High-Quality Shoring, Propping & Scaffolding Systems Supplier

Introduction

Shoring systems play a critical role in construction projects, delivering reliable temporary support to structures, formwork, and excavations to prevent failures during building, renovation, or demolition. At BFS Industries, we provide engineered shoring and scaffolding solutions that meet the needs of contractors and civil engineers seeking safe, durable, and adaptable equipment. From adjustable shoring props to complete scaffolding systems, our products ensure stability, compliance with safety standards, and efficiency on every construction site.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

Shoring & Scaffolding Category

Shoring & Scaffolding Products

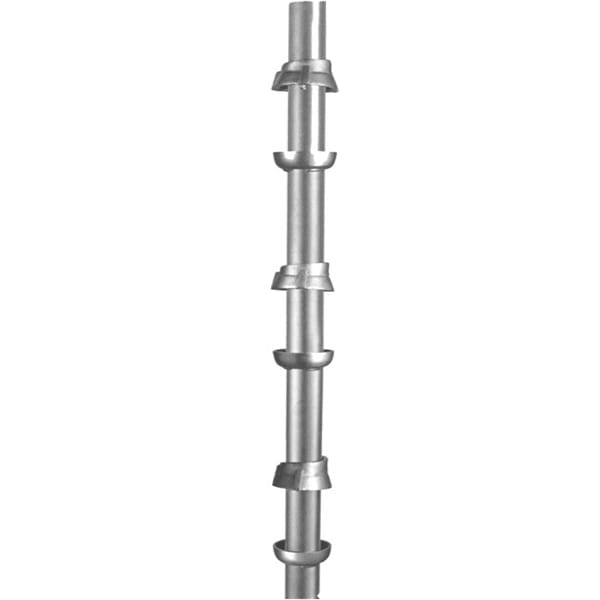

Cuplock Scaffolding Standard

Cuplock Ledger

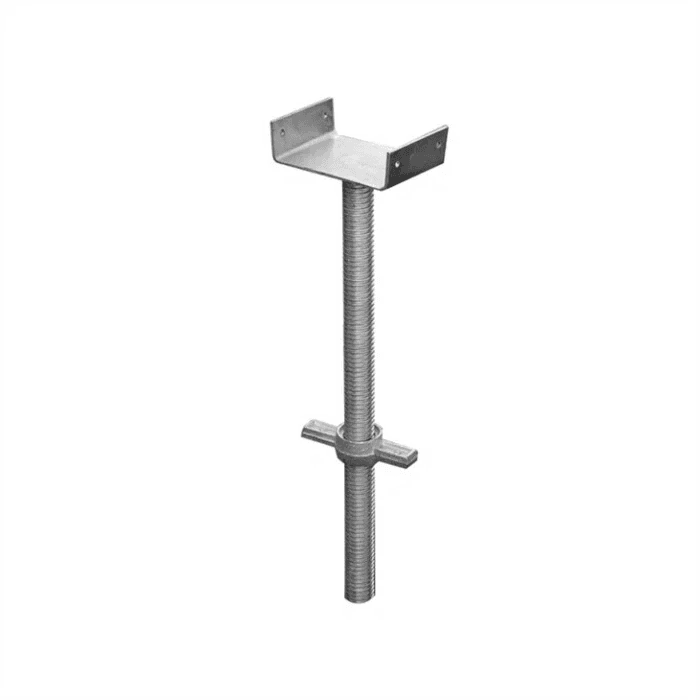

Adjustable U Head

Cuplock Scaffolding Transom

Cuplock Universal Jack

Scaffolding jack Plate

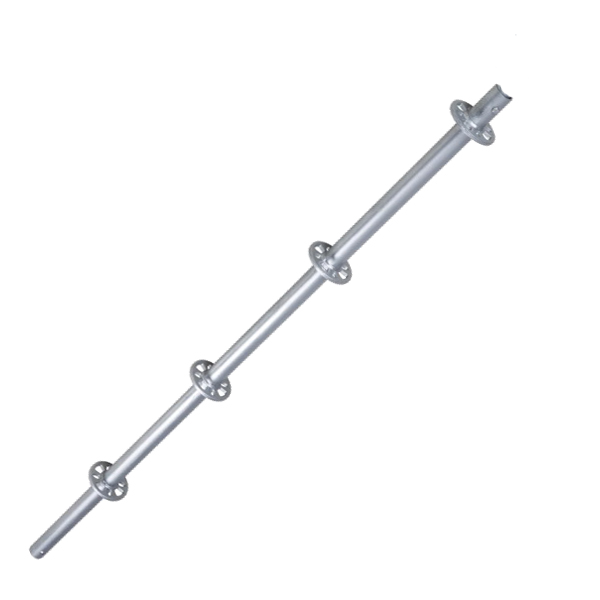

Ringlock Standard

Ringlock Ledger

Ringlock Radial

Ringlock Diagonal Brace

Ringlock GS Spigot Connector(SC)

What Are Shoring, Propping & Scaffolding Systems in Construction?

Shoring scaffolding systems in construction are temporary support structures—such as adjustable props, beams, or hydraulic jacks—used to stabilize trenches, foundations, and buildings at risk of collapse. These systems are vital for ensuring worker safety and maintaining structural integrity during high-risk construction phases, including excavation, foundation work, slab support, and structural repairs. At BFS Industries, we provide engineered shoring scaffolding systems that prevent costly project delays, reduce risks of structural failure, and ensure full compliance with international safety standards.

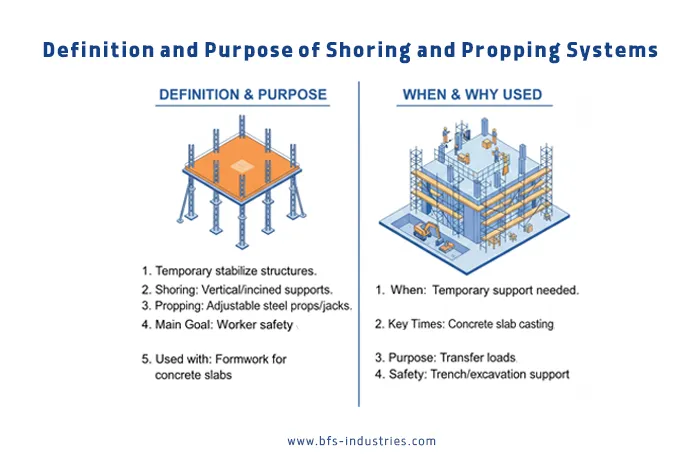

Definition and Purpose of Shoring and Propping Systems

