluating the carbon footprint associated with the production and transportation of shuttering materials encourages the use of locally sourced or recycled options, further minimizing environmental impact and supporting greener construction methodologies.

Final Thoughts and Recommendations

Choosing the right shuttering material is a critical decision that directly influences the overall quality, cost efficiency, and timeline of any construction project. A thorough understanding of each material’s properties, strengths, and limitations enables construction professionals to select the most appropriate option tailored specifically to the unique demands of their project.

When choosing the best material for your project, it is essential to carefully assess factors such as the project’s size, complexity, and budget constraints. Additionally, considering environmental conditions and the local availability of materials ensures practical application and smooth logistics throughout the construction process.

Balancing cost, quality, and sustainability is key. While the initial purchase price plays a significant role, it is important to prioritize long-term savings by opting for materials with high durability and reusability. Furthermore, selecting eco-friendly options—such as recycled plastics or timber sourced from sustainably managed forests—can significantly reduce the environmental footprint of construction activities.

In conclusion, a well-curated shuttering material list serves as a foundation for efficient, high-quality, and sustainable construction projects. By strategically balancing cost considerations, material performance, and environmental impact, construction professionals can achieve optimal outcomes that meet both project goals and responsible building practices.