- Published:

- Written by: B.F.S Industries

Steel Structures or Reinforced Concrete? A Practical Guide for Modern Projects

FREE DOWNLOAD – B.F.S. HOLDING

Explore the full spectrum of services and industries covered by B.F.S. Holding.

Deciding between steel structures or reinforced concrete is one of the most critical determinations a project owner, developer, or structural engineer will make during the conceptual design phase. This choice dictates not only the initial construction budget and timeline but also the long-term performance, maintenance requirements, and architectural flexibility of the asset. While reinforced concrete has long been the default for residential and mid-rise construction due to material availability and perceived lower costs, structural steel offers unparalleled speed and strength-to-weight advantages that can redefine the economic viability of high-rise and industrial projects. The debate is rarely about which material is superior in isolation; rather, it is about which system aligns best with the specific constraints of the site, the financial model of the investor, and the functional demands of the final structure. Factors such as seismic resistance, fire durability, local labor expertise, and supply chain logistics play pivotal roles in tipping the scale. As a partner in comprehensive construction solutions, BFS Industries recognizes that there is no single answer; instead, the industry requires a nuanced understanding of trade-offs. This article provides a structured comparison to support better engineering and business decisions, analyzing cost, speed, durability, and execution risks to help stakeholders navigate the complex landscape of modern structural systems.

Overview of Steel Structures and Reinforced Concrete Systems

A steel structure system relies on organized frameworks of structural steel members—primarily beams, columns, and trusses—connected to carry loads and provide rigidity. These members are typically fabricated off-site in controlled factory environments using hot-rolled or cold-formed steel sections, ensuring high precision and consistent material quality. The primary allure of steel lies in its immense tensile and compressive strength relative to its weight, allowing for slender columns and large, open spans that maximize usable floor area. In a steel building, the structural frame handles the gravity and lateral loads, while floors are often constructed using composite metal decks with a concrete topping or precast planks. Because steel is an isotropic material, meaning it possesses uniform properties in all directions, its behavior under load is highly predictable, simplifying the design process for complex geometries. However, the system relies heavily on the integrity of connections—bolted or welded—which transfer forces between members. The erection process is essentially an assembly operation, requiring heavy lifting equipment but significantly fewer onsite personnel compared to wet construction methods. This system is the backbone of industrial facilities, warehouses, and skyscrapers where minimizing dead load and accelerating occupancy are paramount.

What Is a Reinforced Concrete Structure and How Does It Work?