Shoring and propping systems are essential structural supports used in construction to temporarily stabilize buildings, slabs, walls, or trenches. Shoring refers to the process of providing vertical or inclined supports, while propping specifically involves the use of adjustable steel props or jacks to hold formwork, beams, or floors in place. These systems ensure worker safety and structural integrity during construction, renovation, or demolition. They are commonly used with formwork systems for concrete slabs, beams, and columns. High-quality shoring solutions, including Cuplock, Ringlock, and PAL scaffolding, allow for precise load distribution, quick installation, and compliance with engineering standards like EN1065. Proper use of shoring and propping prevents structural collapse, reduces the risk of accidents, and enables efficient project execution. Additionally, engineered shoring systems can be customized to meet site-specific requirements, offering both heavy-duty and lightweight options for different construction applications.

When and Why Shoring Systems Are Used in Construction

Shoring systems are employed in construction whenever temporary support is needed to maintain structural stability. They are crucial during concrete slab casting, beam installation, wall construction, and renovation projects where existing structures require reinforcement. Temporary shoring ensures that loads are properly transferred to the ground or adjacent supports, preventing sagging, collapse, or deformation. Shoring is also vital in trenching and excavation works, providing safety against soil cave-ins.

Propping and shoring are used to hold formwork in place during concrete curing, ensuring precise alignment and structural integrity. Contractors rely on adjustable steel props, Cuplock, Ringlock, or PAL scaffolding systems to accommodate various heights and load capacities. Using shoring systems not only complies with safety regulations, including OSHA standards, but also accelerates project timelines, reduces material waste, and minimizes the risk of costly structural failures. Properly implemented shoring solutions enhance overall construction efficiency and safety.

