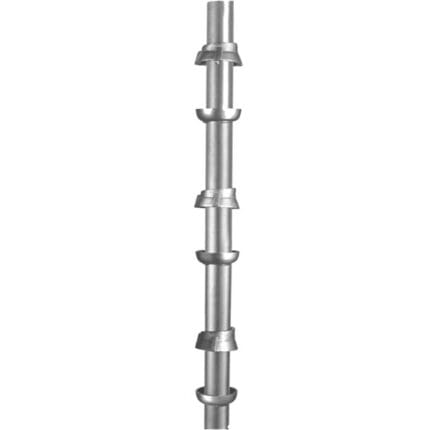

Cuplock Scaffolding Transom

Cuplock Scaffolding Transoms

Cuplock scaffolding transoms are critical components of the Cuplock modular scaffolding system, widely recognized for their versatility, safety, and ease of assembly in construction projects. This note provides an in-depth exploration of their design, types, features, and applications, drawing from various reliable sources to ensure comprehensive coverage.

Design and Materials

Cuplock transoms are manufactured from high-strength steel tubes, typically with an outer diameter (OD) of 48.3mm and a thickness of 3.2mm. This standardization ensures compatibility with other Cuplock system components, such as ledgers and standards. The choice of material, often Q235 or Q345 steel, is significant: Q235 has a yield strength of 235 MPa, while Q345 offers 345 MPa, making it suitable for heavier-duty applications. The 3.2mm thickness balances load-bearing capacity with manageability, ensuring the transoms are not overly heavy for handling and transportation.

To enhance durability, especially in outdoor or corrosive environments, transoms are frequently hot-dip galvanized. This process involves dipping the steel in molten zinc, forming a protective layer that resists rust and extends service life. The design includes jaw-like ends or forged blade ends, which connect securely to ledgers or standards via the Cuplock system’s cup-and-node mechanism. This connection involves inserting the transom’s T-shaped hooks into a lower fixed cup, then securing them with an upper movable cup tightened by hand and fixed with 3-4 hammer blows. Some transoms feature integral locking devices, such as wedge pins, to prevent movement and enhance safety, ensuring compliance with standards like EN 12810 and ISO 9001.

Types of Cuplock Transoms

Cuplock transoms are available in several types, each tailored to specific construction needs:

- Intermediate Transom:

- Purpose: Provides mid-bay support for scaffold boards, crucial when bay widths exceed the safe span (typically 1.2m). For instance, a 2.5m bay can be split into two 1.25m sections using a 1.3m transom, ensuring board stability.

- Design: Features jaw-shaped ends or forged blades at each end, with some models including a locking device for added stability. They are designed to span between inner and outer ledgers, locking them together.

- Sizes and Weights: Available in lengths such as 0.565m, 0.795m, 1.3m, 1.8m, and 2.5m, with corresponding weights like 3.83kg for 0.565m and 17.82kg for 2.5m. A common size, 1.3m, supports a five-board platform (each board typically 225mm wide, totaling 1125mm, close to 1.3m).

- Applications: Used in general construction, facade scaffolding, and birdcage structures for stable working platforms.

- Omega Transom:

- Purpose: Supports Cuplock omega battens, which are scaffold boards with an omega-shaped cross-section, forming a secure working platform without hooks.

- Design: Features an inverted “T” or omega-shaped section (60mm width, 40mm height, 57mm depth) with ledger blades at both ends. The omega shape interlocks with battens, preventing slippage, and connects via forged blade ends to the lower cup.

- Sizes and Weights: Available in 0.8m, 1.3m, 1.8m, and 2.5m, with weights like 2.12kg for 0.8m and 24.8kg for 2.5m.

- Applications: Ideal for heavy-duty construction or industrial maintenance, ensuring robust platform support.

- Loading Bay Transom:

- Purpose: Designed for heavy-load platforms, such as loading bays handling palletized materials, often paired with omega battens.

- Design: Reinforced to handle higher loads, may include a flexible arm gate for operator safety.

