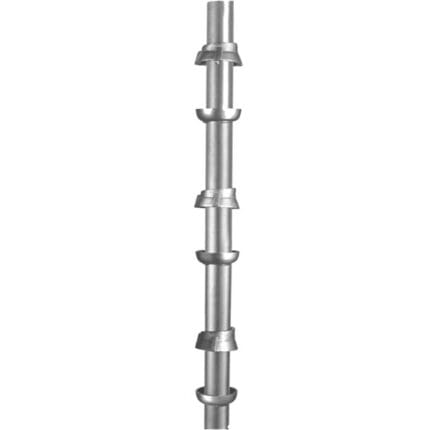

Cuplock Universal Jack

Cuplock Universal Jack: Design, Functionality, and Applications in Scaffolding Systems

The Cuplock Universal Jack is an integral component of the Cuplock scaffolding system, a modular framework widely adopted in construction for its versatility, safety, and ease of assembly. This article provides an in-depth exploration of the Cuplock Universal Jack, covering its design, specifications, functionality, applications, and advantages, drawing from reliable industry sources to ensure a comprehensive understanding.

Introduction

The Cuplock scaffolding system is renowned for its robust design and adaptability, making it a preferred choice for construction projects ranging from high-rise buildings to industrial maintenance. The Cuplock Universal Jack plays a critical role in this system by providing adjustable support, allowing scaffolding structures to remain level and stable on uneven terrain. Its ability to accommodate height variations and bear significant loads enhances the safety and efficiency of construction operations.

Design and Specifications

The Cuplock Universal Jack is engineered to provide precise height adjustments within the Cuplock scaffolding framework. It is available in two primary types—hollow and solid—each designed to meet specific load and structural requirements. The jack is typically constructed from high-strength steel, such as Q235 or Q345, ensuring durability and compliance with international safety standards like EN 12810. To resist corrosion, especially in outdoor environments, the jack is often hot-dip galvanized, extending its service life.

Key Specifications

-

Model Number: FCF04

-

Types: Hollow and Solid

-

Insertion Point: Top of Cuplock standards (vertical tubes)

-

Adjustment Method: Socket base

-

Adjustment Range: Approximately 0.5 meters

-

Load Bearing Capacity: Up to 74 kN

-

Material: High-strength steel (Q235/Q345), hot-dip galvanized

Detailed Specifications Table

The following table outlines the specifications for both hollow and solid Cuplock Universal Jacks, based on data from AffixScaffolding:

|

Product Code |

Description |

Size (mm) |

Weight (kg) |

|---|---|---|---|

|

BFS04670H |

Adjustable Universal Jack |

OD 38/4mm x 670mm |

2.00 |

|

BFS04760H |

Adjustable Universal Jack |

OD 38/4mm x 760mm |

2.25 |

-

Hollow Jacks: Lighter in weight (2.00–2.50 kg), these are suitable for standard load applications where weight reduction is beneficial for handling and transportation.

-

Solid Jacks: Heavier (5.25–6.55 kg), these are designed for heavier loads, offering greater durability and stability in demanding conditions.

The outer diameter (OD) of 38mm ensures compatibility with Cuplock standards, while the 4mm wall thickness in hollow jacks balances strength and weight. The solid jacks, with a fully solid cross-section, provide enhanced load-bearing capacity.

Functionality

The Cuplock Universal Jack is inserted into the top of Cuplock standards, using a socket base mechanism for height adjustments. This design allows for an adjustment range of approximately 0.5 meters, enabling precise leveling of scaffolding structures on uneven or sloped surfaces. The jack can also be used at the bottom of the scaffold in conjunction with base plates or forkheads, providing flexibility in its application.

The adjustment process is straightforward: the jack’s threaded section is rotated to extend or retract, secured by a nut or locking mechanism to prevent unintended movement. When fully braced, the universal jack can bear the full loading capacity of the Cuplock system, making it a reliable component for both access and support structures. Its integration with adapters, forkheads, or base plates enhances its versatility, allowing it to support various scaffolding configurations.

