- Published:

- Written by: B.F.S Industries

The Critical Threat of Cold Joints in Concrete Columns: Ensuring Monolithic Structural Integrity

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

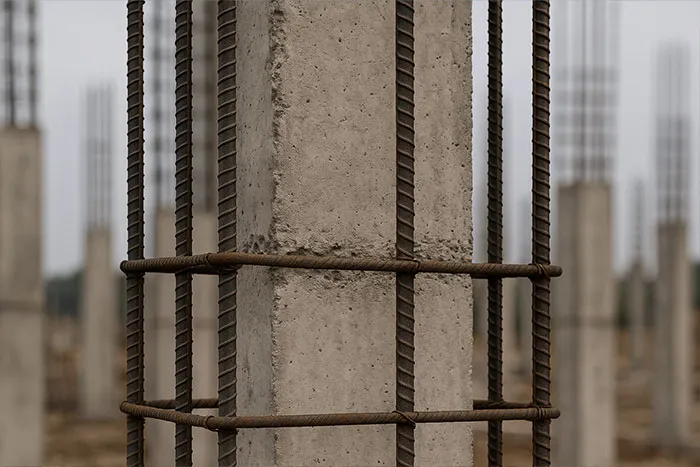

The construction of high-performance reinforced concrete structures demands an uncompromising commitment to quality control, particularly in vertical load-bearing elements. Few defects pose a more immediate and insidious threat to the long-term performance and intended load-transfer characteristics of a structure than cold joints in concrete columns. While often dismissed as purely aesthetic blemishes, a cold joint is, fundamentally, a failure of integration—a plane of weakness that interrupts the essential structural continuity in columns that is vital for resisting bending, shear, and axial compression. This comprehensive guide from B.F.S Industries cuts through common site assumptions to provide expert-level technical analysis, proven preventative strategies, and advanced remedial techniques necessary for achieving a truly monolithic concrete pour in every critical vertical element. We will focus on the logistical, chemical, and field execution challenges that lead to this defect and outline actionable, science-backed protocols to eliminate the risk on your next project.