- Applications: Used in construction sites for material handling, ensuring stability under significant weight.

- Omega Ladder Access Transom:

- Purpose: Creates an opening within the scaffold tower for ladder access, facilitating safe worker movement between levels.

- Design: Typically 1.3m in length, designed to integrate seamlessly with the scaffold structure.

- Applications: Essential for access towers, ensuring safe internal ladder access.

Other specialized transoms, such as deck adapters or hop-up brackets, may extend the working platform by supporting additional boards beyond the scaffold’s interior, though these are less commonly detailed in standard specifications.

Key Features and Specifications

The following table summarizes the specifications for intermediate and omega transoms, based on available data:

| Type | Size (m) | Weight (kg) | Material | Key Feature |

|---|---|---|---|---|

| Intermediate Transom | 0.6 | 3.83 | Q235/Q345 Steel | Jaw-shaped ends, wedge pin lock |

| Intermediate Transom | 0.8 | 4.67 | Q235/Q345 Steel | Mid-bay support for scaffold boards |

| Intermediate Transom | 1.3 | 6.48 | Q235/Q345 Steel | Supports five-board platform |

| Intermediate Transom | 1.8 | 8.29 | Q235/Q345 Steel | Extended bay support |

| Intermediate Transom | 2.5 | 17.82 | Q235/Q345 Steel | Heavy-duty mid-bay support |

| Omega Transom | 0.8 | 2.12 | Q235/Q345 Steel | Omega section 60x40mm, forged blade ends |

| Omega Transom | 1.3 | 7.83 | Q235/Q345 Steel | Secure batten support |

| Omega Transom | 1.8 | 10.0 | Q235/Q345 Steel | Heavy-duty platform support |

| Omega Transom | 2.5 | 24.8 | Q235/Q345 Steel | Robust for industrial use |

These transoms are engineered to support significant loads, with safety factors ranging from 1.6 to 3, depending on the application and compliance with standards like EN 12810 or AS/NZS 1576. Their ease of installation, facilitated by the cup-and-node connection, reduces assembly time, while galvanization ensures longevity in harsh conditions.

Applications

Cuplock transoms are integral to a wide range of scaffolding applications:

- Construction: Used in high-rise buildings, bridges, and residential projects to support working platforms, ensuring worker safety.

- Industrial Maintenance: Employed in refineries, chemical plants, and shipyards where robust, adaptable scaffolding is needed, often utilizing omega transoms for heavy-duty support.

- Curved Structures: The Cuplock system’s flexibility allows transoms to support platforms in trapezoidal or rectangular bays, accommodating curved or complex structures by adjusting ledger angles.

- Shoring Systems: Transoms provide horizontal support in Cuplock formwork systems, ensuring stability during concrete pouring, with intermediate transoms distributing loads evenly.

- Access Towers: Ladder access transoms and intermediate transoms facilitate safe worker movement in mobile or stair towers, enhancing accessibility.

Advantages

The advantages of Cuplock transoms include:

- Time Efficiency: Quick assembly via the cup-and-node system reduces labor costs and project timelines.

- Durability: Hot-dip galvanization ensures resistance to environmental conditions, extending service life.

- Safety Compliance: Designed and tested to meet industry standards, fostering a secure working environment.

- Cost-Effectiveness: Modular design minimizes the need for additional fittings, reducing overall costs.

- Flexibility: Multiple sizes and types allow customization for diverse project requirements, from curved structures to heavy-load platforms.

Conclusion

Cuplock scaffolding transoms are vital for enhancing the safety, stability, and versatility of the Cuplock system. Their robust design, made from high-strength steel with secure connection mechanisms, and availability in various types like intermediate, omega, loading bay, and ladder access transoms, cater to a wide range of construction needs. Their applications span construction, industrial maintenance, and specialized structures, making them a preferred choice for contractors worldwide.

خالد المنصوري –

هل يمكن استخدام هذا الترانسوم مع منصات العمل الخشبية؟ وما هو سمك الأنبوب المستخدم فيه؟