Types of Shoring, Propping & Scaffolding Systems

Shoring scaffolding systems are available in a variety of forms, each designed to meet specific project requirements, ground conditions, and structural demands. Selecting the appropriate type of shoring scaffolding system is essential to ensure safety, stability, and efficiency on construction sites. Below is an overview of the main shoring scaffolding methods commonly employed in modern construction projects.

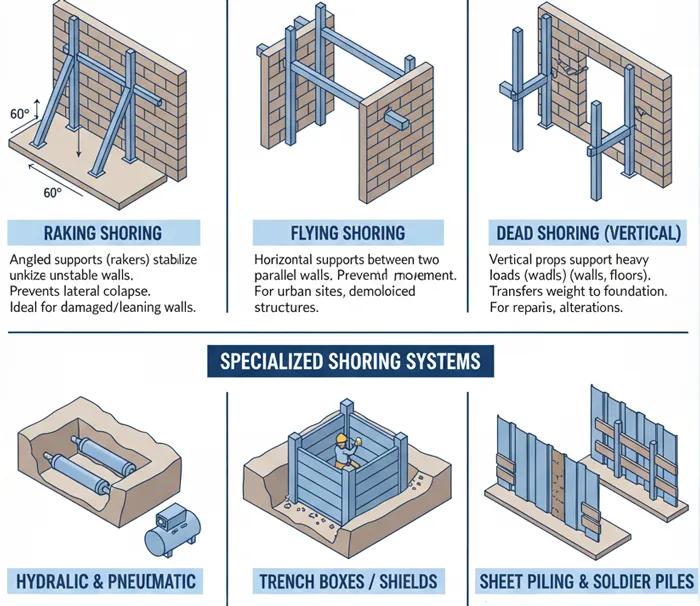

Raking Shoring Systems

Raking shoring is a method within shoring scaffolding systems that uses angled supports, called rakers, to stabilize unstable walls and prevent lateral collapse. Positioned at approximately 60 to 70 degrees, these rakers efficiently transfer loads and are usually connected to steel wall plates for balanced force distribution. This approach is particularly suitable for supporting damaged or leaning walls during excavation or structural repairs, providing reliable lateral stability in critical construction scenarios.

Flying Shoring Systems

Flying shoring, also known as horizontal shoring, is a key method within shoring scaffolding systems used to support two parallel walls—typically when the structure between them has been removed or demolished. This system employs horizontal members, or shores, braced between the walls and supported by vertical posts or standards. All elements are securely wedged to prevent inward movement and potential collapse, with optional diagonal struts for added stability. Flying shoring is especially effective in dense urban sites where space constraints make traditional raking shoring impractical.

Dead Shoring Systems

Dead shoring, also called vertical shoring, is a fundamental technique within shoring scaffolding systems used to support vertical loads from structural elements such as load-bearing walls, floors, or roofs. This method employs vertical props or posts to safely transfer weight to a stable foundation, often incorporating horizontal beams—known as needles—to evenly distribute the load. Dead shoring is commonly applied during the repair, alteration, or reconstruction of damaged or defective load-bearing walls, ensuring stability while structural work is being performed.

Hydraulic and Pneumatic Shoring Systems

Hydraulic shoring is an advanced method within shoring scaffolding systems that employs hydraulic cylinders to apply controlled pressure against trench walls, preventing soil collapse. This system is quick to install, fully adjustable, and adaptable to different trench depths and soil conditions. Hydraulic shoring is widely utilized in urban excavations and sites with unstable soil, providing safe and efficient temporary support for construction projects.

Pneumatic Shoring in Shoring Scaffolding Systems

Pneumatic shoring is a type of shoring scaffolding system that functions similarly to hydraulic shoring but uses compressed air instead of hydraulic fluid to maintain pressure. This makes the system lighter, more portable, and easy to deploy, ideal for small-scale excavations, urban sites, or confined areas where heavy equipment access is limited. Pneumatic shoring ensures trench wall stability, enhances worker safety, and provides an efficient solution for temporary structural support in shallow or challenging construction environments.

Trench and Excavation Shoring Systems

Trench shoring systems are specialized shoring scaffolding systems designed to support the walls of excavations, particularly for pipelines, utility installations, or foundation work. Common methods include:

-

Trench boxes (shields): Prefabricated steel or aluminum structures that protect workers from cave-ins without actively restraining soil movement.

