Concrete Construction Equipment

B.F.S Concrete Construction - Transforming liquid material into structured architectural forms

Concrete construction equipment forms the foundation of safe, efficient, and high‑quality building and infrastructure projects. At BFS Industries, we specialize in delivering engineered concrete construction equipment, including advanced formwork systems and heavy‑duty scaffolding solutions, designed to transform fresh concrete into precise, durable structural elements. Our systems support residential, commercial, and large‑scale infrastructure projects where accuracy, load capacity, and safety are critical.

Concrete Construction Formwork Systems

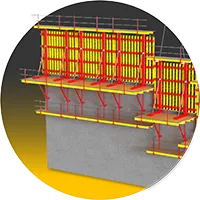

Formwork systems play a vital role in shaping and supporting concrete until it reaches the required structural strength. BFS Industries provides a comprehensive range of concrete construction formwork systems, engineered to withstand high lateral concrete pressure while ensuring dimensional accuracy and superior surface finish.

Our solutions include modular formwork systems for walls, columns, and slabs, tunnel formwork systems for simultaneous casting of walls and slabs in mass housing projects, and advanced slip and self‑climbing formwork systems for high‑rise and vertical concrete structures. These systems are designed for rapid assembly, repeated reuse, and long‑term durability, making them ideal for demanding construction environments.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

Tunnel Form construction

Wall Formwork

Our range of wall formwork products at B.F.S has been designed to support a variety of applications—from lightweight systems that can be lifted into position by hand for small basement projects to heavy-duty systems required for large infrastructure projects.

Development of Employees and Turnover

Our success factors are tremendous innovative strength and internationalization at an early stage. Behind this are around 70 employees who are committed in providing the best individual solution for the benefit of our customers.

Concrete Construction Equipment for Infrastructure Projects

Infrastructure projects demand concrete construction equipment capable of performing under extreme loads and challenging site conditions. BFS Industries delivers specialized formwork and scaffolding systems for tunnels, manholes, dams, wastewater treatment plants, and transportation infrastructure.

Our tunnel lining formwork, dam formwork systems, and special formworks are engineered for accuracy, safety, and long service life. These solutions enable contractors to maintain tight construction schedules while achieving consistent concrete quality across large‑scale projects.

How to Choose the Right Concrete Construction Equipment

Selecting the appropriate concrete construction equipment depends on structural design, load requirements, repetition cycles, and site constraints. Engineers and contractors should evaluate factors such as concrete pressure, formwork reuse rate, assembly time, safety standards, and compatibility with scaffolding and shoring systems.

By choosing engineered concrete construction equipment from BFS Industries, project teams can improve construction speed, reduce labor costs, enhance site safety, and achieve high‑quality concrete finishes with minimal rework.