Applications

The Cuplock Universal Jack is essential in a wide range of scaffolding applications due to its adjustability and high load-bearing capacity:

-

Access Structures: Used in scaffolding towers or platforms where workers require safe access to elevated areas. The jack ensures level platforms, reducing the risk of falls on uneven ground.

-

Support Structures: Employed in shoring systems or formwork setups to support heavy loads during concrete pouring or structural construction. Its 74 kN capacity makes it suitable for heavy-duty applications.

-

Construction Projects: Integral to high-rise buildings, bridges, residential developments, and industrial facilities, where precise leveling is critical for safety and structural integrity.

-

Industrial Maintenance: Utilized in refineries, shipyards, and chemical plants, where adaptable scaffolding is needed for maintenance tasks on complex or uneven surfaces.

-

Curved or Complex Structures: Supports scaffolding in trapezoidal or rectangular bays, accommodating non-standard designs by adjusting to varying heights.

The universal jack’s ability to handle significant loads and adapt to terrain variations makes it a cornerstone of the Cuplock system’s versatility.

Advantages

The Cuplock Universal Jack offers several key benefits that enhance its utility in construction:

-

Adjustability: Provides up to 0.5 meters of height adjustment, ensuring stability on uneven or sloped surfaces.

-

High Load Capacity: Supports loads up to 74 kN, suitable for both light and heavy-duty scaffolding applications.

-

Ease of Installation: The socket base and threaded adjustment mechanism allow for quick setup, reducing labor time and costs.

-

Durability: Constructed from high-strength, galvanized steel, it resists corrosion and wear, ensuring long-term reliability.

-

Safety Compliance: Meets stringent standards like EN 12810, enhancing worker safety by maintaining level and stable platforms.

-

Versatility: Can be used at the top or bottom of scaffolding structures, with adapters or forkheads, accommodating diverse project requirements.

Comparison with Other Jacks

To provide context, the Cuplock Universal Jack can be compared to other scaffolding jacks:

-

Adjustable Base Jack: Typically used at the bottom of the scaffold, with a base plate for ground contact. It has a similar adjustment range but is less versatile for top insertion.

-

U-Head Jack: Designed for supporting beams or formwork at the top of the scaffold, with a U-shaped head. It is less adjustable than the universal jack and specific to certain applications.

-

Screw Jack: A generic term for adjustable jacks, which may not be tailored to the Cuplock system’s cup-and-node connection, potentially reducing compatibility.

The Cuplock Universal Jack’s ability to function at both the top and bottom, combined with its high load capacity, makes it more versatile than these alternatives.

Installation and Safety Considerations

Proper installation of the Cuplock Universal Jack is critical for safety:

-

Insertion: Ensure the jack is securely inserted into the Cuplock standard, with the socket base properly aligned.

-

Adjustment: Rotate the threaded section to achieve the desired height, then secure with the locking nut.

-

Bracing: Fully brace the scaffold structure to maximize the jack’s load-bearing capacity.

-

Inspection: Regularly check for wear, corrosion, or damage, especially in harsh environments.

Safety standards, such as EN 12810 or AS/NZS 1576, should be followed, and workers must be trained in proper scaffolding assembly to prevent accidents.

Conclusion

The Cuplock Universal Jack is a cornerstone of the Cuplock scaffolding system, offering unmatched adjustability, strength, and versatility. Its robust design, with hollow and solid options, supports a wide range of construction applications, from access platforms to heavy-duty shoring systems. By enabling precise leveling on uneven terrain and bearing loads up to 74 kN, the universal jack enhances both safety and efficiency on construction sites. For construction professionals seeking reliable scaffolding solutions, the Cuplock Universal Jack is an indispensable tool.

حسين الكرمي –

هل الجاك مزود بطبقة مقاومة للصدأ؟ وهل يتوفر بقياسات أطول من 600 مم؟