-

Sheet piling: Interlocking steel or vinyl sheets driven into the ground to form a continuous wall, ideal for wet or unstable soil conditions.

-

Soldier piles with lagging: Vertical steel H-beams combined with timber or steel panels to support deeper excavation sides.

These trench shoring solutions are essential for preventing collapses, ensuring worker safety, and maintaining stability in confined excavation environments, providing efficient and reliable temporary support for construction projects.

Temporary vs. Permanent Shoring Systems

Shoring scaffolding systems can be categorized as temporary or permanent, depending on their role in the construction process. Temporary shoring is deployed during phases such as excavation, structural repair, or remodeling and is removed once the permanent structure can support itself. Common examples include trench boxes, hydraulic shores, and cuplock scaffolding.

In contrast, permanent shoring remains integrated into the completed structure, providing long-term structural support. This type is typically constructed from durable materials such as steel or reinforced concrete and is widely used in retaining walls, deep foundation systems, and infrastructure projects that require ongoing reinforcement. Using the appropriate temporary or permanent shoring scaffolding system ensures site safety, structural stability, and regulatory compliance throughout the construction process.

Shoring Components and Equipment in a Shoring System

A shoring system relies on a combination of specialized components and equipment to provide reliable structural support during construction. These elements work in unison to stabilize excavations, walls, and existing structures, ensuring both safety and efficiency on-site. Understanding the role of each component is crucial for structural integrity, worker safety, and compliance with engineering standards. Key components commonly used in shoring systems include: adjustable props, steel or timber beams, hydraulic jacks, trench boxes, wall plates, rakers, and braces, each designed to provide targeted support for various construction scenarios.

Steel Posts and Beams in Shoring Systems

Steel posts and beams are the backbone of many shoring systems, providing essential vertical and horizontal support. Steel posts, including heavy-duty shoring props or slab props, are designed to carry vertical loads, while horizontal members like H-beams or I-beams distribute structural forces across wider spans. These components are highly valued for their durability, load-bearing capacity, and adaptability, making them suitable for a wide range of construction and excavation projects.

Leading shoring prop companies and adjustable U-shaped shoring prop suppliers emphasize the importance of using certified steel posts and beams to create safe shoring systems. Their adjustability allows customization based on specific site conditions, structural requirements, and project complexity, ensuring both worker safety and structural stability.

Shoring Jacks and Frames in Scaffolding Shoring Systems

Shoring jacks—including hydraulic, pneumatic, and screw jacks—provide precise adjustments in height and pressure, ensuring optimal support during construction or excavation. These jacks are often incorporated into frames, which act as the structural backbone, holding all components securely in place.

In scaffolding shoring applications, such as trench shoring systems, steel frames support plates or sheets that stabilize excavation walls, preventing collapse and protecting workers. The combination of adjustable jacks and frames allows for flexible and reliable shoring solutions that can adapt to different soil conditions, structural loads, and site requirements, ensuring both worker safety and structural stability.

Adjustable Props and Acrow Systems in Shoring Solutions

Adjustable props, often called telescopic steel supports, are essential elements of shoring solutions that can be extended or retracted to meet various height requirements on construction sites. These props are widely used to support formwork, concrete slabs, beams, and temporary structures during different phases of building.

Renowned for their versatility, quick installation, and reliable load-bearing capacity, adjustable props play a critical role in structural shoring systems. They are particularly valuable in projects requiring temporary vertical support, allowing engineers and contractors to implement efficient, safe, and adaptable shoring solutions across a wide range of construction scenarios.

Bracing and Support Tools in Shoring Systems

Bracing tools, including wales, struts, and diagonal braces, are essential components of any shoring system, providing critical lateral stability. Wales are horizontal members that connect vertical supports, ensuring even load distribution and structural alignment. Struts and diagonal braces prevent unwanted movement by counteracting lateral forces, maintaining stability under dynamic conditions.

Additional support elements, such as base plates and head assemblies, enhance stability and improve load transfer to the ground, ensuring the overall effectiveness and safety of the shoring system. Proper use of these bracing and support tools is crucial for implementing safe shoring solutions in construction and excavation projects.

