Cuplock Scaffolding System — Modular, Safe & Efficient Formwork Solution

Introduction

The cuplock scaffolding system is a globally recognized and extensively utilized solution in the construction and industrial sectors. It is a type of modular scaffolding, distinguished by its unique and highly efficient method of connecting components. At its core, the system revolves around a “cup” mechanism—a set of two cups, one fixed and one mobile—that locks the horizontal ledger elements to the vertical standard elements. This design simplicity belies its exceptional strength and versatility. Unlike traditional systems that rely on loose fittings and extensive bolting, the cuplock system provides a rigid and secure connection with just a few simple actions. This inherent efficiency translates directly into faster erection and dismantling times, significantly reducing labor costs and accelerating project timelines. It serves a dual purpose, excelling as both a secure access scaffolding and a robust shuttering system (falsework) for supporting concrete structures, making the cuplock formwork system a foundational element of modern, fast-paced construction.

Safety is our unwavering priority, shaping everything we do every single day.

Certified by trusted external bodies to ensure our customers’ complete peace of mind.

Creative design and smart material planning to deliver cost-efficient solutions.

Innovations for now and the future of the civil and construction industries.

cuplock scaffolding system Products

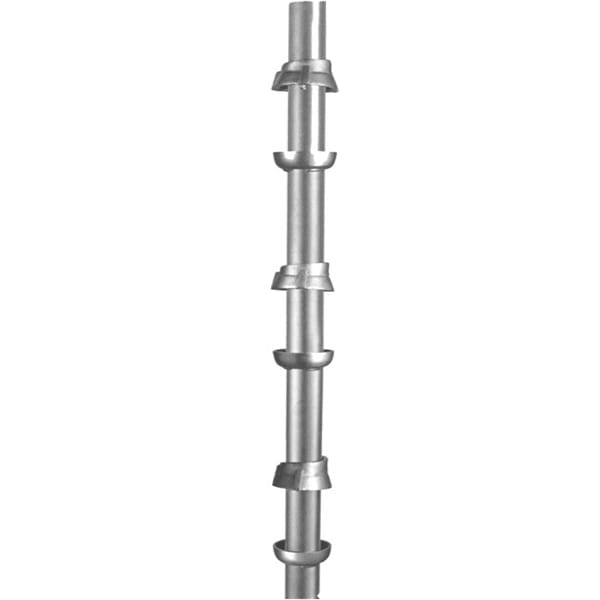

Cuplock Scaffolding Standard

Cuplock Ledger

Adjustable U Head

Cuplock Scaffolding Transom

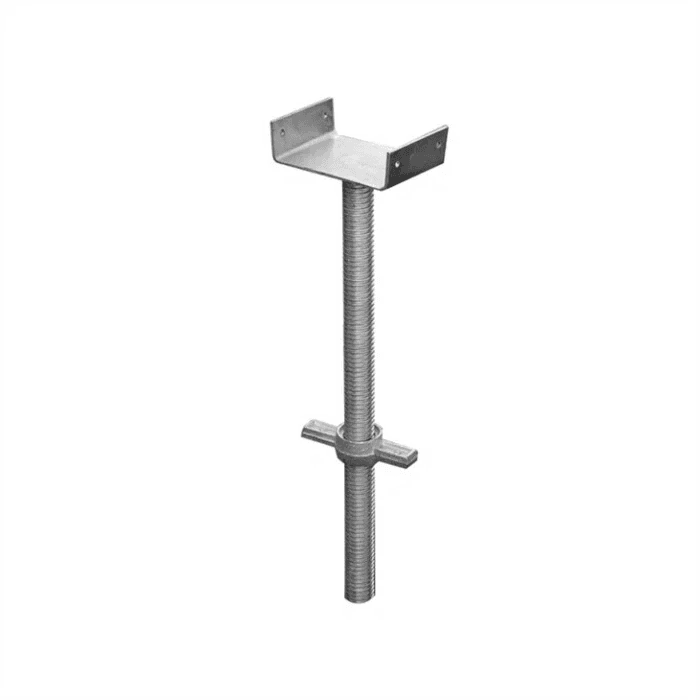

Cuplock Universal Jack

Scaffolding jack Plate

Components and Technical Specifications

The effectiveness of any cuplock scaffolding system is rooted in the precision engineering of its core scaffolding components. These parts are designed to fit together seamlessly, creating a structure of immense strength and stability. The primary material used is high-grade structural steel, often hot-dip galvanized, to provide maximum durability and resistance to corrosion, which is a hallmark of quality steel scaffolding. While the system is brilliantly simple, understanding its constituent parts is key to appreciating its capabilities. The genius lies in the node point, where up to four horizontal members can be secured to a vertical standard in a single, fast, and secure action. This modularity allows for complex geometries and adaptations on-site with minimal hassle. From the load-bearing standards to the versatile ledger beams, each component plays a critical role in the system’s overall integrity.

Standards (Verticals)

The Standards, or verticals, are the foundational load-bearing members of the cuplock shuttering system. They are manufactured from high-strength steel tubes and feature fixed bottom cups welded at standard 500mm or 1000mm intervals. These bottom cups are the base of the node point, designed to receive the ledger blades. A movable, or captive, top cup is situated just above, ready to drop and lock the components in place. Standards are available in various lengths to accommodate different project heights and are connected vertically using a spigot and pin, ensuring a secure and continuous vertical line of support.

