Cuplock Scaffolding Standard

| Material |

Steel sheet (ST37) |

|---|---|

| Diameter Of Steel Tube |

48.3 mm |

| Welding Type |

CO₂ or SMAW |

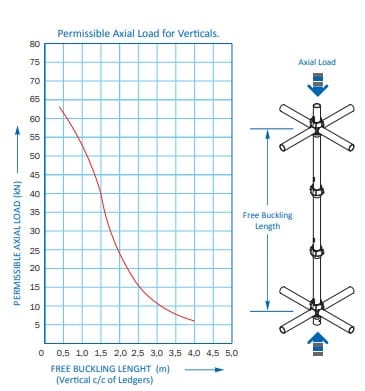

| Load Capacity |

"Depends on design configuration" |

| Surface Coating |

Painted |

| Availability |

"Available for both sale and rental" |

| Delivery Time |

Based on order quantity |

| Shipping Origin |

Jebel Ali, UAE |

Cuplock Scaffolding Standard: Design, Sizes, and Specifications

At BFS Industries, we manufacture high-quality Cuplock Scaffolding Standards designed to meet international safety and performance requirements. As the vertical component of the Cuplock scaffolding system, the standard plays a vital role in ensuring stability and load distribution across construction, maintenance, and industrial projects.

Known for its modular design, quick assembly, and durable material composition, the Cuplock Standard is available in multiple sizes and specifications to suit different project requirements. With precision-engineered cup joints and reliable surface treatments, these standards provide both strength and long-term resistance against wear and corrosion. In this section, we explore the design, material options, dimensions, and applications of the BFS Industries Cuplock Scaffolding Standard, highlighting why it remains a preferred choice for contractors worldwide.

Material Properties of BFS Industries Cuplock Scaffolding Standard

The Cuplock Scaffolding Standard from BFS Industries is manufactured using Q345 carbon steel (GB/T 1591), a trusted low-alloy, high-strength structural steel widely applied in modern construction. Q345 offers a yield strength of 345 MPa and a tensile strength between 470–660 MPa, making it exceptionally reliable for heavy-duty scaffolding applications.

This material ensures excellent mechanical performance, including:

- High durability for long-term use in demanding environments.

- Good weldability for strong and secure joint connections.

- Superior load-bearing capacity, essential for vertical scaffolding components.

By utilizing Q345 carbon steel, BFS Industries guarantees that each Cuplock Standard can withstand significant structural loads while maintaining a relatively lightweight profile. This balance of strength and efficiency makes it an ideal choice for projects requiring safe, stable, and cost-effective scaffolding solutions.