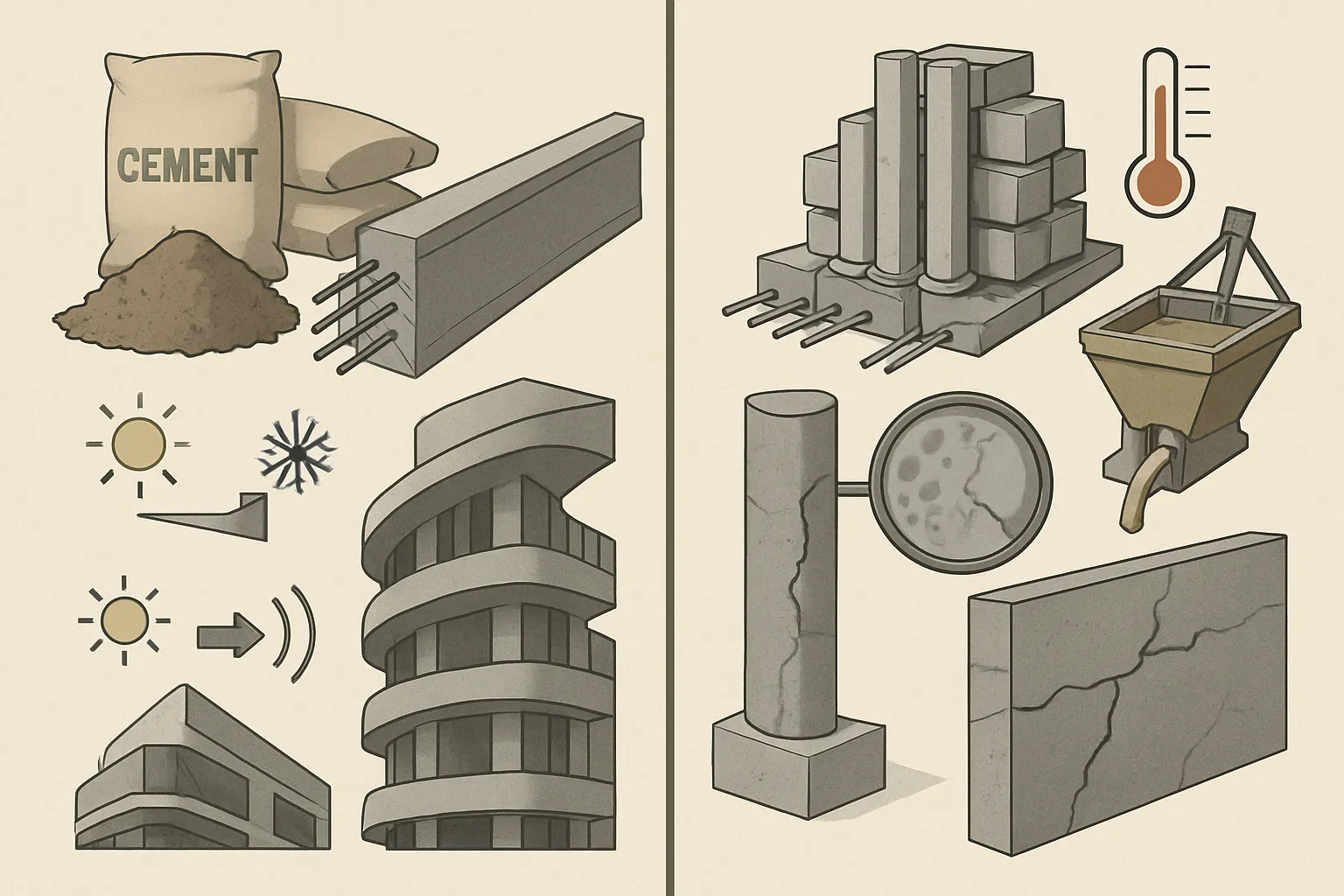

Reinforced concrete (RCC) is a composite material system that ingeniously combines the high compressive strength of concrete with the high tensile strength of steel reinforcement bars (rebar). Concrete, by itself, is brittle and weak in tension; without reinforcement, a concrete beam would fail catastrophically under bending loads as cracks propagate from the bottom surface. By embedding steel bars in the tensile zones of the concrete element, engineers create a unified structure where the concrete resists crushing forces while the steel resists stretching and bending forces. This synergy allows RCC structures to be cast into virtually any shape, providing monolithic connections between columns, beams, and slabs that offer inherent rigidity and continuity. The construction process involves erecting formwork—temporary molds—placing the rebar cages, and pouring fresh concrete which then cures and hardens over time. This method creates a structure with significant thermal mass and acoustic dampening properties, making it ideal for residential and commercial occupancies. The performance of an RCC structure is heavily dependent on the bond between the steel and the concrete, as well as the protection the concrete cover provides to the steel against corrosion and fire. It remains the dominant construction method globally due to the ubiquity of its raw materials—cement, water, and aggregate—and its adaptability to varying site conditions.

Key Comparison Criteria: Cost, Speed, Strength and Service Life

When analyzing steel structure vs RCC structure cost, the industry often focuses heavily on the initial material and labor expenditure, where reinforced concrete frequently appears to be the more economical option. Concrete utilizes locally sourced aggregates and cement, and in many regions, the labor force required for formwork and pouring is less expensive than the specialized certified welders and ironworkers required for steel erection. Consequently, for standard low-to-mid-rise buildings with regular grids, the raw shell cost of concrete is often lower. However, this narrow view often fails to account for the speed of construction and the time value of money, which can drastically alter the financial equation for developers. Structural steel systems can be erected significantly faster, allowing for earlier occupancy and revenue generation, which can offset the higher upfront material costs. Furthermore, the lighter weight of steel structures reduces the load on foundations, potentially saving millions in excavation and piling costs on sites with poor soil conditions. When considering life-cycle costs, steel offers the advantage of adaptability; beams can be strengthened and floors modified with relative ease. Conversely, concrete structures, while robust, can be costlier to modify or demolish at the end of their service life. Therefore, the “cheaper” option depends entirely on whether the metric is the bid price of the frame or the total return on investment of the development.