Ledgers (Horizontals)

Ledgers, or horizontals, are the transverse members that connect the standards, dictating the bay length and width of the scaffold. The ends of the ledgers are forged into a “blade” shape. This blade fits precisely into the bottom cup of the standard. When the top cup is lowered and rotated, it clamps down on the ledger blades, creating an exceptionally rigid and positive-lock connection. This mechanism eliminates the need for any loose nuts, bolts, or wedges, which are common points of failure or loss in other systems. Ledgers come in numerous standard lengths to provide flexibility in grid design.

The Locking Mechanism (Top and Bottom Cups)

The locking mechanism is the defining feature of the cuplock scaffolding system. The fixed bottom cup is welded to the standard and is capable of accepting up to four ledger blades simultaneously. Once the blades are in place, the mobile top cup, which is captive on the standard’s tube, is lowered. A simple rotation of the top cup causes it to tighten against the ledger blades, locking them firmly against the bottom cup. This action can be finalized with a hammer blow, ensuring the connection is vibration-proof and forms a highly secure node point. This joint is so robust it provides structural rigidity without relying on diagonal bracing in many configurations.

Ancillary Components

Beyond the two main components, a range of ancillary parts expands the system’s versatility. Base jacks and adjustable U-head jacks are used at the bottom and top of the scaffold, respectively. Base jacks allow for precise leveling of the structure on uneven ground, while U-head jacks provide a secure platform for supporting formwork bearers in slab formwork applications. Other common components include hop-up brackets (cantilever brackets) for extending work platforms, intermediate transoms for supporting scaffold boards, and steel or timber battens (scaffold boards) that form the actual working deck.

How the Cuplock System Works

The assembly process for a cuplock scaffolding system is a masterclass in operational efficiency. Erection is both rapid and intuitive, requiring minimal specialized training. The process begins with the layout of the scaffold’s base. Adjustable screw jacks are set out according to the required bay dimensions and are adjusted to create a level foundation. The first lift of vertical standards is then placed into the base jacks. Following this, the first level of horizontal ledgers is connected. Operatives simply insert the ledger blades into the fixed bottom cups on the standards. This action is repeated to form a complete grid. Once the ledgers for a bay are in position, the mobile top cups on the standards are dropped and rotated. A single hammer blow to the top cup’s lug securely locks all ledgers in place, instantly creating a rigid and stable structural bay. This process is repeated, with subsequent lifts of standards being connected via their spigot ends and further levels of ledgers being added at the 500mm cup intervals. The lack of loose fittings minimizes the risk of lost scaffolding components and dramatically speeds up the entire erection and dismantling cycle.