Shoring Design and Load Calculations in Shoring and Scaffolding

Effective shoring system design is the cornerstone of safe and efficient shoring and scaffolding practices. The process begins with a detailed assessment of site conditions, load requirements, material selection, and regulatory compliance, ensuring that every factor is accounted for to prevent collapse and maintain structural integrity.

Leading propping and shoring suppliers emphasize precise load calculations and engineered designs to provide reliable temporary support during excavation, formwork installation, or structural repair. Properly designed systems account for vertical and lateral loads, soil stability, and construction dynamics, enabling contractors to implement safe shoring and scaffolding solutions that protect workers, minimize project delays, and ensure compliance with international safety standards.

Factors Affecting Shoring Design in Shoring and Scaffolding Systems

Several critical factors influence the design of an effective shoring system within shoring and scaffolding applications. Soil type and condition are fundamental, as materials like clay, sand, or gravel have unique load-bearing capacities and stability characteristics. The depth and width of the excavation directly determine the level of reinforcement required—deeper or wider excavations demand stronger, more robust systems.

Structural loads must also be considered, including dead loads from permanent structures, live loads from construction activities, and dynamic forces such as wind or seismic activity. Groundwater levels significantly affect soil stability; high water tables often require specialized waterproof shoring solutions, such as sheet piling. Finally, the presence of adjacent structures or underground utilities may necessitate additional support to prevent shifting, settlement, or structural damage during excavation. Proper consideration of these factors ensures safe, reliable, and compliant shoring solutions in diverse construction environments.

Soil Pressure and Structural Load in Shoring Systems

Soil pressure on shoring systems is influenced by multiple factors, including soil type, excavation depth, and surcharge loads such as nearby equipment, spoil piles, or stored materials. These pressures vary depending on soil characteristics—cohesive soils like clay exert different forces compared to granular soils such as sand or gravel.

In addition to soil-related forces, structural loads must be carefully considered. This includes the dead load of the structure, as well as dynamic loads arising from construction activities, equipment movement, or environmental factors. In concrete construction, where slabs, beams, and columns exert significant vertical loads, accurate load calculations are critical to ensure that the shoring system can withstand all applied forces. Proper design prevents potential failure or collapse, ensuring worker safety and maintaining structural integrity throughout the construction process.

Building Codes and Engineering Standards for Shoring and Scaffolding Systems

Effective shoring system design must strictly adhere to local building codes and engineering standards, including regulations such as OSHA’s 29 CFR 1926 Subpart P, which governs excavation and trench safety. These rules require protective systems for trenches deeper than 5 feet and stipulate that designs for deeper or more complex excavations must be reviewed and approved by a registered professional engineer.

Leading companies, including B.F.S Industries, ensure their shoring and scaffolding systems are engineered to meet or exceed these requirements. Compliance with such standards not only enhances worker safety and structural reliability but also mitigates legal risks and potential project delays due to non-compliance. Following engineering best practices guarantees that shoring solutions provide safe, reliable, and code-compliant support for all construction phases.

Shoring for Excavations, Trenches, and Shoring Formwork

Shoring for excavations and trenches is a vital safety measure in construction, particularly in unstable soil conditions or at significant depths. These systems are designed to prevent cave-ins, protect workers, and maintain structural integrity during excavation operations.

In addition to traditional trench shoring, shoring formwork plays an essential role in supporting concrete slabs, beams, and other structural elements during construction. Whether for utility trenches, foundation footings, or deep infrastructure projects, proper shoring and formwork ensure compliance with safety standards and minimize the risk of accidents, structural failures, or project delays.

OSHA Safety Guidelines

OSHA’s excavation standards (29 CFR 1926 Subpart P) are designed to safeguard workers from one of construction’s deadliest hazards—trench cave-ins. These regulations establish clear requirements for protective systems, inspection protocols, and design approvals based on trench depth and site conditions. Whether using sloping, benching, shoring, or shielding, compliance with these guidelines is essential for maintaining on-site safety and meeting federal legal standards.