Construction Speed, Prefabrication and Site Logistics

Construction speed is arguably the most significant differentiator between steel structures and reinforced concrete, heavily favoring steel in time-critical projects. Steel components are pre-engineered and fabricated concurrently with site preparation and foundation work. Once the site is ready, the steel frame can be erected rapidly, often sequence by sequence, without the delays associated with curing times. This “just-in-time” delivery model reduces the need for extensive on-site storage, which is a major advantage in congested urban environments. In contrast, reinforced concrete construction is a linear, wet trade process. Each floor cycle requires formwork installation, rebar placement, inspection, pouring, and a curing period before the formwork can be stripped and moved to the next level. While advancements in jump-form systems and high-early-strength concrete have improved RCC timelines, they rarely match the assembly speed of a steel frame. However, concrete construction does offer logistical advantages in remote areas where transporting massive steel members is unfeasible. Additionally, concrete allows for last-minute site adjustments more easily than steel, where a fabrication error can halt progress until a replacement part is manufactured and shipped. The choice often comes down to the critical path of the project schedule and the availability of a sophisticated supply chain.

Strength, Stiffness and Seismic Performance

The debate of is steel stronger than concrete in compression or is reinforced concrete stronger than steel is nuanced, as “strength” encompasses multiple physical properties including compressive strength, tensile strength, yield strength, and ductility. In pure compression, high-strength concrete is formidable and cost-effective per unit of load carried, which is why the lower levels of supertall skyscrapers are often composite columns or concrete cores. However, steel has a much higher strength-to-weight ratio, allowing it to resist loads with much smaller cross-sections. In terms of seismic performance, the two materials behave differently. Structural steel is naturally ductile; it can undergo significant plastic deformation—bending and stretching—without fracturing, allowing it to dissipate energy during an earthquake. This ductility makes steel highly desirable in high-seismic zones. Reinforced concrete is inherently heavier and more rigid, which attracts higher seismic forces. While modern RCC design utilizes specific detailing to ensure confinement and ductility, the risk of brittle failure remains if the workmanship is poor. A concrete building will be stiffer and sway less in the wind, providing better occupant comfort, whereas a steel building is more flexible and may require supplemental damping systems to control drift and vibration. Thus, the decision involves balancing the need for stiffness (comfort) against the need for ductility (safety).

Fire Resistance, Durability and Maintenance Demands

Fire resistance is an area where reinforced concrete holds a distinct natural advantage over structural steel. Concrete has low thermal conductivity and high heat capacity, meaning it heats up slowly and protects the embedded reinforcing steel from losing strength during a fire. A well-designed concrete structure can withstand significant fire exposure without requiring additional, costly fireproofing materials. Structural steel, on the other hand, loses nearly half of its strength at temperatures around 600°C (1100°F). Consequently, steel structures almost always require passive fire protection, such as spray-applied fire-resistive materials (SFRM), intumescent paints, or concrete encasement, which adds to both the construction cost and the maintenance burden. Regarding durability against environmental elements, both systems face challenges but from different sources. Concrete is susceptible to carbonation and chloride ingress, which can rust the internal rebar and cause spalling, necessitating rigorous crack control and sealant maintenance. Steel structures exposed to the elements require high-performance coating systems to prevent corrosion. However, in a controlled indoor environment, steel is incredibly stable and does not suffer from creep or shrinkage over time, phenomena that can cause long-term deflection and cracking in concrete structures.

Advantages and Disadvantages of Steel Structures

The supremacy of steel in the modern skyline is driven by its ability to achieve architectural feats that are difficult or impossible with other materials. The primary advantage is the creation of long, column-free spans. This is essential for open-plan offices, auditoriums, airport terminals, and industrial warehouses where internal columns would obstruct operations. Steel’s high strength-to-weight ratio results in smaller footprints for vertical elements, maximizing the net leasable area of a building—a critical metric for developers in high-value real estate markets. Furthermore, steel is a highly sustainable choice in the context of the circular economy. Structural steel is 100% recyclable and is the most recycled construction material in the world; a beam taken from a demolished building can be melted down and repurposed without any loss of material properties. This recyclability contributes to LEED points and environmental certifications. Additionally, the prefabrication nature of steel results in higher quality control. Because the connections and members are cut and welded in a factory with automated machinery and strict inspection protocols, the risk of human error on the construction site is significantly reduced compared to the variables involved in mixing and pouring concrete in changing weather conditions.