Cuplock vs Traditional Scaffolding Systems

When evaluating scaffolding solutions, the comparison between a modern cuplock scaffolding system and traditional tube-and-coupler systems is stark. The primary difference lies in efficiency, safety, and component standardization. Traditional systems rely on steel tubes of various lengths and separate couplers (fittings) that must be manually tightened with a spanner. This process is time-consuming, labor-intensive, and highly dependent on the skill and diligence of the operative to ensure every single coupler is tightened to the correct torque. The cuplock system, by contrast, is a pre-engineered modular scaffolding solution. Its node points are fixed, and the locking action is positive and non-ambiguous. This fundamental design difference creates a cascade of advantages that impact project cost, safety, and speed from the ground up.

Speed and Efficiency

The most significant advantage of the cuplock system is the unparalleled speed of erection and dismantling. Studies and site reports consistently show that cuplock scaffolding can be installed up to four times faster than its tube-and-coupler counterpart. This is because there are no loose fittings to handle, position, and tighten. A single operative can securely lock four horizontal members at one node point in seconds. This reduction in labor time directly translates to substantial cost savings and allows subsequent trades to gain access or for concrete to be poured much sooner, compressing the overall project schedule.

Safety and Rigidity

Safety on a construction site is paramount. The cuplock scaffolding system is inherently safer due to its design. The positive lock of the cup mechanism is vibration-resistant and cannot be accidentally dislodged. The connection does not rely on friction, unlike a traditional coupler. This eliminates the risk of human error from under-tightened fittings, a common cause of scaffold failure. Furthermore, the standardized components and pre-engineered node points ensure that the structure is erected as designed, providing a consistent and verifiable load capacity. The rigid node point also means the structure requires less diagonal bracing, reducing component count and simplifying assembly.

Versatility and Component Management

While tube-and-coupler scaffolding is often praised for its flexibility, the cuplock system offers a more structured and versatile modularity. It is exceptionally well-suited for complex geometries, circular structures (like tanks or cooling towers), and heavy-duty shoring applications. The four-way connection allows for easy changes in direction. From a logistical standpoint, the system is far superior. With fewer, standardized components, inventory management, storage, and transport are simplified. The risk of losing small, critical components like couplers or bolts is eliminated, reducing replacement costs and ensuring crews always have the necessary parts on hand. This streamlined logistics is a hidden but powerful cost-saver in steel scaffolding fleet management.

Applications in Concrete Construction and Industrial Projects

The robust engineering and modular flexibility of the cuplock formwork system make it the solution of choice for a vast range of applications, particularly in large-scale Concrete Construction and complex industrial scaffolding scenarios. Its high load-bearing capacity and rapid assembly are ideal for projects where time, safety, and structural integrity are non-negotiable. The system’s adaptability allows it to serve as a single, integrated solution for both access and support, simplifying site logistics and procurement. From supporting massive concrete pours to providing safe maintenance access in operational plants, the cuplock system demonstrates its value across diverse and demanding environments.

Shuttering and Formwork Support

This is a primary and critical application. The cuplock scaffolding system is an outstanding falsework or shoring solution for supporting horizontal formwork. It is extensively used to create a support grid for slab formwork, beam bottoms, and bridge decks. The high-capacity standards, combined with securely locked ledgers, form a table-like structure capable of supporting immense wet concrete loads. The adjustable U-head jacks at the top allow for fine-tuning the height and ensuring the formwork is perfectly level. While cuplock excels at supporting horizontal structures, it is also frequently used as the primary support scaffold for vertical systems like concrete wall formwork, providing stability and access for crews.

Industrial and Infrastructure Projects

In the industrial sector, particularly in oil and gas, power generation, and manufacturing, maintenance and shutdown schedules are critical. Industrial scaffolding must be erected quickly, safely, and often in complex, confined spaces around existing pipework and machinery. The cuplock system’s modularity and speed are perfect for these “shutdown” scenarios. For infrastructure, it is a go-to bridge support system, used to create massive shoring towers for bridge construction and repair. Its ability to be assembled into birdcage scaffolds, staircase towers, and mobile towers makes it a versatile workhorse for large-scale civil engineering projects.