Understanding the Failure Mechanism of Cold Joints

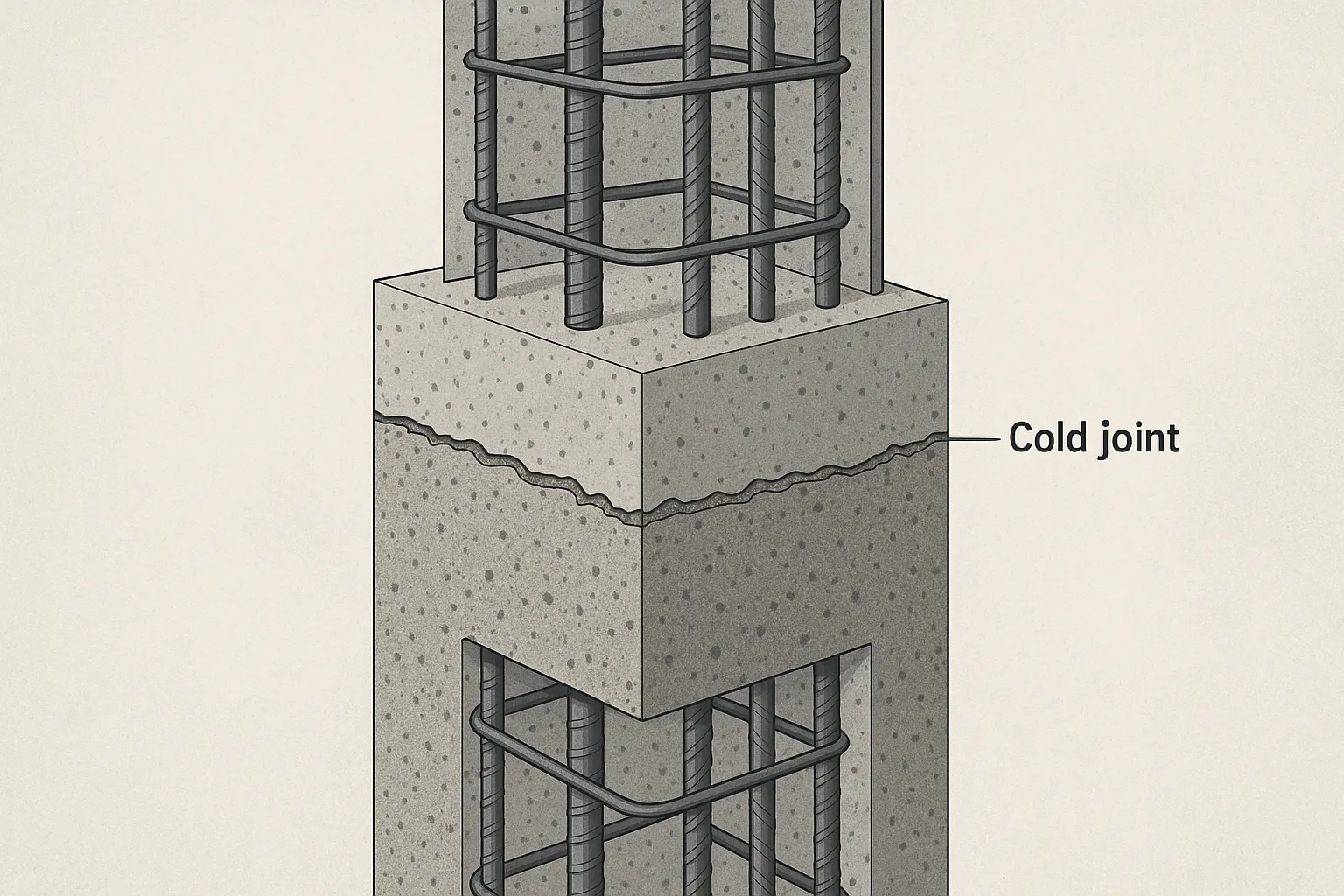

A cold joint forms when a new layer of concrete is poured and placed onto a previously cast layer that has already begun its initial setting phase, resulting in insufficient cohesion between the two layers. This transition from a plastic or fluid state to a semi-solid state creates a discontinuity that is inherently weaker than the surrounding homogeneous concrete mass. The challenge in column construction is the sheer volume of concrete placed vertically and the difficulty in visually verifying proper intermixing at the lift line. When the pour rate drops below the critical speed required to maintain plasticity across the entire cross-section, a fragile interface of hardened cement paste and free water forms, preventing the full molecular and physical bond needed for integral strength. This discontinuity transforms the designed compressive member into a series of stacked, weakly connected blocks, severely compromising the column’s seismic and lateral load resilience.

The Chemical and Physical Dynamics of Cold Joints

The underlying mechanism of a cold joint is directly related to the hydration process. When concrete ceases to be workable, the cement particles stop dispersing efficiently, and the capillary pores begin to dry, making the surface inert. Pouring fresh concrete onto this inert surface—the definition of a cold joint—means the new cement paste lacks the free calcium silicates and aluminates required to chemically react and bond seamlessly with the older, semi-set layer. Instead of a strong chemical link, a weak physical interface forms, often exacerbated by the presence of a film of surface laitance or bleed water residue on the lower lift. Effective prevention demands the strategic use of concrete bonding agents or meticulous construction joint preparation to re-activate the interface, allowing for true chemical integration and restoring the intended load path.

Critical Timelines and the Initial Set

The window for a successful, monolithic pour is defined by the concrete’s initial setting time, which can be significantly influenced by ambient temperature, humidity, and the use of retarding admixtures. For most conventional mixes, the practical limit for placing the second lift without forming a cold joint is between 30 and 45 minutes after the first lift has been fully placed and consolidated. Once the temperature of the lower lift begins to rise, indicating the acceleration phase of hydration, the chemical bonding potential plummets rapidly. Site supervisors must be intimately familiar with the specific mix design’s set time and adjust the pouring sequence in columns to ensure continuous placement and vibration, effectively turning a potential construction joint into a continuous, sound concrete element.