| Feature | Trench Box (Shield) | Hydraulic Shores |

|---|---|---|

| Purpose | Protects workers from cave-ins | Prevents trench wall collapse |

| Mechanism | Steel or aluminum box placed in trench | Hydraulic cylinders apply pressure to walls |

| Installation | Lowered into trench, movable as work progresses | Installed and adjusted with hydraulic pump |

| Soil Support | Does not prevent soil movement | Actively supports soil to prevent movement |

| Use Case | Shallow to medium-depth trenches | Various depths, adaptable to soil conditions |

| Trench boxes protect workers by providing a safe space within the trench, while hydraulic shores actively stabilize the soil. (Source: United Rentals) | ||

Best Practices in Trench Shoring

To ensure safety and operational efficiency during trenching and excavation, implementing best practices is essential. Begin with a thorough soil analysis to classify the type (e.g., Type A, B, or C), which directly influences the choice of shoring. Select an appropriate shoring system based on trench depth, soil stability, and specific project requirements. Ensure proper installation by adhering to both manufacturer instructions and approved engineering designs. Daily and post-condition-change inspections by a competent person are critical to identify potential hazards. Finally, train all site personnel on OSHA standards and shoring safety procedures to minimize risk and maintain regulatory compliance.

Shoring in Building Renovation and Demolition

Shoring in building renovation and demolition plays a critical role in maintaining structural stability during transitional phases. Whether reinforcing weakened walls, supporting partial structures, or preparing for controlled demolition, proper shoring ensures worker safety and prevents unintended collapses. This section explores key applications, methods, and considerations for using shoring systems effectively in renovation and demolition projects.

Temporary Structural Shoring

Temporary structural shoring supports buildings during renovation or demolition, ensuring stability while parts of the structure are altered or removed. This is especially critical in selective demolition, where only specific sections are dismantled and the remaining structure must remain intact. Systems provided by companies like B.F.S Industries offer reliable solutions for safely distributing loads and preventing unintended structural failure during these operations.

Floor and Wall Support Methods

Common methods used in renovation and demolition shoring include:

Post Shoring, which uses vertical props to support floors or ceilings and prevent sagging or collapse;

Beam Shoring, where horizontal beams transfer loads to vertical supports, making it suitable for wider spans; and

Frame Shoring, a more complex system designed to support multiple structural elements—ideal for intricate renovation projects. B.F.S Industries provides durable and adaptable shoring systems for each of these applications, ensuring structural stability throughout the construction process.

Safety During Partial Demolition

Effective safety measures are essential when working with shoring systems to prevent accidents and ensure structural integrity. Oversight by a competent person—a trained individual responsible for evaluating site conditions and supervising shoring installation—is crucial. Regular inspections should be conducted to detect any signs of movement, misalignment, or failure in the system. All workers must receive proper training on shoring safety procedures and OSHA regulations to recognize hazards and respond appropriately. Additionally, load monitoring techniques, such as preload or stress monitoring, help prevent excessive force on the shoring or surrounding structures, enhancing both safety and performance.

Advantages of Using Engineered Shoring Systems

Engineered shoring systems offer significant advantages over traditional, improvised methods by providing greater precision, reliability, and compliance with safety standards. These systems are specifically designed and tested to handle structural loads under a variety of site conditions, reducing the risk of failure and enhancing overall project efficiency. Below are the key benefits of using engineered shoring systems in modern construction.

Increased Safety and Stability

Engineered shoring systems are purpose-built to accommodate defined structural loads and varying soil conditions, significantly minimizing the risk of collapse during construction. Their precision-engineered components ensure consistent performance, enhancing both safety and efficiency on the job site. By providing reliable support, these systems protect workers, nearby infrastructure, and the integrity of ongoing construction activities.

Faster Installation and Reusability

Modular engineered systems, such as hydraulic shores and trench boxes, are designed for rapid installation and removal, streamlining construction timelines. Their modularity enables easy adaptation to various site conditions, while the reusability of components makes them a cost-effective choice for contractors managing multiple projects. These systems offer both efficiency and economic advantages without compromising on safety or performance.

Cost Savings on Long-Term Projects

By preventing accidents and delays, engineered shoring systems help reduce overall project costs. Their built-in efficiency and component reusability make them especially valuable on large-scale or long-duration projects, where labor time, material waste, and safety risks can significantly impact the bottom line. These systems offer a smart investment for contractors seeking both safety and long-term savings.