General Access and Facade Scaffolding

Beyond its heavy-duty support role, the cuplock system is also a highly efficient access scaffold. For building facades, maintenance, or finishing trades like painting and cladding, it provides a safe and stable working platform. The 500mm vertical increments of the cups allow for working platforms to be placed at precise, ergonomic heights. Integrated safety features like guardrail posts and toe-board clips can be easily incorporated, ensuring a fully compliant and safe working environment for all personnel on site.

Safety Standards and Compliance

The design of the cuplock scaffolding system is intrinsically linked to modern safety standards. The core principle of a positive, mechanical lock provides a level of security that systems reliant on friction or loose fasteners cannot match. Reputable manufacturers produce cuplock components in adherence with stringent international standards, such as the British Standard (BS EN 12810/12811) or equivalent OSHA guidelines in the United States. This compliance ensures that the steel scaffolding has undergone rigorous testing for load capacity, material quality, and manufacturing consistency. On-site, safety is further enhanced by the system’s simplicity. The reduced component count and intuitive assembly process minimize the opportunities for error. When erected by trained personnel and in accordance with the manufacturer’s technical guidelines, a cuplock structure provides a secure platform that protects workers and the project itself.

Key Advantages of the Cuplock Shuttering System

The widespread adoption of the cuplock shuttering system is a direct result of its clear and quantifiable advantages over other methods. These benefits are not isolated; they create a synergistic effect that improves a project’s bottom line, safety record, and overall efficiency. The system’s design addresses the most common pain points in construction: time, cost, and risk. By optimizing the assembly process, the modular scaffolding solution allows contractors to reallocate resources, reduce exposure to on-site risks, and meet demanding schedules. The initial investment in a quality cuplock system is quickly recouped through repeated, measurable savings on labor and materials, alongside the invaluable benefit of a safer worksite. The durability of galvanized components also ensures a long service life, making it a sound long-term capital investment.

- Accelerated Assembly: Up to 30-50% faster to erect and dismantle than traditional scaffolding, drastically cutting labor costs and project duration.

- Inherent Safety: The positive-locking cup mechanism with no loose fittings reduces the risk of component failure and human error during assembly.

- High Load Capacity: Engineered from high-strength steel, making it ideal for heavy-duty applications, including shoring, slab formwork, and industrial support.

- Unmatched Versatility: The four-way connection at a single node point allows for easy creation of complex geometries, circular scaffolds, and cantilevered structures.

- Long-Term Durability: Hot-dip galvanized components resist rust and damage, ensuring a long service life and a lower total cost of ownership.

Cost, Suppliers, and Availability

When assessing the cost of a cuplock scaffolding system, it is crucial to look beyond the initial purchase price and consider the total cost of ownership (TCO). While the high-quality, galvanized cuplock formwork system may represent a higher upfront capital expenditure compared to traditional tube and fittings or lower-quality painted systems, the return on investment is realized rapidly. The significant reduction in labor hours for both erection and dismantling provides immediate and recurring cost savings on every project. Furthermore, the enhanced durability of galvanized steel and the absence of small, losable fittings mean lower long-term replacement and maintenance costs. When selecting a supplier, it is vital to partner with a reputable manufacturer like bfs industries. A trusted supplier guarantees not only the quality and compliance of the components but also provides critical engineering support, reliable stock availability, and the assurance of system compatibility, which is essential for safety and performance.

Maintenance and Storage Best Practices

To maximize the long and profitable life of a cuplock scaffolding system, a disciplined approach to maintenance and storage is essential. The robust nature of the steel scaffolding components means they can withstand the rigors of a construction site, but proper care preserves their integrity and ensures safety. These practices are not just about maintenance; they are about professional asset management. An organized and well-maintained inventory of scaffolding components is safer, more efficient to deploy, and ultimately more profitable. It ensures that all components are fit for purpose before they are sent to the next project, preventing costly on-site delays or safety incidents.