Root Causes in Column Construction and Logistics

The majority of cold joint failures are not material-related but logistical and operational. Column construction introduces unique constraints: high lifts, narrow cross-sections, and congested reinforcement often demand high-slump, high-flow mixes. However, high-slump concrete is often more susceptible to rapid moisture loss at the surface, which accelerates the initial set and reduces the time window for the subsequent pour. The primary logistical cause is an interruption in the supply chain—a truck delay, a pump blockage, or a shift change—that allows the previously poured concrete to lie undisturbed long enough to develop firmness. A secondary cause is internal process failure, such as workers dedicating excessive time to finishing the concrete surface or dealing with blowouts at a lower level, diverting attention and resources from the continuous placement of the concrete in the upper lifts.

Logistics of Delivery and Pour Sequence

Managing the concrete delivery rhythm is perhaps the single most important factor in preventing cold joints. The rate of concrete delivery must be precisely matched to the rate of placement and compaction within the formwork. In deep columns, the pouring sequence in columns should be highly organized, utilizing sufficient crew members to transition immediately from compacting one lift to pouring the next. The failure to calculate the required cubic yardage per hour for a continuous lift, coupled with overly optimistic estimates of transit time, inevitably leads to gaps in supply. This gap allows the concrete surface to reach the critical point where it can no longer be thoroughly re-agitated and mixed with the subsequent batch, forming an unrecoverable seam.

Inadequate Preparation of the Construction Joint

While a monolithic pour aims to eliminate construction joints, when a pour is deliberately halted (e.g., at the top of a column below a beam connection), the resulting construction joint must be prepared meticulously to prevent it from performing as a weak cold joint when the next element is cast. This preparation requires the complete removal of the weak, friable material known as surface laitance removal. If left in place, this fine, chalky layer acts as a release agent, preventing a strong bond. Preparation techniques involve hydro-blasting, sandblasting, or scarifying the surface to expose the clean, sound aggregate before applying a concrete bonding agents or a rich cement slurry just prior to the resumption of the pour.

Preventative Strategies in Material Science and Formwork

Preventing cold joints in concrete columns begins long before the first cubic yard arrives on site; it starts with the careful specification and engineering of both the concrete mix and the forming system. Selecting the appropriate concrete grade and additives is crucial. High-performance, low-permeability concrete designed for columns often uses supplementary cementitious materials (SCMs) like fly ash or slag, which generally result in a slightly slower hydration rate, offering a larger time buffer. Furthermore, the choice of formwork is critical. Utilizing advanced column formwork, such as the solutions provided by a leading Concrete Modular Formwork Supplier, ensures dimensional accuracy and minimizes the risk of formwork failure, which is a common cause of unexpected pour stoppages. High-quality Concrete Column Formwork allows for faster, more continuous placement.

Admixture Control and Hydration Management

Strategic use of chemical admixtures is essential for controlling the initial set time, especially in hot weather or when dealing with long transport times. Retarding admixtures are specifically designed to delay the hydration process, extending the plastic state of the concrete and providing an invaluable time margin for deep column pours. However, their use must be carefully calibrated to avoid excessive retardation, which can negatively impact strength development and finishing schedules. A concrete technologist must work closely with the field team, utilizing test cylinders and temperature monitoring to verify that the specified retarder dosage maintains the concrete’s workability for the minimum duration required to complete the placement sequence for the entire column height.

Utilizing Specialized Concrete Bonding Agents

When dealing with deep columns or complex, multi-stage pours where the risk of an accidental cold joint is high, specialized concrete bonding agents are a prudent measure. These agents fall into two main categories: epoxy-based and cement-based polymer modifiers. Epoxy agents provide a high-strength, water-resistant bond but require careful surface preparation and strict adherence to mixing and application guidelines. Cement-based agents, often used as slurries, are compatible with fresh concrete and are applied immediately before the subsequent pour to create a “wetted” and chemically active surface, ensuring the fresh concrete truly adheres and integrates with the previously cast lift, promoting structural continuity in columns.