Limitations and Challenges of Steel Structure Buildings

Despite its strengths, steel construction is not without its hurdles. The most immediate challenge for many project owners is the cost volatility of the raw material. Steel prices are dictated by global commodity markets and can fluctuate wildly based on tariffs, supply chain disruptions, and international trade policies, making budget forecasting difficult for long-term projects. Furthermore, steel structures have poor acoustic insulating properties compared to the density of concrete. Sound travels easily through steel frames and lightweight floor decks, necessitating additional expenditure on acoustic insulation and isolation layers to meet residential comfort standards. Another technical limitation is susceptibility to vibration. Because steel floors are lightweight, they can be bouncy under foot traffic or rhythmic machinery loads, requiring careful dynamic analysis and potentially more expensive floor systems to dampen the movement. Finally, the requirement for specialized labor cannot be overstated. Finding a crew of certified welders and experienced ironworkers is more difficult and expensive in many developing regions than finding labor for concrete works, potentially leading to delays if the local workforce is not skilled in steel erection.

Advantages and Disadvantages of Reinforced Concrete Structures

Reinforced concrete maintains its status as the global standard for construction largely due to its economic resilience and inherent physical properties. The materials required to make concrete are generally available within a short radius of any construction site in the world, shielding projects from the complex logistics of importing prefabricated steel components. This local availability extends to the workforce; the barrier to entry for general concrete labor is lower, making it easier to scale up a workforce for large projects in emerging markets. Functionally, the sheer mass of concrete provides excellent thermal inertia. This helps regulate indoor temperatures, reducing the load on HVAC systems in climates with high diurnal temperature variation. Acoustically, the density of concrete walls and floors provides superior sound isolation between apartments or hotel rooms, a major selling point for residential developers. Furthermore, concrete is incredibly versatile in form. It can be poured into complex curves, arches, and irregular shapes that would be prohibitively expensive to fabricate in steel. This fluidity allows architects to treat the structure as a sculptural element, often leaving the concrete exposed as a finished surface.

Common Drawbacks and Risks in RCC Structures

The disadvantages of reinforced concrete are deeply rooted in its weight and its sensitivity to execution quality. An RCC structure is significantly heavier than a steel equivalent, which translates to larger, more expensive foundations. On sites with low soil bearing capacity, this weight penalty can force the use of deep pile foundations, drastically increasing project costs. The construction process is also weather-dependent; extreme cold or extreme heat can pause pouring operations or require expensive additives and temperature control measures to ensure the concrete cures correctly. Perhaps the most significant risk lies in the “hidden” nature of the defects. Once concrete is poured, verifying the placement of rebar or the consolidation of the mix is difficult. Issues such as honeycombing, segregation, or cold joints in concrete columns may occur if the pour is interrupted or poorly vibrated, compromising the structural integrity. Unlike steel, where a weld can be visually inspected and X-rayed easily, a defect inside a concrete column might only be discovered through destructive testing or, worse, after a structural failure. Moreover, concrete undergoes volume changes over time due to creep and shrinkage, which must be carefully managed with control joints to prevent unsightly and potentially damaging cracks.

Hybrid Solutions: Combining Steel and Reinforced Concrete

Modern engineering increasingly moves away from the binary choice of “steel or concrete” toward hybrid or composite systems that leverage the best properties of both. A common configuration in high-rise construction is the “concrete core with steel perimeter” system. In this arrangement, a central reinforced concrete core houses the elevators and stairs, providing the necessary lateral stiffness and fire resistance to resist wind and seismic loads. Surrounding this core is a lightweight steel frame that supports the floors, allowing for rapid erection and column-free views at the perimeter. Another powerful hybrid technique is the use of concrete-filled steel tubes (CFST) or steel-encased concrete columns. These composite members prevent the local buckling of the steel while the steel tube confines the concrete, significantly increasing its compressive strength and ductility. Composite floor decks, where concrete is poured onto profiled steel sheeting that acts as both formwork and tensile reinforcement, are now the industry standard for commercial office buildings. These systems reduce the slab depth and weight while eliminating the need for temporary propping and stripping of formwork, merging the speed of steel with the solidity of concrete.