Cleaning and Inspection

Immediately after dismantling, components should be inspected and cleaned. Concrete slurry, debris, and dirt must be removed, as they can interfere with the locking mechanism or hide potential damage. A pressure washer is often effective for this. During the cleaning process, each component must be visually inspected. Standards should be checked for straightness, and the cups and spigots for any signs of cracking or deformation. Ledger blades should be inspected for bends or damage. Any component that is bent, cracked, or excessively corroded must be quarantined and removed from service to be repaired or scrapped.

Proper Storage

Proper storage is critical to preventing damage and loss. Scaffolding components should be stored off the ground to prevent prolonged contact with moisture. The use of custom steel stillages or racks is the best practice. Components should be sorted and stored by type and length (e.g., all 3.0m standards together, all 1.8m ledgers together). This systematic organization protects the components, makes inventory counts simple, and dramatically speeds up the process of picking and loading equipment for the next job, saving time and labor.

Why Choose BFS Industries

Choosing a partner for your scaffolding needs extends far beyond the components themselves. At bfs industries, we provide a comprehensive solution built on a foundation of engineering excellence, uncompromising quality, and dedicated customer support. We understand that the cuplock scaffolding system is a critical element of your project’s success, and we commit to being a partner in that success. Our systems are manufactured to the highest international standards, subject to rigorous quality control to ensure every weld, cup, and ledger blade performs flawlessly. But our service doesn’t end at delivery. Our team of experienced engineers is available to provide technical design assistance, helping you optimize your scaffold designs for maximum safety and efficiency. We offer a complete range of solutions, from the versatile cuplock system to specialized heavy-duty shoring scaffolding systems, ensuring we can equip any project, regardless of scale or complexity. Choosing bfs industries means investing in reliability, safety, and a long-term partnership.

Frequently Asked Questions (FAQ) About Cuplock Scaffolding

What is the maximum load capacity of a cuplock system?

The load capacity of a cuplock system is not a single, fixed number. It is highly dependent on the specific configuration, including the bay size (ledger length), lift height (vertical distance between ledgers), and the overall height of the structure. However, the system is engineered specifically for heavy-duty applications. When used as shoring for slab formwork, a standard-duty leg can typically support loads of 40-50 kN (kilonewtons) or more, assuming it is braced correctly. For any specific application, the load capacity must be calculated by a qualified engineer based on the manufacturer’s technical data.

Can the cuplock shuttering system be used for circular structures?

Yes, absolutely. This is one of the system’s key advantages. The circular bottom cup can accept the ledger blades at various angles, not just at 90 degrees. This flexibility allows for the easy creation of curved or circular scaffolding, making the cuplock shuttering system an ideal choice for constructing or accessing tanks, cooling towers, chimneys, and other curved architectural or industrial structures. This is far more difficult and time-consuming to achieve accurately with traditional scaffolding.

Is the cuplock system compatible with other scaffolding types?

Generally, no. The cuplock scaffolding system is a proprietary-style system with unique component dimensions and a specific locking mechanism. It is critically important for safety and structural integrity that components from different manufacturers or different scaffolding systems (e.g., ringlock, kwikstage) are never mixed. Doing so can lead to an insecure connection, component failure, and catastrophic collapse. Always source a complete, compatible system from a single, reputable supplier.

What is the standard finish for cuplock components?

The industry standard for high-quality cuplock scaffolding components is a hot-dip galvanized finish. This process involves submerging the fabricated steel components in a bath of molten zinc. This creates a durable, corrosion-resistant coating that is metallurgically bonded to the steel. This finish is far superior to simple paint or electroplating, as it protects the steel from rust even in harsh coastal or industrial scaffolding environments, ensuring a significantly longer and more reliable service life for the equipment.

How long does Cuplock scaffolding last?

Cuplock scaffolding is designed to be durable and long-lasting. With proper maintenance, it can be used for many years, providing a reliable and safe platform for construction workers.