Execution Excellence: Placement and Consolidation

Flawless execution of the concrete placement process—the true moment of truth—is the responsibility of the field crew and supervision. The primary goal is to ensure that every lift of concrete is placed and consolidated while the preceding lift remains alive and receptive to the new material. This requires meticulous adherence to the calculated pour rate and strict discipline regarding vibration techniques. Concrete placement must be conducted through elephant trunks or tremie pipes to minimize the drop height, preventing segregation during placement, which can cause the aggregate to separate from the paste, leading to voids and poor bonding at the joint interface.

Mastering Concrete Vibration Techniques

Proper vibration is the non-negotiable step for achieving a dense, void-free concrete column and is explicitly detailed in ACI 309 and ACI 301 standards. When pouring the second lift onto the first, the internal vibrator must penetrate the fresh concrete and extend approximately 6 to 8 inches into the previously placed, but still plastic, lower lift. This strategic penetration is paramount, as it achieves two critical objectives: (1) it ensures the complete consolidation of the new concrete, removing entrapped air, and (2) it re-agitates the cement paste at the interface, promoting intermixing and eliminating the thin, inert film that causes the cold joint. Inadequate vibration—vibrating for too short a time or failing to penetrate the lower lift—is a direct cause of a weak cold joints in concrete columns.

Avoiding Segregation During Placement

The velocity and path of the concrete as it fills the column formwork must be controlled to avoid segregation during placement. Dropping concrete freely from excessive heights (over 5 feet) or allowing it to impact reinforcement cages at high speeds causes the heavy aggregate to separate from the lighter cement paste and water, resulting in honeycombing and increased porosity. This is particularly problematic in the upper regions of a column pour where the last batch meets the partially set concrete below, creating an aggregate-rich, paste-poor boundary that is inherently incapable of forming a strong bond. Limiting free fall and using vertical tremies ensures a controlled, homogeneous flow, which is a prerequisite for a successful monolithic concrete pour.

| Column Pour Rate Guidelines for Cold Joint Prevention |

|---|

| Column Dimension (ft) |

| 1 x 1 to 2 x 2 |

| 2 x 3 to 3 x 3 |

| 4 x 4 or larger |

| Notes: Rates assume 70°F ambient temperature and Type I cement. Reduce pause time by 5 minutes for every 10°F increase in ambient temperature. Continuous pour is always the ideal. Rates must be verified against Concrete Modular Formwork Supplier specifications for pressure limits. |