When a Mixed Steel–Concrete Strategy Adds Real Value

A mixed strategy adds value when a project faces conflicting constraints that a single material cannot resolve efficiently. for instance, in a commercial complex comprising a shopping mall podium and an office tower, a hybrid approach is often optimal. The podium, requiring irregular shapes, high fire ratings, and vibration control for heavy foot traffic, might be best constructed in reinforced concrete. The tower above, requiring speed of erection and small column footprints to maximize rent, would benefit from a steel structural system. This transition requires careful detailing at the interface level, but it optimizes the budget and schedule. Additionally, hybrid solutions are excellent for retrofitting. An existing concrete building can be extended vertically using a lightweight steel structure, adding valuable square footage without overloading the existing foundations. By adopting a flexible mindset, engineers can assign concrete to compression-heavy elements and steel to tension/bending-heavy or long-span elements, resulting in a design that is materially efficient and economically superior to a mono-material solution.

Project-Based Decision Guide: When to Choose Steel, RCC or Hybrid

Steel structures are the logical choice for industrial facilities such as manufacturing plants, warehouses, and distribution centers. In these applications, the need for wide spans to accommodate machinery and racking systems, coupled with the requirement for rapid enclosure to start operations, makes steel unrivaled. Steel is also the preferred material for supertall skyscrapers (often in composite forms) where reducing self-weight is critical to making the project engineeringly feasible. Commercial office buildings in dense urban centers often favor steel to minimize column sizes and maximize tenant layout flexibility. Furthermore, temporary structures, airport terminals, and sports stadiums almost exclusively utilize steel due to the requirements for massive roof overhangs and the potential for future dismantling or modification. If the project requires long cantilevers or complex architectural geometries that defy gravity, steel trusses and space frames are usually the only practical solution.

Typical Use Cases for Reinforced Concrete Structures

Reinforced concrete is the undisputed champion for residential towers, hotels, and dormitories. In these sectors, the compartmentation of space matches the structural grid, and the acoustic separation provided by concrete mass is a non-negotiable requirement for occupant comfort. Infrastructure projects such as dams, retaining walls, tunnels, bridges (short to medium span), and water treatment facilities rely heavily on concrete for its durability against soil and water contact. Mid-rise commercial buildings in regions with low labor costs and high steel import tariffs will also default to concrete to keep the budget viable. Additionally, buildings that require high security or blast resistance, such as government bunkers or data centers, often utilize thick reinforced concrete walls for their sheer impact resistance and shielding capabilities. Any project where the structural thermal mass is part of the passive energy strategy will also lean heavily toward an exposed concrete solution.

Key Questions Developers and Engineers Should Ask Before Deciding

To make an informed selection between steel structures or reinforced concrete, stakeholders must evaluate the project constraints holistically.

- What is the cost of capital vs. the construction timeline? If the financing costs are high, the speed of steel may save more money than the material savings of concrete.

- What are the site access conditions? Can the site accommodate large cranes and 40-foot steel delivery trucks, or is it a tight urban lot better suited for concrete pumps?

- What is the seismic zone? High seismicity might favor the ductility of steel or require expensive detailing for concrete.

- What is the intended lifespan and adaptability? Is this a 50-year building or a 100-year legacy asset that will need repurposing?

- What is the local contractor expertise? Are there reputable steel fabricators nearby, or is the local industry predominantly concrete-focused?

- What are the fire rating requirements? Does the cost of intumescent paint for steel blow the budget compared to the natural fire rating of concrete?

Execution Quality: Why Formwork, Reinforcement Detailing and Fabrication Matter

The theoretical strength of a reinforced concrete structure means nothing without precise execution of the reinforcement detailing. The placement, spacing, and tying of rebar determine how the structure handles stress, particularly in critical zones like beam-column joints. Congested reinforcement can prevent the concrete from flowing around the bars, leading to voids that weaken the member. Understanding the types of reinforcement in construction—from standard deformed bars to welded wire mesh and prestressing tendons—is vital for optimizing the structural design. Errors in detailing, such as insufficient lap lengths or improper hook geometry, are common causes of structural failure under seismic loads. Therefore, the “economy” of concrete is contingent on rigorous site supervision to ensure that the steel hidden inside the gray matter is exactly where the engineer calculated it to be.