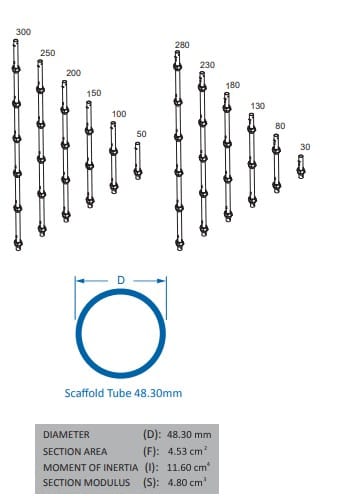

| Code | Item | Length (cm) |

|---|---|---|

| BFS- Cuplock Standard 300 | Cuplock Spigoted Standard | 300 |

| BFS- Cuplock Standard 280 | Cuplock Spigoted Standard | 280 |

| BFS- Cuplock Standard 270 | Cuplock Spigoted Standard | 270 |

| BFS- Cuplock Standard 250 | Cuplock Spigoted Standard | 250 |

| BFS- Cuplock Standard 230 | Cuplock Spigoted Standard | 230 |

| BFS- Cuplock Standard 200 | Cuplock Spigoted Standard | 200 |

| BFS- Cuplock Standard 180 | Cuplock Spigoted Standard | 180 |

| BFS- Cuplock Standard 150 | Cuplock Spigoted Standard | 150 |

| BFS- Cuplock Standard 130 | Cuplock Spigoted Standard | 130 |

| BFS- Cuplock Standard 100 | Cuplock Spigoted Standard | 100 |

| BFS- Cuplock Standard 80 | Cuplock Spigoted Standard | 80 |

| BFS- Cuplock Standard 70 | Cuplock Spigoted Standard | 70 |

| BFS- Cuplock Standard 50 | Cuplock Spigoted Standard | 50 |

| BFS- Cuplock Standard 30 | Cuplock Spigoted Standard | 30 |

Tube Specifications of BFS Industries Cuplock Scaffolding Standard

Each Cuplock Scaffolding Standard by BFS Industries is manufactured from a 48.3 mm outer diameter (O.D.) tube with a wall thickness of 3.2 mm. These dimensions strictly comply with international scaffolding standards, including BS1139 and EN12810, ensuring full compatibility with other Cuplock system components such as ledgers, transoms, and braces. The 48.3 mm tube size strikes the perfect balance between strength and lightweight handling, allowing the structure to carry heavy loads while remaining easy to assemble and dismantle on-site. This makes the Cuplock Standard highly reliable for diverse applications, from building construction to industrial maintenance and integration with advanced Shoring Scaffolding Systems.

Length Variations of BFS Industries Cuplock Scaffolding Standards

To meet diverse project requirements, BFS Industries manufactures Cuplock Scaffolding Standards in multiple length variations. This flexibility ensures that contractors can select the right size for applications ranging from low-height shoring to multi-level construction scaffolding.

All lengths are fully compatible with the Cuplock system components such as ledgers, transoms, and braces, guaranteeing maximum safety and interchangeability on-site.

Here are the available Cuplock Standard sizes (lengths):

| Length (m) | Application |

|---|---|

| 0.3 – 0.8 m | For adjustments, small lifts, and base-level support |

| 1.0 – 1.8 m | Ideal for mid-height structures and modular connections |

| 2.0 – 3.0 m | Used in high-load projects, vertical scaffolding, and tall shoring systems |

Available lengths include: 0.3 m, 0.5 m, 0.7 m, 0.8 m, 1.0 m, 1.3 m, 1.5 m, 1.8 m, 2.0 m, 2.3 m, 2.5 m, 2.8 m, and 3.0 m.

These lengths allow for flexibility in configuring the scaffolding to suit different project heights and structural designs. The effective length of the standard is measured from top to bottom, excluding the spigot, which facilitates vertical connections.