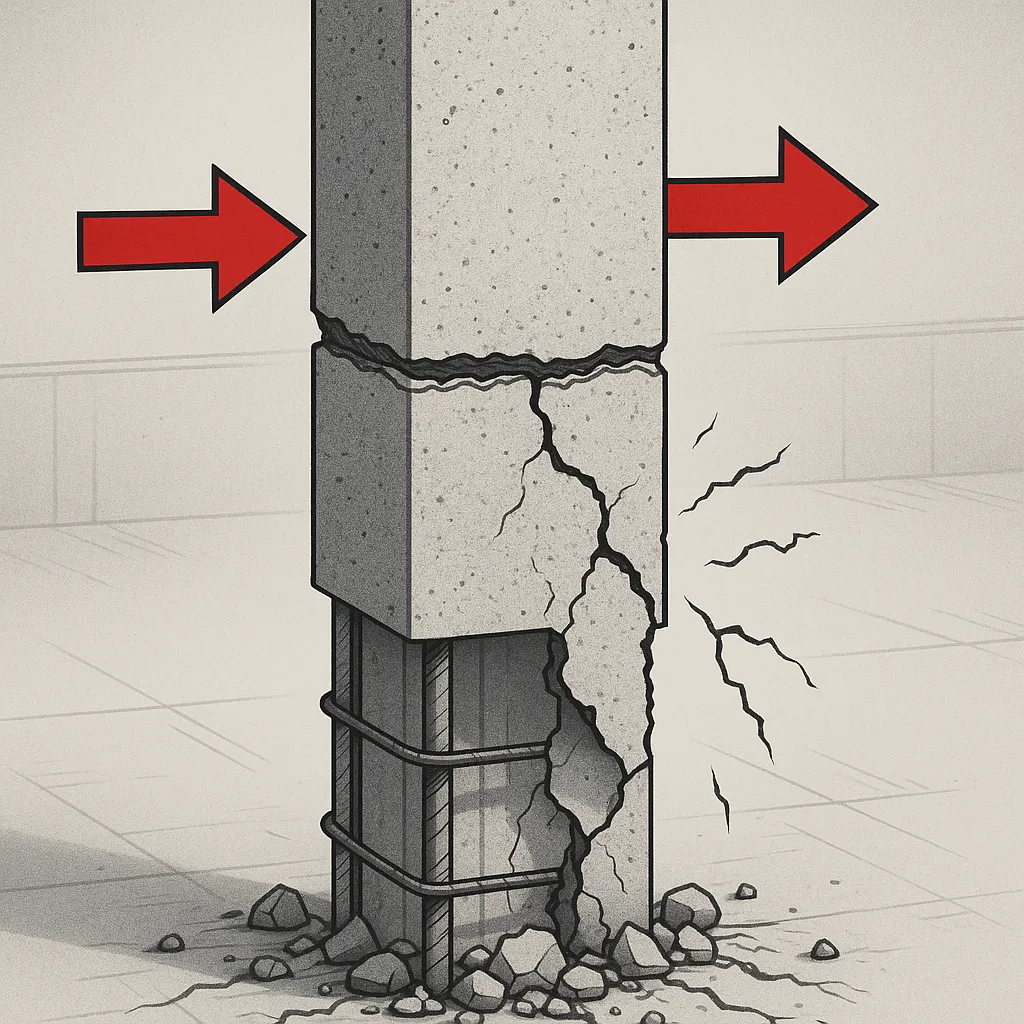

Structural Implications and Code Compliance

The presence of a cold joint fundamentally alters the structural behavior of a column, changing it from a single, continuous component into a two-part assembly resting upon a weakened plane. This plane of weakness is not merely a cosmetic issue; it represents a significant reduction in the column’s moment capacity and shear resistance. While concrete is exceptionally strong in compression, the bond line of a cold joint is poor in tension and shear. Under lateral loads (wind or seismic events), the joint becomes a stress concentration point, leading to premature cracking and failure that can propagate quickly. For instance, in an earthquake, the weak interface of a cold joint will fail long before the surrounding sound concrete reaches its yield strength, resulting in a brittle failure mode contrary to design intent.

Ensuring Monolithic Concrete Pour and Continuity

The very definition of a high-performance column requires a monolithic concrete pour, where the entire member acts as one unit to transfer loads. Achieving this requires that the materials and the placement process work together to create a chemically and physically fused concrete mass. This is where advanced formwork systems and pour planning come into their own. By minimizing the number of construction joints and ensuring that any unavoidable joints are treated meticulously with construction joint preparation techniques and concrete bonding agents, engineers can reliably guarantee structural continuity in columns. Failure to do so necessitates costly and complex remedial measures later, often involving high-pressure epoxy injection, which can never fully replicate the strength of an original, seamless pour.

Compliance with ACI Standards (ACI 309 and ACI 301)

Adherence to industry standards is non-negotiable for critical structural elements. ACI 309 and ACI 301 standards provide the foundational guidelines for proper consolidation and construction practices. ACI 309, specifically focused on Consolidation of Concrete, mandates the correct vibration techniques, emphasizing penetration into the preceding layer to ensure that the interface is re-fluidized. ACI 301, Specification for Structural Concrete, details the requirements for construction joints, including the crucial step of surface laitance removal before a new pour. Compliance is not just a regulatory requirement; it is the blueprint for defect prevention, serving as the ultimate quality control benchmark for avoiding catastrophic cold joints in concrete columns.