How Column Formwork and Pouring Practices Affect Concrete Reliability

In RCC construction, the formwork is not just a mold; it is the primary tool for quality assurance. High-quality Concrete Column Formwork ensures that the finished element is dimensionally accurate, vertically plumb, and free from surface defects. Poor formwork can bulge under the hydrostatic pressure of wet concrete, leading to columns that are out of tolerance and require expensive rectification. Furthermore, the tightness of the formwork joints is critical to preventing grout leakage, which causes honeycombing and exposes the reinforcement to corrosion. The selection of the right formwork system—whether timber, steel, or aluminum—impacts the speed of the pouring cycle and the final surface finish. The interaction between the formwork design and the concrete pouring rate must be carefully managed to avoid cold joints and ensure a monolithic structure that performs as intended.

Fabrication, Welding and Quality Control in Steel Structures

For steel structures, execution quality shifts from the site to the fabrication shop. The structural integrity relies heavily on the quality of welds and the precision of bolt holes. A millimeter of error in a factory-drilled hole can lead to massive delays on site if beams do not fit together. Quality control involves non-destructive testing (NDT) methods like ultrasonic or magnetic particle inspection to verify that welds are free from internal cracks or porosity. The surface preparation of the steel before painting or galvanizing is also critical; if the steel is not properly cleaned (shot-blasted) before the protective coating is applied, the coating will fail prematurely, leading to corrosion issues that are incredibly expensive to fix once the building is clad. Therefore, selecting a certified fabricator with a robust QA/QC program is as important as the structural design itself.

How BFS Industries Supports Both Steel and Concrete Construction Strategies

At BFS Industries, we understand that modern construction is rarely about choosing one material to the exclusion of others. Our expertise spans the full spectrum of structural execution. For reinforced concrete projects, we provide advanced formwork solutions that ensure precision, safety, and speed, helping contractors minimize the common risks associated with on-site casting. Our systems are designed to handle high pour pressures and complex geometries, ensuring that the concrete structure meets the most stringent architectural and structural specifications. Simultaneously, for clients opting for steel construction, BFS Industries offers comprehensive support in structural steel fabrication and supply. We recognize the nuances of both supply chains and the different logistical demands of lifting heavy steel versus pouring concrete. This dual capability positions us as a neutral, technical partner focused on the project’s success rather than pushing a single material agenda.

Engineering Support for Selecting the Right Structural System

Beyond product supply, BFS Industries provides engineering support to help developers and contractors navigate the “Steel Structures or Reinforced Concrete” dilemma. We assist in analyzing the constructability of the design, offering insights into how formwork cycles might impact the schedule compared to steel erection sequences. By evaluating the specific constraints of your project—be it a tight urban infill or a sprawling industrial park—we can recommend the most efficient formwork systems or steel fabrication strategies. Our goal is to ensure that whichever system is chosen, it is executed with the highest level of quality and efficiency. We bridge the gap between the design drawing and the reality on site, ensuring that the theoretical advantages of your chosen structural system are realized in the final built asset.

Conclusion: Steel Structures or Reinforced Concrete – Which Is Right for Your Project?

The choice between steel structures or reinforced concrete is never binary; it is a strategic calculation of risk, cost, time, and performance. Steel offers speed, lightweight efficiency, and architectural daring, making it the preferred choice for high-rise offices and industrial facilities. Reinforced concrete offers robustness, acoustic comfort, and cost-effectiveness for residential and general-purpose construction. Often, the best solution lies in the intelligent combination of both. As the industry evolves, the lines between these systems continue to blur with the rise of composite structures and advanced fabrication techniques. Ultimately, the success of the project depends not just on the material chosen, but on the quality of execution—from the precision of the steel weld to the integrity of the concrete formwork. By partnering with experts like BFS Industries, capable of supporting both steel and concrete methodologies, project stakeholders can ensure that their structural choices translate into durable, profitable, and safe reality.