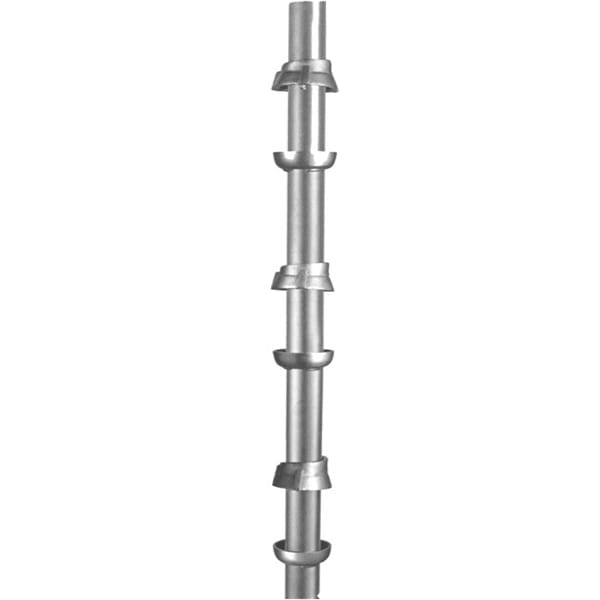

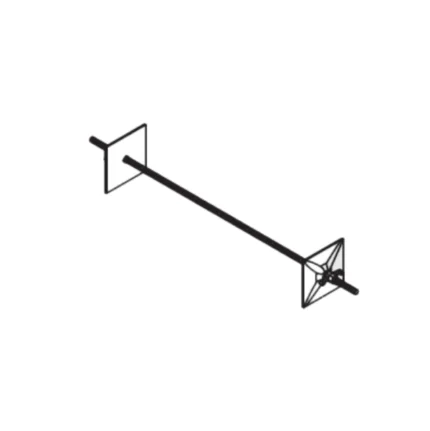

Design Features of Cuplock Scaffolding Standard

The BFS Industries Cuplock Scaffolding Standard features a unique node-point connection system, enabling up to four horizontal members (ledgers or transoms) to attach to a vertical standard in a single action, without the need for nuts, bolts, or wedges. The fixed bottom cup, welded at 500 mm intervals and made from high-quality 5 mm steel plates, is typically positioned 80 mm from the base to enhance structural stability and reduce the need for extra bracing. The movable top cup, either drop-forged or cast, slides over ledger blades and locks them in place with a simple rotation, often secured by a hammer blow, ensuring rapid and secure assembly. Additionally, the spigot and bolting system allows vertical stacking and bolting at the top and bottom for added stability in taller structures. These design innovations make the Cuplock Standard highly versatile, capable of forming complex configurations such as circular scaffolds, staircase towers, and birdcage structures, making it an ideal solution for demanding Concrete Construction projects.

Applications

The BFS Industries Cuplock Scaffolding Standard is a highly versatile solution suitable for a wide range of applications in Concrete Construction and other construction projects. In building construction, it provides reliable support for formwork, access platforms, and shoring across residential, commercial, and industrial sites. In civil engineering projects, the system is ideal for bridge construction, highways, and other infrastructure developments due to its high load-bearing capacity. It is also widely used for maintenance and renovation, including façade scaffolding, masonry work, and access in confined spaces. Furthermore, the Cuplock Standard adapts seamlessly to specialized applications in shipbuilding, oil and gas, and aviation industries, accommodating curved or irregular structures. Thanks to its combination of strength, ease of assembly, and flexibility, BFS Industries’ Cuplock Scaffolding Standard remains a preferred choice for contractors seeking safe, efficient, and cost-effective scaffolding solutions.

Advantages of BFS Industries Cuplock Scaffolding Standard

The BFS Industries Cuplock Scaffolding Standard offers a range of key advantages that make it a preferred choice for Concrete Construction and large-scale projects. Its node-point connection system allows for rapid erection and dismantling, reducing labor costs by up to 30–50% compared to traditional scaffolding. Constructed from high-strength Q345 steel with secure cup connections, the system provides exceptional stability and safety, fully complying with international standards such as EN12810 and ISO9001. The Cuplock Standard is also highly versatile, compatible with a wide array of Cuplock components and adaptable to various configurations, including circular scaffolds, staircase towers, and Shoring Scaffolding Systems. Finally, galvanized surface treatments enhance durability and corrosion resistance, extending the service life of the scaffolding and minimizing maintenance costs. These combined benefits ensure that BFS Industries’ Cuplock Scaffolding Standard delivers efficiency, reliability, and long-term value for contractors.

Conclusion

The BFS Industries Cuplock Scaffolding Standard is a cornerstone of modern scaffolding solutions, crafted from high-strength Q345 carbon steel with a 48.3 x 3.2 mm tube and available in lengths ranging from 0.5 m to 3.0 m. Advanced hot-dip or electro-galvanized surface treatments ensure long-term durability and resistance to corrosion, while its innovative cup-locking system delivers speed, safety, and versatility during assembly and dismantling. Widely used across Concrete Construction, civil engineering projects, and specialized industrial applications, this system provides reliable, efficient, and cost-effective support for temporary structures. With compliance to international standards and compatibility with a wide range of Cuplock components and Shoring Scaffolding Systems, the BFS Industries Cuplock Scaffolding Standard remains a top choice for contractors seeking safe, high-performance scaffolding solutions worldwide.

عادل البدراني –

هل هذا الستاندرد متوفر بطول 3 متر؟ وهل مصنوع من أنبوب مجلفن بالكامل؟