Case Study: The Cost of a Critical Cold Joint Failure

In a recent high-rise commercial project in a major metropolitan area, a series of 15-foot shear wall-columns experienced severe cracking shortly after load application on the third floor. The columns, part of the lateral force resisting system, were poured in two lifts over an unusually hot afternoon. Due to a mixer truck breakdown, the second lift was delayed by nearly 90 minutes. Despite site staff manually scarifying the surface before the second pour, the initial setting had already progressed too far, and no specialized concrete bonding agents were used.

The result was an unmistakable cold joints in concrete columns running horizontally across all affected members. Post-construction ultrasonic pulse velocity (UPV) testing revealed a significant drop in wave velocity (indicating poor density and high void content) along the joint plane, confirming a structural discontinuity. The engineering firm deemed the columns deficient in resisting the required lateral shear loads. The remediation process involved shoring the structure, chipping out the compromised joint sections, and high-pressure injection of structural epoxy—a process that was intrusive, time-consuming, and highly disruptive. The project was delayed by four months, and the total cost for the structural repair and associated delays exceeded $1.2 million. This case underscores that cutting corners on pour logistics and construction joint preparation results in financial penalties that massively outweigh the cost of proper preventative measures.

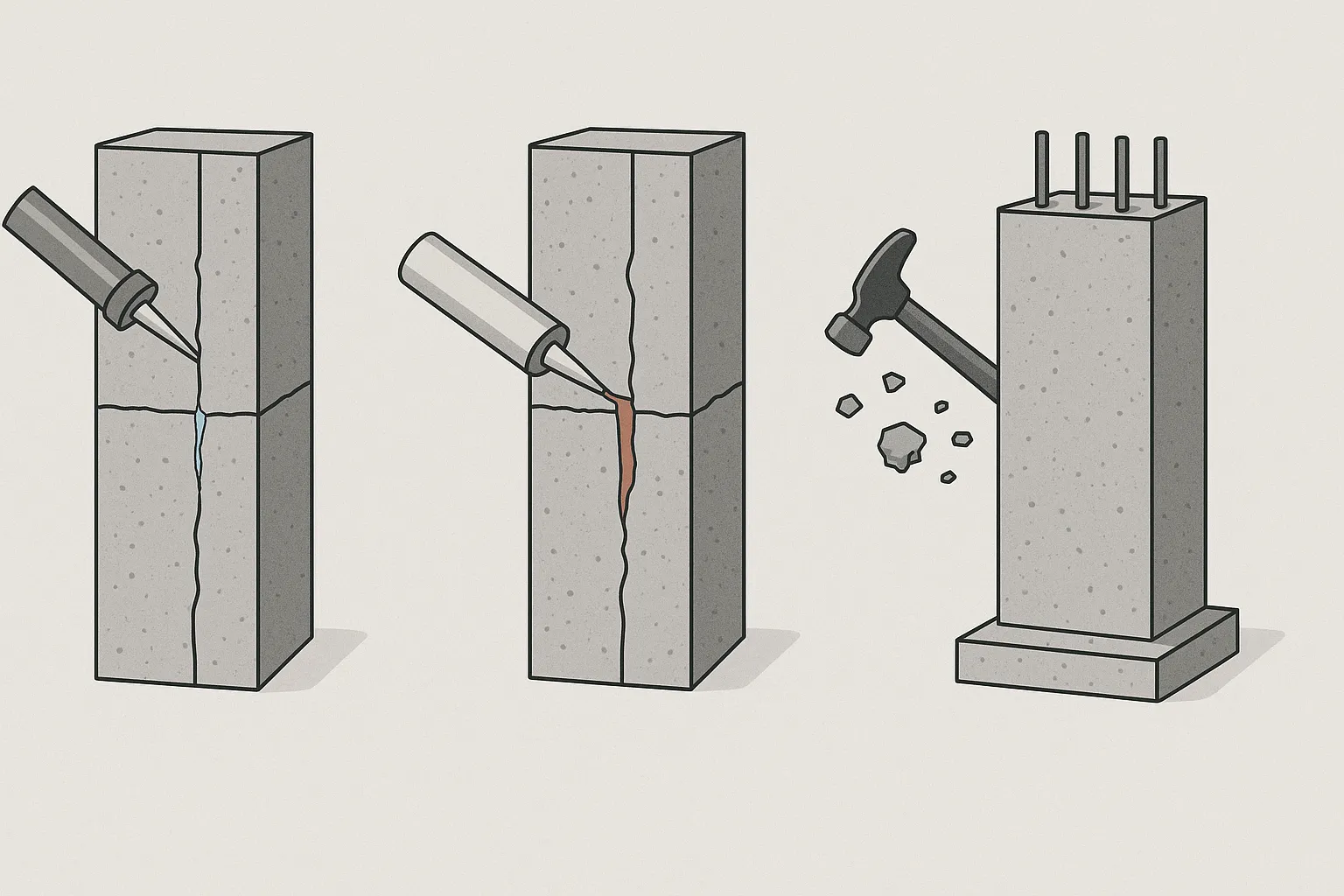

Remedial and Repair Techniques for Cold Joints

When testing confirms the existence of structurally compromising cold joints in concrete columns, immediate and expert remediation is required. The choice of repair technique depends on the severity and depth of the joint and whether the column is subject to compressive, tensile, or shear loads.

- Low-Viscosity Epoxy Injection: For minor, hairline cold joints (less than 0.01 inches wide) primarily under compressive load, a low-viscosity, structural epoxy is injected under pressure. The epoxy penetrates the minute voids and bonds the two concrete lifts together, partially restoring the lost tensile strength and preventing water ingress. This technique is often used in combination with crack monitors to verify the integrity of the repair over time.