Common Mistakes in Shoring and How to Avoid Them

Proper implementation of shoring systems is essential for ensuring structural stability and worker safety. However, mistakes during design, installation, or monitoring can lead to serious hazards, delays, and added costs. Below are some of the most common shoring errors and practical steps to avoid them.

Underestimating

One common mistake in shoring is failing to accurately assess the loads the system must support, which can result in inadequate reinforcement and potential collapse. To avoid this, engineers should perform detailed load calculations that account for all relevant forces—dead loads, live loads, wind, seismic activity, and surcharge pressures. Using structural analysis tools such as SAP2000 or ETABS helps ensure precision and reliability in the design phase, reducing the risk of structural failure.

Poor Bracing Techniques

A frequent mistake in shoring is the incorrect installation or design of braces, which can compromise system stability and lead to dangerous movement or collapse. To prevent this, always adhere to manufacturer guidelines and detailed engineering plans. Ensure that all braces are securely fastened, properly spaced, and accurately aligned. This not only maintains structural integrity but also enhances overall site safety.

Lack of Regular Inspection

| Mistake | Consequence | Prevention Strategy |

|---|---|---|

| Underestimating Loads | Structural failure, collapse | Thorough load calculations, engineering analysis |

| Poor Bracing Techniques | Instability, system failure | Follow manufacturer and engineering guidelines |

| Lack of Regular Inspection | Undetected weaknesses, accidents | Daily inspections by competent person |

| Not Inspecting After Condition Changes | Missed signs of failure or movement | Re-inspect after weather events, soil shifts, or modifications (OSHA) |

How to Choose the Right Shoring System for Your Project

Choosing the right shoring system is critical to ensuring structural safety, project efficiency, and regulatory compliance. The ideal system depends on various factors such as soil conditions, excavation depth, load requirements, and project duration. Below are key considerations to help determine the most suitable shoring solution for your specific construction needs.

Type of Project and Load Requirements

The type of construction project directly influences the selection of an appropriate shoring system. For example, excavation projects typically require trench shoring systems such as hydraulic shores or trench boxes to prevent soil collapse. In contrast, structural renovations or partial demolitions may call for dead shoring or flying shoring to support existing loads temporarily. Accurate calculation of load requirements—including the weight of the structure, live loads from construction activities, and potential surcharge loads—is essential to ensure safety and effectiveness throughout the project.

Site Conditions and Soil Type

Soil conditions play a critical role in determining the appropriate shoring system. According to OSHA classifications, soil types range from Stable Rock, which typically requires no shoring, to Type C soils like loose gravel that demand the most robust support. Type A soils—such as cohesive clay—may need protection for excavations deeper than 4 feet, while Type B soils like silt require shoring beyond 5 feet. Understanding these distinctions is essential, as selecting the wrong system can compromise safety. A geotechnical report is vital in this process, providing detailed information about soil composition, stability, and water table levels to guide proper shoring design and implementation.

Budget and Equipment Availability

When selecting a shoring system, it’s essential to consider both budget constraints and equipment availability. Opt for a solution that aligns with the project’s financial scope without compromising safety or performance. For short-term or smaller-scale projects, renting modular formwork systems such as trench boxes can offer a cost-effective and flexible option. On the other hand, for long-term or recurring projects, investing in shoring equipment may be more economical in the long run. Evaluating the total cost of ownership versus rental fees—along with availability from local suppliers—ensures timely execution and efficient resource use.

FAQs

1. What is the main purpose of shoring systems in construction projects?

Shoring provides temporary support to structures, preventing collapse during excavation, demolition, or renovation.

2. What is the difference between scaffolding and shoring systems?

Scaffolding provides access for workers at heights, while shoring supports structures to prevent collapse.

3. What are the most common scaffolding systems used in construction projects?

Common types include supported scaffolding, suspended scaffolding, cantilever scaffolding, and mobile scaffolding.

4. Is shoring more expensive than scaffolding, and why?

Generally, shoring is more expensive due to its complex design and load-bearing requirements, while scaffolding is more cost-effective and easier to set up.

5. What safety measures should be followed when using scaffolding and shoring systems?

Ensure stable foundations, proper assembly, use of guardrails, and protective gear for workers.