- Rout and Seal (Non-Structural): If the joint is deemed non-structural (e.g., in a parapet or secondary element), a simpler rout-and-seal approach using a flexible, polymer-based sealant can be used to prevent water penetration and freeze-thaw damage. This does not restore structural continuity in columns but provides a durable weather seal.

- Removal and Replacement (Critical): For severe, deep, or wide cold joints in critical load-bearing columns, the only reliable option may be to chip out the concrete surrounding the joint line—sometimes the entire column segment—and recast it. This is a last resort due to the high costs, complex shoring requirements, and extensive disruption.

Pre-Pour Quality Control Checklist for Cold Joint Prevention

This checklist is designed to integrate the best practices of ACI 309 and ACI 301 standards into daily site execution, specifically targeting the unique challenges of continuous column pours.

| Step | Action Item | Responsibility | Status |

|---|---|---|---|

| Material & Mix | Mix design (including retarding admixtures) approved for anticipated ambient temperature? | Concrete Technologist | [ ] |

| Material & Mix | Required concrete bonding agents or cement slurry on site and ready for immediate application? | Materials Manager | [ ] |

| Logistics | Pour rate (cubic yards/hr) calculated and confirmed against batch plant/pump capacity? | Project Engineer | [ ] |

| Logistics | Back-up pump/truck and contingency plan in place for delays exceeding 20 minutes? | Site Supervisor | [ ] |

| Formwork | All Concrete Column Formwork secured and joints sealed to prevent loss of paste/water? | Formwork Crew Lead | [ ] |

| Joint Prep (If planned) | Plan for surface laitance removal (e.g., air-water blast) verified before pour starts? | Quality Control | [ ] |

| Execution | Internal vibrator size and frequency checked; sufficient length to penetrate lower lift (min 8 inches)? | Site Supervisor | [ ] |

| Execution | Dedicated crew member assigned vibration techniques with no other tasks? | Site Supervisor | [ ] |

| Execution | Drop chutes/tremie pipes installed to limit free-fall distance and prevent segregation during placement? | Placement Crew Lead | [ ] |

| Post-Pour | Immediate curing (wet covering/membrane) applied to top surface to prevent premature drying? | Curing Crew | [ ] |

The Role of Advanced Formwork in Monolithic Pours

To consistently eliminate the problem of cold joints in concrete columns, construction firms rely on dependable equipment. BFS Industries is a recognized leader, providing solutions that aid in high-speed, continuous placement. For instance, our range of column formwork is designed for rapid assembly and high internal pressures, which are inherent in deep, continuous pours. The ability to trust the forming system—unlike generic or makeshift column boxes—removes a primary reason for unplanned pour stoppages and subsequent cold joint formation. High-quality Concrete Column Formwork ensures that the concrete can be placed efficiently and without the risk of form failure, thus maintaining the continuous placement schedule required for a true monolithic concrete pour. While our expertise extends across many product lines, from our high-strength jersey barrier forms used for traffic control to general purpose concrete wall formwork supplier systems, our commitment to structural quality starts with the elements that carry the highest loads.

Frequently Asked Questions (FAQs)

Q: How can I visually identify a cold joint in a newly stripped column?

A: The easiest way to identify a cold joints in concrete columns is by observing a distinct horizontal line or seam on the concrete surface, often marked by a slight change in color, texture, or the presence of a thin layer of hardened paste/laitance. The joint line may also appear slightly porous or show evidence of small voids or bug holes directly along the seam. If the joint is structurally severe, the line may already exhibit hairline cracking.

Q: Does a cold joint affect the column’s ability to resist fire?

A: Yes, a severe cold joint can negatively impact fire resistance. Fire rating is dependent on the homogeneous, dense nature of the concrete protecting the reinforcing steel. A cold joint, being a plane of lower density, higher permeability, and reduced bond, provides a pathway for heat and corrosive gases to penetrate the concrete cover more quickly, accelerating the failure of the structural element under fire conditions.

Q: Are all construction joints cold joints?

A: No. A construction joint is a planned discontinuity where the pour is deliberately stopped (e.g., at a column-to-beam interface). A cold joint is an unplanned discontinuity that occurs when a planned continuous pour is interrupted and the concrete on the lower lift is allowed to achieve initial set before the next lift is placed. A construction joint that is not properly prepared (i.e., fails to undergo surface laitance removal and the application of a concrete bonding agents) will perform like a cold joint, but the distinction lies in the planning. For non-structural elements like jersey barrier forms, which often have planned pour breaks, the preparation is less rigorous but still necessary to achieve a clean surface.

Q: What is the most reliable non-destructive testing (NDT) method to verify a cold joint?

A: Ultrasonic Pulse Velocity (UPV) testing is the most common and reliable NDT method. UPV measures the time it takes for an ultrasonic wave to travel between two transducers placed across the joint. If the concrete is sound and homogeneous (monolithic), the velocity will be high. A significant reduction in velocity along the joint line compared to the sound concrete above and below is a strong indicator of a cold joint, void, or discontinuity.

Q: What’s the difference between the forming systems used for columns and walls?

A: Column forms, often supplied by a Concrete Modular Formwork Supplier, are designed to withstand significantly higher hydrostatic pressures than typical wall forms because the concrete is contained within a much smaller, taller cross-section, leading to faster pressure build-up. While a concrete wall formwork supplier provides wide, linear systems, column forms (such as modular steel or fiberglass systems) are specialized for round or square cross-sections and engineered for rapid cycling and reusability, supporting the high-speed placement needed to avoid cold joints.

Preventing cold joints in concrete columns is a function of expert planning, meticulous material control, and disciplined site execution. By recognizing the chemical kinetics involved and treating the concrete pour as a race against the initial set, project teams can successfully achieve the monolithic concrete pour that structural designs demand. The standards established by ACI 309 and ACI 301 standards are the map, and the quality of your formwork and logistics is the vehicle.

We’re confident that integrating these engineering protocols will raise the quality assurance bar on your next build. If you need support selecting the right high-pressure Concrete Column Formwork or navigating the complexities of deep pours, please contact BFS Industries—we’re here to help you build safer, stronger, and faster.